material provided by SIDOROV Alexander Vladimirovich

During the manufacturing process of machines, some of their parts are connected to each other, and permanent or detachable connections are formed. []

One-piece

are connections that cannot be disassembled without breaking or damaging parts. These include riveted, welded, adhesive, soldered, and conditionally interference fit joints.

Detachable

are connections that can be disassembled and reassembled without damaging parts. Detachable connections include threaded, keyed, splined and other connections.

Welded joints

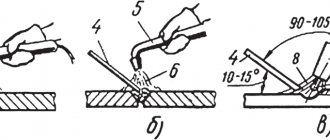

are formed by local heating of parts in the welding zone. Electrical types are the most widespread, the main ones being arc and resistance welding.

The following types of arc welding

:

- automatic submerged arc welding (this type of welding is highly productive and economical, produces good seam quality, and is used in large-scale and mass production for structures with long seams);

- semi-automatic submerged arc welding (used for structures with short intermittent seams);

- manual welding (used in cases where other types of arc welding are irrational, this type of welding is low-productive, the quality of the weld depends on the qualifications of the welder).

contact welding

used in serial and mass production for lap joints of thin sheet metal (spot, seam contact welding) or for butt joints of round and strip metal (butt contact welding).

Advantages of welded joints

:

- low cost of connection due to low labor intensity of welding and simplicity of weld design;

- relatively small weight of the structure (15-25% less than the weight of the riveted one):

- due to the absence of holes for rivets, a smaller area of welded parts is required;

- the parts can be connected without overlays;

- there are no protruding massive rivet heads;

Disadvantages of welded joints

:

- the strength of the weld depends on the qualifications of the welder (it can be eliminated by using automatic welding);

- warping of parts due to uneven heating during the welding process;

- insufficient reliability under significant vibration and shock loads.

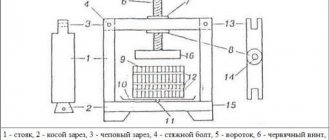

Interference connections

are carried out by selecting the appropriate fits, in which the interference is created by the necessary difference in the landing dimensions of the parts placed on one another. The mutual immobility of the connected parts is ensured by friction forces arising on the contact surface of the parts.

Connections of parts with interference are conventionally classified as permanent connections, although, especially with hardened surfaces, they allow disassembly and reassembly of parts. For this use:

- mechanical interface;

- thermal landings;

- cooling of the covered part.

Advantages of interference connections

:

- simplicity of design and good alignment of the parts to be connected;

- high load capacity.

Disadvantages of interference connections

:

- complexity of assembly and, especially, disassembly;

- dissipation of joint strength due to fluctuations in actual fitting dimensions within tolerances.

Threaded connections

are the most common detachable connections. They are formed by bolts, screws, studs, nuts and other threaded parts.

Threads are classified

depending on the:

- shape of the surface on which the thread is formed: cylindrical;

- conical;

- triangular;

- right (the helix rises from left to top to right);

- single-pass;

- fastening (used in threaded connections; they have a triangular profile, which is characterized by high friction, which protects the thread from self-unscrewing, as well as high strength and manufacturability);

Advantages of threaded connections

:

- high load capacity and reliability;

- availability of a large range of threaded parts for various operating conditions;

- ease of assembly and disassembly;

- low cost due to standardization and high-performance manufacturing processes.

Disadvantages of threaded connections

:

- the presence of a large number of stress concentrators, which reduce fatigue resistance at variable stresses.

Keyed connections

consist of a shaft, key and hub of the female part.

Key

is a beam inserted into the grooves of the shaft and hub to transmit torque between the shaft and the female part.

Keyed connections are divided into

on the:

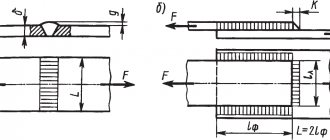

- unstressed (when assembling connections, no pre-stresses arise in the parts): with feather keys (the working edges are lateral, they do not hold the parts from axial displacement along the shaft) based on the shape of the ends they are distinguished: with rounded ends (Figure 1, version 1);

- with flat ends (Figure 1, version 2);

- with one flat and the other rounded end (Figure 1, version 3);

- with wedge keys (they have the form of single-bevel self-braking wedges with a slope of 1:100, do not require locking the hub from longitudinal movement along the shaft, and are good at absorbing shock and alternating loads) (Figure 3);

Figure 1 — Connections with parallel keys

Figure 2 - Connection with a segment key: 1 - setscrew; 2 — spring lock ring

Figure 3 — Connection with a taper key

Figure 4 — Connection with tangential keys

Advantages of keyed connections

:

- simplicity of design;

- comparative ease of installation and dismantling.

