The key specificity of the scheme for drying wood in a vacuum is considered to be a reduction in the time required to complete the operation provided, while maintaining absolutely all the properties of the final lumber product, and in some cases, including increasing resistance to certain operating conditions. The formation of a rarefied atmosphere in the internal size of the working chamber, in which moisture is removed from the wood, completely changes the physical properties of the heat treatment and drying process. The typical degree of vacuum at which thermal drying of wood is carried out is 0.95 mPa, and the speed of the agent of the released steam does not exceed 0.3 m3/s. Under such forcedly developed circumstances, there is absolutely no need to assemble fans, thermometers and moisture level regulators. The progress of the drying process is controlled by special sensors that set the level of readiness for the released moisture based on its number per 1 m3.

What is vacuum drying?

This type of drying is one of the varieties of this kind of technology for processing and preserving various types of materials and food products. A characteristic feature of this technology is the ease of use of drying, processing efficiency, low cost of the process itself and the speed of obtaining the required result.

The principle of influencing the processed material using vacuum drying is based on a minimum temperature level, which is much lower than the boiling point. Thus, in the absence of thermal influence on the material, which can change the structure of the processed raw material, excess moisture is removed from it than during thermal drying.

Vacuum drying of wood

This type of drying is organized through the evaporation of moisture from the internal cavity of the wood. Due to natural conditions, during the growth of a tree, its internal metabolism is carried out by circulating fluid along the entire length of the trunk. If a tree is cut down, this circulation stops, the moisture begins to evaporate and, accordingly, the wood dries. But if drying takes place under natural conditions, it takes a lot of time, which, given the volume of processed wood consumed by humans, cannot provide the required amount of finished material. For these purposes, artificial dehumidification is used, which significantly speeds up this process, minimizes fungal damage to the wood, virtually eliminates the appearance of cracks and increases the service life of lumber.

Depending on the level of moisture in wood, it is divided into several categories, such as:

- Wet. Refers to the type of materials that are constantly in water. The moisture level of such a tree is one hundred percent;

- Recently felled. The degree of humidity varies from 40 to 100%;

- Air dry. Wood that has been lying in the open air for a long time, but under a canopy. Its humidity can range from 15 to 20%;

- Room dry. If the wood is stored indoors, then the temperature regime here is often the same, which dries the material faster, creating a humidity level of 8-10 percent;

- Completely dry. It has zero moisture content, which can only be achieved by artificial drying.

For some types of production, the flexibility of wood is an important factor. The higher the humidity, the easier it is for the tree to bend. In this case, before vacuum drying, it is necessary to give the material the desired shape and fix the workpiece in this position, and then place it in the working chamber.

Method of cooking and keeping in hot compositions

The stabilizing composition, when hot, becomes more fluid and more easily permeates the wood to a greater depth. For thin products, long-term keeping of wood in a cold composition for stabilization is suitable.

Having impregnated the wood with a stabilizing composition, it is necessary for the solution to polymerize. To do this, the wood is dried for a long time in a dark place or in a stove or oven.

Once stabilized by any method, the wood is easy to process. It is perfectly polished, sanded, planed and sharpened.

Subscribe to our Yandex.Zen channel

The principle of vacuum drying of wood

The process of vacuum drying wood includes a number of production stages. To understand the overall picture of this technology, each of the stages is described in detail below:

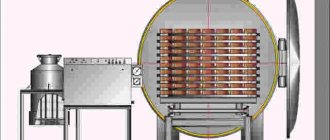

- First of all, it is necessary to load the wood to be processed into the drying chamber. To do this, timber or round timber is laid on special carts in layers, each layer being layered with aluminum plates with heating elements;

- The next step is to set up the equipment, which determines the required level of moisture in the output wood. To do this, depending on the further use of the material and the type of wood itself, the required temperature and degree of vacuum are set. Throughout the entire procedure, the pressure level does not change, only the degree of heating varies;

- When the procedure starts, pressure is not created in the chamber, but only the lumber is heated. This technology is required to prevent board deformation;

- After heating the wood to a certain temperature, the vacuum pump starts, which pumps out all the air from the internal volume of the chamber. When an absolute vacuum is reached, moisture from the deepest part of the tree gradually rises to its top layer, which ensures the necessary humidification process to avoid defective finished products. This eliminates the need to use additional humidifiers. After the liquid reaches the surface of the material, under the influence of temperature it quickly evaporates and settles on the walls of the drying chamber, from where it is pumped out as condensate. Evaporation of moisture under vacuum conditions occurs at a temperature of +40 degrees, and the maximum threshold throughout the entire wood drying process does not exceed +70 degrees.

