- July 22, 2020

- Tools and equipment

- Andrey Sky

Almost any knife, especially for household use, requires regular restoration of the cutting edge. Due to constant mechanical impact, the tip becomes dull and deformed, which is why its performance is lost. Therefore, the sharpening process is a mandatory technological operation as part of the maintenance of this tool. This procedure can be performed with makeshift tools, but it is much more convenient to use special equipment like a sharpening machine. How to sharpen knives correctly on such a unit? Several aspects of the operation need to be taken into account at once - this applies to preparatory work and setting up equipment in compliance with safety rules.

When is it necessary to sharpen a knife?

If the tool is in good condition and fully ready for cutting operations, there is no point in adjusting its edge. On the contrary, performing this procedure may disrupt the initially correct edge geometry and reduce the quality of the cut.

But there are signs that clearly indicate that the use of an electric knife sharpener or other tool is required to restore the tip to working condition. For example, if small particles of metal are chipped off the edge. Some models of knives, depending on the material used, even pose a risk of injury in a dull state.

Another sign of a non-ideal state of the tip is the poor quality of the cut in principle. If the knife does not cut, but tears the product, it is necessary to correct it. The essence of the sharpening operation will be to restore the desired blade profile. In other words, the rounded edge of the tip must be given the shape of a cone.

A bread slicer for each

Everyone has knives. Regardless of who you are—an experienced nymphomaniac who won’t go out on the street without three blades and a multi-tool, or an inveterate pacifist and non-resistance to violence—you definitely have a knife. If not with you, then at home in the kitchen. Or in the car. Expensive or cheap, warehouse, tourist, hunting, bought from a fashion catalogue, given to a friend “for a penny”, made in the zone or machined at a secret factory from a rocket nozzle - there are countless of them.

Typical “knife in the car just in case”

Three quarters of them are stupid. Sometimes you go with friends to the pampas, you need to cut something, and they’re like: “Oh! I have a knife in my glove compartment!” Something fearful is brought into the light of God, whose wit varies from “dumb as a Siberian felt boot” to “only used to cut up dead mongrels.” And what? They used this to open cans, chop nails on a dare, and pick at bricks. This is how it became. It’s easier for me - I always have a “folding bag” with me, for a quarter of a century now. And it's sharp.

Do you want the same? Learn to sharpen.

How to choose a sharpening machine?

For household work, it is best to use electric models for household use. Today these are universal units with a desktop installation method that cope with the restoration of blades not only of knives, but also of axes, chisels, all kinds of cutters and scissors.

It is advisable to give preference to knife sharpening machines with an adjustable angle, which will initially improve the quality of the operation. Moreover, it is important to pay attention to the configuration of the working equipment. Firstly, much more sharpening capabilities will be provided by a machine that allows the use of an abrasive disc and tape. Secondly, it is more convenient to use a setup with two circles on different sides. The fact is that the process of point correction may require the use of abrasives with different degrees of grain size. To avoid wasting time on reinstalling them when moving from one circle to another, it makes sense to take care in advance about the possibility of installing two elements simultaneously from different sides.

Checking the sharpness

Using a professionally sharpened blade, they shave the hair on the arm and “plane” a sheet of paper suspended by the tip without catching. There is a test for kitchen knives: place a tomato on a stand and, without much effort, without holding anything, cut off half or a slice from it. You can also use your thumb to evaluate the sharpness of a specimen if you have some experience: you should run the pad across the blade; tactile sensations will not deceive the knife tester.

Paper

Checking shaving hair on the arm

Using a tomato

Features of professional sharpening machines

Such equipment has several technical and operational differences from household analogues. But it’s worth emphasizing right away that the cost of this machine can be 2-3 times higher than models for home use.

So, we are talking about more productive, functional and precise units that can confidently adjust the shape of an edge made of tool and high-speed steel. As a rule, professional electric knife sharpeners have a durable metal base, a balanced rotor, almost always the ability to install two wheels, and a powerful three-phase motor.

In terms of functionality, it is worth emphasizing the possibility of adjusting the reach, point-by-point adjustment to the dimensions of the tool being processed, and automatic wetting of the working equipment, which protects it from overheating.

