Purpose of the device

When driving off-road, a driver may encounter an insurmountable obstacle. Then the car will have to be pulled out of the mud or sand with something. A winch is the ideal tool for this. Some vehicles have the device installed on the front bumper from the factory. Purchasing a ready-made winch can cost a lot of money, so it makes sense to make it yourself using improvised materials.

A factory or homemade winch with a manual drive (or with an electric drive from a starter) allows you to pull out a car without a tow. Experienced car enthusiasts prefer home-made devices that fully meet their needs. Factory winches often fail or cost a lot of money.

There are different types of structures. It is impossible to say unequivocally which one is better. Different types are used for different situations and purposes.

Pros and cons of the device

As often happens, car enthusiasts have ambivalent attitudes towards homemade pullers. Some consider them an excellent replacement for a winch, while others are exactly the opposite - categorically against their use.

The advantages of the self-extractor include:

- low cost of construction;

- the ability to do it yourself;

- ease of use and reliability;

- small dimensions;

- does not require special fastening;

- ease of installation (you can do without a professional);

- If used correctly, the traction force will be limited only by the engine power.

If used incorrectly, the self-extractor can cause quite serious troubles. There have been cases when a stake driven weakly into the ground could not withstand the load and broke the windshield.

There are other disadvantages:

- there is a risk of damage to the steering rods;

- the cable is wound unevenly around the disc;

- inconvenience of using the device.

If we compare a self-puller with a winch, then in terms of functionality and ease of use, the winch wins many times over. In cases where the driver goes fishing or relaxes in nature several times a year, a self-puller is an ideal option. If the car constantly drives off-road, you should think about purchasing a winch.

Device types

Classification is the first thing you need to know about the traction device. They are divided depending on the type of design, drive and technical features. Some types of winches are easy to make yourself - this is the simplest mechanism with a manual drive . And complex structures will work reliably only if they are manufactured in a factory.

This specificity must be taken into account when choosing a type for self-production. There are removable and stationary winches. The first option can be removed from the car, carried out maintenance or used for other economic purposes.

Classification depending on the type of drive:

- Manual. Its advantages are its small size and relatively light weight. The work is carried out according to the drum principle. The cable is pulled onto a separate reel, and it is rotated by hand. The disadvantage lies in the limitation of the mass with which work can be done - no more than 1 ton.

- Mechanical. The drum with the cable is rotated by the machine's engine. The design is heavy, so car enthusiasts rarely use it.

- Electric. The best option is for the drum to be driven by an electric motor. The latter is powered by a battery or the vehicle's electrical system. The load capacity in this version is 4 tons.

- Hydraulic. The design is complex, but it works silently and with great traction force. But such systems are unreliable and expensive. Another drawback is that it is impossible to make a hydraulic drive system yourself.

The manual winch is ideal for DIY. The system has a simple design that can be easily made from available materials. There are no complicated moving parts. You just need to decide on the parameters. If desired, you can install an electric motor on such a device, which will eliminate physical labor.

Pros and cons of self-pullers

The attitude of SUV owners towards self-extractors is ambiguous. Some consider them to be a completely worthy replacement for a winch, while others, on the contrary, speak extremely negatively about these devices. Let's try to highlight the main pros and cons that a self-extractor for a UAZ or other SUV has.

- simplicity and reliability of design;

- low cost or ease of self-production;

- takes up little space in the trunk;

- does not require special fastening or professional installation;

- When used correctly, the traction force is limited only by the engine power.

Perhaps the device has other advantages. Now let’s list the obvious disadvantages of self-pullers:

- risk of damage to the vehicle (especially steering rods);

- limited functionality (the winch can be used for many other tasks besides pulling out a car);

- uneven winding of the cable;

- inconvenient to use (it’s easier to pull the car out with a winch).

The list may also not be complete; perhaps self-pullers have other disadvantages.

A simple option made from scrap materials

Some motorists often drive into a field or forest, which may result in problems negotiating difficult areas - mud and sand. The car gets stuck, and you have to puzzle over how to get it out. The simplest hand-made homemade winch can be made in the field.

Materials:

- Scrap and pipe cuttings.

- Cable.

- A piece of pipe for a lever.

It is unlikely that you will have the materials with you on the road. But everything you need can be found in the nearest village. Instead of a cable, a strong rope will do.

Manufacturing procedure:

- Drive a crowbar or a small diameter tube into the ground to create an axle.

- A larger diameter tube is placed on the axle, to which a cable is attached.

- A lever is slipped under the lower turn of the cable. This could be another tube, a shovel handle, or a pole. The main thing is that the material is durable.

