In mechanical engineering and other areas of industry, production activity consists of the production of blanks and parts that are obtained by mechanical processing. Modern materials can have very high levels of hardness and strength, which makes their processing more difficult.

In order to ensure fast and high-quality machining in the manufacture of cutting tools or their edges, carbon tool steels are used. Their peculiarity is their high resistance to mechanical stress.

Carbon tool steels

Such metals can also be used in the production of critical parts that are subject to high demands in terms of strength and hardness.

- Main characteristics

- Application

- Classification

- Marking

Main characteristics

Considering the main properties of tool steel, the following points should be noted:

- Low sensitivity to overheating. During machining, the removal of a layer of material from the workpiece occurs due to the applied demand. Heating a metal leads to a change in its basic qualities. Therefore, high-quality carbon tool steels do not heat up even during prolonged friction with other surfaces.

- Low sensitive to welding to workpieces. Due to the pressure exerted when feeding the tool at the time of processing the workpieces, the friction zone may heat up slightly, which causes an increase in the plasticity of some materials. If tool steel is welded to the surface, additional resistance will arise and the quality of the resulting part will significantly decrease.

- In order to simplify the processing of metal, it is made more susceptible to processing by cutting.

- Susceptibility to calcination is also determined by the specific chemical composition.

- High ductility in a hot state makes it possible to obtain workpieces using the metal melting method.

- High resistance to the decarburization process allows you to get the best results when carrying out hardening or other chemical-thermal treatment processes.

- During processing, shock loading may occur, which in most cases causes the formation of cracks. High-quality carbon tool steel does not have this disadvantage.

- Wear resistance and high strength, surface hardness.

The chemical composition of carbon tool steels largely determines the basic performance qualities of the metal.

Application

The use of carbon tool steels largely depends on the chemical composition. Most often used to obtain:

- Cutting tool. For many years, tools were made using ordinary steel, which could become hot during use and wear out quickly. At that time, lathe and drilling machines were installed, which could carry out processing only at low speed and low feed. The emergence of modern equipment, in particular CNC machines, has led to increased requirements for tools. Only the advent of tool steel and hard alloys made it possible to fully unlock the potential of modern equipment. Also, do not forget that in order to obtain high-quality surfaces, the feed rate must increase significantly; productivity can be increased by increasing the feed. Modern cutting tools can withstand repeated heating and cooling cycles, and their service life increases by several tens of times.

- High quality parts. An example is the design of an internal combustion engine, which has surfaces with precise dimensions and roughness. To ensure that the moving elements do not change their shape during operation due to heating, they are made of tool steel.

- Instruments used to make precise measurements. To obtain small parts with linear dimensional accuracy of several hundred millimeters, the workpiece should not be heated or deformed due to the pressure exerted by the cutting tool.

- A casting mold that must withstand significant pressure.

For the manufacture of parts, the most suitable brand is U7 or U7A, for the manufacture of cutting and other tools, U10 or U12. This pattern is due to the fact that harder metals must be used to produce cutting tools.

The marking of carbon tool steels in this case indicates the percentage of carbon and the presence of other impurities. The properties of carbon tool steel are largely determined by the carbon concentration - the higher, the harder the surface, but the brittleness also increases.

For cold pressing, grades U10 – U12 can be used. The tests carried out indicate that their hardness is 57-59 HRC. Among the features we note:

- Sufficiently high viscosity.

- High level of resistance to plastic type deformation.

- Increased wear resistance.

If the dimensions of the tool are large, then alloys that contain useful impurities can be used. It is customary to divide quality tool steels into 5 main groups:

- Wear-resistant, heat-resistant and high-hardness - a group represented by high-speed alloy steel. In addition, this group includes alloys with a ledeburite structure, which is characterized by a high carbon concentration (more than 3%). The use of tool carbon steels of this group is in the manufacture of tools that can be exposed to high temperatures due to high cutting speeds.

- Heat-resistant and tough steels are represented by an alloy that contains molybdenum, chromium and tungsten. The chemical composition of tool carbon steel of this group is characterized by a low carbon concentration.

- Non-heat-resistant, ductile and high-hardness steels have a small amount of impurities and an average carbon value. This group is characterized by a low hardenability index.

- Average heat resistance, high hardness, wear resistance are qualities characteristic of metals with 2-3% carbon and 5-12% chromium.

- Low heat resistance and high hardness are characteristic of steels with a hypereutectoid structure. In most cases, they do not have alloying elements or their concentration is very low. The high level of hardness is ensured by the high concentration of carbon.

High-quality tool steel can be subjected to additional chemical-thermal treatment to change the composition and rearrange the crystal lattice, due to which unusual performance qualities are achieved.

