The method of ultrasonic flaw detection of welds has been used since 1930. Since then, various methods of echolocation have been developed. They reveal a violation of the integrity of the diffuse layer, the correspondence of the surfacing to the base metal in chemical composition, slag inclusions and oxide impurities are identified. The ultrasound (ultrasound diagnostic) procedure is comparable in accuracy to X-rays and radar. The device detects the smallest defects that reduce the strength of joints.

Among the non-destructive methods of seam inspection, ultrasonic has become the most accessible and effective, and has been put on stream. The results of checking the welder’s work are recorded in a special journal. The scope of application of ultrasonic testing of welded joints is limited only by the geometric parameters of the parts being welded. They diagnose the seams of pipelines, high-pressure vessels, and metal structures under heavy load.

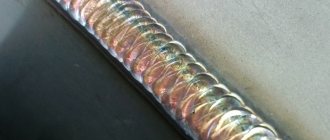

What is ultrasonic testing of welding joints

Ultrasonic testing (UT) or ultrasonic flaw detection is a non-destructive testing method. Parts and materials exposed to it are not damaged. It is used in many areas and sectors in industry, medicine, etc.

This method is actively used in the inspection of welds such as butt, corner, overlap and T-joints with structural penetration (these are those seams in which, after welding, there will be no unwelded area left inside). The figure shows, as an example, a T-weld with structural penetration T8 according to GOST 5264)

The technique is based on the use of ultrasound (a sound wave with a frequency above the hearing threshold of more than 20 kHz; frequencies from 180 kHz - 10 MHz, and sometimes up to 100 MHz, are used for control).

Ultrasound testing uses 2 basic principles:

- Change in amplitude of the reflected signal (defects are detected).

- Measuring the time it takes a wave to travel through a product (thickness is determined)

Based on these 2 principles, inspection of welded joints, metal during incoming inspection, and various equipment that has been in use for a long time is carried out and its residual life needs to be assessed.

Scope of application of this technique when identifying defects

Ultrasound-based inspection of welds is quite clear. And with a correctly carried out weld testing method, it gives a completely comprehensive answer regarding the existing defect. But the scope of application of ultrasonic testing also has.

Using ultrasonic testing it is possible to identify the following defects:

- Cracks in the heat-affected zone;

- pores;

- lack of weld penetration;

- delamination of deposited metal;

- discontinuity and lack of fusion of the seam;

- fistulous defects;

- sagging of the metal in the lower zone of the weld;

- areas affected by corrosion,

- areas with inappropriate chemical composition,

- areas with distortion of geometric size.

Such ultrasonic testing can be carried out in the following metals:

- cast iron;

- copper;

- austenitic steels;

- alloy steels;

- and in metals that do not conduct ultrasound well.

Ultrasound is carried out within the geometric framework:

- At the maximum depth of the seam - up to 10 meters.

- At the minimum depth (metal thickness) - from 3 to 4 mm.

- The minimum seam thickness (depending on the device) is from 8 to 10 mm.

- The maximum metal thickness is from 500 to 800 mm.

The following types of seams are subject to inspection:

- flat seams;

- longitudinal seams;

- circumferential seams;

- welded joints;

- T-joints;

- welded pipes.

For milling metal processing, as a rule, face and cylindrical cutters are used. Sandblasting will help get rid of many metal contaminants. Read more about this here.

Do you want to open a business in the field of metalworking and welding? Read step by step on how to do this at https://elsvarkin.ru/prakticheskoe-primenenie/kak-otkryt-biznes-v-sfere-okazaniya-uslug-po-metalloobrabotke-i-svarke/ link.

Main areas of use of this technique

It is not only in industrial sectors that the ultrasonic method of monitoring the integrity of seams is used. This service - ultrasound scans - is also ordered privately during the construction or reconstruction of houses.

