Benefits of sawdust logs

The following arguments can be given in favor of briquettes pressed from sawdust:

- Long burning time - 4 hours.

- Minimal smoke generation.

- Environmentally friendly. The starting materials are natural materials, so you can fertilize the beds with ash.

- High energy output. It far exceeds the energy capabilities of firewood and is comparable only to high-quality coal.

- Constant combustion temperature.

- Economical. The cost of 1 ton of such fuel will be cheaper than the corresponding amount of firewood or coal.

- Possibility of self-production.

There are also disadvantages. The main one is the fear of moisture. They cannot be stored in the open air, because... they will quickly absorb moisture and therefore will burn poorly. Therefore, it is necessary to allocate a dry room for storage.

Any significant mechanical impact on sawdust briquettes is contraindicated. If you buy special equipment for their production, the cost will be high and not always justified.

Replacing coal and firewood with sawdust briquettes makes heating a country home more environmentally friendly. While heating with wet wood leads to the release of harmful substances, “Eurowood” is completely safe in this regard

It is profitable to set up handicraft production if the sawdust is free, and you can use existing equipment for installation.

Drawings of a screw press for sawdust

Share on social media networks:

Many modern privatized houses are equipped with solid fuel heating systems, which involve the use of coal and firewood. Such heating boilers will also usually operate on pellets and fuel briquettes, which are made from wood waste. To increase the energy efficiency of alternative fuel, it is subjected to compression using special equipment that you can make yourself. For this you will need high-quality and detailed drawings of a sawdust screw press, which can be found in special books or on the Internet. Let us consider step by step the specifics of the design of this equipment and assembly in this article.

Press for making fuel briquettes with your own hands

The purchase of ready-made equipment for the production of briquettes, depending on its capacity, will cost from 300 thousand to 1 million rubles.

Of course, for a private owner who wants to start producing this fuel purely for his own needs, such costs are impractical, since they will not pay off soon. It would be more correct to make a press from scrap materials, especially since there is nothing complicated in its design.

You can build the necessary equipment from scratch or use ready-made mechanisms.

Homemade machine

Making an installation from scratch

You can create the significant force required to compress raw materials using:

- lever (you can act on it with your own weight);

- screw mechanism.

A lever press can even be made from wood; for a screw press, you will definitely need steel blanks and a lathe.

A screw extruder (press for sawdust) can theoretically also be made with your own hands, and some craftsmen have even succeeded, but such an undertaking is very expensive due to the complex processing of parts and the need to use special high-quality steel.

Heating with pellets is not only economical, but also environmentally friendly, because recycled materials are used as fuel. You can make or convert a solid fuel tank for pellets.

You will find detailed instructions for making a solid fuel boiler with your own hands.

Are you unsure about choosing a pellet boiler? Follow this link: you will find reviews from real users about these boilers. Read and draw conclusions.

Manufacturing a press based on a ready-made mechanism

To make briquettes, you can use some device that is more accessible than a real machine - a jack or a small hydraulic press. All that remains is to equip it with a punch and a matrix.

It should be understood that any homemade press, even one made on the basis of a hydraulic jack, will not be able to develop the forces that ensure the release of lignin. Therefore, instead of it, third-party binders have to be added to the raw material.

In this capacity they use:

- Cheap glue, for example, wallpaper.

- Clay (add 1 part to 10 parts sawdust).

- Soaked paper, including corrugated cardboard - the lignin contained in it, when in contact with moisture, exhibits its adhesive properties (this property of paper is used when spraying a heat insulator like "Ecowool").

Another difference from industrial technology is that the source material is not dried, but rather soaked in water - then the particles stick together better. Then the finished briquette is dried in the open air.

How to grind raw materials

In the hassle of making a homemade press, we must not forget about such an important stage in the production of briquettes as grinding the raw materials. It is very difficult to cut it by hand - mechanization is also necessary here

Some people make shredders themselves from an old activator washing machine - they install knives instead of the activator.

Another option is to purchase a rotary machine.

The purpose of this device is precisely to chop vegetation - summer residents use it to make fertilizers from leaves and grass.

Do-it-yourself sawdust production machine – Machine tools, welding, metalworking

Briquettes made from sawdust are otherwise called Euro firewood. This new type of fuel appeared due to the fact that people increasingly began to think about the environment and use natural resources sparingly. Pressed sawdust has the same moisture content as the original wood, but differs in specific gravity and calorific value - pellets have higher values. And it’s more convenient to store them.

Description and differences

Pressed tyrsa is logs of various shapes . The most popular forms are:

- square column (can be with or without a hole);

- rectangular parallelepiped;

- hexagonal column (there is a hole along the entire length);

- round log.

Of course, the shape will not affect the calorific value, although it may affect the efficiency of the loading device. This is the main difference between sawdust and fuel in the form of coal and firewood. Briquettes are suitable for boilers and furnaces that have automatic loading. But it is necessary to select raw materials so that the shape matches the device.

When heated, the fuel will decompose into pyrolysis gases, which, when mixed with oxygen, begin to ignite. But the structure of sawdust is still more reminiscent of coal.

The humidity of briquettes in the case of sawdust and firewood affects the calorific value and combustion mode. It is very important to purchase a quality product, and it must be packed in film so that it does not get wet during transportation. Such fuel is stored indoors, where moisture and sunlight cannot reach.

Terms of use

If you need to light a regular stove or fireplace, then briquettes are quite simple to use - you need to proceed as you would with firewood. In a brick stove and fireplace, the heating time should be no more than two hours. If you do not take care of this, the masonry may begin to collapse.

If coniferous or bark briquettes are used for the firebox, then the chimney must be cleaned quite often. Volatile compounds formed from the abundance of resins will remain on its walls. In smoldering mode, the burning time of sawdust will be longer than that of firewood. One bookmark is enough for the night. But the chimney also gets clogged faster. It is recommended to carry out cleaning twice a year.

Briquette production

Wood sawdust, when squeezed, begins to release lignin - a mixture of aromatic polymers. It is this substance that glues the raw materials together, resulting in a monolithic product with great strength. On average, the pressure on sawdust should be 300-1000 kg/cm2, humidity - 6-12%. But these indicators may differ depending on the method of manufacturing the material.

If pressing takes place at home, then you need to resort to tricks, since it will not be possible to create strong pressure, therefore, very little lignin will be released. The following are usually used:

- manure;

- wallpaper glue;

- clay.

Using these additives, you can create strong adhesion between sawdust.

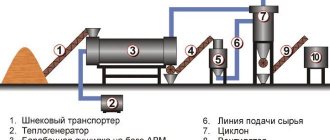

Industrial manufacturing

On an industrial scale, sawdust is sorted to prevent diseased wood from getting into it, and dried using special installations, bringing it to a certain level of humidity.

Then the dry material is sent to extruders or a special press, where pressure is created and given the required shape. The outside of the sawdust will char slightly - this is normal as the briquettes heat up under pressure.

To give the material the desired shape, they resort to traditional hydraulic presses and screw devices. In the first case, you can simultaneously work on several briquettes. Impact presses are considered the most difficult to operate. In addition, they are less efficient.

Pressing method at home

It is difficult to provide the required pressure for lignin release with homemade devices - this is the main problem of those who decide to start producing fuel on their own. You have to make a machine for pressing sawdust with your own hands, which will be ineffective, and also resort to additional binders.

