The cost of traditional energy resources is rising, and increasingly, owners of private houses are deciding to use various types of biomass for heating. One of these types of fuel is pellet. It consists of pressed granules, and small sawdust, peat, straw, etc. can be used as materials. Since the production of this type of fuel in the CIS countries is poorly developed, many people decide to make pellets with their own hands.

One of the practical types of fuel is pellets

What are pellets?

Pellets

are a granular type of solid fuel, cylindrical in shape, made from compressed waste from agricultural production and the woodworking industry. The main materials for the manufacture of fuel pellets are:

- sawdust, wood chips, bark, slabs of coniferous and deciduous (the best option) wood species;

- peat;

- sunflower husks (the most common solution), rapeseed (the best option), straw of various grain crops, corn, husks, cake and much more;

- charcoal;

- household waste.

The base binder is a substance of plant origin - lignin, a natural polymer contained in almost any plant, capable of being plasticized during granulation under the influence of a sufficiently high operating temperature.

Types of wood pellets

Pellet factories produce two types of fuel pellets: white or light, and gray.

Light pellets

Manufacturers of heating materials classify light pellets as higher quality and environmentally friendly raw materials that do not contain ash or tree bark. Most often, clean sawdust or chips cleared of bark, as well as shavings, are granulated. Another feature of the production of light pellets is the drying of raw materials in special chambers that do not have contact with solid fuel. This is explained simply: during operation, dryers using conventional types of fuel drive sawdust through the working chamber along with combustion products, which also contain ash impurities. This affects the quality and ash content of finished granules.

White pellets have high heat transfer and combustion temperature, and their price is much higher.

Gray pellets

Any wood raw material is suitable for pellet production of gray granules. This can be croaker, bark, logs of different tree species, and all kinds of waste from wood production. The color of the granules is affected by the bark, as well as the drying process. Some manufacturers add a little peat or sunflower husk to the starting material, which reduces the cost of the finished product. When the pellets burn, a little coke is formed, and the boiler ash receptacle has to be cleaned much more often. The ash content of gray granules can reach up to one percent.

Pellet classification

The main regulatory document predetermining the production of pellets is the European Union standard EN 14961-2, adopted in January 2011, on its basis an international quality certificate EN Plus is issued. There are three classes of granular fuel:

- ENPlus-A1 – best premium quality, diameter up to 8.00 mm, ash content up to 0.70%, another name is “white granules”;

- ENPlus-A2 – with ash content up to 1.50%, also called industrial granules, can consist of mixed wood species;

- EN-B – standard quality, with ash content up to 3.00%, an alternative name for agropellets.

In terms of cost, the most expensive pellets are ENPlus-A1 class, the cheapest are EN-B class, it is better not to take substandard fuel.

Homemade press

If you have a drawing and certain design skills, you can make a press for fuel briquettes with your own hands.

There are two types of homemade devices for briquetting - those operating from a jack and those with a manual drive.

A description of the assembly of the structure will help you understand how to make a press and which option is best to use.

Manual

To make a hand press, you need a punch. It is constructed from thick metal sheet. A pressure lever is attached to the material, and the structure is secured using hinges.

The punch is installed in a special form. Usually it is made square. The mold is made from metal. Using a thin drill, holes are drilled in the bottom and sides to allow moisture to escape during the pressing process.

To collect the released water, a container is used in which the finished press is installed.

From the jack

To obtain higher quality solid fuel and improve the design of the press, a hydraulic jack is used.

The manufacturing process of such equipment consists of the following stages:

1. The base for the press is formed from the channels. All metal parts are fastened by welding.

2. Racks are attached to each corner of the prepared base in a vertical position. Each support is taken 1.5 meters high.

3. The mixer is welded to the stands. The drum can be made from a pipe with a large diameter or take a ready-made part from an old washing machine.

4. A galvanized steel tray is fixed under the mixer, from which the raw materials will penetrate into a special mold.

5. Holes are created in the thick-walled pipe intended for the matrix. They should be evenly distributed throughout the circular contraction. The width of each opening should be from 3 to 5 millimeters.

6. At the bottom of the mold, a flange is fixed using a welding machine, to which the bottom is screwed.

7. The finished form is connected to the base.

8. After this, a punch is cut from steel sheets. It should have the same shape as the matrix. Using a rod, the punch is connected to a hydraulic element.

