In fact, the design of a lathe, regardless of its model and level of functionality, includes standard structural elements that determine the technical capabilities of such equipment. The design of any machine belonging to the category of turning group equipment consists of such basic elements as a headstock and tailstock, a support, a device apron, a gearbox for changing speeds, a feedbox, an equipment spindle and a drive motor.

Main parts of a metal lathe

Headstock

Tailstock

Caliper

Drive shafts

Gear shift lever

Limbo

History of the device

The history of a lathe with a caliper begins in 1712, when Andrey Konstantinovich Nartov, a mechanic from Russia, was the first to invent this mechanism. This significantly simplified the work with the device, because the turner no longer needed to hold the cutting tools with his own hands while processing the desired element.

This invention gave a powerful impetus, followed by the rapid development of metal and wood lathes.

Although the creation of the turning device and caliper is attributed to the Englishman Maudsley, the Russian mechanic was still more than seventy years ahead of him.

Repair cost

| Type of work | Price |

| Spindle Prevention | 9,000 rub. |

| Troubleshooting clamping devices | 19,000 rub. |

| Burnout (damage) of the stator winding | 30,000 rub. |

| Replacing bearings with rotor balancing | 50,000 rub. |

| Replacing spindle sensors | 10,000 rub. |

| Maintenance | 10,000 rub. |

| Non-standard work | 10,000 rub. |

| Major renovation | 50,000 rub. |

| Modernization of machine tools | 30,000 rub. |

Our main specialization is machine repair

If your machine does not work, our specialist will arrive as soon as possible and fix it. Call and consult by phone: 8

- Thanks to the use of modern devices, we can more accurately identify faults. And we save your money on repairs

- If your machine does not break down as usual. We will send it to our technicians and they will solve any problem

Read useful information:

Machine support repair

In the modern world, various machines are widely used, because... they allow you to perform many operations. This unit consists of many parts, where the main role is played by the machine support. And it often happens that the work of the tool freezes due to the breakdown of the caliper or other parts.

Further

Types of production machines, their setup and maintenance.

To work effectively with machine tools, you need to understand the types and purposes of machines, be able to carry out setup and independent maintenance. In this article we will analyze the main types of machines and general setup rules.

Further

Machine head repair

The headstock is an important element of the machine. If this part fails, it is very difficult to cope with the repair yourself and you have to contact specialized workshops

How to prevent breakdowns, what is important to know when doing your own repairs and how much the services of qualified craftsmen cost - all this can be found in the article

Further

Repair of coordinate machines

What is a coordinate machine? How to repair it yourself and is it worth it?

Further

Causes of machine gearbox malfunctions, methods for eliminating them, cost

The article talks about common failures of the gearbox of a lathe. Their causes and ways to eliminate them yourself are described. The approximate cost of repairing a machine gearbox in Moscow is also given.

Further

When concluding a long-term service agreement, you receive a discount of up to 20%. Don't forget, we have a guarantee on all types of work.

- engineer - mechanic

- CNC programmer

- Service engineer

- Electrician

- Electronics engineer

- Locksmith - repairman

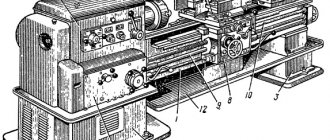

The main components of a lathe

A unit such as a lathe, regardless of the model, is composed of similar structural elements, which mainly determine all the capabilities of the device.

Name of the main components of the screw-cutting lathe design:

- Bed - this element of the turning device serves as nothing more than one of the main supports for both headstocks and is a platform for moving the support and tailstock. All elements of the device are attached to it. The bed consists of two longitudinal walls, which are connected by transverse ribs for reliability and strength. The headstock of the lathe is fixed to the left side of the bed, the opposite side is where the tailstock is located.

- The headstock holds and rotates the workpiece along its own axis. In the inner part of this element of the lathe there is a spindle that rotates at different frequencies in rolling bearings and thereby transmits the rotation of the workpiece. The outer sides of both walls of the headstock are equipped with gearbox handles, which are switches for the number and speed of spindle revolutions. Instructions for the correct switching of these handbrake in order to set the required number of revolutions are located in the form of a metal plate on the outside of the walls of the headstock.