Hardness is considered the main parameter, the high value of which does not allow the use of steel in the manufacture of tools or parts that are subject to shock or vibration during operation. This recommendation is due to the fact that as the carbon concentration increases, the hardness increases, but the viscosity decreases.

A decrease in viscosity causes an increase in the fragility of the structure; as a result of the impact load, cracks and other defects may appear, and the surface may break off. The classification by hardness level is as follows:

- High viscosity and low hardness are characteristic of metals that contain no more than 0.4-0.7% carbon.

- High wear resistance and hardness of the surface layer are achieved when the metal structure is saturated with carbon to 0.7-1.5%.

A higher carbon concentration makes the metal very brittle, which does not allow it to be used as a material in the manufacture of tools. In addition, alloying elements can increase toughness and reduce brittleness under conditions of high carbon concentration.

Methods of obtaining

The following low-carbon steels are distinguished depending on the smelting method:

- Converter furnaces. The metal melts due to the chemical heat of exothermic reactions. Excess carbon is removed by blowing oxygen through the metal mirror. The advantage of this method is high productivity. The downside is the increased concentration of nitrogen at the outlet.

- Open hearth furnaces. Liquid fuel is burned in the working chamber. The required melting temperature is achieved due to the heat of the exhaust gases. With this method, the alloy turns out to be more deoxidized and with a lower content of non-metallic impurities.

- Electric furnaces. They have a more advanced smelting method. All high-quality grades of low-carbon steel are smelted only by this method. The advantage here is the ease of adjusting the thermal regime and the possibility of using slags and fluxes. The downside is significant energy costs.

Low-carbon steel is in greater demand in mechanical engineering and, especially, construction. It is these industries that provide it with constant demand for several decades. And judging by the expanding cities and developing industries, the need for carbon steel will only increase.

High carbon steel

High carbon steel is steel that contains a higher amount of carbon, from 0.6% to 2%.

During the production process, high-carbon steel undergoes heat treatment to impart certain mechanical properties.

As a result, small cracks in the seams may form in places where the alloy was exposed to high temperatures, which in turn prevents good welding of the steel.

To prevent this phenomenon and increase welding productivity, as well as eliminate the appearance of hardened zones, preheating of the workpiece to 200-2500C is used. After this, the alloy welds perfectly and creates reliable connections. High carbon steel is generally not used for structures.

High carbon steel and its grades

The grade of high-carbon steel is designated by the letter U - carbon tool, after the letter there is a number that shows the percentage of carbon content. For example, U7 contains 0.65-0.74% carbon, U13 contains 1.25-1.35% carbon.

The special properties of tool steel are affected by the presence of manganese; after the digital designation there will be the letter G. For example, sheet 65G. High-carbon steel grade from U7 to U13, silicon content 0.15-0.35%, sulfur 0.030%. Grades U10A, U12A are used for the manufacture of the matrix, but with subsequent hardening.

Small, low-responsibility magnets are made from U8 and U10.

High-carbon steel grades 55, 60,70 are distinguished by very good hardness and strength; taking this into account, they are suitable for the manufacture of wire for cables, rods, rolling mill shafts and other products that undergo heavy loads during operation.

High-quality carbon structural steel 15, 35, 45, 50 is used for parts with subsequent carburization to increase the hardness and wear resistance of parts such as shafts, gears, axles, nuts, bolts, couplings, and various parts that experience friction.

Also, if the steel is high-quality, then the letter A is placed after the letters and numbers, and high-quality steel Ш. Grades ШХ4, ШХ15, ШХ15СГ, having a chromium alloying additive, are used for the manufacture of bearings.

High carbon steel properties

High-carbon steel properties: As carbon increases, cementite increases and ferrite decreases. This results in the metal acquiring a less ductile structure and toughness, but maintaining strength and hardness.

The quality of high-carbon steel properties largely depends on the content of harmful impurities; the less of them, the higher the quality of the steel. The presence of manganese increases the hardenability of steel and significantly increases its strength.

Manganese also eliminates the harmful effects of sulfur, which, if there is a lot of it, leads to the formation of cracks during forging.

High-carbon steels belong to the class of steels that are difficult to weld, so they are not used in welded structures, and welding is used only for repair work or surfacing.

Thus, the properties of high-carbon steel allow it to be used for the manufacture of high-strength tools, measuring instruments, in addition to all of the above.

