This is a type of rolled metal that has a U-shaped cross section. This structure is formed from a wall and two shelves. Modern construction is unthinkable without such elements, which, with a relatively low weight, can easily withstand significant loads. If you need a channel, the dimensions of which must be strictly defined, then you need to remember that there are equal and unequal flange products. In the second case, the dimensions of the shelves forming the U-shaped section will be different.

The following types of channels are used in construction:

- shelves having an internal slope;

- with parallel internal edges;

- bent equal-strength and unequal-strength;

- special;

- cold rolled

WHAT IS A CHWELLER?

.

The very word “channel” in German is translated as “skirt”; these two items have some distant similarities. The channel is a structure made of non-ferrous or ferrous metal, in cross section resembling the letter P in various variations, since the edges can be either parallel to each other or located at an angle. A distinctive feature of this product is strength, so most often channels are made of steel and its alloys, and are used to strengthen any supports, components, surfaces made of fragile materials, frames.

The production of channels is strictly regulated, which means that the products produced by a metalworking enterprise must comply with state standards, that is, be universal in use. Each type of channel has its own GOST.

Geometric indicators

The state standard regulates all sizes of rolled metal products, according to production technology. The main parameters are:

- thickness, wall height;

- rolling length;

- internal corner radius;

- shelf curvature radius;

- thickness, shelf width.

There is also a distribution according to the level of rolling accuracy:

- marking “A” - high accuracy;

- "B" - increased;

- "B" is normal.

Product designation

To make choosing the right product easier, the distance between shelves is used. This is the number that appears after the designation of the element, but there are also differences in length: it varies from 4 to 12 meters.

From the point of view of counteracting large loads directed vertically downward, the channel is second only to the I-beam. The width of the shelves varies and starts from 32 mm, and can reach 115 mm, therefore the load capacity varies within a wide range. The situation is similar with height, which ranges from 5 to 40 cm.

It must be remembered that the standard channel 10, the dimensions of which can be different, will be the cross-section that is required in a particular case and depends on the place of application. The letter found after the number indicating the distance between the shelves will tell the specialist about the type of product. If a product with the “U” index is used, then we are talking about inclined internal edges. When the shelves are located parallel, this is a “P” series channel. There are also “L” - light, “S” - light varieties.

Weight of products

The indicator is based on several parameters:

- length;

- width;

- the material used;

- the thickness of the cross beam and parallel shelves.

Part 12P, made of aluminum alloy and steel, can have different weight categories with the same external characteristics. There are also multi-shelf products, when the side edges have different heights. Of course, you can calculate the weight of such products, but only using specific formulas.

Standard metal beams weigh 4.8-48.3 kg. According to modern GOST and European standards, a deviation of 6.5% is possible for each piece, if the difference in the mass of the entire batch is no more than 4%.

Application of channels

Today, the demand for such products is quite high, which is due to the widespread use of concrete and metal structures. The attractiveness of the channel lies in the fact that it is light in weight and can withstand quite a significant load. The channel owes this feature to its U-shaped profile, which provides the necessary combination of structural properties and reliability. Metal structures of this type can be used both for construction and for repair work. They are used in a wide variety of fields, from mechanical engineering to the creation of various shelving.

Various metal structures that are erected for advertising purposes or for laying communications are also places where such elements are in demand. Channel 20, whose dimensions vary widely, is excellent for this purpose.

Its type depends on where the metal structure will be used. For example, to work under heavy loads, it is better to use a design with inclined shelves. In fact, the outer contour of the product still remains U-shaped, but the inner one already has some deviations from this shape, because the slope of the inner walls can be large. This results in increased wall thickness and higher reliability.

The type of channel and its parameters are selected only after calculations have been carried out, and they must be performed by a specialist. Otherwise, problems may arise due to the wrong choice of thickness or other characteristics of the product, which means the reliability of the structure will decrease.

WHY DO YOU NEED A CHWELLER

As mentioned earlier, this rolled metal product is found everywhere.

Steel channels, especially strong and reliable, thanks to these qualities, they are used to strengthen walls, reinforce concrete structures, build power lines, and make floors. This ensures the durability of these structures. If the channel is perforated, that is, it has holes for fastening, it can be used in installation work without welding. Also, pipes made of less durable materials can be laid inside the channel, this gives the pipeline high wear resistance.

Aluminum channels are used in lighter structures, in the manufacture of office partitions, shop windows, shelving, in everyday life, in repair, finishing and construction work, and in mechanical engineering.

Area of use

We have already mentioned the use of channels in different types of construction. Their main task is to strengthen concrete structures, increase the strength and service life of the building. In addition, channels are used to reinforce power lines, bridges, industrial buildings, and structures.