Disadvantages of keyed connections

:

- the keyway weakens the shaft and hub of the female part not only by reducing the cross-section, but, most importantly, by a significant concentration of bending and torsion stresses;

- labor-intensive manufacturing.

Spline connections

are formed by protrusions - teeth on the shaft and corresponding depressions -

splines

in the hub of the female part. The working sides are the sides of the teeth. Simply put, spline connections can be considered as multi-key connections.

Spline connections are distinguished

:

- by the nature of the connection: fixed (for securing the female part to the shaft);

- movable (allow the part to move along the shaft);

- by outer diameter (most technologically advanced);

- straight-sided (have a constant thickness of teeth) (Figure 5);

Figure 5 - Straight spline connection

Figure 6 — Involute spline connection

Figure 7 - Triangular spline connection

Advantages of spline connections

(compared to keyed connections):

- provide better alignment of the parts to be connected and more accurate direction during axial movement;

- the number of connection parts is reduced (a spline connection is formed by two parts, a keyed connection is formed by three or four);

- with the same dimensions, they allow the transmission of large torques due to the larger contact surface;

- ensures high reliability under dynamic and reverse loads;

- the shaft is weakened slightly by the teeth;

- The length of the hub decreases.

Disadvantages of spline connections

(compared to keyed connections):

- more complex manufacturing technology;

- higher cost.

Classification

The different types of compounds can be divided into two main groups. The first of which, according to the principle of operation:

- Movable. Parts can move relative to each other.

- Fixed. Both parts of the part are rigidly fixed to each other.

In turn, each type of previous classification can be carried out in two connection methods:

- Detachable. It is used when periodic replacement of parts, assembly and disassembly of the mechanism as a whole is required. These are the following types of connections: threaded (using running bolts), toothed, keyed, etc.

- One-piece. Such connections can only be dismantled using mechanical action, which destroys the mating parts. What types of connections are these? Among them are welding, gluing, riveting, flaring, crimping, interference fit, stitching, core punching, etc.

So, let's take a closer look at the main types of parts connections.

Solder connection

To connect wires in this way, you need to master soldering technology. First of all, it is necessary to strip the wires, getting rid of unnecessary insulation, to a characteristic shine. It should be said right away that soldering aluminum wires is not so easy, so you shouldn’t even try to do it without special materials. As for copper, it can be soldered without problems. To ensure high-quality soldering, the ends of the wires stripped of insulation are tinned. To do this, they are heated with a soldering iron and applied to rosin. Rosin degreases the soldering area and the solder literally envelops the end of the conductor with a thin film. After this, the ends of the wires are twisted using pliers for reliability.

After this, you can begin the soldering process, which is the final stage. We can assume that the simplest thing left is to apply the required amount of solder to the twisted area using a heated soldering iron.

After cooling, if required by the technology, the soldering joints are treated with a special compound to get rid of excess rosin or flux, after which the joints are insulated using insulating tape or another method.

Connecting wires in a junction box

This option has both its advantages and disadvantages. Soldering is a fairly reliable method of connecting wires, as long as increased currents do not flow through the wires, leading to heating of the connection point. Since solder itself is a soft alloy, and its melting point is relatively low, when the joint is periodically heated, the solder seems to evaporate, which leads to weakening of the contact. If the problem is not detected in a timely manner, this can lead to overheating of the contact and fire of the insulation. It is not difficult to imagine what consequences await the electrical wiring, and at the same time the room in which it is laid. It is for this reason that electricians do not use this connection method, although there are other negative aspects.

A negative factor is weak mechanical strength, although it depends on how well and securely the wires are twisted. Considering the fact that the solder is relatively soft, then without any problems, by applying force, the soldering point can be weakened, which is the negative factor. As a rule, experienced electricians will not take responsibility for connecting wires in this way, and this process takes a lot of time.

Threaded method

An old and long-tested mounting option. The following elements are used for it: bolts, screws, studs, screw ties and others. Fastening is carried out through threads on the fastener and in the hole of the part.

Spiral projections on the rod and in the technological hole of the parts are called threads. Let's look at the main fasteners:

- A bolt is a threaded rod with a fastening head at one end. Its shape can be hexagonal, square, round, etc.

- The screw differs from the previous product in that there is a slot (slot) for a screwdriver on the head. It can be hexagonal, straight, cross, etc. According to the type of head, products can be countersunk, cylindrical, semicircular, semi-countersunk.