Source: https://metallsmaster.ru/vysokouglerodistaya-stal/

Surface hardening

Main article: Surface hardening

Surface hardening processes harden only the outer surface of a steel part, creating a hard, wear-resistant shell ("casing") but maintaining a tough and ductile interior. Carbon steels are not very hardenable, meaning that they cannot harden thick areas. Alloy steels have better hardenability, so they can be through-hardened and do not require hardening. This property of carbon steel can be beneficial because it gives the surface good wear characteristics but leaves the core flexible and shock absorbent.

High carbon steel: characteristics, properties, grades and markings

High-carbon steel, due to a number of undeniable advantages that it has, is successfully used for the production of products used in many industries.

Meanwhile, the use of steels in this category is not always advisable, so it is very important to have a good understanding of the properties and quality characteristics of such alloys.

Features of the material

Any steel, as is known, is an alloy of iron and carbon, to which various alloying elements can be added.

The division of steels into low-, medium- and high-carbon types depends on the amount of carbon present in their composition.

This element, which has a serious impact on the characteristics of the finished alloy, can be contained in steels from 0.02 to 2.14%. In steels classified as high-carbon, the amount of this element in the composition starts at 0.6%.

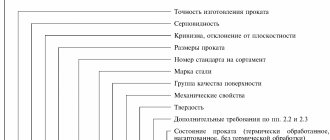

Steel grades and the proportion of various elements in their composition

One of the distinctive features that high-carbon steels have is that products made from them are difficult to weld; welding leads to cracks appearing in the weld zone.

This is explained by the fact that such materials, having a certain chemical composition, have a tendency to form hardened zones in those places where the metal is exposed to thermal effects.

Due to this feature of high-carbon steels, welding products made from them should only be done using electrodes with low thermal power. The welding arc used to connect products made of high-carbon steels must be of the recovery type.

The use of an oxidizing arc in such cases will lead to the fact that carbon will be burned out of the steel composition, and, as a result, the metal in the weld area will become more porous. Meanwhile, such a negative effect can be avoided if the products to be joined are preheated to a temperature of 200–2500.

Content

- 1 Type 1.1 Mild or low carbon steel 1.1.1 High strength steel

- 2.1 Low carbon steel

Carbon steel

Carbon steel is characterized by a carbon content of up to 2.14% without the presence of alloying elements, a small amount of impurities in the composition, and a small content of magnesium, silicon and manganese. This in turn affects the properties and features of application. It is the main product of the metallurgical industry.

Compound

Depending on the amount of carbon, carbon and alloy steel are divided. The presence of carbon gives the material strength and hardness, and also reduces viscosity and ductility.

Its content in the alloy is up to 2.14%, and the minimum amount of impurities due to the manufacturing process allows the bulk to consist of iron up to 99.5%. High strength and hardness are what characterize carbon steel.

Impurities that are constantly included in the structure of carbon steel have a small content. Manganese and silicon do not exceed 1%, and sulfur and phosphorus are within 0.1%. An increase in the amount of impurities is characteristic of another type of steel, which is called alloyed.

The lack of technical ability to completely remove impurities from the finished alloy allows the following elements to be included in carbon steel:

- hydrogen;

- nitrogen;

- oxygen;

- silicon;

- manganese;

- phosphorus;

- sulfur

The presence of these substances is determined by the steel melting method: converter, open-hearth or other. And carbon is added on purpose. If the amount of impurities is difficult to regulate, then adjusting the level of carbon in the composition of the future alloy affects the properties of the finished product. When the material is filled with carbon up to 2.4%, steel is classified as carbon.

Characteristic

The characteristics and structure of the metal are changed using heat treatment, through which the required surface hardness or other requirements for the use of the steel structure are achieved.

However, not all structural properties can be adjusted using thermal methods. Such structurally insensitive characteristics include rigidity, expressed by the elastic modulus or shear modulus.

This is taken into account when designing critical components and mechanisms in various fields of mechanical engineering. In cases where the calculation of the strength of an assembly requires the use of small-sized parts that can withstand the required load, heat treatment is used.

This effect on “raw” steel makes it possible to increase the rigidity of the material by 2-3 times. The metal that is subjected to this process is subject to requirements regarding the amount of carbon and other impurities. This steel is called high quality.

Classification of carbon steels

According to the direction of application of products, carbon steel is divided into tool and structural.

The last of them is used for the construction of various buildings and frame parts. Tools are used to make durable tools for performing any work, including metal cutting.

The use of metal products in the household required the classification of steel into different categories with specific properties: heat-resistant, cryogenic and corrosion-resistant.

According to the method of production, carbon steels are divided into:

- electric steel;

- open hearth;

- oxygen converter.

Classification of regular quality steel

Properties of steels of ordinary quality Within the quality group, low-carbon steel of ordinary quality is divided into three more categories, designated by capital letters A, B, C.