With such a device, which can be assembled in ten minutes, you can move any heavy object, not just a car. The lever is rotated so that the cable is wound around the pipe. Such a manual winch will help to quickly solve the problems of moving heavy loads. This is not a full-fledged device, but it will get the job done.

How to get a car out using the simplest means?

There are situations on the road when you can’t count on outside help. The prudent driver has a crowbar in the trunk, which serves as an axis of rotation, and a piece of pipe as a drum. A lever is welded to it. The presence of a cable is assumed by itself. It takes a little sweat to get the car out of the mud.

Making a device that will help you out in a difficult situation is simple:

- The crowbar is driven into the ground and a pipe is put on. It should provide a place for attaching the cable - some kind of hole or welded ears.

- One end of the sling is hooked to the pipe, the other - to the car. Make a loop, insert a lever and begin to rotate.

- The cable is gradually wound up, the car moves slowly.

It is known that the longer the lever, the less physical effort is required. If the size is too large, it is inconvenient to use: the optimal parameters are 80 cm with a slight tolerance in one direction or the other.

The use of a manual mechanical winch to pull out a car requires compliance with certain conditions. Choose a direction that prevents the car from getting stuck even more in the mud. The wheels are set straight to reduce drag. If possible, choose a higher location for fixing the device - the required physical strength is reduced.

Manufacturing a system with a universal drive

The manual system is easy to manufacture. Of the special skills the master is required to do, only own a welding machine. Any metal will do the job. The appearance of the device is not so important, the main thing is performance and resistance to heavy loads. The frame should not be deformed.

Materials and tools:

- Rectangular tube for frame.

- Shaft for the drum, you can use a round tube.

- A sheet of metal with a thickness of at least 3 mm for the manufacture of drum disks.

- Threaded rods M10-M12, 24 cm long – 6 pieces, nuts.

- Tube diameter 14 mm - 6 identical pieces of 20 cm.

- Asterisks - large and small. Chain.

- Hubs to secure the drum to the shaft and secure the shaft to the frame.

- Drive lever.

- Cable with carabiner.

- Welding and electrodes.

- Grinder and grinding disc for it.

- Paint and primer.

- Wrenches included in the set.

Some materials are better purchased - for example, tubes for the studs and shaft. The rest can be picked up from old mechanisms - cars or motorcycles. Any metal will do, even used.

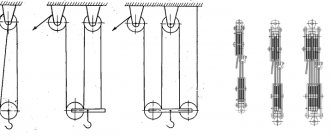

Manufacturing procedure:

Read also: Checking a film capacitor with a multimeter

- They sketch out a drawing, because this will make it easier to navigate during assembly - you won’t have to stand guessing over the half-finished product and think about what to do next.

- Cut out the frame parts from a pipe with a cross-section of 2 by 2 cm. Connect the frame parts together strictly perpendicularly. The cut on the workpieces is made at an angle of 45 degrees.

- Lay the frame blanks on a flat surface. The joints are spot-tightened by welding, after which they check whether everything is installed correctly. The angles of the connections must be strictly 90 degrees. If there is a lack of accuracy, corrections are made and then the parts are welded.

- Scale is removed with a grinder and a grinding wheel. The finished frame is sanded and then coated with a primer. After the latter has dried, the metal is painted with enamel in 2 layers. You can use regular paint. The goal is to protect the metal from corrosion, since operating conditions will be difficult, with dirt and moisture.

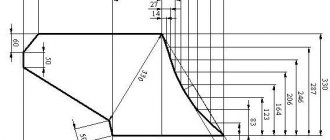

- Creating a drum. Take a sheet of metal and cut out 2 circles, their diameter is about 30 cm. On each circle you need to make 7 holes:

- One in the center. The diameter must match the shaft size.

- 6 holes at a distance of 7 cm.

- The discs are fastened together using pins. The pin is inserted into the hole of one disk in a vertical position. Tubes with a diameter of 14 cm are put on the studs, and a second disk is installed on them. The studs must not only be secured with nuts, but also additionally reinforced with locknuts to ensure reliable connections.

- The drum is ready, now the shaft is mounted. It is made from a metal pipe, but you can take a finished product from any mechanism. The latter option is preferable: since the accuracy of the factory part is higher, vibrations of the drum will be small or absent altogether.

- A large diameter sprocket is mounted on the shaft on the outside of the drum. A sprocket from a motorcycle gearbox will do. To secure the drum to the frame, the outer sides of the shaft must have hubs.