- A stud is a rod with threads on both ends. Unlike previous options, it does not have a head.

- The mounting pin is slotted at one end.

- Nut is a prism with a through hole or plugged on one side.

Washers are available for these hardware: flat, spring, and deformable. This type of fixation is used everywhere.

Screwless fittings

The main holding element when attaching screwless fittings is the dowel element, cast integrally with its body. The dowel has the shape of a sleeve with pointed annular or semi-circular projections.

The fittings are installed by pressing dowels into pre-drilled holes using special equipment. Screwless fittings are technologically advanced. Provides sufficient strength.

Construction nails

The design of construction nails with a flat head corresponds to GOST 4028-63 and is shown in Figure 8.

Symbol of nails with a flat head with a core diameter of 1.2 mm and a length of 25 mm: nails P 1.2 × 25 GOST 4028-63.

Upholstery staple

The general view of the brackets is shown in Figure 9.

Screws with a semicircular head (GOST 1144-80)

Symbol of the screw: screw 3 × 20 GOST 1144-80. The general view of the screws is shown in Figure 10.

| Rice. 8. Construction nail | Rice. 9. Brace | Rice. 10. Screw |

Hex head screws (GOST 11473-75)

The general view of screws with a hexagonal head is shown in Figure 11. Symbol: screw 4 × 50 GOST 11473-75.

Screws with countersunk head (GOST 1145-80)

A general view of screws with a countersunk head is shown in Figure 12.

Symbol: screw 3 × 20 GOST 1145-80.

Bolt with an enlarged semicircular head and a mustache (GOST 7801-81)

The general view of bolts with an enlarged semicircular head and mustache is shown in Figure 13. Symbol: bolt M6 × 40 GOST 7801-81.

Screws with a semi-countersunk head (GOST 1146-80)

The dimensions of screws with a semi-countersunk head are shown in Figure 14. Symbol: screw 3 × 20 GOST 1146-80.

| Rice. 11. Hex head screw | Rice. 12. Countersunk screw |

| Rice. 13. Bolt with an enlarged semicircular head and a mustache | Rice. 14. Screw with a semi-countersunk head |

Hex head bolts (GOST 7798-70)

The main type of hex head bolts is shown in Figure 15. Symbol: bolt M 12 × 60 GOST 7798-70.

Hex nuts (GOST 5927-70) are shown in Figure 16. Symbol: M8 nut (GOST 5927-70), where H is the height of the nut; M – thread diameter; S – turnkey size.

Rice. 15. Hex bolt

| Rice. 16. Hex nut | Rice. 17. Puck |

Washers (GOST 11371-68)

The main type of washers is shown in Figure 17.

Symbol: washer 12 (GOST 11371-68).

Keyed

The keys secure the shaft with parts that transmit rotation and vibration. The design of such elements can be prismatic, wedge, segmental, tangential. Such fasteners form the following types of connections:

- Unstressed ones are carried out using prismatic segment keys. There is no pre-stress during assembly.

- Stressed ones are produced by tangential and segmental keys. Mounting stress appears during assembly. Used for complex mechanisms.

Spring terminals

Quick installation of electrical networks is sometimes simply necessary. For example, install temporary lighting on a balcony, terrace, gazebo. Wago spring terminals are an excellent product for such work. A modern and of course reliable way to connect wires. Although they are new to the electrical accessories market, installation using spring terminals is quick and, importantly, convenient.

Vago clamping terminals

The main difference between the use of the Vago terminal blocks themselves: they are more convenient to connect any wires in electrical boxes than with twisting. Here, for high-quality installation, a unique clamping mechanism is used, rather than a simple screw. Manufacturers produce both disposable and reusable vagon systems.

- In the usual version, this product is used for one-time use; during repair work in the future it cannot be restored. It is removed and a new one is installed in its place.

- Wago reusable terminals are a little more expensive, but with their help you can disconnect the assembled contacts several times, rewiring the circuit to suit your needs. This speeds up the process of repairing or installing permanent and temporary networks. A simple lever-type mechanism provides the advantage that it is possible to carefully but efficiently fix any wire without damaging or squeezing it.

With the help of a vault, it’s easy to do the fastening yourself; you just need to strip the insulation and insert the required wires into the mounting hole. Press the lever. It is important to correctly calculate the load on the wires using an online calculator.

Evaluation of the wago clamping system: Unique ability to combine any aluminum, copper and other conductors. There is an option for connecting multi-core cables simultaneously (two or more).