Main types of blades

Before you start learning how to sharpen blades, you need to know what types of blades there are. Different types of steel have some nuances:

- Carbon steel. The material is an alloy of carbon and iron. They are easy to sharpen and maintain their sharpness for a long time. People are attracted by the affordable price. Tools made from this material quickly rust in an acidic environment.

- Low carbon stainless steel. They are a compound of chromium, iron, carbon. Compared to carbon steel, this material dulls quickly due to its low hardness. The main advantage of stainless steel is its resistance to rust formation.

- Damascus steel. Blades made of this material are multi-layered products that have an unusual pattern on their surface.

- High carbon stainless steel. High carbon content, plus the addition of molybdenum and vanadium make this material more durable than conventional stainless steel. The products dull slowly and are protected from corrosion.

Ceramic blades belong to a separate group. This material has a high sharpness from the factory, which does not dull over a long period of time. However, ceramic tools are fragile and are not resistant to strong impacts, falls, or the application of breaking force.

The best manufacturers of sharpening machines

In the budget segment, for simple sharpening tasks you can find good offers from domestic manufacturers. These are machines costing up to 3-4 thousand rubles. from brands such as “Vikhr”, “Kraton”, “Caliber”, etc.

The middle and most popular segment is represented by models with a price tag of approximately 5 to 10 thousand from Bosch, Metabo and Makita. According to reviews, one of the best knife sharpening machines in this group is the Bosch GBG 60-20 model. It has balanced characteristics and decent German workmanship.

Private craftsmen and industrial workers will be interested in professional models. This is a narrow, but technologically developing class of sharpening machines from companies such as Inforce and Proma in the BKL line.

Rules of use and care

A sharp knife is safer than a dull one. It has a smaller area of contact with the object and, at the same pressure, is less likely to jump off it. Therefore, it is more difficult for them to get hurt. The knife will cut into an object without effort if you keep the blade sharp, protecting it from cutting hard materials. The cutting board should be made of wood or plastic. After work, the cutting tool is rinsed or washed using non-aggressive household chemicals and wiped dry. Knives should not be stored “in bulk” with other metal products; ideally, a separate box or special stand would be suitable.

Use wooden or plastic cutting boards

For storage you should use special boxes

Wash with warm water and non-aggressive detergents

Abrasive wheel selection options

This consumable material for a processing machine is available in a wide range. The sharpening wheel specifically for a knife should be designed for working with steel and the possibility of finishing correction.

The shape of the profile is fundamentally important for working with sharpening. In this case, equipment with a straight profile is used, which is optimal for straightening the blade.

The grit size will determine what type of finish a particular abrasive wheel can provide. For a sharpening machine used to correct a knife blade, almost all types of fractions can be used. Usually there are three ranges - from 400 microns, from 1000 microns and from 5000 microns. Accordingly, coarse, medium and fine sharpening is provided. Sometimes you can limit yourself to just finishing touches if the blade requires only minor editing.

The type of abrasive itself is equally important. Although knives are not overly demanding tools in terms of machining and dressing, today it is better to give preference to the more durable and efficient alumina blades. This material is hard and resistant to damage.

What tools can you use?

Experts recommend straightening with musat or a grindstone in order to ensure careful use of your product. But practice shows that in the process of cutting materials of increased hardness, nicks and dents of the cutting edge on the blade may occur. Also, as a result of previous edits, the sharpening angle of the blade and the descent parameters of the knife blade change. Some negative changes, such as cracks and fractures, are detected by sharpening specialists only when the surface is repeatedly magnified using optical inspection tools.

Depending on the condition and material of the product, certain types of devices and special equipment are used, ranging from “diamond” files to sharpening stations. How much it costs to sharpen a knife is determined individually in each specific case and depends on the type of equipment used, the cost of “consumables” and the complexity of the work performed. For example, chopping or slicing some foods requires a “razor sharpening,” while chopping and chopping ingredients requires sharpening the knives to normal sharpness.