- The drum assembly with the shaft is mounted through the hubs on the frame. The structure is secured with bolts. Before installing the drum, you should prepare a platform on the frame. A drive will be installed on it - manual or electric. When using an electric drive, a motor is placed on the platform with a small sprocket attached to its shaft.

- A universal drive is often installed: a handle is placed on the reverse side of the output shaft of the electric motor. In the absence of electricity, the winch can be turned manually.

- It is important to properly tension the chain. It should not sag, but strong tension is also unacceptable - this will cause the sprockets to wear out faster, and the chain may break. Check the chain tension by rotating the drum - the chain should not hinder its rotation when the cable is unwound.

- The end of the cable is secured to the shaft and wound around the drum. A carabiner is hung on the other, free end of the cable.

- A shank is attached to one end of the frame. With its help, the winch is secured to the car frame.

The winch is created in a day. Since it will be installed on an SUV, the operating conditions will be appropriate. To prevent dirt and sediment from getting on the drum, it is covered with a casing. This way the mechanism will last longer and the cable will not wear out.

The design is simple, reliable, and easy to make yourself . Yes, it does not have the ability to change the gear ratio, there is no reverse and other additional functions. A self-made electric winch is capable of dragging a heavy load across the terrain, be it a car or something else.

UAZ 3962 My model is on the list › Logbook › Wheeled “winch” aka “self-puller”

When I bought the jack, it turned out that it would not be possible to use it on a loaf, and then the idea came to me to make such a gadget that would allow me to jack the wheels.

Thought and done! It took two old brake drums and ten homemade stud nuts from 45X. Here is the result: But in the end it turned out that the idea of guano would not work in real conditions anyway. And it turned out that it all really works, like a self-puller... The first pancake was lumpy - there was no anchor (it’s done now)

the second application and subsequent ones are successful

With a free differential only on both bast shoes and a block is required

Well, a little video from before the anchor era:

I unsuccessfully tore the turf there and sat down on level ground, almost on the bridges

Or you can use it as a stationary swan or a second pair of wheels:

Impressions of the device: advantages 1. cheap 2. compact 3. really works, but I don’t recommend installing it on the front axle. disadvantages: 1. takes a long time to bring into working position 2. to pull forward, modification of the front bumper is necessary. 3. in a hard rut you can hang on them Summary: The device is useful and is permanently registered in the car. Here's how I broke this device (the bugs have now been fixed) And this version No. 2, by the way, is also not successful...

Assembly Tips

Design development is carried out carefully, as well as assembly. The task is to treat each operation as responsibly as possible. The goal is to complete the assembly with high quality. This will avoid troubles when operating in extreme conditions. Therefore, there is no need to force the work, even if it is really necessary.

Steps to achieve high build quality:

- The work is done slowly and thoughtfully. A raw, unfinished unit cannot be used.

- Follow the drawing.

- Weld seams are treated with an anti-corrosion compound. Welding is done in carbon dioxide to obtain a high-quality seam.

- The electric drive control panel is placed as far away from rotating parts as possible.

- Electrical wiring is carefully insulated. The contacts are protected by additional insulation from moisture and dirt.

Read also: Welding inverter cedar circuit

Negative results often arise due to hasty actions. The issue of moving cargo in a horizontal plane with its own device will be successfully resolved. To lift loads above the ground, the cable must be pulled over a strong support.

One of the popular ways to make a homemade electric winch is to use a car starter. This device is equipped with a powerful high-torque electric motor with a supply voltage of 12 volts, which allows the winch to be used on an SUV.

When manufacturing, you should remember the limitations:

- The starter is designed for short-term operation. This does not mean that it will immediately burn out under prolonged load, but the motor housing does not provide sufficient winding cooling. If you plan to use the winch regularly and the work periods will be long, you should take care of additional cooling. For example, weld aluminum corners onto the body as cooling fins;

- The car starter is started using a retractor relay with a bendix. You don't need a solenoid for the winch, but a contact starter wouldn't hurt. The current at the contacts will be large, and it is better to leave the standard switching circuit. Depending on the gearbox used, the bendix should be fixed by welding in the position of maximum engagement or removed from the solenoid relay;

How to make a winch from a starter

Let's take the Zhiguli starter as the initial donor. It is quite reliable and at the same time has a compact size. Another advantage of this choice is that a VAZ starter can be found almost for free at any dismantling of domestic cars.

The drawing shows the device and components of the starter. In the upper part there is a retractor relay with power contacts. They can be used if large loads on the winch are expected. On the left is the bendix mechanism, which must be removed along with the cone housing.