Ultrasound testing is most often used:

- in the field of analytical diagnostics of components and assemblies;

- when it is necessary to determine the wear of pipes in main pipelines;

- in thermal and nuclear energy;

- in mechanical engineering, oil and gas and chemical industries;

- in welded joints of products with complex geometry;

- in welded joints of metals with a coarse-grained structure;

- when installing (welding connections) boilers and equipment components that are susceptible to high temperatures and pressure or the influence of various aggressive environments;

- in laboratory and field conditions.

Field testing

The advantages of ultrasonic quality control of metals and welds include:

- High accuracy and speed of research, as well as its low cost.

- Safety for humans (unlike, for example, X-ray flaw detection).

- Possibility of on-site diagnostics (due to the availability of portable ultrasonic flaw detectors).

- During ultrasonic testing, it is not necessary to take the controlled part or the entire object out of service.

- When performing an ultrasound scan, the object being tested is not damaged.

Why is ultrasound testing performed?

With this non-destructive testing method it is possible to:

- Assess the size of corrosion areas;

- Identify internal (subsurface) defects - cracks, lack of fusion, metal delamination, pores, slag inclusions and other non-continuity of the weld and base metal.

- Assess the quality of the seam and determine the depth of the defects.

This method diagnoses equipment, both existing and new (before commissioning), and also monitors the quality of welding after it has been completed.

When performing control, in some cases it is not even necessary to empty vessels and pipelines (removing the medium), which makes this technique very popular.

Ultrasonic flaw detector device

Each device has an ultrasound emitter, amplifier and receiver. The main difference between the different models is the type of generator. Piezoelements are the most widely used. The sensor sends signals at regular intervals.

The pauses between pulses are several microseconds. Their duration is set by the user, taking into account the desired defects, density and structure of the metal. The reflection reveals the defect and its main parameters: size and depth of location. The emitter is placed in a dynamic probe, which moves along the seams being examined.

The accuracy of the device depends on the sensitivity of the receiver, which detects the reflected wave. It is important for the user to take into account the fact that the wave changes direction at the boundaries of the media. Things are easier with the definition of shadow areas - in these places the wave is reflected. The device catches the sound signal, converts it into electricity and displays it on an oscilloscope.

Equipment used

The following equipment is used for ultrasonic testing:

- Flaw detector.

- Piezoelectronic transducer (PET).

- Lemo connecting cable.

The flaw detectors currently used are small in size, convenient to use and not difficult to carry. Depending on the manufacturer, the functionality of flaw detectors varies from the simplest with monochrome displays such as UD-2-70 to the most compact and advanced with color displays and program control.

Piezoelectronic transducers (or PETs for short) differ in frequencies, input angles, radiation methods, and so on.

The following types are used to control welds:

- straight and inclined;

- combined and separate-combined;

- focusing, non-focusing, as well as chordates;

- contact and non-contact.

Combined transducers - have only one piezoelectric element which is both an emitter and a receiver at the same time.

Separately combined converters already have 2 piezoelements, one of which is a source of waves, and the other a receiver. These converters provide more accurate defect detection. They can be used to monitor surface defects and control surfaces with high roughness.

Preparation and properties of ultrasonic vibrations

Acoustic waves or ultrasonic vibrations are generated at a frequency exceeding the 20 kHz parameter. Mechanical vibrations that can be dissipated by elastic, solid media, the range is usually 0.5 - 10 MHz. The propagation of waves through the metal structure occurs by acoustic ultrasonic waves affecting the equilibrium of the central point.

Ultrasonic method technique

There are several methods of ultrasonic non-destructive testing, the most common of which is piezoelectric. The plate, charged with electricity at a certain frequency, vibrates, mechanical vibrations are transmitted to the environment in a wave state. Electric wave generators are used regardless of the purpose, the size of the equipment, and can produce different parameters.

The speed of ultrasonic testing directly depends on the properties and type of physical medium. The speed of propagation of a longitudinal wave is twice as high as that of a transverse wave. Information is received by a plate made of a piezoelectric element, which converts energy into pulsed energy. The process uses short alternating pulses of various types of vibrations, which makes it possible to determine the depth and properties of the defect.

