In a short time, inverter welding machines have gained unprecedented popularity among specialists. Despite the reliability of the power supply, repair of a welding inverter may sometimes still be necessary. Diagnosis of a malfunction and replacement of a failed part, if you have some skill, can be done at home. To carry out repairs, you must first familiarize yourself with the design of the device and only then proceed with the repairs.

Equipment delivery

Repair of welding equipment is carried out only after diagnostics, which is possible only in a service center. In addition, after eliminating the malfunction, testing is required within several hours. This approach guarantees customers the quality of work performed and spare parts installed.

If necessary, service center specialists will provide assistance in disconnecting and connecting equipment, and will also organize delivery: mobile teams consisting of several people will go to the site, disconnect the equipment and deliver it to the service center. Upon completion of the repair work, the equipment will be delivered to the customer and the necessary measures will be taken for further operation. Alternatively, you can use a courier service.

The cost of equipment delivery is negotiated with each customer individually.

Repair of welding machines: service centers in Moscow

Rinstrum

Address: st. Grishina, 18, bldg. 2, Moscow

Telephone,

Repairs welding machines in Moscow

Repair of household appliances in Moscow

⚙ washing machines, ⚙ refrigerators, ⚙ electric stoves, ⚙ gas stoves, ⚙ gas water heaters, ⚙ water heaters, ⚙ dishwashers, ⚙ microwave ovens, ⚙ vacuum cleaners, ⚙ irons, ⚙ blenders, ⚙ convection ovens, ⚙ multicookers, ⚙ mixers , ⚙ bread makers, ⚙ juicers, ⚙ meat grinders, ⚙ coffee machines, ⚙ coffee grinders, ⚙ kettles, ⚙ pumps, ⚙ voltage stabilizers, ⚙ sewing machines

Air conditioning equipment repair in Moscow

⚙ air conditioners, ⚙ split systems, ⚙ heating boilers, ⚙ electric heaters, ⚙ air purifiers

Repair of mobile devices and gadgets in Moscow

⚙ smartphones, ⚙ phones, ⚙ tablets, ⚙ GPS navigators, ⚙ e-books, ⚙ PDAs

audio and video repair in Moscow

⚙ TVs, ⚙ LCD TVs, ⚙ car radios, ⚙ video cameras, ⚙ satellite receivers, ⚙ speaker systems, ⚙ DVRs, ⚙ audio players, ⚙ DVD

Computer equipment repair in Moscow

⚙ laptops, ⚙ computers, ⚙ hard drives, ⚙ game consoles, ⚙ monitors, ⚙ motherboards, ⚙ servers, ⚙ network equipment, ⚙ modems, ⚙ switches, ⚙ uninterruptible power supplies

Office equipment repair in Moscow

⚙ printers, ⚙ MFPs, ⚙ copiers, ⚙ risographs, ⚙ scanners, ⚙ projectors, ⚙ plotters, ⚙ laminators, ⚙ shredders, ⚙ calculators, ⚙ cartridges, ⚙ mini PBX

Repair of garden equipment in Moscow

⚙ chainsaws, ⚙ trimmers, ⚙ lawn mowers, ⚙ brush cutters, ⚙ motor cultivators, ⚙ car washes, ⚙ snow blowers

Repair of tools and construction equipment in Moscow

⚙ power tools, ⚙ petrol tools, ⚙ rotary hammers, ⚙ drills, ⚙ grinders, ⚙ jigsaws, ⚙ compressors, ⚙ welding machines, ⚙ generators and power plants, ⚙ electric motors, ⚙ laser levels

Photographic equipment repair in Moscow

⚙ cameras, ⚙ SLR cameras, ⚙ lenses, ⚙ flashes

Repair of binoculars and telescopes in Moscow

Watch repair in Moscow

Repair of medical equipment in Moscow

⚙ inhalers, ⚙ tonometers

Repair of commercial equipment in Moscow

⚙ cash registers, ⚙ scales, ⚙ banknote counters, ⚙ banknote detectors, ⚙ banknote packers, ⚙ data collection terminals, ⚙ barcode printers, ⚙ barcode scanners

Repair of musical instruments in Moscow

repair of electrical equipment in Moscow

repair of industrial equipment in Moscow

repair of industrial refrigerators in Moscow

repair of personal electric transport in Moscow

repair of measuring instruments in Moscow

ℹ️ Do you need service services? In the city of Moscow, we have assembled service centers that can perform scheduled or warranty repairs of any equipment, as well as configure or install it. Contact specialists from one of the organizations represented who will provide you with professional technical assistance! To quickly find a suitable service center, use quick links that group services by type of service offered.