- Tailstock – supports the remainder of the element during processing. Additionally, it is used to install other working tools.

- Caliper - moves the cutting device in all directions to the axis of the turning device.

- Feed box - the design of almost all lathes is characterized by this element, which rotates the drive shaft and lead screw and changes the number of their revolutions around its axis. There are a large number of feedbox systems.

- Apron - used to change the movements of the drive shaft.

- On this device, it is strictly forbidden to simultaneously turn on the feed mechanism from the lead shaft together with the closure of the uterine nut on the lead screw. This action in almost all cases leads to breakdown of the elements of the turning device. To prevent this, there is a special mechanism in the lathe that completely blocks the entire device.

Caliper structure

A lathe support is a unit that ensures the fixation of the cutting tool, as well as its movement in the inclined, longitudinal and transverse directions. It is on the support that the tool holder is located, moving with it due to a manual or mechanical drive.

Support with carriage for machine Optimum D140x250

The movement of this unit is ensured by its structure, which is characteristic of all lathes.

- The longitudinal movement, for which the lead screw is responsible, is performed by the caliper carriage, while it moves along the longitudinal guides of the frame.

- Transverse movement is performed by the upper - rotating - part of the support, on which the tool holder is installed (such movement, due to which the depth of processing can be adjusted, is carried out along the transverse guides of the support itself, which are shaped like a dovetail).

Quick-change tool holder MULTIFIX cartridge type

The tool holder, also called the cutting head, is installed on the top of the support. The latter can be fixed at different angles using special nuts. Depending on the need, single or multiple tool holders can be installed on lathes. The body of a typical cutting head has a cylindrical shape, and the tool is inserted into a special side slot in it and secured with bolts. There is a protrusion on the bottom of the cutting head that fits into a corresponding slot on the support. This is the most typical tool holder mounting scheme, used primarily on machines designed to perform simple turning work.

Main components and mechanism of action of the headstock

This element of the lathe is one of the main parts of any turning device. The accuracy of the location of the workpiece and the amplitude of its movements depend on it. In addition to the front headstock, all machines also have a back headstock - the cutting tool is attached to it. Both headstocks are fixed to the bed, which is the basis for any machine, and differ only in their location.

There are also grinding machines on which a third special grinding headstock is additionally attached, which is responsible for moving the grinding platform of this device.

There are the following main elements of a turning device that regulate the speed of turning the element being processed:

- Two bearings.

- Spindle.

- Pulley.

- A special gearbox, which is responsible for changing the rotation speed of the element being processed.

The main element of the headstock of a lathe is the spindle, the main task of which is to regulate the movement of the wrapping on the element being processed.

On the right side, facing the tailstock, there is a thread attached. Chucks are attached to it, which hold the part that is being processed. The spindle is mounted on two bearings, on which the accuracy of the work performed fully depends.

Also, a guitar of gears is fixed in the internal structure of the headstock. They transmit rotation from the gearbox output shaft to the feedbox shaft.

The headstock body is the main platform for all components. Its shape directly depends on the model of the turning device and can be very diverse. The lower surface of the body is smooth; all the guides are fixed into the tongue, which is located in the middle.

A gearbox is installed on the outside of the headstock of the lathe, which operates using gears.

Why is it needed and how does it work?

A lathe is designed for the manufacture of wooden products that have a cylindrical or similar shape. This is an indispensable thing when renovating a country house with a wooden staircase, a carved porch, but not only.

If you have some experience, a turning tool will allow you not only to save on purchased decorative elements, but also to earn money, because handmade wooden products are highly valued.

Whether such a machine is needed in a home workshop is up to the master to decide.

Of course, if you need several handles for chisels, it is easier to buy them, but if you want to make an all-wood staircase, then a set of balusters will cost a very large sum. It is much cheaper to make them yourself. By the way, you don’t even have to spend money on buying equipment - a simple machine can be made in your own workshop using scrap materials.

The operating principle of a wood lathe is not particularly complicated. The cylindrical workpiece is fixed along the axis of rotation. Torque is transmitted to it. By bringing various cutters or grinding tools to the workpiece, it is given the desired shape.