The jack performs the function of a press; a punch and a matrix are also required - they will give the briquette a certain shape.

You can create a press yourself using a hydraulic bottle jack as a basis. The current path can be anything . But you need to determine the pressure yourself using the formula P=S*K, where:

- K is the coefficient of the required pressure in tons (optimally 0.5−1);

- P—pressure (tons);

- S - briquette cross-section (indicated in square centimeters).

For example, if we are guided by this formula, then the jack must have a force of 25-30 tons to create a round briquette (diameter eight centimeters). With a diameter of five centimeters, a force of 20 tons is sufficient. Of course, one jack will not be enough; you will also need:

- seamless pipe (inner diameter should be equal to the diameter of future briquettes);

- steel rod as a punch (the outer diameter is 0.05 mm less than the pipe diameter);

- steel channel (thickness about 5 mm);

- steel strips differing in thickness, width, length;

- nuts, M8 strikers (the length is a couple of centimeters longer than the width of the channel);

- steel plate 3 cm thick and measuring 50 by 50 cm.

The rod and pipe are usually made by a turner, since it will be difficult to select elements with the required clearance.

Machine assembly

The length of the briquettes should be slightly longer than the stroke of the jack rod. Next, you need to determine the size of the pipe by adding the stroke of the rod and the length of the briquettes. The length of the rod should be equal to the stroke of the rod, multiplied by two. Then they find the height between the lower and upper channel beams by adding:

- stroke of the jack rod;

- pipe along the length;

- height jack.

Get the value and add a margin of a couple of centimeters. A rectangular structure is made from the channel, which must meet all requirements, and fixed to the slab with the lower part. Then proceed as follows:

- The joints are secured with bolts. If a welded structure is needed, then a reinforcement is installed at each corner. The structure is welded to a metal plate.

- Next, guides are welded to the top of the structure, which will prevent the pipe from moving to the sides.

- The jack is secured with bolts. In the middle, guides from channels are attached: one is fastened tightly, the other is equipped with a hinge and a lock.

- After this, you can conduct a trial production of the material. The rod is inserted halfway into the pipe and filled with sawdust. Fix and raise the jack rod to the maximum. A mark is placed on the rod and the jack is lowered. The side guide is released and the pipe is pulled out.

Now all that remains is to inspect the resulting briquette. If it is hard enough, you need to lightly hit the surface. If no cracks appeared, then the pressure was enough for lignin to be released in sufficient quantities. If the log has fallen apart, the creation procedure should be repeated, but add a few strokes with the lever.

It may happen that the press force is not enough to create a solid briquette. Then, instead of pure sawdust, you will need to load into the device a mixture of them with a binder of your choice. Proportions are selected individually using the sampling method.

Litter and manure are considered a more suitable type of additional binder. But you can also use glue or clay. After pressing, the resulting block must be dried. The drying time is also selected individually, as it depends on the air temperature in the room and the initial humidity of the material.

Unfortunately, the resulting fuel will have a higher ash content and a less efficient calorific value. It is not recommended to use it in an oven or boiler with automatic feed. It is better to purchase better quality material here.

Useful tips

Fuel briquettes are superior to firewood in terms of calorific value, but heating with them will not always be more economical.

The method of such a firebox is justified only in two cases: in the presence of free sawdust in large quantities and in a system for automatically feeding briquettes into the desired device.

In other cases, there are no special advantages over the firewood familiar to many. In fact, sawdust will cost more. The difference in price will be more significant than the difference in heat transfer ability.

If you plan to produce briquettes for sale, then you need to find free raw materials and special equipment. A license is not required to produce this type of fuel, but a sanitary and epidemiological certificate is required. After preparing the fuel, you must immediately protect it with plastic wrap from moisture. Store in a special room.

Pressed sawdust is a good alternative to coal and firewood. But with a complete transition to them, you still need to weigh the pros and cons, calculate whether such fuel will really be more profitable than firewood.

Do-it-yourself machine for making fuel briquettes from sawdust and production version

Modern technologies manifest themselves in places where, it would seem, nothing new can be invented. An example of this is fuel briquettes or, as they are also called, Euro firewood. This is the same wood, but due to special processing it has received new properties that allow it to burn with greater efficiency.

Equipment for the production of briquettes

Pressing and drying equipment, which is a technological line for the production of briquettes, is not available at home due to its high cost and size. Home craftsmen use homemade machines that allow them to form the mixture for fuel briquettes into bricks or “washers”. The main elements of such an installation are the mechanism that creates pressure and the form itself. How to combine them into one is up to you, there are many options.

At the moment, a homemade briquette press is made by home craftsmen in 3 versions:

- with manual drive;

- using jacks;

- with hydraulic drive.

The first option is the simplest. A frame is made from a metal profile pipe by welding, which for convenience can be attached to the wall of a house or barn. A round or rectangular shape is fixedly mounted at the bottom of the frame, and a long lever is attached to the top on a hinge. A pressure element is attached to it, entering the mold with a small gap.

The second and third options differ in that the sawdust press is mechanized by a jack or a hydraulic drive installed instead of a lever. In order for water to flow out of the mold during pressing, several small holes are made in its bottom part. The design of such a machine is shown in the video:

DIY sawdust production machine

Heating with sawdust and shavings has become commonplace. This is due to the low cost of raw materials and its good specific calorific value during combustion.

By creating a homemade briquette press, you can get high-quality fuel for practically nothing. Its design is simple, but you need to know some of the nuances of production technology and the requirements for the original wood material.

Briquette creation technology

The production of pellets and briquettes from wood waste by pressing is a long-established process.

Therefore, when creating a homemade machine to obtain high-quality “European firewood”, you do not need to invent anything, but you can apply existing developments.

Description of the physics of the process

The use of bulk wood material for heating finds its application in small boiler rooms and furnaces.

Sawdust provides the same energy as wood of similar mass and moisture content, but storing it in its natural state creates dirt and dust.

Therefore, such waste is pressed into briquettes of various shapes.

With some assumptions, we can say that wood consists of fiber (cellulose) and its binding substance - lignin.

Each piece of sawdust and shavings retains its integrity thanks to this polymer.

In order to establish strong connections between the individual pieces, they also need to be glued together.

The chemical composition of wood and sawdust-pressed products is the same.

But the physical structure of the briquette is different from the structure of a solid mass, which leads to its longer combustion

During the pressing process, strong pressure is applied to the sawdust, as a result of which lignin is released from it and holds the material together in the mold. This bond, of course, is not as strong as in solid wood, but it is enough so that the resulting briquette does not fall apart.

The amount of lignin in wood relative to dry mass depends on the tree species:

- fir: 30%;

- pine: 27%;

- spruce: 27%;

- aspen: 22%;

- birch: 19%.

The higher the percentage of lignin content, the less pressure is needed to release it. Therefore, it is easier to independently produce briquettes based on sawdust from fir than from birch.

In addition to the classic press for producing fuel from bulk materials, there is also an extrusion machine.

The essence of its work is that, under the action of a screw, the substance passes through a gradually narrowing channel. This creates very high pressure.

However, implementing this option at home is complex and requires specific knowledge, so it is better to focus on models with a mold.

Use of adhesive

In the industrial production of pressed fuel, machines are used to create pressure in the range of 500 – 3000 atm.

Some manufacturers (for example, the German company “RUF”) form a briquette through a combination of compression with a force of 2000 atm. and heating the raw materials to a temperature of 150°C.