- To further speed up drying, rubber layers are located on the inner walls of the chamber, which, when a vacuum is created, begin to be drawn into the chamber, simultaneously squeezing the wood. Thanks to this, drying is accompanied by additional pressure;

- The final stage of drying consists of lowering the temperature of the material being processed. In order to prevent its deformation, the heaters are turned off, but the vacuum is maintained. In this position, the tree continues to be under pressure and cools down at the same time. When the temperature of the lumber is compared to room temperature, the vacuum is released and the finished product is removed from the unit.

Benefits of the procedure

Stabilization is a special type of wood treatment that involves safely filling the pores with protective compounds.

Its main goal is to maintain the decorative properties of wood while increasing strength, hardness and resistance to external factors. A similar effect is achieved through the use of special compounds that have the ability to polymerize.

This is a rather labor-intensive and responsible process, the organization of which must be approached with full responsibility and the sequence of actions must be followed in accordance with the chosen technology.

Thanks to conservation, wood acquires the following characteristics:

- density and hardness;

- resistance to high moisture, temperature changes and ultraviolet radiation;

- flame resistance;

- impermeability to paints and varnishes;

- resistance to chemical and biological influences;

- inertness to deformation and rotting;

- decorativeness and aesthetics;

- susceptibility to manual and mechanical processing.

Drying wood: vacuum pump

There are a number of features when drying wood under vacuum conditions. These nuances directly affect the choice of a suitable vacuum pump that will fully provide air rarefaction under the required circumstances. Thus, the following types of vacuum pumps are used:

- Screw vacuum pumps. This technology allows you to generate a fairly high degree of vacuum during one cycle. The most popular industries where such technology is used are the chemical and pharmaceutical industries. Another advantage is the good resistance of the units to the influence of high humidity, as well as the absence of lubricants, which prevent contamination of the created vacuum by exhaust gases. Screw technology also implies the presence of explosion-proof units. They are necessary for drying processes during which explosive vapors are released from the processed material.

- Water ring vacuum pumps. They are widely used in enterprises whose main activity is the production and drying of ceramics or building materials. This is due to the fact that the only working fluid used by the pump is ordinary water.

- Rotary vacuum pumps. Thanks to its technological features, it prevents the ingress of released moisture from the material into the working area of the pump, which ensures the absence of contact with already released moisture and the material being dried. This concept is popular in those industries where raw materials react negatively to repeated exposure to humidity, thereby losing their functional characteristics.

The above types of vacuum pumps are used in such types of processing as:

- Production of powdered milk;

- Drying of discharged waste during wastewater treatment;

- Drying wood;

- Bringing synthetic granules to the final condition and a certain level of moisture;

- Drying parts and finished ceramic products;

- Drying of components and individual spare parts.

Types of pressure impregnation

Autoclave equipment may have one or more options for vacuum saturation of wood with preservative solutions. All of them provide reliable protection for the tree for many years:

- Vacuum-pressure-vacuum. The most common method. Air is pumped out of the cell membranes using a vacuum, then under pressure they are filled with a protective mixture, and the solution is vacuum fixed in the cellular structure of the wood.

- Pressure-pressure-vacuum. In this case, the air is removed by the “squeezing out” method by increasing the pressure on the material, after which the wood structure is filled with impregnation and vacuum fixation occurs.

Production of pre-pressure impregnated wood - Multi-cyclic. Here the processing-saturation cycle is repeated several times. This method provides more complete and reliable protection from all external influences.

- Vacuum – atmospheric pressure – vacuum. The technology is similar to the vacuum-pressure-vacuum method, only the solutions do not enter the cellular structure of wood under increased pressure, but flow smoothly, filling the airless space.

In addition to standard methods for processing dried material, there are also autoclave technologies for preserving raw wood. These techniques require more sophisticated equipment, but also provide high quality during further processing:

- Diffusion-autoclave treatment. The raw material is loaded into an autoclave chamber, heated with saturated steam, and then maintained under negative pressure. This process helps remove moisture and air from cell membranes. Further saturation with the preservative is carried out using conventional technologies.

- Impregnation-drying. This technique is only suitable when exposed to oils and compounds with organic solvents. Drying is carried out in the same liquid in which impregnation will be carried out. Drying can be done under vacuum or at normal atmospheric pressure, but the temperature must be above 100°C. Its duration depends on the shape and size of the product, it can be 3-20 hours, after which one of the standard impregnation methods is performed.

Perhaps, when coming to the market to buy building materials for their bathhouse or summer kitchen, an ordinary person, seeing the prices for a regular board and a board after vacuum technology, will make a choice in favor of a simple, unprocessed one. But is it worth it?

After all, if the equipment was used correctly during processing and the seller has a quality certificate, then such building material will eliminate the need for increased care about its protection for many years.