Wago universal clamps allow you to fix any thin stranded conductor without damaging it. Another plus is the compact size of the pads.

Wago self-clamping terminals

Excellent quality and durability. The Vago type block has a technological hole that provides access for a screwdriver with a voltage indicator. The operation of any power line can be checked at any time. Perhaps one drawback is the considerable cost of the terminals themselves. But this type of wire connection is the most modern and fastest.

Toothed (spline) connections

The fastening occurs due to the protruding teeth on the shaft and the recess under them in the hub.

Dimensions are fixed by standards. This method is used for movable and fixed fastenings.

There are three options for fixation in terms of rigidity: light, medium, high. The difference is in the number and height of the teeth. It lies in the range of 6-20 pieces. Tooth Shape:

- Triangular ones are in little demand. Used for small stationary shafts and low torque.

- Straight-sided. Centered along the side edges, along the inner and outer diameters.

- Involute. Suitable for large shafts.

Where are these types used? The purpose of connections of this type is to transmit torque. The most well-known application is in power tools.

We looked at detachable mounts. Next, we will study the main types of permanent connections.

Definition of detachable connectionsIn every machine there are links formed by connecting parts. Detachable connections are connections that can be disassembled without compromising the integrity of the component parts of the product. Detachable connections can be either movable or fixed. The most common types of detachable connections in mechanical engineering are: threaded, keyed, splined, wedge, pin and profile. More than 60% of detachable connections in mechanical engineering are threaded connections.

Threaded connections

A threaded connection is a detachable connection of the component parts of a product using a part with a thread. A thread consists of alternating projections and depressions on the surface of a rotating body, located along a helical line. The body of rotation can be a cylinder or a round hole - cylindrical threads. Sometimes a tapered thread is used. The thread profile corresponds to a certain standard. A detailed classification of threads and images of threads in the drawings can be found here, and the main parameters of various threads can be found here.

Types of threaded connectionsName

| Image | Note |

| Bolted connection | Used for fastening parts of small thickness. If the thread breaks, it is easily replaced. |

| Screw connection | The screw can have any head. The thread is cut directly into the body of the part. Disadvantage: The threads in the housing can be damaged, which leads to the replacement of the entire housing. |

| Pin connection | Tightening is done with a nut. The pin is screwed into the body. If a thread in the body breaks, a new thread of a larger diameter is cut or, if this is not possible, the entire body is replaced. |

| Pin connection | Tightening is done with two nuts. If the thread breaks, it is easily replaced. |

Basic structural forms of bolt and screw heads a) Hexagonal head for tightening with a wrench;

b) Round head with a slot for tightening with a screwdriver; c) Countersunk head with a slot for tightening with a screwdriver. Fastening and sealing threads.

They are used in threaded products intended both for fastening parts and for creating a seal. These include threads: cylindrical pipe, conical pipe, conical inch, round inch.

Typically, such threaded connections are used for hermetically sealing metal pipes.

Two pipes are connected using a cylindrical coupling (fitting). The coupling in the hole has a through thread corresponding to the threads on the pipes. A locknut is screwed onto one pipe, and then a coupling. Then the second pipe is screwed into the coupling, and finally the coupling is tightened with a lock nut. For a reliable hermetic connection of pipes, before assembly, the threads should be wrapped with tow or a special synthetic thread. You can use a liquid sealant for sealing, which hardens in the thread, but such a connection, in case of repair, will be very difficult to disassemble. Large diameter pipes are connected using flanges.

The pipe flanges are tightened together using bolted connections.

Set screws and connections.

Set screws are used to fix the position of parts and prevent them from moving.

a) With a flat end, used for fixing small thickness parts. b) Tapered shank. c) Stepped shank. Stepped and tapered shanks are used for fastening pre-drilled parts. Example of using a set screw with a tapered shank. Bolts and connections for special purposes.

| Foundation bolts. Special fasteners made in the form of a threaded rod. They serve mainly for fastening various equipment and building structures. They are used in places where strong and reliable fastening of structures in concrete, brick, stone or other foundations is necessary. The bolt is placed in the base and filled with concrete. GOST 24379.1-80 |

| Eye bolt (loaded bolt) - designed for gripping and moving machines and parts during installation, development, loading, etc. GOST 4751-73 |

| Hook with a loaded bolt - designed for hooking and moving various loads. |

Nuts

In detachable threaded connections, bolts and studs are equipped with nuts. The nuts in the holes have the same thread as the bolts (type, diameter, pitch). The threaded hole in the nuts is determined from the tables. For metric threads, the hole diameter is calculated using the formula D = d - p, where d is the diameter of the external thread (bolt); p - thread pitch. For example, for an M14 nut with a pitch of 2, the hole diameter will be D = 14 - 2 = 12 mm. The most common are hex nuts, which are tightened with wrenches.

a) Nut with chamfer; b) Flow nut; c) Nuts for loaded connections; d) Slotted nuts; e) Nuts for tightening with low tightening force without a key.