The assembled mechanism is fixed on top of the form to the racks. The tray is fixed at the bottom.

To speed up the process of removing pressed briquettes, it is recommended to weld the disk and spring to the bottom of the matrix. It must match the diameter of the punch. This mechanism will allow you to automatically push out finished products after turning off the hydraulics.

Pressed wood raw materials require drying. The lower the moisture content of the briquettes, the better they burn. In addition, dry briquettes have higher heat transfer.

Self-made compact fuel can significantly reduce the cost of heating your home. Ready-made briquettes can be used both for the boiler and for the stove. But it should be borne in mind that the quality of the product largely depends on the density indicator.

It is almost impossible to make compressed firewood using homemade equipment that will burn for a long time and give off a large amount of heat.

Therefore, if you need to use fuel with high performance, it is better to purchase it in specialized stores.

Basic parameters of pellets

Pellets for heating are granules of white or shades of brown, with a length from 10.00 to 30.00 mm, a diameter of 6.00 and 8.00 mm, less common fuel with a diameter of 10.00 mm, the maximum diameter of the granules is 25.00 mm. The darkening of pellets is associated with the presence in the structure of the material of various non-combustible residues (dust, earth, and a number of others).

The main parameters of pellets are:

- ash content (the lower, the better and the less ash, so the boiler will have to be cleaned much less often);

- humidity;

- calorific value (ENPlus-A1 – 18.0 MJ/kg, ENPlus-A2 – 18.0 MJ/kg, EN-B – 15.0 MJ/kg).

- total length;

- degree of density;

- diameter;

- bulk mass;

- abrasion class.

Pellet manufacturing technology

The production of pellets consists of pressing waste that has been previously dried to a certain moisture content and crushed to a given fraction under a pressure of about 300 atmospheres. At the same time, the use of glue and other additives is prohibited (sometimes unscrupulous businessmen add sand and other non-combustible impurities to them to increase the weight of the granules, and synthetic polymers to ensure adhesive properties).

Main stages of pellet production:

- Grinding. The raw material enters the crusher and is crushed to a given fraction;

- Drying. The resulting raw material is dried to the moisture percentage specified by the technology (about 10% plus or minus 2%);

- Pressing. The dried raw material enters a press granulator, in which it is pressed into granules of a given length and diameter. As a result of compression, friction, and adiabatic processes, the temperature can reach 100°C Celsius, as a result, thermal energy is generated that softens lignin and the particles stick together into granules. This process is called pelletization;

- Cooling. To ensure the strength of the fuel granules, the pellets are cooled after pressing;

- Packing and sending to the consumer.

In some cases, water treatment and additional grinding are performed before pressing; everything directly depends on the type and quality of the raw materials from which the granules are made. Pressing is carried out in molds, ring-type dies using rotary rollers (rollers), which press the raw material into cone-shaped dies located on the matrix. On the other hand, the resulting granules are cut with special knives. After cooling, the pellets are sieved and small particles are sent for recycling. Closed cycle technology is virtually waste-free; only non-combustible impurities are removed. In order to make one ton of pellets, three to five cubes of wood waste are needed. The raw material is compacted approximately three times. To prepare one ton of pellets you need from 30.00 to 50.00 kW per hour.

Industrial technology

The pellet production process can be divided into several stages. First, the preparation and crushing of raw materials is carried out. In industrial conditions, the material is also sorted and, after purification from impurities, enters the pre-crushing line. After this, the raw materials must be dried. For this purpose, aeration or drum drying units are used. The residual moisture content of sawdust should be below 14%.

The next stage in the production of pellet fuel is fine crushing of the material. The use of special equipment allows you to reduce wood chips to the state of flour. The maximum fraction size after this process is 4 mm. Then the moisture content of the material is controlled again and, if necessary, secondary drying is carried out. Otherwise, the raw materials will not be pressed.

At the final stage of production, the crushed dry material enters special pressing plants. It is pressed through a matrix with cone-shaped holes of certain sizes. Thanks to the special shape of the channels, the sawdust is compacted. Also, under pressure, the temperature of the raw material increases and the substance lignin is released. It is contained in any type of wood and promotes strong bonding of the fraction. When leaving the pressing plant, the granules can have a temperature of up to +90°C and must be cooled.