The density of such products reaches 1.2 kg/dm3.

An industrial sawdust pressing machine is expensive and has high productivity.

It is unprofitable for the production of briquettes in small quantities

If you make a briquette press from scrap material with your own hands, you will not be able to achieve such characteristics. Therefore, the products will definitely have a lower density and be more prone to crumbling. Insufficient lignin release can be compensated for and greater strength can be achieved by adding a third-party adhesive, such as:

- Wet clay. The required mass fraction of this binder is from 5 to 10% of the total weight.

- Wet corrugated cardboard.

- The cheapest wallpaper glue diluted in water.

The percentage of corrugated cardboard or glue is determined experimentally, since it depends on the size of the sawdust, its humidity and the pressure created in the mold.

Requirements for raw materials used

Even when using industrial equipment, it is difficult to obtain high-quality briquettes or pellets from wood waste if their thickness is more than 4 mm. The size of the material for homemade devices should be smaller. This is due to lower pressure and lack of heating of the raw material.

Ideally, the sawdust diameter and chip thickness should not be more than 2 mm. The vast majority of wood waste fits these parameters.

But there are times when the raw materials are clogged with small branches, wood chips or wane (pieces of bark).

Then, before pressing, to obtain a homogeneous mass, it is necessary to carry out preliminary preparation - crush the material by passing it through a crusher.

You can make a crusher for producing wood waste up to 2 mm thick yourself.

An ordinary garden shredder will not work, as it produces a large fraction size

To achieve good briquette density, you must avoid raw materials clogged with grass, sand or soil.

The soil-vegetative layer, unlike clay, does not have astringent properties, so the pressed product will crumble easily.

https://www.youtube.com/watch?v=19zCuiHDWbo

You also need to comply with the percentage ratio of the amount of bark - it should not be more than 5%. It is impossible to measure this, but visually sawdust with a significant amount of wane appears darker.

You can dry the raw materials in the summer either in the sun or in a ventilated area.

In winter, drying should be carried out in a veranda or other utility room with a slightly positive temperature.

For more intense evaporation, forced ventilation can be used.

The moisture content of sawdust or shavings should be measured according to the table above.

Using a moisture meter will not give the correct result, since it can only determine the value on the surface of the heap

If the pressure in a homemade press for making briquettes from sawdust is insufficient to release lignin, then the raw materials are not dried, but rather soaked in water along with an additional fastening agent. In this case, better homogeneity is achieved during mixing, and excess moisture will be removed during compaction.

Basic elements of the press

The main elements of an ordinary press are a mold (a glass into which the bulk substance is placed), a piston and a pressure-creating mechanism. It is not difficult to make them yourself, since they are typical for briquetting machines.

Mold device

The glass into which sawdust or shavings are poured is called a mold or chamber. The parameters of the briquette will depend on its geometry.

Whatever the cross-sectional shape of the glass will be, this will be the type of briquette.

But its length can be very different, but definitely not exceeding the height of the molds

Typically the chamber is constructed from scraps of round or shaped steel pipe.

The base of the piston, which enters the glass, is cut out of a thick-walled (at least 3 mm thick) plate. When making a mold, you need to take into account the ratio of the following quantities:

- cross-sectional area of the mold (s, cm2);

- applied pressure to the piston (u, kgf);

- specific pressure on raw materials (p, kgf/cm2).

These quantities are related by the relation:

p=u/s

Briquettes using an additional binder hold their shape well if they are formed at a specific pressure of more than 150 atm. (1 atm.

≈ 1 kgf/cm2). Based on the possibility of the force generated by the piston, the cross-sectional area of the chamber is calculated.

For example, if there is a 10 ton hydraulic jack, then:

s

For such conditions, a profile square pipe with a side length of 80 mm or a round pipe with a nominal diameter of up to 90 mm is suitable.

The length of the resulting briquette (l) depends on the height of the mold (h), the density of the raw material in the initial dry (q1) and briquetted (q2) state:

However, after the first compression, you can pour the chips into the glass again and repeat the procedure. In this way, you can bring the length of the resulting product almost to the height of the pressing chamber.

During the compression of sawdust, moisture is released from the briquette. In order for it to come out freely, the chamber is perforated with small but frequently spaced holes.

You can ensure the outflow of water from the chamber through holes that are made using a 2-3 mm metal drill

After the briquette is formed, it must be removed from the mold.

Using a spring and a false bottom, as is often recommended on the Internet, is impractical.

High pressure completely compresses the spring, so over time its shape becomes distorted, causing it to lose its properties.

Therefore, you need to either make a detachable bottom of the mold and push out the briquette, or build a collapsible cup. In the second case, you will need to make an additional shirt for him from a rod.

Available methods of creating pressure

There are three common ways to achieve pressure that are well suited for a homemade fuel briquette press: using a lever, a hydraulic jack or a screw. Each of them is good in its own way, and their implementation in practice is not very difficult.

Video for a snack

Good luck and see you again, Andrey Noak was with you!

Sawdust, agricultural waste, leaves and other plant debris are all excellent fuels.

But for an ordinary boiler it becomes “digestible” only in the form of pressed briquettes - without processing it will have to be added every 5 minutes, and most of it will spill through the grate.

Powerful presses for working with such raw materials are produced in abundance today, but due to the high cost, it is profitable to buy such a unit only for the purpose of organizing constant production.

The average person has to make a press for making fuel briquettes with his own hands.

The source material, most of which is usually sawdust and wood trimmings coming from wood processing enterprises, is crushed and thoroughly dried.

Ultimately, the moisture content of the raw materials is brought to 8% - 10%.

In addition to components of plant origin - wood waste and husks of various agricultural crops - coal dust can be used to make briquettes.

The next stage is the actual production of briquettes from the prepared mass.

To do this, use one of two methods:

- Pressing:

raw materials are poured into round or rectangular shapes (this element is called a matrix), where it is compressed using a powerful hydraulic press. The part that directly impacts the raw material is called a punch. The machine develops a pressure of 300 - 600 atm. - Extrusion:

An extruder is very similar to a screw grinder. The screw forces the raw material through a gradually narrowing molding channel and the resulting pressure reaches 1000 atm.

Strong compression leads to the following phenomena:

- The temperature of the mass increases greatly.

- Particles of raw materials begin to release a sticky substance - lignin. Under heating conditions, it reliably binds the crumbly mass, turning it into a solid solid briquette.

- The density of the material increases to 900 - 1100 kg/cubic. m. For comparison: the density of wood is only 500 - 550 kg/cubic. m. Along with the density, the energy value of the fuel per unit volume also increases: now its reserve for the winter will take up half as much space. And pressed logs will burn longer than regular logs.

Manufacturing equipment

All equipment that is used to produce chips can be divided into 2 types:

- woodworking, for which shavings are only a by-product;

- wood processing, for which shavings are the final product.

Woodworking devices and their prices

All equipment used to produce chips can be divided into 3 types:

- machines;

- electrical;

- manual.

Machine units

For most machines, shavings are waste products resulting from wood processing. All machines differ in purpose:

- jointers;

- milling;

- surface planers;

- multilateral;

- universal.

Planing equipment is designed to create a flat surface located at a certain angle to other surfaces.

Such machines consist of two powerful cast-iron plates, one of which can be lowered relative to the other.

The front plate is a guide and is always parallel to the second, which is called the bed.