Angles of direction of ultrasonic vibrations

At the boundary between two media, the result of the incidence of a longitudinal acoustic wave in an inclined type is the appearance of reflection and transformation of ultrasonic waves. There are main types of control:

- reflected;

- refracted;

- shear transverse;

- longitudinal waves.

The process occurs by dividing the wave incident at an angle into transverse and longitudinal, the propagation of which is carried out directly by the material.

Angles of direction of ultrasonic vibrations

There is a certain value of the feed angle, the direction of ultrasonic vibrations, if violated, ultrasonic testing will not spread deep into the metal, but will remain on its surface. This method is used for certain parameters and tasks; the wave moves only along the surface of the material, which allows you to control the quality of the weld.

Essence of the method

Echo method (in some sources – echo-pulse). This is the most commonly used ultrasonic testing method and is most often used to inspect welds. The principle of the method is as follows: a sound wave passing through the controlled product is reflected from the surface of the defect (if there is one) or from the surface of the bottom (if there are no defects). If a defect is detected, the device records this with a signal on the display. To use this method, access from only one side is sufficient and in some cases there is no need to disassemble the equipment.

You can control welds without removing the reinforcement using inclined probes. To carry out the control, it will be necessary to clean the seam to a distance of 100 mm in both directions; the roughness should not exceed Ra 3.2. You will also need to apply a coupling fluid (gel, glycerin, mineral oil, etc.)

Echo-mirror method . To implement it, 2 probes are used, one is a transmitter that emits sound waves. The second is a receiver, a receiver of reflected waves from a defect or bottom surface. They are located on one side of the controlled part and move together.

This method is used to identify vertically located defects, most often lack of penetration, lack of fusion and cracks located at the root of the weld.

Delta method. The principle of the method is as follows: the emitter introduces sound waves into the product, which are scattered and transformed at the edges of the defect into a longitudinal wave, which is recorded by a longitudinal wave receiver. One-sided access is sufficient for control. This method is difficult to use due to the need for extremely precise adjustment of the flaw detector. There are also high demands on the competence of the flaw detector. This method is actively used where the presence of vertically oriented defects is expected.

The mirror shadow method is based on measuring the reduction in signal strength from a defect. During testing, the signal passes through the cross section of the object twice.

This method is often used in conjunction with the echo method for additional control.

Shadow (in some literature amplitude-shadow) - this method is based on reducing the amplitude of the sound wave after passing through the defect. It requires two-way access. The emitter is installed on one side, and the receiver on the other, and sound is performed. An important feature is that it is impossible to determine the depth of the defect. It is used to control sheet structures.

The reverb-through method is used for inspection in polymers, multilayer materials and composites. The sensors are located on one side of the test object; the sound wave transmitted through the body of the object makes several reflections from the bottom surfaces.

Acoustic emission method. This method is used where it is necessary to identify defects at an early stage of their formation. The method is based on the ability to study low-frequency sound waves during the occurrence of defects such as cracks and structural changes.

Many sensors are installed on the controlled products, which record these waves and transmit them to amplifiers. Next, the signal enters the information processing unit, in which extraneous noise is filtered out. The resulting value is displayed.

Below is a diagram of acoustic emission testing.

This method is most often used at chemical and petrochemical industry facilities: tanks, containers and pipelines.

Properties of ultrasonic wave

A sound wave as a type of mechanical vibration has the following properties:

- Period—(T)—the time during which one complete oscillation occurs.

- Wavelength – (λ) is the distance a wave travels in one oscillation.

- Purity (f) is an important characteristic that shows how many oscillations occur in 1 second.

- Amplitude (dB) is the maximum deviation of a wave from its equilibrium state.

Ultrasonic testing also takes into account the type of waves:

- longitudinal wave (tension/compression)

- transverse (shear)

- surface (Rayleigh wave)

- Head wave

- Lamb wave (in plates)

- Porchhammer waves (in rods)

Direction angles

When carrying out ultrasonic testing, PETs (piezoelectronic transducers) are used. They, in turn, differ in the angle of wave input into the controlled materials by:

- Direct.