Grindstone

A whetstone is an abrasive material of natural or artificial origin with a rough surface. Today, the existing assortment is represented by hundreds of product items of various shapes, materials and grain sizes. Whetstones for manual sharpening are usually produced in the form of rectangular bars. They are convenient both for working “on the knee” and in conjunction with accessories or equipment. Numerous sharpening devices are often loaded with bars of certain sizes. Before use, the stones are soaked in water for 5-10 minutes so that when rubbing against the metal, an abrasive suspension is formed, which speeds up the sharpening process.

The following types of product exist:

- Ceramic sharpening stones are made from a special type of this material with low abrasive wear. Such bars are easy to work with and inexpensive, but processing with ceramic stones requires a significant investment of time. They are suitable for straightening blades and bringing surfaces to a mirror shine.

- Water-based artificial sharpening stones, compared to their natural counterparts, have the same grain size of silicon carbide, aluminum oxide or chromium. They are capable of turning high hardness steel 60-62 HRC. They have minimal wear, and in soft operating mode they bring any blade to sharpness without chipping the steel cutting edge. But the stone requires regular cleaning: when working, the edges of the stone quickly become clogged with metal powder and become “licked”.

- Diamond sharpening stones are diamond patterned coating deposited on a solid metal or plastic substrate. Such whetstones are indispensable for sharpening ceramic knives. This type of product is wear-resistant and provides high speed in a wide range of jobs. But crumbs of different sizes leave behind scratches. Using a diamond stone, you can quickly sharpen knives if there are no increased demands on the quality of sharpening.

The unit of grain size is Grit; the higher the number, the finer the grain of the abrasive material. The highest quality sharpening of a knife can be achieved by using at least 3 stones of different grain sizes, moving from coarse-grained stone to fine-grained stone with a gradual increase in the number of grits. To sharpen regular kitchen knives, a second step using medium-grain stones is sufficient.

The full list of works includes the stages of sharpening one-sided and two-sided symmetrical knife surfaces.

| Stage number | the name of the operation | Abrasive grain size (grit) | Purpose |

| 1 | Rough processing | 400-1000 | Forming bevels, creating a sharpening angle |

| 2 | Medium sharpening | 1000-3000 | Obtaining the required cutting edge sharpness |

| 3 | Finishing | ≥ 3000 | Final straightening of the blade, grinding and polishing |

There are combined designs with different surface grains, which during operation are simply turned over to the required side.

Ceramic

Water

Diamond

Tilt angle

Sharpening direction

Musat

The classic musat is a device of simple design. It consists of a round rod with marks and a handle at the end. The sharpening base is chrome steel coated with diamond sand or ceramics.

By running a knife across the musat at an angle of 15-25º, as if cutting off the top layer, you can straighten a curved cutting edge or remove burrs even from a chef’s cleaver.

The undeniable advantages of the product are:

- efficiency of use, musat is always at hand, and editing the cutting edge takes seconds;

- safety of use, the magnetized rod collects the resulting metal filings, preventing them from getting on the food.

Handling musat requires a certain skill; the possibility of damaging the blade by incorrect actions is the main disadvantage of the device.

Sharpening with support

Aweigh

Machines with abrasive and felt wheels and sanding belts

Electrically driven machines are equipped with abrasive felt wheels with a diameter of 175 mm. They carry out stripping, cleaning of semi-finished knives and finishing of the finished tool. Felt wheels with a coarse and fine wool coating structure are made from tightly compressed wool; they are intended for grinding and polishing products. Specialized grinding machines are equipped with paper sanding belts with an abrasive coating in the form of a loop moving on pulleys in a circular motion. Using grinders, sharpening, initial and finishing processing of cutting tools is carried out.

This equipment, due to the need for a 3-phase power supply, high power consumption and cost, is suitable only for professional use. It is difficult to say how many items will need to be sharpened in order for the costs to be justified, so machines are in demand exclusively in knife manufacturing factories or in specialized tool sharpening centers.

Mechanical sharpener

A standard mechanical sharpener is a plastic body with a transverse slot into which a knife blade is placed. With forward movements toward and away from you, metal cutters, located wedge-shaped in the slot, sharpen the edge of the blade to a working sharpness. Modern models with main (coarse) and final (fine) slots are equipped with a diamond grinding stone or ceramic discs.