Repair speed of welding equipment

To solve a problem related to a malfunction of the welding machine, it will take from 3 days to two weeks. The service center always has in-demand spare parts in stock; Deliveries from time-tested manufacturers are carried out daily.

In the event of a microprocessor failure, repair work may take a little longer: spare parts are supplied to order from the equipment manufacturer after diagnosis. The exact timing of repairs depends on the date of receipt of delivery.

It is important to note that our technicians work not only on weekdays, but also on weekends. This is due to the lack of active traffic on the roads: it is easy to get to the service center without traffic jams. Delivery of the welding machine will also be much faster.

Repair work for regular customers on weekends is carried out at a discount.

Repair of inverter power unit

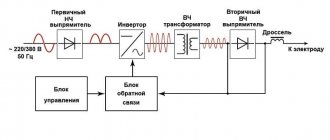

Electrical circuit of a welding inverter.

To repair the inverter power unit, the following tools may be required:

- pliers;

- two soldering irons with a power of 40 and 100 watts;

- screwdrivers of various types;

- wrenches and socket wrenches;

- knife;

- wire cutters;

- tester for electrical network;

- oscilloscope;

- calipers;

- micrometer.

The most typical breakdown of the power unit of a welding inverter is the failure of a powerful transistor. In most cases, a damaged transistor can be identified visually: it has defects, burnouts or deformation. Repairing an inverter if a defective transistor is detected is reduced to replacing it.

There are many cases when a transistor breakdown is only a consequence and not a cause. With this development of events, replacing the transistor assembly may not give a visible effect.

If, after replacing the transistor, the functionality of the device has not been restored, then it makes sense to move on to the next step, namely diagnosing and replacing elements from the diode bridge.

Before repairing the diode bridge, you should check the functionality of all elements. This can be done by alternately measuring the resistance on the legs of the elements. If the resistance between the multimeter probes located on the diode legs is zero or infinity, then this element should be replaced.

New transistors or diodes should be selected from analogs with similar characteristics. As a rule, analogues of the vast majority of models of electronic components are available for sale.

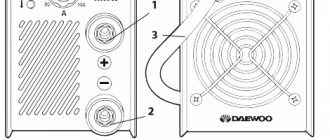

Components of a welding inverter.

When repairing the inverter power unit, you should adhere to the following rules:

- Do not use an electrical appliance with an open insulating casing.

- Diagnostics and replacement of all electronic components must be carried out on a de-energized welding machine.

- It is best to remove accumulated dust and debris from the device using a compressor or a can of compressed air.

- Cleaning the board from sticky traces and used flux should be done using plastic-neutral solvents. It is recommended to use a special brush for cleaning electronic components.

- A working device should be stored in a disconnected state and with the casing completely closed.

Payment Methods

The convenience of cooperation with us is due to the fact that we offer clients several methods of payment for work performed: cash and non-cash payments, bank transfer. When interacting with legal entities, an invoice is issued and the necessary package of documents is prepared.

Please note that we do not accept payments through electronic wallets and payment systems.

The cost of urgent repair work doubles; This service is at the discretion of the client.

Design of welding inverters

Unlike a transformer, which consists of electrical components, an inverter is equipped with electronics. The inverter transformer is very small, no larger than a pack of cigarettes. If a 160 A welding transformer weighs about 20 kg, then the same welding inverter transformer weighs 250 g, which is why the inverter is so compact and light.