Washers

The washers are designed to increase the supporting surface and protect parts from scuffing. Washers are usually shaped like a disk with a hole in the middle. The diameter of the hole must match the diameter of the bolt.

The washer is placed under the head of the bolt, in case of tightening with a bolt, or under the nut, in case of tightening with a nut. In vibration-loaded mechanisms, springy split washers (engraving washers) are used to prevent self-loosening of threaded connections.

To calculate loads and select threads for loaded bolts, it is convenient to use the Hardware website.

Keyed joints

Keyed joints are used to secure rotating parts (gears, pulleys, couplings, etc.) to a shaft (or axle), as well as to transmit torque from the shaft to the hub of the part or, conversely, from the hub to the shaft. Structurally, a groove is made on the shaft, into which a key is placed, and then a wheel, which also has a keyway, is put on this structure. Depending on the purpose of the key connection, there are keys of different shapes: a) Parallel key with a flat end; b) Parallel key with a flat end and holes for mounting screws; c) Key with a rounded end; d) Key with a rounded end and holes for mounting screws; e) Segment key; e) Wedge key; g) Wedge key with stop. Example of installing a segment key

Segment keys, like prismatic keys, work with lateral edges, that is, they prevent the wheel from turning on the shaft, but due to their design features they are used for small torques and are often used for conical ends of shafts.

Example of using a taper key with a head

Wedge keys have the form of single-bevel self-braking wedges with a slope of 1:100. The grooves in the hubs also have the same slope. The head is used to knock the key out of the groove.

To calculate the loads and materials of keyed connections, it is convenient to use the “Hardware” website.

Spline joints

Spline joints are used to connect shafts and wheels due to protrusions on the shaft and in depressions in the wheel hole. According to the principle of operation, spline connections resemble keyed connections, but have a number of advantages:

- better centering of parts on the shaft;

- transmit more torque;

- high reliability and wear resistance.

Depending on the profile of the teeth, there are three main types of connections:

a) Straight-sided teeth (number of teeth Z = 6, 8, 10, 12), GOST 1139-80; b) Involute teeth (number of teeth Z = 12, 16 or more), GOST 6033-80; c) Triangular teeth (number of teeth Z = 24, 36 or more). Spline connections are widely used in mechanisms where it is necessary to move the wheel along the axis of the shaft, for example, in car speed switches.

Spline connections are reliable, but not technologically advanced, so their use is limited due to the high cost of manufacturing. Technical characteristics and strength calculations of spline connections can be viewed on the website

Wedge connections

Wedge connections of parts are carried out using wedges - parts with two working edges in the form of inclined planes.

The wedges are inserted into a groove, which, when released, holds the part on the base. An example of fastening with a wedge when assembling a hammer: The edges of the wedges have a slope from 1/20 to 1/100, which ensures self-braking of the wedge. At large slopes, devices (screws and cotter pins) are required to protect the wedge from spontaneous extension. Also, wedge connections can be made not by expanding the groove, but by holding the wedge in the groove, for example, a rod-bushing connection:

When connecting a rod to a bushing, the thickness of the wedge, as a rule, is from 0.25 to 0.5 of the diameter of the rod, and the height is from 1.1 to 1.2 of the diameter of the bushing.

Pin connections

Pin connections are used to connect axles and shafts with parts installed on them when transmitting small rotating moments.

The pins are cylindrical or conical rollers. For pins and holes in parts, interference fits are selected.

The most common pins are: A) Cylindrical - unhardened with a diameter from 0.6 to 50 mm according to GOST 3128-70 or hardened with a diameter from 0.6 to 20 mm according to GOST 24269-80; B) Conical (Conical pins are manufactured with a taper of 1:50, ensuring self-braking) GOST 3129-70; B) With notches. Pins with notches are installed in holes made by rough processing - drilling.