- Inclined.

Direct —create and receive ultrasonic waves at right angles to the testing surface.

Oblique transducers - create and receive ultrasonic waves at various angles different from the normal to the surface. Most often in practice, probes are used with insertion angles of 50, 65 and 70 degrees.

What defects can be identified

During inspection, the following defects can be identified:

- Pores.

- Bundles.

- Slag and other inclusions.

- Lack of penetration.

- Lack of fusion of edges.

Only the main defects are listed. Using ultrasound, you can identify other discontinuities, as well as their location and size.

Theory of technology

Ultrasonic flaw detection technology. (On the left there is no defect, on the right there is a defect)

Ultrasonic vibrations are based on ordinary acoustic waves, which have a vibration frequency above 20 kHz. The person does not hear them. Penetrating into the metal, the waves fall between its particles, which are in equilibrium, that is, they oscillate in the same phase. The distance between them is equal to the ultrasonic wavelength. This indicator depends on the speed of passage through the metal seam and the frequency of the vibrations themselves. The dependence is determined by the formula:

L=c/f, where

- L is the wavelength;

- c is the speed of its movement;

- f – oscillation frequency.

The speed depends on the density of the material. For example, ultrasonic waves move faster in the longitudinal direction than in the transverse direction. That is, if there are voids (another medium) in the path of the wave, then its speed also changes. At the same time, encountering various defects along the way, waves are reflected from the walls of shells, cracks and voids. And, accordingly, deviation from the directional flow. The operator sees the change in movement on the monitor of the ultrasonic instrument and, based on certain characteristics, determines which defect stands in the way of the movement of acoustic waves.

For example, attention is paid to the amplitude of the reflected wave, thereby determining the size of the defect in the weld. Or by the time of propagation of an ultrasonic wave in the metal, which determines the distance to the defect.

Area of application - where ultrasonic testing is used

Ultrasonic testing is a very universal method and has a very wide range of applications. With its help, you can control both metal and non-metal products such as ceramics, polymers, glass. The only limitation is the control of porous materials in which strong wave attenuation occurs. It is also very difficult to use this method when inspecting products with complex configurations (threaded connections) and when inspecting small thicknesses.

Ultrasonic flaw detection (ultrasonic flaw detection) is used to control welds and base metal during technical diagnostics, construction, reconstruction during operation and installation. Used on such objects as:

- boiler inspection facilities (boiler equipment);

- lifting structures (cranes, hoists, elevators, etc.);

- gas supply facilities;

- mining industry (building and construction, as well as equipment of mines and mines);

- coal industry;

- control objects of the oil and gas industry;

- metallurgical industry;

- chemical and petrochemical industry facilities;

- railway transport;

- grain storage and processing;

- construction objects (buildings and structures, as well as metal structures);

- electric power industry.

Scope of application of ultrasonic testing

This control method is used in the industrial sector, as well as in the reconstruction and construction of houses. Ultrasonic testing is often used:

- For analytical diagnostics of units and components.

- To determine the wear of pipes in the main pipeline.

- In nuclear or thermal energy.

- In the field of mechanical engineering, oil and gas, chemical industries.

- When checking welds of structures with complex configurations.

- When diagnosing metal compounds with a coarse-grained structure.

- When welding joints of units and boilers of equipment that are under the influence of pressure, high temperature, and aggressive environment.

The technique is used both in field and laboratory conditions.

A seam checked for defects is a guarantee that the structure is safe for use, reliable and can be used for its intended purpose. Without monitoring for compliance with standards, putting the structure into operation is impossible. The accredited construction laboratory IRONCON is ready to carry out ultrasonic diagnostics of welded joints at the customer’s site in full compliance with current control standards.

Advantages and disadvantages of the technique

The advantages of the method are:

- Speed of inspection - data is obtained without delays in real time (no development of films or decoding of data from magnetic tapes is required).

- The high versatility of the method allows you to control a large range of materials and products.

- It is possible to perform control in all spatial positions.