The catalog contains perforated products. They are equipped with special holes necessary for the rapid installation of structures without electric welding. Also, between the channel shelves there may be pipes for supplying utilities and cable lines.

Aluminum channels are relevant for light parts of a building, such as internal partitions, showcases, and shelving.

Types of channel

The special channel is intended for use in the automotive industry (GOST 19425-74) and in carriage building (GOST 5267.1-90).

They are manufactured in lengths from 4 to 13 m, but on special order they can be longer than 13 m. The lengths of special channels are:

- channel of measured length;

- multiple measured length;

- measured length with a remainder of up to 5% of the batch weight (residue of at least 3 mm);

- multiple measured length with a remainder of up to 5% of the batch weight;

- of unmeasured length.

Depending on the rolling accuracy, the special channel is divided into: high strength - A, normal strength - B.

Steel bent equal-flange channels in accordance with GOST 8278-93 are manufactured on pipe mills from coiled steel of ordinary quality and high-quality carbon structural steel. The height of the equal-flange channel ranges from 50 to 400 mm, width from 32 to 115 mm.

The different lengths of bent equal-flange channel are:

- channel of measured length;

- measured and unmeasured lengths in an amount of no more than 5% of the batch weight;

- multiple measured length;

- multiple measured lengths from unmeasured lengths in an amount of no more than 5% of the lot weight;

- unmeasured length;

- limited length within unmeasured.

Steel bent unequal-flange channels are manufactured on roll forming mills from rolled cold-rolled and hot-rolled steel of ordinary quality, high-quality carbon structural and low-alloy steel in accordance with GOST 8281-80. They are also divided by numbers, which indicate the distance between the shelves (in mm). The length varieties are the same as for equal-flange channels.

Depending on the rolling accuracy, bent channels are divided into: high precision - A, increased precision - B, normal precision - B.

The highest category of quality for bent unequal and equal flange channels corresponds to channels with categories A and B.

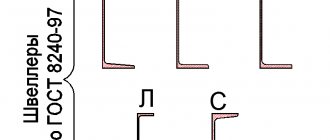

Forms of bent channel: U - with a slope of the internal edges of the shelves, P - with parallel edges of the shelves, L - light series with parallel edges of the shelves, S - special.

Classification of channels

| No. | Name of channels | Description |

| 1 | Rolled according to GOST 8240-97, DSTU 3436-96 | |

| Steel channel | ||

| 1.1 | Channel. Series U | Channel with a slope of the internal edges of the shelves. Series U. |

| 1.2 | Channel. Series P | Channel with parallel flange edges - P series. |

| 1.3 | Channel. Series E | Economical channel with parallel flange edges - E series. |

| 1.4 | Channel. Series L | Light channel with parallel flange edges - L series. |

| 1.5 | Channel. Series C | Channel with a slope of the inner edges of the shelves - series C. |

| Channel according to the manufacturer's specifications | ||

| 1.6 | Channel according to specifications | |

| Special channel | ||

| 1.7 | Channel. Series C | Channel with a slope of the inner edges of the shelves - series C. |

| Special channel for tractors and carriage building | ||

| 1.8 | Channel | Special channel for tractors and carriage building |

| 2 | Bent channel | |

| 2.1 | Channel according to GOST 8278-83 | Channel. Bent equal flange |

| 2.2 | Channel according to GOST 8281-80 | Channel. Bent unequal |

Some features of choice

The range of channels, of course, is significantly inferior in variety to the range of angles, but this does not prevent the selection of a product of the required dimensions and characteristics to solve a specific design problem. When choosing a specific brand from the assortment, you should be guided by the following rule, which is relevant for products of any profile: having decided on the type of channel that meets your requirements, you should include in the specification for the drawing the brand that is located closer to the beginning of the table.

The assortment, in which various types of channels are presented in table form, allows you to determine not only their sizes, but also a number of other important parameters:

- linear meter weight;

- cross-sectional area;

- axial moment of inertia;

- axial moment of resistance;

- radii of inertia.

The last three parameters are calculated relative to the central axis of the channel section.

It is very important to choose those brands of channels whose mechanical characteristics are not lower than the calculated ones by more than 5%. If this condition is not met for the selected brand of product, then it is better to take a channel one number higher.