The highest quality sharpening is achieved with sharpeners belonging to the group of professional sharpening systems in the segment of inexpensive devices.

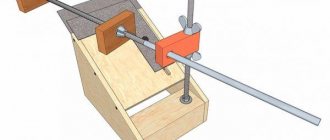

This system consists of a tripod with a suspended “boom” of the sharpening mechanism, driven by the performer’s hand. Thanks to its compact size, it easily fits on the table where a specialist sharpens knives.

The system consists of a plate with a vertical stand, where a ball joint is fixed. Before the procedure, the specimen to be sharpened is securely fixed to the base using a stop with a clamping bar or neodymium magnets. At one end, a steel guide is threaded into the hinge hole, equipped at the other end with a sharpening stone and a handle. The guide with the sharpening stone is lowered onto the knife blade, then at an angle of up to 45º to the horizontal, reciprocating movements are made, reminiscent of moving a violin bow. If it is necessary to change the sharpening angle of the tool, the hinge bar is fixed higher or lower on the vertical stand, thereby changing the angle of inclination of the guide relative to the plane of the blade. To help sharpeners, manufacturers apply marks on the stand with graduated angles of inclination.

By sequentially changing the grit of abrasive stones, high-quality three-stage sharpening of knives on both sides is performed. The main advantage of the Edge Pro, Ganzo, Ruixin, Profile and others systems is the ability to sharpen any tool, including scissors. But the design features of some models do not allow the full length of the surface of the bar to be used in the work. Original pocket sharpeners are represented by DMT, Lanski systems, portable and folding models in the “butterfly” style, gaming keychains and accessories.

Electric sharpener

It is a device with an electric drive for a block of sharpening discs, powered by a 220 V network. The sharpener is equipped with slots for rough sharpening or fine-tuning knives, which just need to be inserted into the slot and drawn along the entire length. It is suitable for straightening ceramic knives. The disadvantage of many models is the non-adjustable sharpening angle.

Sandpaper

When roughing workpieces, sharpening and polishing the blade, sandpaper with a grit of P120-P2500 on a paper or fabric base is used, including the popular “zero” P400. In addition to independent use, belts for grinding machines are cut from sheets of consumables. Forms 155-165 mm long covered with paper successfully replace abrasive stones of standard sizes in sharpening systems. Low wear resistance and water resistance are considered disadvantages of the abrasive material.

How to check the grinding wheel?

Whatever wheel is used in the work, it must be carefully checked before performing the operation. The audit must begin with a visual inspection. The item should not have the slightest crack or even chip.

Next, a check is performed on the machine. For this procedure, it is better to use a professional knife sharpening machine, which provides more effective safety features and customization options. On it, in particular, it will be possible to check the abrasive wheel for runout. This defect is expressed in vibrations, when, upon external observation, the outer edge of the disk moves away from the center to the sides. If such a flaw occurs, then the abrasive will need to be corrected with a special diamond device.

Can't do without a knife

The knife occupies one of the main places in world history along with fire, the wheel, and electricity. Ancient people began using the first stone knives back in the Paleolithic era. Then bone, wood, copper, iron and, finally, with the advent of technology for producing an alloy from iron ore, steel.

It is no longer possible to imagine everyday life without a knife. It is used by everyone, from housewives to special forces. A knife is a tool for many professions: cook, butcher, fisherman, hunter, huntsman, shoemaker, and so on. Even a skydiver needs a sharp knife to free himself from tangled lines.

What is this important item structurally?

If we take the general diagram, the device, for example, of a kitchen knife is presented below.

General sharpening technology

First of all, you need to consider the operation from the outside. It is usually performed in two stages.

Initially, a smooth edge of the chamfer is formed so that it is sharp and without external defects. We can say that this is a rough sharpening, during which the general geometry of a sharp blade is simulated without the previous roundness. At this stage, wheels with a large grain fraction can be used.

The second stage involves performing a much more important operation to restore the blade. How to properly sharpen knives on a sharpening machine as part of the finishing edit? Much will depend on the experience of the performer, but in any case, you should focus on the existing shape of the blade, which was modeled during rough processing. At this stage, small irregularities and burrs are usually removed that cannot be carefully removed with large-format abrasive.