A long drum with knives attached to it is installed horizontally between the plates, and the upper edge of each knife at the top point always coincides in height with the frame and is also parallel to it. A deviation of even 0.5 mm will lead to a deterioration in the quality of woodworking.

Joining equipment processes only industrial wood, that is, suitable for the manufacture of joinery and carpentry products.

Therefore, the waste from jointing machines is of fairly high quality , as well as a moisture content in the region of 12–16% .

A jointing machine is available in any carpentry or carpentry workshop, so waste from its work is not difficult to find. The quality of processing with such a machine is directly related to the total length of the working surface , that is:

- beds;

- guide;

- spaces between them.

The greater this distance, the longer workpieces can be processed without loss of quality, creating a smooth surface along the entire length. The shorter the working surface, the higher the likelihood that the planed surface on long workpieces will have some defects, especially if a person without much experience operates the machine.

The total length of the working surface of industrial machines is 2 meters, which allows processing workpieces with a maximum length of 4 meters.

Milling machines differ from jointing machines in that they are designed to select a pattern .

This type of equipment is equipped with a flat horizontal bed as well as two vertical guides. Both guides can be adjusted, thanks to which the optimal wood processing mode is selected.

In addition, the machine is equipped with a mechanism for changing the height of the cutter, which is installed vertically, thanks to which the position of the knives relative to the fed workpiece is adjusted .

This allows you to set the knives along the top or bottom edge of the cutter without calculating millimeters of shift in the desired direction, and then adjust the height of the cutter using a lifting mechanism, shifting the pattern up or down.

On jointing and milling machines, much depends on the skill of the operator, so an inexperienced machine operator cannot feed the wood correctly, which is why the quality of the processing suffers.

In addition, they process one face, sometimes taking into account the direction of the adjacent face.

But they cannot make parallel surfaces, because this requires thicknessing machines. This type of equipment is a very wide jointing machine, consisting of a powerful body, in the upper part of which a drum with knives is installed. A lifting table with a feeding mechanism is installed under the drum.

Using the feed table, set the required distance to the drum, trying not to remove a layer more than 5 mm thick in one pass.

The feeding mechanism consists of toothed drums that push the wooden product forward.

In this case, the wooden product moves along a flat table slab, and a rotating drum with knives cuts off everything above the set limit. , 2 parallel surfaces appear on the wooden product .

The multi-sided machine is also equipped with a drive that ensures the movement of the wooden workpiece forward, however, the number and location of cutters depends on the model and purpose of the machine.

The most advanced and accurate samples of this equipment are equipped with 4 cutters, which ensure processing of the workpiece from all sides.

Moreover, each cutter is coordinated with its bed, due to which there is no backlash in the wooden part, and the quality of its surface treatment is maximum.

Universal equipment combines both methods of wood processing, but unlike milling machines, all working tools are installed horizontally.

This complicates setting up the machine in milling mode, but seriously reduces its cost, because the drum and cutter are installed on the same shaft, so they also have a common engine and drive for the working tool. Such machines are not used at chip factories and other enterprises, because there the quality of processing is more important than versatility.

Therefore, manufacturers produce universal machines of medium and small sizes - they do not provide the same quality of processing as full-size units, but they are much easier to transport from place to place .

For garages and home workshops, the smallest devices are most often purchased, which in skillful hands provide fairly high quality wood processing. A significant disadvantage of universal and, especially, small-sized units is their small resource , so they cannot be used for processing large volumes of wood.

We have prepared links to sites where you can see modern woodworking machines for various purposes, as well as get acquainted with their characteristics:

| Machine name | Brief description and characteristics | Cost of rubles or USD | Seller or manufacturer website |

| HP-400 | Planing machine, maximum width of the processed surface 400 mm, maximum thickness of the removed layer 3 mm, weight 300 kg, engine power 3 kW. | 125860 | www.stanki-proma.ru |

| JJ-6 | Planing machine, maximum width of the processed surface 150 mm, engine power 1.1 kW, weight 103 kg, total length of the working surface 1215 mm. | 49000 | jet-krd.ru |

| Kraton WMT-318 | Thicknessing machine, maximum planing width 318 mm, depth 0-3 mm, feed speed 8 m/s, weight 31 kg, motor power 1 kW. | 25000 | kraton.ru |

| TFS-75/30 | Milling machine, engine power 1.1 kW, weight 138 kg. | 81200 | www.stanki-proma.ru |

| FS-1A | Milling machine, engine power 3 kW, weight 250 kg, tenoning carriage and other equipment are installed to facilitate wood processing and increase safety. | 103500 | rustan.ru |

| WoodTec 412 | Four-sided longitudinal milling machine, power 16.75 kW, weight 2300 kg, feed speed 8-33 meters per minute. | 16100 USD | woodtec.com.ru |

| BELMASH SDM-2500M | Multifunctional household woodworking machine, performs all basic operations, motor power 2.5 kW, weight 68.8 kg. | 32 000 | belmash.ru |

| SD-5 | Multifunctional household woodworking machine, performs all basic operations, motor power 2 kW, weight 40 kg. | 27630 | www.muravey.ru |

Electrical

This type of equipment includes various electric planers , including their extended modification - electric jointer .

An electric planer consists of two metal strips (soles), between which a rotating drum with knives is installed.

On older models, the front sole is not adjustable, so the tool always removes the same layer thickness.

On more modern tools, it is possible , using a regulator located on the front handle, to set the required thickness of the layer being removed .

The motor and gearbox are mounted on the side and connected to the drum shaft with a rubber or plastic ring. The housing covers all rotating parts, so the electric planer is completely safe from above. The difference between an electric planer and an electric jointer is only in the overall length and the length of each sole.

In this case, the size of a plane from one manufacturer may correspond to the size of a plane from another. The optimal speed for processing wood with this tool is determined by the master independently, taking into account:

- motor power;

- thickness of the removed layer;

- characteristics of wood.

The more powerful the motor, the faster you can move the tool forward and the more layer you can remove per pass.

Therefore, the speed of movement of a plane or jointer on wood directly affects the size of the chips - the faster the tool moves, the larger the waste produced.

Setting the gap, that is, adjusting the thickness of the layer being removed, also affects the speed of wood processing and the size of the chips. The larger the gap, the slower you have to move the tool, so to get the thickest chips you need the most powerful electric planer.

Here are links to the official websites of manufacturers of electrical equipment for wood processing, where you can not only look at photographs of this equipment, but also find out their characteristics:

| Machine name | Brief description and characteristics | Cost of rubles | Seller or manufacturer website |

| IE-5709M | Electric planer from the Rebir company, motor power 1450 W, planing width 102 mm, weight 4.6 kg, ability to work in milling mode (milling attachment required) | 8060 | www.rebir-online.ru |

| R-110/1150EM | Electric planer from the Interskol company, motor power 1100 W, planing width 102 mm, weight 4.5 kg, ability to work in milling mode (milling attachment required) | 6300 | www.interskol.ru |

| Makita 1806B | Makita electric jointer, motor power 1.2 kW, planing width 170 mm, weight 9 kg. | 28000 | makita-online.ru |

Manual

Manual equipment includes all types of planes and jointers, as well as various chisels and chisels. All these tools work on the principle of cutting the top layer of wood, only in planes and jointers the thickness of the layer depends on the settings of the tool, and the size and shape of the shavings from under chisels and chisels depends on the intention of the one who works with them.