Profile connections

Profile connections, in contrast to keyed, wedge and pin connections, are connections in which the parts are fastened together through mutual contact along a non-circular surface. Often such connections are used to attach levers to shafts.

| Example of a profile connection. | To prevent the part from jumping off the shaft, additional fastening is done with a nut (or bolt). |

Profile connections can have a variety of shapes - bevel, rectangle, ellipse and the like. Compared to keyed and splined connections, profile connections provide better centering and higher strength. The disadvantage of profile connections is the difficulty in making a profile hole.

Welding

What makes them special? These types of joints are formed by heating and fusing the material at the attachment point to form a weld. This clutch is considered one of the most common.

There are several welding options. The most popular of them:

- Electric arc welding. Three main subtypes can be distinguished: automatic submerged welding (characterized by high productivity and quality, used in mass production), semi-automatic submerged arc welding (used for short intermittent welds), manual (lower productivity speed, quality depends directly on the experience of the welder).

- Contact welding. Used in mass production for thin sheet metal. The seam is made as an overlap.

One of the popular mounting options is shown in the photo.

Often used in suburban construction.

Connection using terminal blocks

Electricians often use terminal blocks to connect wires, as it is simple and quite reliable. Almost all types of terminal boxes are designed for screw connections of electrical wires. It is possible to select terminal boxes for any number of wires, as well as for any cross-section. In other words, manufacturers produce these boxes in different sizes.

Connecting wires in terminal blocks

The terminal box is a plastic housing that houses terminal blocks with screws. The terminal block has special sockets into which the wire, stripped of insulation, is inserted and clamped. After the wire is clamped with a screw, you should check how reliable this connection is. To do this, just pull the wire with force. This type of connection is characterized by the fact that the connection points remain uninsulated, so it is used in conditions where the room is dry, without the presence of humidity, especially increased humidity.

A disadvantage is the fact that aluminum conductors are quite plastic and lead to weakening of the contact. This, in turn, increases its resistance, which leads to heating of the attachment point. In order for the contacts to remain reliable, they need to be tightened from time to time.

The advantages include ease of connection and its reliability, as well as low cost and connection speed. In addition, terminal blocks allow you to connect wires of different types and different cross-sections. In addition, the design of the terminal blocks is such that there is no accidental contact with live wires.

A simple terminal block and easy modification. Let's do it simply but RELIably!!

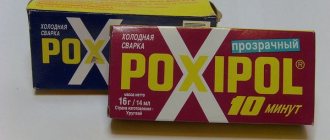

Adhesive joints

This type of fastening does not require heating of the surfaces.

Each type of metal has its own adhesive that will ensure a tight adhesion. For such operations, parts are prepared. The surface is sanded, degreased, a special primer is applied, and then a gluing operation is performed. The compositions used differ in additional properties and adhesion to various surfaces.

Connection with bolts

To connect wires in this way, you need to have a bolt of the required size, a nut and several washers, which depends on the number of wires being connected. The connection is simple, affordable and very reliable.

Bolted wire connection

First of all, the wires are stripped to a metallic shine, after which a loop in the form of a ring is formed at the end of the wire without insulation, the diameter of which should be slightly larger than the diameter of the bolt. Forming such a ring is quite simple if you wrap the wire around the bolt and then tighten it. After the preparatory work, the connection process begins, which consists of the following operations:

- A washer is placed on the bolt.

- Then one of the guides is put on.

- After this, the second washer is put on.

- The second conductor is put on.

- The next washer is put on.

- The connection is securely twisted using a nut.

To make the connection reliable, the wires are twisted using tools in the form of keys for bolts. Electricians often use this type of connection, especially in industrial electrical networks where there is plenty of usable space. The main purpose is to connect copper and aluminum wires using a separating washer.

Rivet fixation

This coupling method is mainly used for joining sheet metal and shaped profiles. The technological hole in the surfaces is made by drilling, then a rivet is inserted.

Due to mechanical action, the rod and head are deformed, fill and fix the hole. This operation is performed manually and mechanized. Rivets are used to fix material that is not amenable to welding, soldering, gluing, and to parts where it is necessary to delay the destructive process.

Modern technologies

In many cases, the methods discussed are gradually becoming a thing of the past. They were replaced by factory wire connectors, which made installation and switching work much easier and faster:

- Terminal blocks, inside of which there are tubular brass sleeves. Stripped wire strands are inserted into these tubes and secured by tightening the screws.

- PPE caps, inside of which there are compression springs. The cores are inserted into the cap and then turned clockwise with little effort, thereby reliably compressing the connected wires inside.

- Self-clamping terminals. It is enough to place the wiring in them, and there it is automatically fixed due to the pressure plate.