Cutting edge and abrasives for sharpening

Despite the apparent simplicity of sharpening the blade, in fact the shape of the cutting edge looks quite complex. The sharpening angle creates only the general edges of the cutting edge; the edge itself is formed by the leads, narrow strips of the blade, which constitute the edge that cuts the material.

In order to remove the cutting edge of the blade, it is necessary to process the slopes with abrasive, creating a wedge.

Selecting an abrasive is not an easy task; in the modern world, various types of synthetic sharpening materials are widely used, such as electrocorundum or diamond bars with a binder.

But, as before, professional sharpeners believe that the best result is achieved only when using abrasive bars of natural origin: novaculite or Arkansas, Japanese water stones.

Sharpening knives requires the mandatory use of oil or water. This allows you to wash away dirt and solid abrasive particles from under the blade, which would otherwise scratch the blade; in addition, the presence of lubricant will protect the surface of the stone from ingrained dirt and metal shavings.

It should be noted that the surface of the sharpening stone must be perfectly flat, otherwise the cutting edge will be wavy, which will have an ambiguous effect on the quality of sharpening.

You need to be especially careful when sharpening a knife one and a half times; in this case, there is a risk of cutting your hand when sharpening on the sharp edges of the blade. For perfect sharpening, it is necessary to alternately change the grain size of the stone, moving from coarse grain, whose task is to roughly create edges and descents, and ending with polishing, which polishes descents and creates leads.

The grain size of the abrasive is determined by the size of its particles; the larger the particle size, the rougher the processing of the blade edges.

It is optimal to have 2-3 whetstones with different values for sharpening a knife. The first one is for rough sharpening, the second one is for edging and the third one is for grinding. Although the final straightening can be done with a polished piece of steel, a leather belt or a ceramic block.

Technique for sharpening knives on a machine

Now you can move on to the most important stage - direct work with the knife.

It is advisable to position the blade against the direction of movement of the disk, which will prevent the metal from crumbling at the edge and minimize the risk of the same burrs forming. The only disadvantage of this method of positioning the knife is the risk of cutting it into a circle, which will ruin the tip at one point and may well deform the entire knife. Therefore, at first, beginners can experiment with positioning the knife in the direction of the abrasive stroke.

At the editing stage, additional devices will be required for sharpening the knife on a sharpening machine. We are talking about a whetstone with the finest grain, which will allow you to carefully trim the edge in certain areas. The process of fine-grained sharpening on a machine should be performed with a minimum number of movements. There is a high risk of knocking down a chamfer, which will ruin the entire result. You need to act carefully and balanced - along the entire length of the blade. Both sides are processed in this way so that the shiny surface of the knife is equally visible.

Other scissors...

Manual and mechanical, of various designs - the knife-loving public has come up with a lot of things, but personally I respect only two varieties.

Firstly, the grinder. This is a belt surface grinding machine that allows you to perform a variety of operations - from sharpening a blade to making a knife (and other useful things made of wood and metal) in general.

Making a grinder with your own hands is especially chic; many topics are devoted to this on specialized forums. With proper practice, sharpening a knife with this device is literally a matter of minutes. I don't have a grinder, but I want one. Of course, there is nowhere to put it... But I still want to.

Secondly, musat. In essence, it is a round (less often semicircular or oval) file with a very fine notch. Musats are made of steel (including diamond-coated) and metal-ceramic.

Despite all its primitiveness, it is the musat that is the primary tool for straightening knives in the kitchen. However, it all depends on practice: in the same way, it is necessary to maintain a constant correct angle in relation to the blade. Whether to steer the blade towards yourself or away from you is your own choice. The main thing is to develop the correct movement.

I almost never use other “sharpeners” and don’t see much point in them. It will be interesting - I'll tell you next time.

What is the correct knife sharpening angle?