Planers and jointers are a body that is also a frame into which a knife is inserted and fixed. The method of fixing the knife depends on the design and type of tool - in wooden planes and jointers it is fixed with a wooden wedge, in metal ones a special bolt is used for this.

Conventional planes and jointers are used to level various planes, but they are most effective where the width of the workpiece does not exceed the width of the knife. If the width of the part is greater, then it all depends on the skill of the person working with the tool.

When processing uneven and rough surfaces, these tools produce short chips of small width, but as the surface is leveled, the width and length of the chips increase.

When leveling smooth and relatively flat surfaces, the length of the chips can reach half a meter, and its width is equal to the width of the knife.

There are planes for special jobs, such as cutting half or quarter, creating a figured profile and many others. This is a specialized carpentry tool, the correct use of which takes a long time to learn, so they are used only where a high percentage of manual labor is acceptable.

Such work includes hand-made furniture from solid wood, beds and much more. The size and shape of the chips depend on:

- sole shapes;

- range of motion;

- knife clearance;

- shape, breed and humidity of the workpiece.

Wood processing devices

This equipment includes:

- machines for making wood wool;

- one of the types of shredding machines;

- combined devices that combine different principles of influencing wood.

The basis of the machine for producing wood wool is a longitudinally moving carriage on which dividing and cutting knives are installed. The operating principle of this machine, as well as a lot of other useful information, can be found here (Wood wool - production and business).

Disc chippers produce large chips that are sometimes mistakenly classified as wood chips. But chips appear as a result of crushing wood, and this unit cuts it.

The basis of devices of this type is a heavy steel flywheel (disc 1–3 cm thick), on which knives are mounted.

The processed wood enters at an angle of 10–45 degrees, and the direction of movement coincides with the direction of rotation of the flywheel.

When a knife encounters wood , it cuts it at a certain angle , that is, it is crushed, and in most cases the width of the chips is equal to the width of the processed wood, and the length is 1–3 times greater.

The outside of the disc is covered with a steel casing, which protects against knives and prevents chips from flying out. In the casing, along the path of movement of the knives, a receiving hole is cut, to which a feed chute is welded, preventing the deflection of the processed wood.

On the reverse side there is a flywheel drive , which is connected through a belt drive to an electric or gasoline engine . More detailed information about devices of this type can be found here (Equipment for wood processing).

The shavings that are obtained using this machine are a cut of wood across the grain, so they are easily broken into long and thin needles .

By changing the feed angle of the processed wood within small limits, you can slightly increase or decrease the width of each needle, as well as the overall size of the chips.

Indeed, even within one layer of wood, the bending strength of the fibers is much higher than across them, not to mention a cut in which several layers are located nearby.

Combined devices combine various methods of influencing wood, but their final product is not a board or timber, but shavings.

One of the representatives of this family is the SS-6 wood flake machine, which combines a jointer and a machine for producing wood wool.

From the first, he took a wide drum with knives mounted on it, and from the second, a movable carriage that moves the material being processed so that the knives process the entire surface , and not just a separate area.

Reducing the drum rotation speed led to an increase in the length of the chips, so its product occupies an intermediate place between wood wool and wood planing waste.

Quite long (2–10 cm), these shavings have good strength because they are cut along the grain and are suitable for the manufacture of wood concrete and fiberboards. Here at this link you will find more information about the SS-6 machine, its characteristics and application features.

The economic side of the coin

To produce 1 ton of fuel briquettes you need to take approximately 2 tons of wood waste or 1.5 tons of straw. At the same time, the electricity consumption is approximately 100 kWh/t.

The calorific value of this heating product is 19 MJ/kg, which is much higher than that of conventional firewood (only 10 MJ/kg).

With the right choice of equipment, manufacturing and storage of products, the technology pays for itself in about 2 years.

After reading my article, you can decide for yourself what is better: make heating material from unnecessary raw materials, save time and money, or continue heating with wood. After all, when using briquettes, you can dispose of waste that is unnecessary in everyday life, and heat your dacha or bathhouse with environmentally friendly fuel briquettes. If you want to organize your own pellet production, then you will simply need information about organizing the technological chain, and my new book “Typical mistakes of equipment manufacturers when planning pellet production” will help you with this.

What are pellets and what types are they?

Pellets are fuel granules that are made from waste from the wood processing industry, some crop residues (straw, sunflower husks, buckwheat, etc.) and even from chicken droppings. Their production technology is such that no additives or binders are required. That is, it is absolutely safe and 100% natural fuel, which is also made from waste.

Pellets are a good fuel

Since the raw materials for fuel pellets can be different, the characteristics of the fuel are different. Pellets are divided into three categories:

- White. This is a premium fuel with the highest performance (and price). So named for its characteristic color - light yellow, almost white. But color is secondary, characteristics are primary and the main thing is very low ash content. After the combustion of white ash pellets, no more than 0.5% of the fuel volume remains. The boiler will need to be cleaned very rarely. White fuel granules are obtained from shavings without bark and other foreign inclusions. As a rule, this is carpentry or furniture production.

- Gray. Raw materials for this type of pellets may contain a certain percentage of bark, pine needles and some other impurities. But the ash content should not be more than 1.5%.

- Industrial or dark pellets. This type of fuel pellets is made from straw or cake in its pure form or with the addition of wood waste. The ash content of this type of fuel is much higher than those described above, however, it cannot be higher than 5%.

White and gray pellets are used for individual heating. They are also called “first class” or first-cash. They have a diameter of 6-8 mm, a density of approximately 600 kg/m3, and the amount of heat generated is about 4.7 kW/h. They are burned in special boilers, which are called pellet boilers. Typically, this equipment is very demanding on fuel quality. In addition to low ash content, there are requirements for the integrity of the granules and the absence of a dust fraction. Otherwise, the pellet boiler burner becomes clogged and the boiler shuts down. Industrial pellets are also burned in special furnaces, but they have a completely different structure and much larger volumes.

Characteristics of pellets from different raw materials

In principle, any pellets can be poured into solid fuel boilers, only they are usually used at the smoldering stage. When the oven is already preheated, add a certain amount of granules.

How to make briquettes?

The technological process used in production cannot be carried out at home. The reason is the lack of pressing or extrusion equipment capable of creating a pressure of at least 30 MPa. Without this, lignin cannot be isolated from wood and homemade briquettes will not be compressed. The solution is simple: you need to add a binder, which is ordinary clay. It is mixed with sawdust in a ratio of 1:10 by weight (1 kg of clay per 10 kg of waste), diluted with water and mixed thoroughly.

The resulting composition is filled into the mold and the mechanism is activated. If the production of fuel briquettes is done manually, then it is necessary to apply maximum force and hold the lever until the water runs out. Then the product is carefully removed and placed on an area in the open sun to dry. You can start filling out the form again and extruding the next “brick”.

Application of a ready-made mechanism

A briquette press can also be created on the basis of a ready-made mechanism. To do this, use a hydraulic press or jack. The master can only supplement this unit with a matrix and a punch. Any handmade device for pressing sawdust cannot ensure the release of lignin. Instead, you will have to add extraneous binders. Suitable for this:

- affordable wallpaper glue;

- soggy paper;

- clay.

Clay should be added in a volume of 1 part to 10 parts of sawdust. If we are talking about wet paper, then corrugated cardboard, which contains lignin, is used for this.