Basic elements of a welding inverter

All elements are enclosed in a metal case. A wide adjustable shoulder strap is attached to the top. The device is comfortable to carry and climb to heights. The case has additional ventilation grilles for efficient cooling. The device has two connectors: “plus” and “minus”. The ground cable and the electrode holder cable are connected to them. On the front of the case there is a control panel with a power on indicator and an overheat protection indicator, a power on button and smooth adjustment of the welding current. Models that provide different welding modes have a mode switch. The inverter is connected to the network using a power cable. The base of the device has support legs.

Repair

Now in every locality you can find many centers of various sizes that repair inverter welders. This has led to the fact that equipment repairs are carried out by specialists with, to put it mildly, low competence . There are known cases when used parts were installed instead of new spare parts, or jumpers were made altogether. All breakdowns are divided according to severity. Let's look at them in order of increasing complexity.

Simple breakdowns

The cause of such malfunctions is violations of the equipment operating mode . Diagnosis does not require special tools; a visual inspection is sufficient. Minor faults include:

- Lack of food;

- Excessive dustiness of the housing;

- Power loss;

- Weak arc;

- Loosening bolted connections;

- Splashes of molten metal.

This may include condensation on the internal elements of the unit. If left unaddressed, it will lead to more serious problems.

Average

This type is characterized by the failure of various semiconductor elements, as well as electronic parts. To repair such faults, you must know how to use a soldering iron. Medium failures include problems with the following parts:

- Resistors;

- Capacitors;

- Transformer;

- Diodes;

- Circuit board;

Complex

The most serious faults are those that cannot be detected by visual inspection . In this case, the technician requires good skills in repairing electrical equipment. Otherwise, you need to start looking for a place where the welding inverter will be repaired.

General information

The inverter is a product of the development of semiconductor technologies, for example, Cascade and Laurel. Compared to transformers, they compare favorably with the following parameters:

- Light weight;

- Compact dimensions;

- Seam quality;

- Economical energy consumption;

- Additional functions.

For home use, the main disadvantage of transformers is the increased requirements for the power supply network, since the power of these devices is very high, sometimes reaching 8 kW. In addition, their operation is accompanied by numerous voltage surges, which negatively affect the integrity of the wiring and can damage household appliances powered by electricity.

Thanks to the last point, inverters are valued by novice welders, because they can facilitate the process of joining materials. The following functions are implemented on modern devices:

- Hot start . Simplifies arc formation by increasing the current level before starting work.

- Anti-stick electrode . If there is a danger of sticking, the current level is automatically reduced, allowing the connection to continue.

- Arc Force . As the arc length increases, the automation independently regulates the current strength, preventing breakage. This function is especially useful when the seam is directed vertically.

Factors leading to failure

Welding repair is an unpleasant event that costs the user time and money. To avoid unscheduled repairs, you should know the reasons that can lead to failure. They can be divided into two types:

- Violation of operating conditions.

- Damage to unit components.

The most common factors leading to problems are:

- Untimely removal of moisture can damage the electronic components of the system.

- Excessive dust leads to malfunctions of the cooling system.

- Exceeding the duration of switching on the device leads to overloads.

The most common malfunctions, as well as methods for eliminating them, are shown in the table below:

How to do a DIY repair?

Inverter welding repairs should begin with a careful study of the device diagram . After this, it is necessary to localize the problem - in the vast majority of cases, the reason lies in the internal part of the device, so it is necessary to dismantle the protective housing and carefully examine the condition of all components.

First of all, the quality of the connections - perhaps the problem lies on the surface, and fixing it will not take much time.

Dark areas on the electronic circuit, as well as burst capacitors, indicate failure of these elements.

Electronic or semiconductor elements cannot be repaired - they are replaced with similar ones.

During use, the markings may be erased. In this case, special tables are used to select spare parts. The most vulnerable element of the inverter is the power unit .

This is where the diagnosis should begin. For this work, you will need a multitester, which can also be used to check other elements of the device. The most complex component of the inverter is the control board, which is responsible for the functioning of the entire device. Its signals are checked using an oscilloscope.

At the end of the work, it is necessary to check and clean all connector contacts.