Necessary machines for the production of pellets

Equipment for the production of sawdust pellets includes:

- crushers (chopping machines) for grinding the raw materials used to a given fraction;

- dryers to ensure the required percentage of humidity of the initial, base raw materials;

- hammer mills (in some cases they are replaced by flaring machines, disintegrators, everything depends directly on the characteristics of the feedstock), make it possible to obtain raw materials with a fraction of up to 4.00 mm;

- screw mixers (used when using overdried raw materials with a moisture content of less than 8.00%, by dosed supply of steam or water);

- presses (differ in the type of matrix used, which can be flat or round).

Dryers, in turn, are divided into:

- principle of operation (can be drum or belt (cost more, but are more productive and safer to use));

- drying technologies (using flue gases, water vapor or hot air);

- the fuel used (gas, wood waste, coal, etc.).

To burn pellets, special equipment is used - a pellet boiler.

.

The optimal solution in terms of price/quality/performance ratio on the Russian market is heating appliances from the Polish manufacturer Metal-Fach, including boilers from the SD DUO

,

SD DUO BIO

,

SMART

,

SMART EKO

,

SEG, SEG BIO

.

They have a steel heat exchanger (P265GH steel with a thickness of 4.00 to 6.00 mm is used for production), an efficiency of over 90%, an innovative, modern type controller FL 310LGRTC

, with continuous logic and PID control, as well as an upper combustion chamber and a retort type burner.

Also worthy offers are:

- domestic boilers created in Krasnoyarsk, ZOTA

Pellet

series ; - joint development of the Russian-Polish company Vulkan

, the

EKO

; - pellet boilers from the legendary Italian company FACI

Caldaie,

FACI SSL/SSP

.

You can purchase pellet boilers in a wide range, get the necessary advice, order installation, warranty and post-warranty service in Krasnoyarsk from the Kras-Kotel company.

Production flow diagram

In order to produce fuel pellets that meet all the required characteristics, it is necessary not only to use high-quality raw materials and special equipment for the production of pellets for these purposes, but also to strictly adhere to the technology.

Technological scheme for the production of fuel pellets

The pellet manufacturing process consists of several stages.

- First, the wood raw material is cleaned from foreign impurities and its primary crushing is carried out. As a result of this process, for which conventional crushers are used, wood raw materials are divided into fairly large fractions.

- This is followed by drying, during which the moisture content of the wood raw material is brought to a value not exceeding 12–14%. For drying raw materials, drum or aeration type installations are used.

- After drying, the wood raw materials are subjected to finer grinding, for which hammer-type crushers are mainly used. The output from such installations is fine sawdust or even crumbly wood pulp, reduced to the state of flour, from which the highest quality fuel pellets are produced.

- If, after repeated grinding, the moisture content of the resulting wood pulp does not reach the required minimum value (10–12%), this parameter is artificially increased using steam or ordinary water for this purpose.

- After the parameters of the raw material for the production of fuel pellets are brought to the required values, it is fed to a pressing plant - a pelletizer. In such installations, which may differ from each other in design, the bulk mass is pressed through the holes of the matrix, resulting in the formation of dense cylindrical granules of a certain diameter. Exerting significant pressure on the crumbly wood pulp promotes its spontaneous heating. At the same time, a natural component is released from it - lignin, which has good binding properties. It is this component that ensures the formation of a dense briquette with a stable internal structure from individual particles of crumbly wood raw materials.

- Matrices, in the working cavities of which crumbly wood raw materials are converted into dense fuel briquettes, can be cylindrical or flat. Installations of the first type, as a rule, are produced in a stationary design and are used primarily to equip industrial enterprises. Their design includes a special cutting device that allows the production of pellets of approximately the same length. Flat-type matrix installations, which can be equipped with one or more rollers, are characterized by compact dimensions. This type of equipment is most often used to organize the production of pellets at home or in a small enterprise.

- The finished pellets, the temperature of which, as a result of their spontaneous heating during the pressing process, can range from 65 to 90°, are cooled, dried if necessary, and then packaged and sent to consumers or to a warehouse.

The stages of pellet production are demonstrated in detail by relevant videos that are easy to find on the Internet.

How to distinguish high, premium quality pellets from substandard fuel?