General information about briquettes

The raw material for this type of biofuel is small wood waste, mainly sawdust. Of course, you can burn them this way, but it’s not very convenient, it takes a lot of fuel and it burns out quickly. And all because the density of wood pulp is low, much more heat will be produced if the raw material is pre-compressed. This is the briquette production technology.

First, sawdust and other waste are processed, crushed and dried. The humidity of raw materials before pressing should be in the range of 6-16%, which is ensured by drying equipment. Then comes the actual production of fuel, which is done in two ways:

- Using a hydraulic press, the raw materials are formed into rectangular or cylindrical briquettes. The process takes place at pressure from 30 to 60 MPa and high temperature;

- Using the extrusion method on a screw press, a 4- or 6-sided briquette is extruded from the finished mixture under a pressure of about 100 MPa. The product undergoes heat treatment.

It should be noted that the production of fuel briquettes from sawdust does not involve the addition of binding components to the mixture. Under the influence of high pressure and temperature, the particles are glued together by lignin, which is found in any wood. The result is “bricks” or “sausages”, whose calorific value is up to 5 kW/kg. The production process is shown in the video:

Types of presses

Presses used for processing sawdust come in 4 types. Differences between devices are noted in the principle of operation and cost.

The requirements for preparing raw materials are the same:

- uniform grinding to obtain fractions of no more than 25x25x2 mm;

- humidity level is within 4-10%.

Each model has both advantages and disadvantages, so before choosing, you should carefully read the technical characteristics:

- The mechanical impact press is similar in principle to a hammer drill, where the crank mechanism transmits a series of shocks to the piston with a frequency of 20 times per second. The impacts cause sawdust to be forced through the die. The equipment copes with pressing not only waste wood, but also a mixture of coal dust, straw, peat, and residues after processing MDF. The main advantage of the press is long-term operation without human intervention. High productivity is also noted. The weak point is the crank assemblies, which is due to the simultaneous impact of two forces on them: impact and friction.

- A hydraulic press is a device consisting of two parts (mold, cylinder). According to the principle of operation, the equipment resembles the action of a jack, where a hydraulic cylinder exerts pressure with a piston on a mold filled with prepared raw materials. The result is a formed briquette. The equipment is considered simple and reliable to use, there are practically no wear parts. The pricing policy for this type of model is competitive. The downside is low performance. There is also a nuance in the production process - a binding component is added to the prepared sawdust.

- The principle of operation of a screw press (extruder) is similar to a meat grinder. Crushed and dried sawdust is fed through a screw through a die, as a result of which the mass is compressed and pressed under high pressure. The process involves exposure to high temperatures, without which the equipment may jam. The hot flow provokes the release of lignin (a natural binder) from the wood, which holds small raw materials together and is the key to high-quality molding. The screw device is considered a leader in terms of productivity; the production process is carried out continuously. One of the disadvantages is the need for warming up, which makes the preparation procedure lengthy. You also need to take into account that the finished product has a lower calorie content due to exposure to high temperatures (above 120°C). Components such as the screw and die wear out quickly due to increased friction during operation.

- The pellet press is similar in principle to a feed pellet mill, only sawdust is used instead of grain crops. Compared to other types, the equipment has a simple structure, but at the same time it has good performance and an affordable pricing policy. The press is equipped with various devices to improve the quality of the resulting product. These are: a mixer for mixing raw materials, a humidifier for overdried workpieces, various cutting attachments that change the shape of the briquettes. The production process involves the use of an additional binder to increase density. One of the disadvantages is the need to grind the raw materials during preparation to the smallest fraction. Using such equipment it will be possible to produce briquettes only of small size.

Each model has both advantages and disadvantages, so before choosing, you should carefully read the technical characteristics

Homemade press

If you have a drawing and certain design skills, you can make a press for fuel briquettes with your own hands.

There are two types of homemade devices for briquetting - those operating from a jack and those with a manual drive.

A description of the assembly of the structure will help you understand how to make a press and which option is best to use.

Manual

To make a hand press, you need a punch. It is constructed from thick metal sheet. A pressure lever is attached to the material, and the structure is secured using hinges.

The punch is installed in a special form. Usually it is made square. The mold is made from metal. Using a thin drill, holes are drilled in the bottom and sides to allow moisture to escape during the pressing process.

To collect the released water, a container is used in which the finished press is installed.

From the jack

To obtain higher quality solid fuel and improve the design of the press, a hydraulic jack is used.

The manufacturing process of such equipment consists of the following stages:

1. The base for the press is formed from the channels. All metal parts are fastened by welding.

2. Racks are attached to each corner of the prepared base in a vertical position. Each support is taken 1.5 meters high.

3. The mixer is welded to the stands. The drum can be made from a pipe with a large diameter or take a ready-made part from an old washing machine.

4. A galvanized steel tray is fixed under the mixer, from which the raw materials will penetrate into a special mold.

5. Holes are created in the thick-walled pipe intended for the matrix. They should be evenly distributed throughout the circular contraction. The width of each opening should be from 3 to 5 millimeters.

6. At the bottom of the mold, a flange is fixed using a welding machine, to which the bottom is screwed.

7. The finished form is connected to the base.

8. After this, a punch is cut from steel sheets. It should have the same shape as the matrix. Using a rod, the punch is connected to a hydraulic element.

The assembled mechanism is fixed on top of the form to the racks. The tray is fixed at the bottom.

To speed up the process of removing pressed briquettes, it is recommended to weld the disk and spring to the bottom of the matrix. It must match the diameter of the punch. This mechanism will allow you to automatically push out finished products after turning off the hydraulics.

Pressed wood raw materials require drying. The lower the moisture content of the briquettes, the better they burn. In addition, dry briquettes have higher heat transfer.

Self-made compact fuel can significantly reduce the cost of heating your home. Ready-made briquettes can be used both for the boiler and for the stove. But it should be borne in mind that the quality of the product largely depends on the density indicator.

It is almost impossible to make compressed firewood using homemade equipment that will burn for a long time and give off a large amount of heat.

Therefore, if you need to use fuel with high performance, it is better to purchase it in specialized stores.

Conclusions and necessary video on the topic

Making a homemade lever press. Manufacturing of important parts and description of the working principle:

Refinement of the machine design and the briquette pressing process itself:

Machine for simultaneous production of several briquettes based on a hydraulic jack:

It’s not difficult to make your own sawdust briquetting machine. You can choose to use a lever, hydraulic or screw principle for creating pressure. However, we must not forget that the quality of manufactured products depends not only on the assembled mechanism, but also on the preparation of raw materials. A correctly set up process will help provide your own household with high-quality and inexpensive fuel and even organize its sale.

Types of fuel briquettes

Briquettes are divided into types depending on their shape. Mainly the following types can be found on the market:

- RUF. These are pressed rectangles measuring 15 x 9.5 x 6.5 cm. They are made from natural wood sawdust with the addition of special components.

- Nestro. Visually, these are cylinders with a diameter of 6 to 9 cm and a length of 5 to 35 cm, without holes. The material for production is pressed wood pulp. It is dried, placed in a loading container, and then fed through a screw for pressing. Dispensers distribute the mass into molds under pressure.

- Pini kay. In shape they are polyhedra with the number of faces from 4 to 6. During the production process they are subjected to processing at high temperatures and pressing under high pressure, up to 1100 bar. As a result, combustion efficiency, moisture resistance, and density increase.