The value is not universal, so you should focus on the specific type of knife and its application. It can be said that in the first stage of rough modeling of the geometry, some metal should be left for later removal for straightening purposes. When final sharpening knives, the angle is usually kept in the range from 7° to 45°. Moreover, average values of about 25° usually apply to kitchen tools, and the upper bar, up to 50°, applies to special models for tourist and hunting purposes.

About angles

Holding a knife at the desired angle while sharpening is not as easy as it might seem at first glance. And what is this corner like? For the vast majority of the inexpensive knives mentioned above, the sharpening angle is 20-30 degrees. There are many ways to “calculate with your hands” the desired tilt of the blade; The simplest one is to fold a sheet of thick paper into a triangle, one fold is 45 degrees, the second is half as much, 22.5. We place the resulting pyramid on the block, carefully press the blade against it and remember the tilt and position of the hands.

20-25 degrees is a good angle for a well-worn carbon Opinel

For the same purposes, you can use special wooden corners or several coins glued with superglue. Or simply buy a special clip for the blade, which will prevent the edge from being too “collapsed”.

True, if the steel is completely “plasticine”, they try to increase the angle as much as thirty-five degrees - cutting such a product will be quite lousy, but it will take a long time. Here you can also play with a sheet of paper, but you will have to fold it not in four, but in three - as a result you will get a corner with a working side close to 33 degrees.

For soft steels there is another trick: the angle is maintained around 30 degrees, but one side of the cutting edge is smoothed almost “into a mirror”, and the other is sharpened on a rough, coarse-grained whetstone. This method is popularly called “gypsy”; at the industrial level, it degenerated into the notorious “laser-sharpened knives” (although, of course, there was no smell of laser there).

Small teeth on one side, a smooth surface on the other, and even the top layer of steel is carburized to increase hardness - it cuts well until it gets dull. For cheap domestic stainless steels such as 40X13, 65X13 or the favorite of Chinese manufacturers 420J2, this method works well - try it yourself.

Features of sharpening knives on a manual machine

Today there are many purely mechanical sharpening machines without an electric drive. They have a wide variety of design options and functionality. But when handling such a tool, it is important to consider several nuances. Firstly, a manual knife sharpener is usually mobile, which means that it will need to be well secured each time. This should be done on a workbench or other hard and stable table. Secondly, the sharpening process is performed with translational movements in only one direction. It should also be noted that with intensive use of manual sharpeners with a configuration of two V-directional abrasive stones, the knife will wear out much faster than when working with an electric machine.

How to do it manually?

Regardless of whether you decide to master manual sharpening or use small-scale mechanization means, the right thing to do is start with a block of the coarsest grain size and move on to finer ones. It is advisable to hold the knife perpendicular to the block. The most important thing is to maintain the same angle of inclination of the blade to the surface at all times. Movements when sharpening should be uniform and monotonous. The sharpening stone and the surface on which it rests should not move. To do this, you can put a piece of sheet rubber on the table, or, failing that, a moistened sheet of paper.

Grinding the first third of the knife edge "G. SakaiFoldingHunter" on a 600 grit water stone (before starting work, a block of natural stone is soaked in water for 15 minutes, and then its surface is lubricated with soapy water)

Don’t forget to periodically check how much metal is being removed from the handle, and don’t press the knife too hard - the pressing force against the block should be small but constant. Moving the knife away from you or towards you is a matter of taste; to save time, I do it in both directions. To begin with, you should practice using a regular board instead of a sharpening stone, and, say, a short ruler instead of a knife. Hands will remember.

Many consider the sharpening process to be a kind of movement meditation; in principle, that’s how it is. The need for constant control and concentration on the task at hand forces you to disconnect from external factors. It turns out to be a kind of zen.

What should you know about sharpening stones?

Comprehensive maintenance of knives, even if you have a machine with abrasive wheels, is unlikely to do without a touchstone. This granular block will allow, if necessary, to correct the result obtained on the machine, as well as support the operation of the tool in the field, if necessary.

In addition, some electric units are fully equipped with such bars as consumables. How to sharpen knives correctly on this type of sharpening machine? The principle is somewhat similar to mechanical and electrical machines on circles. The only difference is that the operator does not need to make any special efforts. The main work will be done by the device itself. The maximum that will need to be done is to ensure external control of the process.