Low-carbon steel of ordinary quality of group “A” contains alloys that differ in mechanical properties; in industry it is found in the form of sheets, profiles low-carbon rolled products.

Group “B” is classified according to chemical qualities, processed under pressure under high heat, blanks are stamped and forged.

Low-carbon steels of group “B” are determined by their physical properties and chemical composition.

Low carbon steel can be of three types:

- Regular quality. In such alloys the sulfur content does not exceed 0.06%, phosphorus 0.07%.

- High quality. Contains: sulfur up to 0.04%, phosphorus up to 0.035%.

- High quality. Sulfur content up to 0.025%, phosphorus up to 0.025%

- Special quality. Low impurity content: sulfur up to 0.015%, phosphorus up to 0.025%.

Steel forging temperature

[20]

| Steel type | Maximum forging temperature | Combustion temperature | ||

| (°F) | (°C) | (°F) | (°C) | |

| 1.5% carbon | 1920 | 1049 | 2080 | 1140 |

| 1.1% carbon | 1980 | 1082 | 2140 | 1171 |

| 0.9% carbon | 2050 | 1121 | 2230 | 1221 |

| 0.5% carbon | 2280 | 1249 | 2460 | 1349 |

| 0.2% carbon | 2410 | 1321 | 2680 | 1471 |

| 3.0% nickel steel | 2280 | 1249 | 2500 | 1371 |

| 3.0% nickel-chromium steel | 2280 | 1249 | 2500 | 1371 |

| 5.0% Nickel (Cemented) Steel | 2320 | 1271 | 2640 | 1449 |

| Chrome vanadium steel | 2280 | 1249 | 2460 | 1349 |

| High speed steel | 2370 | 1299 | 2520 | 1385 |

| Stainless steel | 2340 | 1282 | 2520 | 1385 |

| Austenitic chromium-nickel steel | 2370 | 1299 | 2590 | 1420 |

| Silicon manganese steel spring | 2280 | 1249 | 2460 | 1350 |

References

- ^ a b c d f f d

“Classification of carbon and low-alloy steels” - Knowles, Peter Reginald (1987), Structural Steel Design

(2nd ed.), Taylor and Francis, p. 1, ISBN 978-0-903384-59-9. - Low Carbon Steel Technical Basics Page

- Ehlert, Glenn, Density of Steel

, retrieved April 23, 2009. - Modulus of elasticity, strength properties of metals - iron and steel.

, retrieved April 23, 2009. - Degarmo, p. 377.

- "Low carbon steels." efunda. Retrieved May 25, 2012.

- Ameristeel article on carbon steel Archived October 18, 2006 Wayback Machine

- Nishimura, Naoya; Murase, Katsuhiko; Ito, Toshihiro; Watanabe, Takeru; Novak, Roman (2012). "Ultrasonic detection of spall damage during low-velocity multiple impact." Central European Engineering Journal

.

2

(4): 650–655. Bibcode:2012CEJE…. 2..650N. doi:10.2478/s13531-012-0013-5. - Fundamentals of Engineering page on medium carbon steel

- Fundamentals of Engineering page on high carbon steel

- Smith, page 388

- Alvarenga HD, Van de Putte T, Van Steenberghe N, Sietsma J, Therrien H (October 2014). "The influence of morphology and microstructure of carbides on the kinetics of surface decarburization of C-Mn steels." Metal Mater Trans

A.

46

: 123–133. Bibcode:2015MMTA … 46..123A. Doi:10.1007/s11661-014-2600-у. - Smith, page 386

- Smith, pp. 386–387.

- Smith, pp. 373–377.

- Smith, pp. 389–390.

- Smith, pp. 387–388.

- Smith, page 391

- Brady, George S.; Clauser, Henry R.; Vaccari A, John (1997). Handbook of Materials

(14th ed.). New York, NY: McGraw-Hill. ISBN 0-07-007084-9.

Production

The metallurgical industry produces metal alloys. The specificity of the process for producing carbon steel is the processing of cast iron billets with the reduction of suspended matter such as sulfur and phosphorus, as well as carbon, to the required concentration. The differences in the oxidation technique by which carbon is removed allows us to distinguish different types of smelting.

Oxygen converter method

The basis of the technique was the Bessemer method, which involves blowing air through liquid cast iron. During this process, carbon is oxidized and removed from the alloy, after which the iron ingots gradually turn into steel. The productivity of this technique is high, but sulfur and phosphorus remained in the metal. In addition, carbon steel is saturated with gases, including nitrogen. This improves strength but reduces ductility, making the steel more prone to aging and high in non-metallic elements.