Main parts of lathe:

- a frame on which all components are fixed;

- electric drive;

- headstock;

- tailstock;

- handyman

For ease of operation, schemes for changing the rotation speed are used. In professional equipment, this is a real gearbox, a system of gears that allows you to regulate speed within a very wide range. This is difficult; it is enough to equip a homemade wood lathe with a belt drive with several pulleys of different diameters.

Spindle

The name of this element comes from German and is translated as “spindle”. This part is a shaft that is equipped with a mechanism for fastening the workpiece that is being processed. Usually the shaft is made with a hole in which the rods are processed. The spindle neck is conical or cylindrical.

Basic standards for spindle operation:

- Wrapping accuracy - it is adjusted based on standards, and has a direct dependence on the purpose of the device itself, its accuracy.

- The rigidity of the spindle assembly itself - this requirement is also met based on generally accepted standards.

- Vibration resistance is in no way a determinant of the quality of the workpiece.

- Spindle speed - the higher the speed of this unit, the higher the quality of the finished product.

- Load-bearing capacity - this parameter almost entirely depends on the quality of the spindle supports and the fluid for lubricating the device.

- Durability - this item depends only on the quality of the bearings.

- Heat allowed for bearings.

One of the main conditions for the manufactured part to be processed as accurately and accurately as possible is the correct torsion of the spindle. It should rotate evenly and easily.

Adjustment

In order to maintain the tailstock on a lathe in proper working order, it must be periodically adjusted, and in case of malfunctions, it must be repaired in a timely manner.

First, you need to set the part as it should, adjust it and center it, and then adjust all the parameters of this unit. Periodic adjustment is needed for the following reasons:

- gaps may appear between the bearings and the spindle body (if we are talking about a turning unit where the quill rotates);

- the center of the assembly may shift relative to the quill, then adjustment will be needed;

- There may be play in the fastening of the headstock to the frame and other reasons.

The first time the tailstock is adjusted is when the machine is put into operation.

The tailstock is repaired as it fails, when its faults are clearly visible. Typical signs that a part needs to be sent for repair may include the following:

- the workpiece processing mode has changed;

- beats appeared during the rotation of the workpieces.

The spindle repair process is considered the most labor-intensive and costly. You can’t do this without turning skills, and the machine itself must be available. The difficulty lies in restoring the accuracy of the hole (boring followed by finishing) in which the quill is fixed.

The process is complicated by the fact that the outer surface is cylindrical, while the inner surface is conical. In addition, the quill itself is made of a very durable material - it is “hardened” alloy steel.

After repair, check the mechanism for radial runout: with proper troubleshooting, it should be zero, the tailstock will not “knock” and will restore all its original characteristics.

DIY lathe headstock

The headstock for a lathe can be made independently without any problems.

For this purpose you will need:

- Wooden plank.

- Plywood, ten millimeters thick.

- A thin sheet of metal that is cut with special scissors.

It is much easier to make a headstock with your own hands if the basis of this device is an ordinary unnecessary drill. After this, it will only be necessary to make a stand, which will subsequently be the mounting platform for the drill, which has a strict horizontal axis.

The middle of the front and middle of the tailstock must be securely fastened, this is extremely necessary. For the tailstock, it is necessary to establish in advance the limits of the possibilities of wrapping along the axis and rigidly securing it in place.

The power of the electric motor should be selected independently, based on the purpose of the turning device. Although the engine power does not need to be less than 250 W. Otherwise, it will not be possible to turn out any necessary parts.

Peculiarities

The area of use of any machine depends on its design features. This machine unit has the following main features:

- Multiple speeds and feeds. This allows the worker to select the optimal method for processing a particular part.

- You can carry out milling, end tool processing, and grinding (both inside and outside the part).

- The feed box is structurally similar to the unit with which milling machines are equipped. In addition, there is a speed change handle for convenient operation.

- The headstock has corners that are rounded. This is typical for devices that were produced in the sixties in the USSR.

- The guides of the device are quite strong, extremely accurate and durable. This is due to their careful grinding during the production of the device. In addition, the machine is equipped with an independent lubrication system powered by an electric hydraulic power station. It provides lubrication of the guides.

- The built-in gearbox makes it possible to cut different types of threads. The worker does not need to change gears every time.