When purchasing pellets, you need to pay attention to:

- the surface of the material must be smooth, shiny, without signs of deformation (swelling and microcracks);

- diameter (this parameter is established by the standards, the minimum value is 4.00 mm, the maximum is 10 mm, also standard are fuel pellets that have a diameter of 6.00 and 8.00 mm, please note that a pellet boiler operates on pellets of a certain fraction);

- length (this parameter should be about 20.00 - 30.00 mm, this is the optimal value, although the equipment can work on pellets with a length of over 50.00 mm);

- smell (the granules should have a slightly sweet smell of freshly prepared glue, this is a clear sign of excellent quality);

- color (it is important to remember that the highest quality pellets are white or slightly cream-colored, agropellets are predominantly dark, and in wood pellets, dark color indicates that bark, other impurities have been added, or wood species have been mixed);

- dust (there should be a minimum amount of dust on pellets, so it is better to buy fuel in sealed packaging);

- impurities (the presence of non-combustible impurities in the granules themselves can only be checked by burning them and determining the residue in the form of solid particles).

Press for making fuel briquettes with your own hands

The purchase of ready-made equipment for the production of briquettes, depending on its capacity, will cost from 300 thousand to 1 million rubles.

Of course, for a private owner who wants to start producing this fuel purely for his own needs, such costs are impractical, since they will not pay off soon. It would be more correct to make a press from scrap materials, especially since there is nothing complicated in its design.

You can build the necessary equipment from scratch or use ready-made mechanisms.

Homemade machine

Scheme

Homemade lever and screw presses do not require the use of purchased products, but they cannot boast of significant compression force. It is proposed to assemble a press based on a hydraulic jack or the same press.

It can be equipped with an electric motor or a manual drive:

- We will attach the punch to the hydraulic installation. Its dimensions must correspond to the dimensions of the matrix in which the raw materials will be compressed into a briquette.

- We will make the matrix itself from a thick-walled pipe - this is the simplest option. Holes will be made in its walls to allow air and moisture to escape.

- We will equip the matrix with a removable bottom. Having removed it, the finished briquette can be pushed out with a punch into the receiving tray.

Drawing diagram for the production of briquettes from soaked paper pulp

The working mechanism is placed in a housing equipped with two handles for easy transportation.

Necessary materials

In addition to the hydraulic installation, you will need some types of rolled steel:

- Channel.

- Equal angle corner 100x100 mm.

- Sheet thickness 3 – 6 mm. A punch will be cut from it. The thickness of the workpiece depends on the diameter of the matrix: the larger it is, the thicker the punch should be.

From the same sheet we will cut out a removable bottom for the matrix.

- A pipe with a diameter of 25 - 30 mm - the punch rod will be made from it.

- A thick-walled pipe is a blank for the matrix. The diameter depends on what size briquettes the user wants to receive. The thinner they are, the higher their density, but the productivity of the machine will decrease.

- A large diameter pipe is a blank for the mixer body. If there is no suitable pipe, the drum can be made from a sheet of tin.

- Galvanized steel for the manufacture of trays.

In total, you will need two trays - for loading the prepared material into the matrix and for receiving the finished briquettes.

Manufacturing and assembly instructions

The order of operations in the manufacture of the press looks like this:

- It is necessary to weld the base of the device from the channels.

- From the corner we make 4 racks 1.5 meters long. They are welded vertically and with the same pitch.

- Next, you need to make a drum from a pipe or sheet of tin in which the raw materials will be mixed. If you have a broken washing machine, the drum, as well as the bearings, can be removed from it.

- The drum must be attached to the stands. If possible, it should be equipped with an electric motor. If the motor is too high-speed and it is not possible to reduce the rotation speed of the drum to an acceptable value due to the difference in pulley diameters alone, a gearbox should be used.

- It is necessary to attach a tray under the drum through which the prepared material will be fed into the matrix.

- In the walls of the pipe used as a blank for the matrix, it is necessary to make several holes with a diameter of 3 - 5 mm. They must be distributed evenly so that air and water are squeezed out throughout the entire volume of the briquette.

- A flange must be welded to the bottom of the matrix, to which the removable bottom will be screwed. This bottom is cut from a steel sheet in the form of a disk with eyes.