Since we are talking about a compact, low-power mechanism, it makes no sense to make a gearbox for a winch from a flywheel gear. It is enough to pick up a unit from a large drill. Finding one will also not be difficult, since there are more tools with a burnt out motor at flea markets than with a broken gearbox.

There are no special requirements for the gearbox, the main thing is that the diameters are more or less suitable.

For our adaptation, of course, we need to reduce the speed.

We separate the Bendix housing from the winch, and we are left with only an electric motor with a rotor shaft. The coupling of the gearbox shaft with the mating part of the starter motor is done locally. There are many ways - from banal electric welding to making a transition coupling with cotter pins.

If it is necessary to increase the gear ratio, you can use a starter with a planetary gearbox. Adapting it to your design is not much more difficult than connecting the shafts directly, and the useful power of the winch will increase significantly.

To protect the operator from rotating parts, the space between the gearbox and the engine is closed with a pipe of a suitable size, possibly made of plastic. The casing does not carry a power load, so the gearbox housing must be firmly connected to the motor housing.

Simple threaded studs will not work here; you need to work on the design. In this case, the housing must be dismountable for periodic inspection and maintenance (cleaning, lubrication) of the motor bearings and gearbox mechanism.

Next we make the drum. You can make it at home from a piece of steel pipe with a diameter of 120-180 mm and sheet iron 2-3 mm thick.

We cut out round cheeks and weld them to the pipe. In the center of each sidewall we drill a hole for the power shaft.

The power shaft with the working gear in this design is borrowed from a decommissioned electrified valve mechanism, which is used on gas and oil pipelines. Be sure to use a standard pair of gears, otherwise it will be difficult to pair the main sprocket with the gearbox output.

All elements must be securely welded together; any weakness will sooner or later crack, and the structure will fall apart at the most crucial moment.

A channel or steel strip with a thickness of at least 5 mm is used as a frame. The winch elements should not have any play relative to each other.

The side walls are made of sheet iron 3-5 mm. Thinner sheets may become deformed when the cable is pulled under load.

The most important part is attaching the drum axis. For this, powerful bearings with podiums from some mechanism from the times of the USSR were used. You can find such spare parts at scrap metal collection points or in the workshops of abandoned factories.

The podiums are welded to the side walls. If you managed to find only bearings, weld the outer race. Nothing will happen to the rolling mechanism; the bearings simply cannot be replaced.

We attach the gearbox to the frame so that its gear meshes with the power gear on the drum shaft. We remind you that initially we had a set of a shaft and a set of gears. We install an eyelet between the walls - a leash for the cable.

Read also: Carbon equivalent of steel 09g2s

We connect the gearbox with the electric motor from the starter, put the winch in good shape: we clean the welds with a grinder, remove rust, and cover the tool with paint.

The design has been tested to lift weights up to 200 kg. In this version, two gearboxes are used - from an electric drill and a homemade one from a gas electric valve. It feels like there will be enough traction for another 100-150kg.

If you install a starter with its own planetary gearbox, the gear ratio of which will be added to the two existing ones, the capabilities of the device will double.

The video shows an example of a winch using a starter.

How to use the device?

Be sure to provide for the possibility of reversing the power supply to the winch. Reverse is necessary in such devices. Since this is a regular car electric motor, changing “+” to “-” will change the direction of rotation of the shaft.

Let the power starter be the old one, from the solenoid relay. And the start buttons come from ancient electromechanical devices. The button block can provide for polarity reversal.

If the winch is used in a car, do not connect it to the standard battery with the engine turned off. With a good load, you will drain the battery in 10-15 minutes.

The dimensions allow the winch to be placed on the bumper of an SUV prepared for off-road use.

Coil processing

Cable reels come in a variety of sizes, so they can be used to create a variety of furniture, from stools to dining tables.

The cable coils themselves are strong and do not have severe mechanical damage after use. These or other imperfections can be removed using a sander.

When preparing the reel, pay attention to the vertical post. Winding the cable tightly may leave imprints on the wood surface, which will also have to be removed with a sander.

What can you create with a foundation?

Small round coffee table

Depending on the condition of the boards, the reel for assembling the table can be used completely or in parts. For example, from the upper or lower circle, as shown in the photo, you can get good furniture by screwing several stable supports around the perimeter.

If desired, such furniture can be used as a computer or office desk.

If the condition of the reel is generally good and the system is stable, it can be used completely without disassembling it. In other words, it is enough to sink the mounting bolts into the wood, grind the parts and apply a paint coating that will give the product a finished look.