- Automation of the method is possible.

- Control of large thicknesses (up to 3–5 m).

- The method is harmless to humans.

- Most equipment is compact and portable (facilitates work in the field).

Just like a coin has 2 sides, this method also has its 2nd side – disadvantages.

The disadvantages of the method include:

- It is difficult to estimate the actual size of the defect.

- A number of limitations when testing materials that have a granular or coarse-grained structure in which strong wave attenuation occurs.

- There is a dead zone when inspecting surface and subsurface defects.

- High quality surface cleaning is required when testing by contact methods.

Procedure for carrying out ultrasonic testing

Let us consider the procedure for carrying out ultrasonic flaw detection using the example of weld inspection. Before inspection, all work on this equipment must be completed.

Before starting, it is necessary to clean the area along the weld seam to a distance D, which is calculated by the formula D = Lmax + 30 mm; where L is the length of the probe’s movement zone (usually 120 - 150 mm).

Cleaning for rental does not need to be done, but only metal splashes and corrosion with a depth of more than 1 mm can be removed. All nicks, dents and irregularities must be removed. Cleaning is carried out using metal brushes, files, and also using a grinding machine using abrasive wheels.

The roughness of the prepared surface should not be higher than Rz40 and the temperature at which the control will be carried out should be in the range from minus 30 to plus 30 degrees.

Next, to create acoustic contact, a contact fluid (glycerin, mineral transmission and machine oils, specialized fluids and gels) is applied to the surface.

Afterwards, the flaw detector is adjusted on standard samples SO-2 and SO-3, and the sensitivity is set using an artificially made reflector (defect) on a standard enterprise sample - SOP. The designs of SOPs with artificial reflectors are given below.

Standard sample (SOP) with a notch, this is used for setting up a flaw detector with a combined probe

SOP “punt” - in which a hole with a flat bottom is made for setting up a chord-type probe.

The serviceability of PEPs is checked using standard samples of the enterprise SO-2 and SO-3. CO-3 is used to determine the exit point and boom.

Using CO-2, the insertion angle is determined.

The enterprise standard sample (SOP) shows the maximum permissible defect for a given test object at a given thickness. It is used to adjust the sensitivity of the flaw detector. First, the signal received by a single reflected beam is adjusted, and then the signal received during control by a direct beam is adjusted. The most commonly used methods of control are direct and single-reflected beams.

Next, the object itself is sounded. The transducer is placed perpendicular to the weld seam and smoothly moved, moving away and bringing it closer, making a kind of reciprocating movement. In the process of making movements, the transducer is turned at an angle from 10 to 15 degrees to the right to the left. The movement step should be no more than 5-6 mm.

During the scanning process, the flaw detector monitors the received signals on the display of the flaw detector and, in case of defects, marks the location on the product with a marker or chalk.

Below you can see the sound diagrams for various welding joints.

Flaw detection procedure

- Paint and rust are removed from welding seams and at a distance of 50 - 70 mm on both sides.

- To obtain a more accurate ultrasound result, good transmission of ultrasonic vibrations is required. Therefore, the surface of the metal near the seam and the seam itself are treated with transformer, turbine, machine oil or grease, glycerin.

- The device is pre-configured according to a certain standard, which is designed to solve a specific ultrasound problem. Control:

- thicknesses up to 20 mm - standard settings (notches);

- over 20 mm - DGS diagrams are adjusted;

- connection quality - AVG or DGS diagrams are configured.

- The finder is moved in a zigzag along the seam and at the same time they try to rotate it around its axis by 10-150.

- When a stable signal appears on the device screen in the ultrasonic testing area, the finder is deployed as much as possible. It is necessary to search until a signal with maximum amplitude appears on the screen.

- It should be clarified whether the presence of such vibration is caused by the reflection of the wave from the seams, which often happens with ultrasound.

- If not, then the defect is recorded and the coordinates are recorded.

- Inspection of welds is carried out in accordance with GOST in one or two passes.

- T-seams (seams at 90 0) are checked using the echo method.