- The matrix is welded or screwed to the base under the loading tray.

- We cut out a round punch from a steel sheet. This is simply a disk whose diameter allows it to freely enter the matrix.

The rod is made of a pipe: a diameter of 30 mm is sufficient. One side of it is welded to the punch, and the other is attached to the hydraulic unit.

Next, the entire assembly should be attached to the racks exactly above the matrix.

To reduce the time spent on removing the finished briquette from the matrix, and thereby make the machine more productive, a spring with a disk of the same diameter as the punch can be welded to the bottom of the matrix.

After turning off the hydraulic unit and removing the punch, the product will be pushed out automatically by the spring.

Advantages and disadvantages of solid fuel in the form of fuel pellets

The main advantages of pellets:

- environmental cleanliness (when burning this type of solid fuel, carbon dioxide is released in volumes equal to the volumes formed during the natural decomposition of various wood wastes);

- fire safety (pellets are less susceptible to spontaneous combustion than other types of solid fuel);

- optimal humidity (8-10% versus 30-50% for logs) and density (one and a half times higher than that of firewood);

- remarkable calorific value, one ton of fuel pellets is enough to produce 3500 kW/h of thermal energy;

- constant and very high bulk density, which facilitates logistics, loading and transportation of pellets;

- the uniformity of the structure in shape and size makes it possible to automate all processes of loading and loading and combustion of fuel pellets in boilers.

Cons of pellets:

- high cost of solid fuel at the present stage;

- to burn pellets you need a special pellet boiler equipped with automation, which also costs more;

- the volume of supply on the market is low, the situation will improve over time, but pellets must be purchased in reserve and stored in warehouses, preventing excess moisture from entering.

Benefits of pellets

Pellets have a number of advantages over other types of heating material:

- Great heat dissipation

- Convenient storage,

- Economical use,

- Fire safety,

- Environmental friendliness,

- Possibility of storage near living quarters,

- Does not cause allergies during combustion and storage,

- Availability,

- Economic benefit: the use of pellets reduces the cost of heating a house and outbuildings several times,

- High thermal conductivity.

In Russia, this type of fuel is just gaining popularity, but in European countries and the USA it is widely used.

Heating pellets are not only more profitable than chips with peat, briquettes or coal, but also much more convenient during transportation, unloading and loading.

Pellet cost

Let's take the initial data:

- the average cost of industrial pellets in the Krasnoyarsk Territory as of December 2015 is 3,500 rubles per ton (3.50 per kilogram);

- the price of birch firewood is 1,300 rubles per cubic meter, in terms of tons (a cubic meter of dry birch firewood equals 650 kg of weight) is 1,846 rubles per ton (1.85 rubles per kilogram);

- the calorific value of birch firewood is 10 MJ/kg;

- The calorific value of wood industrial pellets is 18 MJ/kg.

In order to obtain 100 MJ of thermal energy, you need 10 kg of firewood (100/10), that is, 18.50 rubles, or 5.5 kg of pellets (100/18), that is, 19.44 rubles. The difference in cost is 1 ruble per 100 MJ. Moreover, it is necessary to note the undoubted advantages of pellets with an ash content of 1.5% over firewood with an ash content of 10%, the difference is obvious. It should be taken into account that the pellet market is growing dynamically, and with an increase in supply, the price will undoubtedly decrease. By the way, pellets can be made independently from agricultural or wood waste. Read below how.

Equipment for pellets (with video)

There are companies in Russia that develop equipment, machines, and production lines, including those for the production of fuel pellets and briquettes, which can manufacture equipment directly taking into account your wishes on an individual order. In this video, there is a company that manufactures just such equipment:

Until recently, pellet manufacturers focused primarily on Western consumers. But it turns out that enterprising people have been successfully using such units on their farms in Russia for a long time. OGM-1.5 presses and AVM-1.5 dryers have been working regularly for one of my farmer friends since Soviet times, slightly modernized, with a new set of rollers and dies, they produce a variety of products.

Mini-equipment for pellets is usually multifunctional. By changing matrices, you can produce pellets from straw, hay, husks, and garden waste. This is both waste disposal and the production of raw materials for heating housing, greenhouses, and livestock buildings.

It can also be used to produce feed, fertilizers and many other things needed on the farm according to the required recipe.