Of course, a lot will depend on the sharpening stone itself. They are ceramic, abrasive and natural. If we are not talking about using the product as part of an electric machine, then before work it is better to moisten it with a soap solution. This technique will improve glide and prevent intense spraying of small particles from metal and abrasive.

Why is it necessary to keep the knife sharp?

It turns out that sharpening a knife is necessary primarily to make your own work easier. The mood from using such a knife is elated; remember your state of trying to cut something with a blunt instrument to no avail. Do you remember?

And in emergency situations, for example, when it is necessary to cut the locked seat belts of a car, a question of life and death generally arises.

When it comes to sharpening a knife, many people may find this activity boring, time-consuming and uninteresting.

However, if you make an effort, you can learn to enjoy sharpening a knife, turn “tedious” work into a kind of meditation, distraction from other matters, and concentration of thoughts.

Believe me, it's worth it.

Safety requirements

Using a tool sharpening machine is a very reasonable and convenient way to solve the problem of dull blades. But we must not forget about safety. How to properly sharpen knives on a sharpening machine without harming your health? First of all, you can only work on proven and serviceable equipment, as well as on tested equipment, as already mentioned. During the operation, sudden manipulations and changes in the operating mode are excluded. All actions are performed smoothly and without jerking. Also, in the room where sharpening is carried out, there must be active ventilation. Small particles of abrasive and metal released during such operations must be removed immediately, as they pose a threat to the respiratory system.

Use of alloying additives in steels

Each brand of alloy has its own composition, therefore the properties are different.

- Molybdenum.

One of the most valuable supplements. The steel becomes more ductile and durable. Japanese steel grades contain up to 8% of this element, therefore they are known for their high quality.

- Vannadium, chromium, tungsten

. Significantly increase the hardness of steel, but slightly reduce the strength. Chromium steels are resistant to wear and corrosion, but are quite brittle. Steel with a chromium content of more than 13% is considered stainless.

- Manganese

. Increases strength, rigidity, wear resistance. Many knife steels contain this element.

- Nickel

. Increases viscosity, hardness, wear resistance. Contained in knife steel AUS-8, which is one of the leaders in terms of price/quality ratio. In our range of knives, most of them are made from this steel.

- Silicon

. Increases blade strength.

There is an important characteristic that unites all types of knives from any steel, any purpose and any blade shape. That is the main feature that can differentiate a professional’s knife from an amateur’s. This is the sharpening angle, in other words, the sharpness of the blade.

Without a well-sharpened blade, work turns into torture, the efficiency of use decreases greatly, and precious time increases exponentially.

Interesting fact!

A dull blade will hurt you more easily than a sharp blade. The reason is excessive force on the knife, which can slide off the surface.

Methods for checking the blade tip

After carrying out the work, you need to check how sharp the blade is. Several methods are used for this.

On paper

Try to cut a sheet of paper while holding it with one hand. If you can do it without problems, the sharpening is good. A sharp blade will cut the sheet under its own weight.

On a tomato

Often the sharpness of kitchen blades is tested on tomatoes. If it is blunt, the vegetable will be crushed. You need to put it on the table in front of you, try to cut the tomato with the blade horizontally without holding it with your hand. A sharp blade will easily cut a vegetable.

Checking knife sharpening on tomatoes

Testing on hand hair

One of the testing methods that people often use after turning tools. To do this, the knife is pressed effortlessly against the skin of the hand. It should be easily passed through the hair. If the hairs are cut, the blade is sharp, suitable for various types of work.

Everyone uses knives. However, these tools become dull over time, making it impossible to work with them. To restore the sharpness of steel, you can use different devices. Taking into account the angles for different types of knives, you can carry out the work yourself.

7-step instructions for sharpening and finishing a kitchen knife

So, in sharpening a knife, one goal is to remove enough metal from the blade so that the cutting edge becomes sharp again. You need to start work with a coarse-grained abrasive and finish with a fine-grained one.

It is important to remember the following principles of sharpening knives:

- The most important thing is to choose the optimal sharpening angle and maintain it along the entire cutting edge while sliding along the block.