The chemical composition and heat transfer of all these types of pressed sawdust are the same, they differ only in density. This fuel is not characterized by sparks flying in different directions. Its high density and low hygroscopicity make it possible to store this fuel in a small pantry next to the stove.

In addition to sawdust, sunflower husks, buckwheat, paper, small branches, fallen leaves, and straw are used to produce briquettes. The equipment for this has a fairly simple design, and you can make it yourself

If you have the necessary raw materials to form briquettes, you can make them yourself.

Press design characteristics

Pressing equipment for the production of briquettes for fuel is a device that operates mechanically and consists of the following elements:

- Base - In most cases, demonstrated by a table, which is used to attach the main structural components of the press.

- The matrix is one of the main components of the device, which forms its key shape.

- Power frame. This piece of equipment is fixed to the base. Its main function is to transmit force to the compressible raw material, which is performed through the punch.

- Drive unit. Depending on the type of screw press for sawdust, a mechanical or manual type of influence can be applied:

- For manual drive equipment, an additional lever is used, with the help of which the client’s force is applied.

- Mechanical - hydraulic booster or electric motor.

to contents ^

Briquette manufacturing technology

The process of producing heating material is labor-intensive and requires sequential operations.

If necessary, you need to prepare the raw materials before use:

- Crushing of material;

- Drying of crushed raw materials;

- Grinding (the better the components of the briquettes are crushed, the higher the heat transfer rates).

To make it yourself, the raw materials need to be mixed with a binder. Clay in accordance with 1 to 10 is quite suitable for this, where 1 kg of clay and 10 kg of crushed material are taken

The resulting mixture must be mixed with water to form a homogeneous mass, it is important that it is neither liquid nor solid

The resulting mass must be loaded into special equipment. During pressing, excess liquid is released and the product receives its final shape. If you use a homemade press, there is a possibility that a small amount of moisture will still remain inside the product.

An obligatory point in the manufacture of heating material is drying after pressing. You can dry it outdoors, in the sun and wind. The time of this stage depends on the volume of briquettes, as well as on the pressing technologies used.

After drying, the product must be moved to a special storage place or packaged.

Types of wood chip waste and methods for their production

Despite the fact that in Russia there is GOST 5244-79, which determines the qualities and characteristics of chips, its effect only applies to some aspects of the use of this product. It has been in operation since 1979, so it is largely outdated and does not meet modern requirements.

All chips can be divided into:

- length;

- width;

- structure.

Short chips are obtained by jointing and milling at high rotation speeds of the working tool, that is, a cutter or drum.

The higher the rotation speed, the cleaner the machined surface and the shorter the chips.

When jointing or milling along the grain, longitudinal chips are obtained, which have a strong structure and good strength.

When milling across the fibers, the waste is brittle and is divided into segments even with slight pressure. However, the segments themselves are not inferior in strength to longitudinal chips.

Long chips are obtained by reducing the rotation speed of the working tool. Another way to adjust chip length is to change the speed at which wood is fed to the processing or processing equipment.

The faster the wood arrives, the longer the chips are, and the quality of the planed surface decreases.

Reducing the feed rate reduces chip length but improves surface quality. This effect is insignificant when jointing, but is very pronounced when milling.

Chip width depends on factors such as:

- the angle of inclination of the plane being processed relative to the impact of the cutting element of the processing or processing equipment;

- deviation of the direction of wood supply from a line perpendicular to the direction of influence of the cutting element of processing or processing equipment;

- the width of the area where the wood and the cutting element of the processing or processing equipment come into contact.

In addition to chips, which are waste from jointing and milling machines, there are other types of chips that are obtained during wood processing:

- manually;

- on a machine for producing wood wool;

- using one of the types of grinding equipment.

Manually obtain shavings when working:

- a plane, including a figured one;

- jointer;

- electric planer;

- electric jointer.

The waste that appears when working with a planer and jointer is characterized by a large width and length, which depends both on the length of the workpiece and on the skill of the worker.

Shaped planes produce relatively long, curling and not very wide waste, which is caused by their shape. Electric planers and electric jointers produce short to medium length scraps, the thickness depending on the tool setting .

There are special machines that process wood into wool - a special type of very thin shavings that are small in width and long in length.

You can read more about this type of waste in this article.

In addition, there is another way to obtain chips, which in their parameters are closer to wood chips. Sharp knives are fixed to the disk, then the wood is fed at a certain angle, on which many characteristics of the chips depend. As a result, planing occurs across the grain , but due to the fact that the cutting direction does not change, the chips are longer and wider.

Is it worth making briquettes at home?

In real life, sawdust fuel briquettes made by yourself do not turn out quite the way they are presented by some online resources. This casts doubt on the feasibility of the entire enterprise, and here’s why:

- On colorful videos from the Internet, the process looks simple and easy. In reality, this is hard work; in order to prepare the required amount of fuel for the season, you need to spend a lot of time and physical effort;

- The heat released by homemade briquettes during combustion is much lower than that of factory-made products. The whole point is the insufficient density of the “bricks”, since home appliances cannot provide the required pressing pressure;

- drying in the sun cannot be compared with industrial dryers, so the fuel contains moisture, which affects the calorific value;

- homemade sawdust fuel contains clay, which is not burned in the boiler firebox. This means there will be more ash left.

Do-it-yourself sawdust screw press

If you need to make briquettes in the form of fuel for personal use and in small volumes, then the right solution would be to make a screw press with your own hands. If you have design experience or technical education, then making a graphic representation of the device on your own will not be difficult. If you do not have confidence in your abilities, then you can use one of the professional drawings.

The most common models of homemade screw presses are the following types of devices:

- Lever. This installation is based on a lever, with the help of which physical force is applied to the raw materials loaded into the matrix.

- Screw. Auger equipment, the operating mechanism of which is driven by a screw shaft. It is equipped with a wheel and handles.

Related materials

To produce the device you may need the following materials:

- A tool set for carpentry and plumbing work, among which the central role is played by pliers, hacksaws for metal and wood, a hammer, files, screwdrivers and other abrasive devices.

- Electric drill or screwdriver.

- Set of drills for working on wood and metal.

- Manual welding machine.

- Wooden and iron semi-finished products - boards, profiles, etc.

Device production process

Specifically, the manufacture of a screw press for sawdust must be carried out according to the following instructions:

- Carefully study the existing drawing of the upcoming device for creating solid fuel briquettes.

- Do some preparatory work on the components of the upcoming press. At this stage of production, it is necessary to perform a semi-finishing of the parts and make the necessary holes.

- Make the final assembly of the device. In order not to waste your energy and time, it is recommended to carry out this stage of work very quickly to the future place of application.

- Perform commissioning work, for which create several briquettes using 40-60% of raw materials from the maximum potential design characteristics.

to contents ^

Manufacturing and assembly instructions

The order of operations in the manufacture of the press looks like this:

- It is necessary to weld the base of the device from the channels.

- From the corner we make 4 racks 1.5 meters long. They are welded vertically and with the same pitch.

- Next, you need to make a drum from a pipe or sheet of tin in which the raw materials will be mixed. If you have a broken washing machine, the drum, as well as the bearings, can be removed from it.

- The drum must be attached to the stands. If possible, it should be equipped with an electric motor. If the motor is too high-speed and it is not possible to reduce the rotation speed of the drum to an acceptable value due to the difference in pulley diameters alone, a gearbox should be used.

- It is necessary to attach a tray under the drum through which the prepared material will be fed into the matrix.