- Lever-type terminal blocks. This connecting element is reusable. It is enough just to lift the lever, insert the conductor into the contact hole and lower the lever back, reliable fixation is ensured.

We do not talk in detail about all existing terminal blocks, since there is a separate article about this, where each type of wire clamp is discussed in detail.

We hope that we have clearly explained to you how to connect the wires correctly. Choose the method that suits you best. When choosing, take into account the cross-section and material of the conductors, the location of the connection (outdoors or indoors), and the amount of load current that will flow in this electrical circuit.

Advantages and disadvantages of types of connections

Each fastener has its own characteristics. Let's consider all the options in terms of advantages and disadvantages:

- Threaded. Withstands heavy loads, reliable adhesion, a wide range of products, ease of installation and dismantling, the ability to use mechanization, low cost. Disadvantages: increased amount of tension concentrates, reduces resistance.

- Keyed. Simple design, easy installation and dismantling. Disadvantages: the veneer groove weakens them by reducing the cross-section of the shaft and hub. This also occurs due to concentrations of torsional and bending stresses. A labor-intensive process for manufacturing fasteners.

- Serrated. Forms good adhesion and precise direction of axial movement, transmits greater torque, fewer parts, reliability under reverse and dynamic loads, less shaft weakening, reduced hub length. Disadvantages: increased price, complex production technology.

- Welding. Low cost of work, the connection is hermetically sealed and tight, the use of automated processes, the ability to work with thick profiles. Disadvantages: in manual welding, the quality depends directly on the qualifications of the worker, deformation of the surface of parts when heated, low reliability under vibrations and shock impacts.

- Soldering. No deformation of the surfaces of parts, high accuracy, desoldering possible. Disadvantages: the process of preparing the base is complex; a minimum gap must be ensured.

- Glue. Low cost, no weakening of the working section, possibility of combined use with other types of fasteners, tightness of the joint, increases the anti-corrosion properties of the seam, resistance to water, chemicals, temperature changes, simple application technology. Disadvantages: careful preparation of the base; if the composition is incorrectly selected, the strength characteristics may be reduced.

- Riveted. Possibility of application to materials that cannot be welded, reliability, prevents the appearance of fatigue cracks. Disadvantages: labor-intensive, material-intensive, the process causes deformation of the surfaces of parts due to mechanical stress.

- Pressure connections. The design is quite simple, the parts are well arranged relative to each other, and can withstand heavy loads. Disadvantages: difficult to assemble, strength dissipates under the influence of vibrations and vibrations.

As you can see, each type has its own advantages and disadvantages. Taking these factors into account, the optimal types of fasteners are selected in each specific case. Let's look at where different connections are used.

Twist

Let's start with the simplest and most well-known method - twisting. It can also be called the oldest; it’s not for nothing that electricians call twisting the “old-fashioned method.”

We will not tell you that such a connection of wires is durable and reliable. According to the main document in electrical engineering, PUE (“Rules for Electrical Installations”), twisting is generally prohibited, despite the fact that half a century ago it was used everywhere. The fact is that in those days the load in the apartments consisted only of lighting, radio or television. If you consider the current load in modern apartments with a huge amount of household appliances used daily, then no old insulation, core cross-sections and methods of connecting wires are any longer suitable.

Nevertheless, we will talk about twisting, and even first of all, because it is the main stage of such connection options as welding and soldering.

Positive sides

The most important advantage of twisting is that it requires absolutely no material costs. All you need is a knife to remove the insulating layer from the wire cores and pliers to make the connection.

The second indisputable advantage of twisting is its ease of execution. You don’t need any special knowledge or skills; it can be done by anyone who has ever held pliers in their hands.

Several wires can be connected simultaneously in a twist, but their total number should not exceed six.

Negative sides

The main disadvantage of twisting is its unreliability; it weakens over time. This is due to the fact that there is residual elastic deformation in the cable or wire cores. At the point of twisting, the contact resistance increases, which can lead to contact failure and heating. In the best case, you will detect this in time and re-seal the connection; in the worst case, a fire may occur.

Electrical wires made of different metals cannot be connected using twisting. As an exception, you can twist copper and aluminum wire, but only if the copper core is first tinned with solder.

In electrical engineering there are concepts of detachable or permanent connection. So twisting does not apply to one or the other. A detachable connection is characterized by the fact that its ends can be disconnected many times. This cannot be fully done in twisting; every time after the next unwinding and twisting of the cores, they will deteriorate. It is also impossible to call twisting a permanent connection, because it does not contain the concepts of strength, reliability and stability necessary for this. This is another disadvantage of the twist connection.