- The flaw detector enters all the inspection results into a data table, from which it will be possible to easily re-detect the defect and eliminate it.

Sometimes, to determine the more accurate nature of the defect, the characteristics from ultrasound are not enough and it is necessary to apply more detailed studies using X-ray flaw detection or gamma flaw detection.

Results Evaluation Options

Interpretation of the results obtained by ultrasonic testing methods when sounding welded joints is one of the important stages of the work.

When a defect is detected, measure:

- The depth of the defect.

- Length.

- Distance between defects (if there are several of them).

- Maximum amplitude from the signal.

- Total length of defects.

The results are recorded in the control log, as well as in the conclusion or protocol. The control log indicates:

- The number of the welding joint according to the form and its type;

- length of the controlled area;

- SOP No.;

- operating frequency and input angle;

- control results;

- areas that could not be controlled (in the absence of access);

- date of inspection and signature of flaw detectors.

Defects detected during inspection are described using alphanumeric designations. To indicate defects, GOST 14782 should be used.

What defects does ultrasound diagnostics reveal?

Using ultrasonic testing of pipes and structures, a number of different defects are determined, for example:

- cracks in the heat-affected area;

- pores in joints;

- lack of penetration;

- delamination of deposited metal;

- lack of fusion of the seam;

- fistulous defects;

- metal sagging that occurs in the lower section of the welded joint;

- corrosion damage;

- material mismatch in chemical composition;

- zones with distorted geometric dimensions.

Diagnostics can be carried out in metals such as copper, cast iron, alloy and austenitic steels. At the same time, there are certain geometric frameworks for applying the method, in particular:

- Seam depth (max) – 10 meters;

- Depth (min) – 3-4 mm.

- Seam thickness (min) – 8-10 mm.

- Metal thickness (max) – 500-800 mm.

Using ultrasonic testing of pipes and structures, various types of seams are checked: longitudinal, flat, circular, T-joints, as well as welded joints.

Training and certification of specialists

Ultrasonic flaw detection specialists are trained and certified in special certified organizations. There are 3 levels of qualification for flaw detectors.

Level I is assigned to beginners whose work will be carried out under the supervision of a specialist with level II or III. A first-level specialist cannot independently choose a control method, evaluate the results, or select technology and mode.

Level II flaw detectorists can independently carry out and supervise the work. Make a decision on the choice of control method, methods, technologies, and also evaluate the control results. They can develop technological maps and approve them.

Level III flaw detectors can supervise the work of level I and II flaw detectors, conduct training and certification.

Ultrasonic inspection of pipeline welds

Often, ultrasonic inspection of pipeline welds is carried out only on one side. In this case, inclined and straight probes are used. Depending on the wall thickness, PEPs are selected according to frequency.

The table below shows the criteria for selecting a converter.

If pipelines with a diameter from 10 to 530 mm with a small wall thickness (up to 8-9 mm) are monitored, it is better to use chordal separate-combined transducers. This will increase the speed of control and the accuracy of the results obtained.

The criteria for selecting a converter depending on the pipeline diameter and wall thickness are given in the table below.

Critical angles

When performing ultrasonic testing, the operator needs to select the type of transducer, calibrate and configure the device for the expected defects of the object. Critical angles of incidence (longitudinal and transverse) must be taken into account when ultrasound passes through solid surfaces of materials.

The first critical angle is the smallest angle of incidence of the longitudinal wave at which the refracted ray does not cross the boundary of the second solid medium. For example, for the plexiglass-steel boundary it is 27.5º.

We recommend reading: Welding technology for internal combustion engine blocks

The second critical angle is considered to be the smallest angle of incidence of the longitudinal beam at which refraction does not penetrate through the boundary into the second solid medium and internal damage is not detected. For plexiglass-steel it is 57.5º.

The third critical angle is the smallest angle of incidence of the transverse beam at which there is no reflected longitudinal wave. The beam travels along the surface of the object without recognizing defects inside it. To cross the steel-air boundary, the angle is 33.3º.