- In the walls of the pipe used as a blank for the matrix, it is necessary to make several holes with a diameter of 3 - 5 mm. They must be distributed evenly so that air and water are squeezed out throughout the entire volume of the briquette.

- A flange must be welded to the bottom of the matrix, to which the removable bottom will be screwed. This bottom is cut from a steel sheet in the form of a disk with eyes.

- The matrix is welded or screwed to the base under the loading tray.

- We cut out a round punch from a steel sheet. This is simply a disk whose diameter allows it to freely enter the matrix.

The rod is made of a pipe: a diameter of 30 mm is sufficient. One side of it is welded to the punch, and the other is attached to the hydraulic unit.

We fix the receiving tray under the matrix

It is important to install it in such a position that it does not interfere with removing and installing the removable bottom of the matrix. To reduce the time spent on removing the finished briquette from the matrix, and thereby make the machine more productive, a spring with a disk of the same type can be welded to the bottom of the matrix diameter the same as the punch.

To reduce the time spent on removing the finished briquette from the matrix, and thereby make the machine more productive, a spring with a disk of the same diameter as the punch can be welded to the bottom of the matrix.

After turning off the hydraulic unit and removing the punch, the product will be pushed out automatically by the spring.

Work methodology

If you still want to make a briquette press based on a screw and hinge mechanism, know: there is no need to use purchased units. However, they will not have a high compression force. This is why the press can be made on the basis of a hydraulic jack, equipped with an electric motor or a manual drive.

A punch is fixed to the hydraulic installation, the dimensions of which must match the dimensions of the matrix, in which they will actually develop into briquettes. The matrix can be made from a thick-walled pipe, which will be a simplified option. In order to allow moisture and air to escape, holes must be made in the walls of the pipe. The matrix must have a removable bottom. If you remove it, the finished briquette can be pushed into the tray with a punch. The finished mechanism should be supplemented with 2 handles, which provide ease of transportation.

Necessary materials

In addition to the hydraulic installation, you will need some types of rolled steel:

- Channel.

- Equal angle corner 100x100 mm.

- Sheet thickness 3 – 6 mm. A punch will be cut from it. The thickness of the workpiece depends on the diameter of the matrix: the larger it is, the thicker the punch should be.

From the same sheet we will cut out a removable bottom for the matrix.

- A pipe with a diameter of 25 - 30 mm - the punch rod will be made from it.

- A thick-walled pipe is a blank for the matrix. The diameter depends on what size briquettes the user wants to receive. The thinner they are, the higher their density, but the productivity of the machine will decrease.

- A large diameter pipe is a blank for the mixer body. If there is no suitable pipe, the drum can be made from a sheet of tin.

- Galvanized steel for the manufacture of trays.

In total, you will need two trays - for loading the prepared material into the matrix and for receiving the finished briquettes.

Operating principle

Before you make a sawdust press, you need to understand most of the principle of making briquettes for fuel:

- The raw material is poured into a matrix prepared for this purpose and compacted.

Main! Try to load the equipment with the maximum allowable amount of raw materials.

- Using a system of levers, the main force is supplied to the punch.

- This structural element compresses the loaded raw material, organizing it into a dense briquette.

- The form must be unfixed, and the fuel material must be sent to dry.

Main! Materials such as wood chips, sawdust, paper waste, seed peelings and nut shells can be used as raw materials for this device.

Ready-made equipment for home production

The production of fuel briquettes requires special equipment.

Therefore, in order to create high-quality products with your own hands, you need to purchase:

- Grinding device.

- Drying machine.

- Press.

But it is not practical to buy expensive machines for briquetting wood waste at home.

It makes sense to use powerful installations only when producing fuel briquettes in large volumes.

You can make briquettes as a material for heating a private home without a dryer. It is easy to remove moisture from prepared raw materials in a natural way. To do this, sawdust or wood shavings are laid out in a small layer on the street under a canopy.

A homemade press is often used to create compact fuel. Such a device will not provide a high compression density of the material, but will still make it possible to make fuel suitable for home use.

Equipment selection

When choosing a sawdust press, important factors to consider are:

- purpose of equipment;

- what raw materials does it work with;

- type of briquettes produced;

- device power;

- planned volume of finished products;

- complete with other equipment to obtain a high quality product;

- functionality of the selected model;

- operating mode of the unit and features of its maintenance.

You also need to pay attention to components that are subject to wear. Frequent repairs and their cost will help determine the rationality of purchasing a particular model.

When choosing a press for personal use, you should remember that the equipment should be simple with the ability to customize parameters. If the product is not planned to be put up for sale, then it is enough to purchase just one unit. To make your purchase cheaper, you can take advantage of interesting offers on the sale of used devices.

When choosing a press for personal use, you should remember that the equipment should be simple with the ability to customize parameters

Homemade briquettes - pros and cons

The reasons why this type of fuel is very attractive are clear. When a person has his own wood production or the opportunity to cheaply buy sawdust for briquettes, then thoughts about making them at home are quite natural. The fact is that not every heating equipment is suitable for burning sawdust. As a rule, fine wood in a conventional stove or boiler burns quickly and gives off little heat, and even half will spill into the ash pan.

It turns out that not everything is so simple here either, and here’s why:

- Buying factory drying and pressing equipment is an unreasonably expensive undertaking. It is cheaper to purchase ready-made European firewood.

- You can make a briquette press yourself and make them in an artisanal way. But the products will be of low quality and will provide little heat, and will take a lot of time.

After squeezing out the water and subsequent drying, the briquette becomes quite light

Point two requires clarification. Due to the impossibility of following the technology, the “bricks” after drying are light due to their low density. Their specific heat of combustion is three times lower than that of wood, which means that for heating they will need three times as much. The whole process will take a lot of time and consume a lot of energy. And it is very difficult to store such a volume of fuel so that it does not accumulate moisture.

Educational video for enthusiasts who want to start manual briquetting of various household waste:

This is interesting: We make it with our own hands - a lean-to canopy made of metal profiles

Homemade or purchased

The purchase of a press is justified in cases where it is planned to set up production. There is no need to purchase equipment for the production of briquettes, which will subsequently be used only for household needs. In addition, the cost of the units is high, not everyone can afford it. Yes, and installation requires a separate room.

According to the technological process, raw materials need to be prepared before processing, which means a dryer and a grinding device are required. In addition, after production, finished briquettes need to be stored in a dry room, which simply may not be available.

Handicraft production will not produce a high-quality product; the briquettes will have insufficient density, and this reduces the specific heat of combustion. Having weighed all the factors, we can summarize that there is no point in purchasing expensive equipment.

If your house has a boiler for solid fuel, you can build a press with your own hands. This will require available materials, as well as familiarization with design diagrams in order to choose the appropriate option.

Advantages of using ready-made presses for production purposes:

- simple equipment design;

- the ability to replace worn components;

- selection of models of different power and performance;

- the technological process does not require special knowledge and skills;

- You can set up a workshop in a small room.

When deciding to start production, it is worth considering important factors:

- type of raw material, its availability;

- approximate volume of processing for a certain period of time;

- required areas;

- scheme for selling finished products.

For large-scale production, it is recommended to purchase automatic and semi-automatic equipment. The units are characterized by high efficiency and wear resistance of working units.

The production of fillers for animal trays can be put into production using granulators. The diameter of the products produced just meets the standards, and high density is not required.