- The preselectivity of the gearbox allows you to quickly and smoothly switch modes.

- Structurally, the device is designed in such a way that there is no need to service its rear part. This is especially convenient for industrial premises with a small area.

- There is a container with electrical equipment and a container for coolant and lubricant.

- The machine has a built-in container for metal filings. If necessary, it can be quickly emptied.

- There is a fuse that prevents the feed mechanism from overloading.

- The device is equipped with a vernier, which makes it possible to determine with high accuracy how transversely the caliper element has moved.

- Device speeds can be controlled mnemonically.

- The cutter head is fixed without gaps, which ensures high processing accuracy.

- The lead screw is automatically lubricated as the thread is formed.

- The spindle assembly is designed so that there is no need to dismantle it when changing drive belts.

We recommend watching a video review of the control handles:

Setting up the lathe before starting work

Setting up a lathe means, first of all, preparing a kinematic diagram for work, which is determined by the technological map of the device.

First of all, all controls are brought to a static position.

Next comes the adjustment of the kinematic chain of the main movement. The required rotation speed of the spindle assembly is immediately set. This value determines the cutting speed of the required element.

Video: headstock of a wood lathe.

Selecting the type of cooling

Cooling of the rotation zone is required to increase service life. There are two types.

Water (liquid)

Differences:

- They are very quiet - the liquid flows almost silently. But at the same time there is another loud sound from the movement of the impeller.

- The presence of a circuit that includes a system of tubes, a container, and a pump. It is necessary to constantly monitor the moisture supply and its temperature.

- Can operate at low speeds.

Air

Distinctive features:

- Strong and not the most pleasant sound.

- Chips may fly away under the influence of a jet of air.

- It is necessary to clean the shirt where metal particles become clogged at regular intervals.

- It is required to monitor the temperature very carefully; ideally, install a sensor with a signal, because the entire device is very sensitive to overheating.

As a result, we recommend using the air option when working with soft materials, but when the workpiece is made of durable metal, it is better to use liquid cooling.

Manufacturing of the bed

The bed is a frame that combines all parts of the machine into a single whole. The strength of the structure as a whole depends on its reliability, therefore the best material for the frame is a steel angle. You can also use a rectangular profile pipe.

First of all, the dimensions of the future unit are outlined. This indicator largely depends on what specific products the machine is needed for. The average bed size of a home lathe is 80 cm. Using a grinder with a metal circle, cut two identical workpieces.

Laying wooden blocks, the angles with the shelves up and inward, are laid on a flat surface, their upper edges should create an ideal plane. The same distance is maintained between them, approximately 5 cm. To orient them correctly, use a strip of appropriate thickness.

The longitudinal parts of the base are fixed with clamps. Cross members are made from the same square. There are three of them. Two are attached to the edges of the structure, the third, which is a support for the headstock, is approximately twenty centimeters from the left edge. The exact dimensions depend on the type of motor used and the parameters of the pulley that could be found.

All that remains is to weld the frame into a single whole. The seam must be reliable and of high quality; it can be welded manually or using an automatic machine.

It is important to immediately decide how the machine will be used. Desktop installation or production of a stand-alone unit is possible. In the second option, it is necessary to provide legs. They can be made from the same square, or they can be cut from timber of suitable thickness. The use of wooden legs will allow you to save on material, in addition, the machine can be made collapsible.

Selecting the type of cooling

Cooling of the rotation zone is required to increase service life. There are two types.

Water (liquid)

Differences:

- They are very quiet - the liquid flows almost silently. But at the same time there is another loud sound from the movement of the impeller.

- The presence of a circuit that includes a system of tubes, a container, and a pump. It is necessary to constantly monitor the moisture supply and its temperature.

- Can operate at low speeds.

Air

Distinctive features:

- Strong and not the most pleasant sound.

- Chips may fly away under the influence of a jet of air.

- It is necessary to clean the shirt where metal particles become clogged at regular intervals.

- It is required to monitor the temperature very carefully; ideally, install a sensor with a signal, because the entire device is very sensitive to overheating.

As a result, we recommend using the air option when working with soft materials, but when the workpiece is made of durable metal, it is better to use liquid cooling.