Installation

If for some reason you do not have the opportunity to use other methods of connecting electrical wires, you can use twisting, just do it well. Very often it is used as a temporary option and is subsequently replaced by more reliable switching methods.

How to connect wires using twist? To begin with, the cores are stripped to 70-80 mm. The main thing is to twist all switched conductors into one single twist at the same time, and not wind one around the other.

Many people mistakenly begin to twist the wires together from the place where the insulating layer ends. But it is better in this place to clamp both wires with one pair of pliers, and with the other, grab the ends of the wires and perform rotational movements in a clockwise direction.

If the wire cross-section is small, you can twist it by hand. Align the conductors along the cut of the insulation and hold them firmly in this place with your left hand. Bend all switchable ends into one single bend at an angle of 90 degrees (a bend length of 10-15 mm will be enough). Hold this bend with your right hand and rotate clockwise. This must be done firmly and firmly. If it is already difficult to twist your hands at the end, use pliers as described above. As soon as the twist becomes smooth and beautiful, you can trim the bend.

You can connect several wires this way, but then to make it easier to twist them, make the bend longer, somewhere around 20-30 mm.

How to properly twist wires is shown in this video:

There is also a way to twist wires using a screwdriver, see about it here:

For information on twisting wires using a special tool, see here:

Now the resulting twist must be carefully insulated. Electrical tape is used for this. Do not spare it, wind it in several layers, and insulate not only the connection itself, but also step 2-3 cm over the core insulation. This way, you will ensure the insulating reliability of the twist and protect the contact connection from moisture.

You can also insulate the connection of wires using heat pipes. The main thing is not to forget to put the tube on one of the cores to be connected in advance, and then push it into the place where it is twisted. When exposed to heat, the thermal tube shrinks, so slightly heat its edges and it will firmly grip the wire, thereby providing reliable insulation.

If the twisting is done well, there is a chance that it will serve you for many years, provided that the load current in the network is normal. But it’s still better not to stop at this stage and strengthen the joint by welding or soldering.

Types of connections. Application examples

Threaded, adhesive, and welded connections are found everywhere in any industry. For example, construction, furniture, heavy industry and so on. Keyed and splined fastenings are widely used in power tools, equipment, and mechanical engineering. Interference connections are installed on the shafts of gear rings and worm wheels. Soldering is often used in electronic systems where maximum precision is required. Riveting is used for stitching together sheets of thin metal. However, as shown in the last photo, fairly large channels can be fastened using rivets. This is just a small list of the applications of individual fastening options.

We can say that with technical progress, clutch technology is rapidly developing, which means that new types of parts connections will appear. The modern world is filled with units, machines and mechanisms. The quality and service life of the components depend on how firmly the parts are secured. It is also important that the connection does not distort the shape of the product and does not introduce additional changes to the design. Therefore, it must comply with technological standards. If you follow them, the number of emergency situations at enterprises will be reduced significantly, and the units themselves will last a very long time.

So, we found out what types of connections there are.

Welding connection

Welding - it is important to heat the metal, but not to melt the insulation.

Connecting wires by welding requires certain skills, since the quality of the connection directly depends on the quality of the welding. To weld wires, they are twisted and then their ends are welded. As a result, a ball appears at the end of the twist, formed as a result of the melting of the wire strands. This place ensures the reliability of the entire connection, providing minimal resistance for the passage of electric current. The lower the resistance, the less the connection heats up, ensuring the reliability of the electrical wiring. In addition to the fact that such a joint practically does not heat up, if the currents do not exceed permissible values, the welding site has increased mechanical reliability.

The disadvantage of this method is obvious, since such electrical wiring has poor maintainability. This is not surprising, since the joints are permanent. In case of repair, the connection will have to be removed by biting off the welding area with pliers. As a rule, it is not always possible to connect the wires back in the same way.

There are a number of other disadvantages associated not only with the presence of a welding machine, with the skills to work with it, but also with the presence of special electrodes, with the presence of flux, as well as with the presence of conditions: the use of welding work is not always justified. This connection method is mainly used in exceptional cases. You can, of course, practice on your own if you have a welding machine, but this training will take a lot of time and a lot of conductors. It is very important to quickly weld the twisted ends of the wires without burning the insulation. After the welding areas have cooled, they must be insulated by any available method.

Welding copper strands, tinning with tin, how to make quality stranding