How to decorate a tabletop

The external appearance of finished furniture depends almost entirely on the production technology and finishing method. Despite the simplicity, utilitarianism and external similarity of tables made from cable coils, there are many options for their decorative design. Along with ordinary finishing variations, including ordinary colors, there are design ideas that can practically transform furniture, making it a piece of art.

Unique table uses

How and where to use furniture made from wood spools? Almost everyone believes that the only area for introducing such crafts is a space for relaxation in a garden plot. In fact, this is not so, and a correctly made and decorated table can be used not only in the country, but also in the interior of a city apartment.

I suggest you familiarize yourself with the fascinating variations of using homemade tables.

Just a country table made of wood reels is an original solution in itself, even without any special finishing

Cable reels, adapted as stands for flowerpots, a convenient and reliable solution

Furniture set for a personal plot - an elegant, comfortable and cheap solution

Coffee table in the interior of a modern living room

The originality of this table lies in the wrapping of the support with hemp rope

A tabletop combined with a bookshelf is a nice and immediately convenient solution from the outside

Another bookshelf, but here the vertical supports connecting the top and bottom bases are made to be the most stable

Interesting read: DIY liquid granite

A stand for flowers, in which a coil of wire is not placed on the base, but placed on its edge

Do-it-yourself winch - price

If you have your own garage or shed with rubbish accumulated over several years of home plumbing, the cost of the product is determined by the price of a can of spray paint for final finishing.

Basically, the components are as follows:

- Starter from a VAZ 2101 car without a planetary gearbox (working, lying in the garage);

- A gearbox in a housing from a domestically produced electric drill (purchased at a flea market for the equivalent of 0.5 vodka);

- A piece of water pipe found in a barn;

- Metal for the frame, body walls, drum. Also found in a barn;

- Drum axle - purchased at a scrap metal collection point for pennies;

- The rope and hook were purchased at a tourism supply store.

Taking into account the cost of a new winch, the cost of the issue can be considered zero. At the same time, the owner can vouch for the safety of the device. Every detail and weld is personally checked by the manufacturer.

Homemade winch from a starter: drawings of an electric winch, photo of making a homemade product with your own hands.

To make a homemade winch, the author used a starter from a VAZ 21015. The engine from a car starter is designed for short-term operation and quickly overheats, but is quite suitable for making an electric winch.

We will also need a reduction gearbox from a hammer drill; you can find a gearbox at a flea market; in this homemade product, the author took a gearbox from an old Soviet-made drill with a gear ratio of 1 x 20.

The motor shaft needs to be connected to the gearbox shaft; this can be done using an adapter coupling and cotter pins, or simply weld them together.

Assembled into a single body.

Now we will make a drum for the winch from a piece of metal tube and sheet metal 3 mm thick.

A bolt is fixed in the pipe for fastening the cable.

We cut out two circles from metal with a hole in the middle and weld them to the pipe.

The gear and shaft need to be welded to the drum. In this homemade product, the shaft and gear are taken from a decommissioned oil pipeline valve mechanism.

The drum rotates on two bearings that are welded to the winch frame covers.

Drum with gear assembly.

As an option, you can take the drawings of a hand winch drum.

To prevent the cable from flying off the drum, we weld a guide eye to the winch body.

The gearbox is mounted on the winch frame; the author attached the gearbox using a pipe clamp for threading.

We compare the gear of the gearbox shaft with the gear of the drum. Gear ratio 1 x 5.

Reverse connection diagram on a winch.

We wind the cable onto a drum, the thickness of the cable is 6 - 10 mm.

Advice! Do not connect the electric winch to the car battery when the engine is off, the battery will discharge in a few minutes.

Also, you cannot cling to a metal cable the car from which the electric winch is powered; alternatively, you can use a fabric cable or remake the brush assembly on the electric motor, insulating the mass on the winch itself.

A homemade winch from the starter will easily pull a passenger car out of the mud, including a UAZ “loaf”.

Homemade author: Nikolay Evdokimov.

Interesting video: the author shows his homemade winch from a VAZ 21010 starter

Conclusion

In some cases, a self-retractor is quite capable of replacing a winch. Of course, if the car participates in competitions or is used on very difficult off-road conditions, where it needs to be pulled out of captivity every few minutes, then it is better to use a winch, and of considerable power. If the car is used for fishing, hunting or other rides on not very difficult off-road conditions, then a self-extractor is quite suitable. Of course, a winch is in most cases more convenient and preferable, but given its cost, it is not always available. A self-puller will cost a ridiculous amount, but it is quite capable of coping with tasks that are usually assigned to a winch.

Another design option