- Movements should be smooth, without pressure.

- All bars must be moistened with water, or better yet, with a soap solution: before sharpening (so that the blade glides better and metal dust does not clog the pores), during the process (to remove the resulting suspension) and at the end, to clean the bar.

Read also: How to connect a stepper motor without a controller

And one more important tip - the first time it’s better to practice on a knife that you don’t mind ruining. Especially if your main knife is too good and expensive. Well, let's start practicing.

Step 1. Rinse the stone with water, and then run over it, say, with a sponge with a drop of dishwashing liquid.

Step 2. Next, sit down at the table and place the stone on a wooden board, for example, a cutting board. You can place a towel under the stone. For some it is more convenient to place the block perpendicular to themselves, and for others at an angle of approximately 45 degrees. Over time, you will understand how it is more convenient for you to work.

Step 3. Now you need to decide on the sharpening angle and fix the position of the knife. What should the angle be? The general principle is that the smaller it is, the sharper the blade, and the larger it is, the longer the blade retains its sharpness.

- Regular kitchen knives are sharpened to an angle of 40-45 degrees. If you are sharpening a fillet knife (designed for cutting thin pieces of fish, poultry and meat), then you should sharpen it sharper - at an angle of 30-40 degrees. The selected value must be divided by 2, and then we will get the angle that should be between the blade and the surface of the block. That is, to sharpen a blade at 45 degrees, you need to sharpen each side at 22.5 degrees to the sharpening surface.

A simple technique shown in the photo below will help you fix the knife at an angle of 22.5 degrees.

- Remember, you should try to stick to the chosen angle throughout the entire work.

Step 4. Place the knife across the block so that the upper edge of the handle is above the lower edge of the stone. Holding the handle with one hand and the blade with the other, we begin to slide along the block away from ourselves along the trajectory shown in the picture below.

Watch a short and clear video:

- The point is that the cutting edge sliding along the stone should always be perpendicular to the direction of movement.

- At the bend of the blade, the knife handle needs to be slightly raised to maintain the selected angle.

- Remember also that you can’t put pressure on the blade, but you shouldn’t give it any slack either.

Thus, you need to pass the blade along the stone about 40-50 times, namely until a “burr” (burr, microsaw) appears along the entire length of the cutting edge. Its appearance will tell you that the excess metal has worn out and there is no point in grinding further. Then you need to turn the blade over and repeat the same steps. Clearly in the video:

- A burr is a small roughness that is difficult to see, but can be felt by carefully running your finger along the edge of the blade (but not along the edge, so as not to cut yourself).

During operation, a suspension will appear on the blade - metal dust, which must be periodically washed off with water.

Step 5. So, the burrs have appeared, now we proceed to finishing. To do this, we repeat the same manipulations on a stone with half the grain size. An alternative finishing method is using musat.

- Musat is a steel rod of oval or round cross-section with longitudinal notches. It is only suitable for editing and maintaining sharpness, but not for sharpening a knife. It is recommended to edit the knife with musat every time before and after work.

How to sharpen a kitchen knife with musat can be seen in the following video master class from the respected knifemaker Gennady Prokopenkov, who, by the way, specializes in making kitchen knives.

Step 6. If desired, you can bring your knife to a razor sharpness. To do this, take any leather or leather belt, treat it with GOI, Dialux or any other abrasive paste, and then do the same steps, but only in the direction from the cutting edge.

Step 7. Finally, we check the quality of sharpening. This is done very simply. It is enough to cut a tomato or cut paper. If you wanted to achieve razor sharpness, then you should try to shave the hair on your arm. The sharpest knives can even cut hair, as shown in the photo below, but in the kitchen such sharpness is not required for the most ordinary knife.

Why does the blade become dull?

There are a number of factors that influence the process of dulling a cutting edge:

- Excessive force transmitted to the tool when cutting. This causes the blade to bend.

- Incorrect turning process.

- Cutting hard materials.

- Improper storage.

- Impacts against metal objects.

- Destruction of metal due to corrosion.

Blacksmiths do not recommend washing knives under hot water. This is due to the fact that the metal is affected by aggressive salts, which reduce the sharpness.