We make pellets with our own hands

You can make pellets with your own hands. To do this we need to assemble a granulator. It is necessary to take wood or agricultural waste, grind it to a particle fraction of 30.00-50.00 mm, dry it to a moisture content of 15.00%, grind it to particles with a fraction of 2.00 mm and place it in a granulator. In the case when you use agricultural waste, such as sunflower husks, rapeseed or sawdust, as the initial, basic raw material, you do not need to crush anything. But if branches, bark, or various substandard lumber are used, it is necessary to crush, although the use of a granulator allows you to omit this operation. The dryer is made from an ordinary metal barrel. It is better to use a granulator with a flat matrix (a cylindrical matrix in the shape of a perforated drum is a more complex solution) and a perforated disk with outlet holes in the shape of a cone with a diameter of 8.00-10.00 mm, this is the optimal solution. You need to buy a matrix and rollers (the production of spare parts is carried out by manufacturers of equipment for the production of animal feed). The matrix is also made independently, from steel with a thickness of at least 20.00 mm, and gears are used as rollers. You will also need a gearbox and an electric motor with a power equal to or greater than 15.00 kW. It is necessary to ensure rotation in the range of 60-120 revolutions per minute. The shaft can be installed both horizontally and vertically; the main thing is to make tanks for loading the raw materials and subsequent unloading of pellets.

Stages of making pellets:

- we take or make a matrix, make a hole in the center for the gearbox and always a groove intended for landing;

- gears (rollers can be used, the width of which must match the width of the working surface of the matrix used), are put on the shaft strictly perpendicular to the axis of the installed gearbox shaft using a conventional coupling;

- the cylindrical body is welded from sheet steel or steel pipe, taking into account the dimensions of the matrix, which should rotate easily and freely, providing holes for unloading pellets and a tray also made of sheet steel or steel pipe, the bottom and top of the structure can be made detachable to facilitate maintenance;

- the output shaft of the selected gearbox is strengthened in the lower part of the machine using a coupling and always bearings;

- the matrix, as well as the rollers, are installed in a cylindrical body;

- the resulting structure is mounted on a frame made of a channel or an ordinary angle and is rigidly fastened; all that remains is to install the engine and connect the output shaft to the installed gearbox.

The future belongs to pellets and pellet boilers. Kras-Kotel specialists will help you make the right choice of pellet boiler, taking into account all your wishes and the characteristics of your home.

Share on social media networks:

Homemade granulators

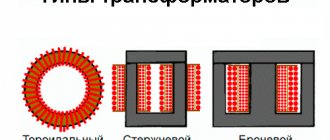

Although a lot of equipment is required for the production of pellets, the main device is a granulator. With its help, pellets are formed from raw materials. There are several models of granulators:

- Screw. The structure is similar to a household meat grinder. The same screw shaft and matrix - a grid through which raw materials are pressed. They can be used for soft materials such as straw. It doesn’t “pull” wood, even well-chopped wood—it doesn’t have enough effort. In principle, if the parts are strong enough, you can install a more powerful motor.

Schematic diagram of a screw extruder (granulator)

Yandex.RTB RA-1479455-8

- With a flat matrix. There is a metal circle in which holes of the required diameter are made (usually 3-4 mm). There are toothed rollers that force the raw materials through the holes, forming granules. Design of the main unit of a granulator with a flat matrix

- With a round matrix. The idea is the same, only the matrix is made in the form of a ring, so the rollers are located in a different plane. This option has greater productivity, but granulators of this type are rarely made by hand.

Structure of a granulator with a cylindrical matrix

The simplest screw extruder in structure. It is often made for pressing feed, but can also be used to make fuel pellets from soft raw materials. If you need to make equipment for the production of pellets, this is the easiest option. Provided you know how to operate a lathe and welding machine.

Homemade screw granulator

As with any equipment of this type, the screw granulator has a matrix. In this case, it is similar to the mesh of a meat grinder, only it is made of a much thicker plate. The second important unit is the screw shaft. All these details can be made with your own hands. How to describe it in words is useless, watch the video.

Making a matrix for a finished screw.

The screw and matrix are “packed” into a housing or sleeve. How to make it, see in the next video.

After assembling the main unit, you need to install a motor with a gearbox and a hopper into which chopped straw will be supplied. You can run it.