Given the low quality of steel produced by the Bessemer method, it was no longer used. It was replaced by the oxygen-converter method, the difference of which is the use of pure oxygen, instead of air, when purging liquid cast iron. The use of certain technical conditions during purging significantly reduced the amount of nitrogen and other harmful impurities. As a result, carbon steel produced by the oxygen-converter method is close in quality to alloys melted in open-hearth furnaces.

The technical and economic indicators of the converter method confirm the feasibility of such smelting and make it possible to replace outdated methods of steel production.

Open hearth method

A feature of the method for producing carbon steel is the burning of carbon from cast iron alloys not only with the help of air, but also by adding iron ores and rusty metal products. This process usually takes place inside furnaces, to which heated air and combustible gas are supplied.

The size of such melting baths is very large; they can hold up to 500 tons of molten metal. The temperature in such containers is maintained at 1700 ºC, and carbon burning occurs in several stages. First, due to excess oxygen in flammable gases, and when slag forms above the molten metal, through iron oxides. When they interact, slags of phosphates and silicates are formed, which are subsequently removed and the steel acquires the required quality properties.

Steel melting in open hearth furnaces takes about 7 hours. This allows you to adjust the desired composition of the alloy when adding different ores or scrap. Carbon steel has long been manufactured using this method. Such stoves, in our time, can be found in the countries of the former Soviet Union, as well as in India.

Electrothermal method

It is possible to produce high-quality steel with a minimum content of harmful impurities by melting it in vacuum furnaces of electric arc or induction furnaces. Thanks to the improved properties of electric steel, it is possible to produce heat-resistant and tool alloys. The process of converting raw materials into carbon steel occurs in a vacuum, due to which the quality of the resulting workpieces will be higher than the previously discussed methods.

The cost of such metal processing is more expensive, so this method is used when there is a technological need for a high-quality product. To reduce the cost of the technological process, a special ladle is used, which is heated inside a vacuum container.

Case-hardened, temperable and high-strength steels

Case-hardened steels are low-carbon (up to 0.25 C), low- (up to 2.5%) and medium-alloyed (2.5...10% total content of alloying elements) steels. They are intended for machine parts and devices operating in friction conditions and experiencing shock and variable loads.

Steel grade 15ХА with a tensile strength σ in MPa is intended for the manufacture of small parts operating under friction conditions at medium pressures and speeds. For the manufacture of critical parts operating at high speeds, high pressures and shock loads, steel grades 18ХГ and 25ХГМ . For large, critical, heavily loaded parts, steels 20ХН and 20Х2Н4А .

In the manufacture of large, especially critical, heavily loaded parts operating at high speeds with the presence of vibration and dynamic loads, steel with a tensile strength in MPa grade 18Х2Н4МА .

The performance of such parts depends on the properties of the core and surface layer of the metal. Case-hardening steels are saturated with carbon from the surface (cemented) and subjected to heat treatment (hardening and tempering). This treatment provides high surface hardness (HRC 58...63) and maintains the required toughness and specified strength of the metal core.

Improved alloy steels are medium-carbon (0.25...0.6% C) and low-alloy steels. To ensure the necessary properties (strength, ductility, toughness), these steels are thermally improved by hardening and high tempering (at 500...600°C).

Improved and case-hardening steels after heat treatment give strength up to σ in MPa and toughness up to KS= 0.8...1.0 MJ/m2. Such strength is not enough to create new modern machines. Steels with a strength limit of σ in MPa are required. For these purposes, complex alloyed and maraging steels are used. The properties of such steels and their purpose are shown in table. 2.

Table 2. Improved alloy steels

| Brand | Limit strength at stretching _ σв, MPa | Relative elongation δ,% | Specific viscosity KS, MJ/m2 | Purpose |

| 40ХС | 1250 | 12 | 0,35 | Some parts operating under conditions of increased stress and alternating loads |

| 40HFA | 900 | 10 | 0,9 | |

| 30HGFA | 1100 | 10 | 0,5 | Parts operating under friction conditions and critical welded structures operating under alternating loads and temperatures up to 200°C |

| 40ХН2МА | 1100 | 12 | 0,8 | Large, critical, heavily loaded parts with complex shapes |

Complex alloy steels are medium-carbon (0.25...0.6% C) alloy steels that are heat-strengthened during low tempering or subjected to thermomechanical treatment.

Maraging steels are a new class of high-strength alloy steels based on carbon-free (no more than 0.03% C) alloys of iron with nickel, cobalt, molybdenum, titanium, chromium and other elements. Maraging steels are hardened in air from 800...860°C, followed by aging at 450...500°C.