Determining the weight and price of a channel per meter: table of sizes, cost of profiles

Complex calculations of specific gravity, in addition to mathematical skills, also require updating the school course in physics and geometry. Therefore, it is better to use ready-made calculations given in special tables, or use an online calculator. To do this, just enter the necessary data and get an accurate result. The cost of channels is determined in accordance with linear meters. The price formation is influenced by the profile height, which determines the product number, as well as the grade of steel from which the product is made. For example, a channel made from low-alloy steel will cost an order of magnitude more than similar products made from carbon steel. This is due to the fact that the first type of raw material has increased strength characteristics.

The current average prices for channels on the Russian rolled metal market are shown in the table:

| Channel number | Weight per linear meter, kg | Length in ton, m | Price per linear meter, rub. |

| 5 | 4,8 | 207 | 200 |

| 6,5 | 5,9 | 169 | 240 |

| 8 | 7,1 | 142 | 265 |

| 10 | 8,6 | 115 | 350 |

| 12 | 10,4 | 97 | 420 |

| 14 | 12,3 | 82 | 480 |

| 16 | 14,2 | 71 | 520 |

| 18 | 16,3 | 60 | 600 |

| 20 | 18,4 | 55 | 760 |

| 22 | 21,0 | 48 | 870 |

| 24 | 24,0 | 42 | 1020 |

| 27 | 27,7 | 35 | 1150 |

| 30 | 31,8 | 32 | 1400 |

| 40 | 48,3 | 21 | 4250 |

Above is a general table. In order to have an idea about each type of channel, its individual features, sizes and characteristics, it is worth getting to know each type in more detail. Below, as an example, we will consider the most popular types and sizes of channels that are in high demand and widely used.

Marking

If you look at the range of channels, you can see that it includes metal profiles with a wide range of sizes. With such a variety of options offered, it is very difficult to choose exactly the brand of channel that will be optimally suited for solving a particular problem. Naturally, the manufacturers took this point into account. To designate their products, they use markings, which can be used to get a fairly complete picture of the characteristics and dimensions of the U-shaped profile.

Markings that comply with GOST 8240-97 include both digital and alphabetic designations. The first number in the designation is the main characteristic; it corresponds to the size of the channel, that is, the distance between its flanges. By the letter in the marking you can determine what type the channel is. These can be products in which the internal edges of the shelves are made with a slope or are parallel to each other (“U” and “P”, respectively), metal profiles of economical (“E”) or light (“L”) type, special purpose (“S” ).

If you need to know all the other dimensions of a channel of a certain brand from the assortment, then for this there is a special table in which they are indicated. The choice of a product of a certain brand is made depending on what kind of loads the structure for which it is planned to be used will be subjected to.

Characteristics of channel 10: dimensions, weight, cost

The range of channel 10, as a fairly popular rolled metal product, is quite wide. The characteristics of its varieties and types are regulated by GOST No. 8240, developed back in 1989. The properties of products include the parameters of shelves and walls, in particular their height and width, and also the radii of curvature of channels marked 10U are taken into account.

Channel 10 has three subtypes with corresponding markings:

- U – a profile in which the internal shelves are made with a slope;

- P – channel, where the edges of the flanges are parallel;

- E - economical products with parallel placement of shelves.

Helpful advice! Each type of channel has its own designation, for example, 10P, 10U or 10E. The corresponding values are contained in a separate table. Despite the same numerical data, these are different types of products.

The most used in various industries is, due to its size, the 10P channel. It is widely used in individual construction for the construction of load-bearing structures. The number 10 in the marking, in fact, indicates its height, equal to 100 mm, and the letter P indicates the type of profile, while emphasizing the parallel arrangement of the shelves. This type of channel has the following parameters:

- width is 46 mm;

- wall thickness – 4.5 mm;

- shelf thickness – 7.6 mm;

- radius of curvature – 7 mm;

- The radius of curvature at the edge of the shelf is 4 mm.

To determine the weight of channel 10, it is necessary to know the cross-sectional area. This figure corresponds to 10.9 cm². This type of channel is produced in lengths from 4 to 12 m. Longer products are made to order. The weight of 1 meter of channel 10 with a steel density of 7.85 g/cm³, according to calculations, is 8.59 kg. The error in the indicated mass values may be 3-5%. The average price of channel 10 per meter is 356 rubles.

Aluminum channel

The classic U-shaped structure made of steel not only has greater resistance to bending, but also has good resistance to torsional deformation, so the scope of application of such products is very wide. The use of aluminum has further expanded the scope where these metal structures are used today.

Channel 16, the dimensions of which are ideal for those structures that experience light loads, is used no less often than its steel variety. Aluminum structures are well suited for applications where it is necessary to contain elements in contact with the environment. Aluminum itself differs favorably from steel in that it does not interact with air or water, therefore the reliability of the future structure does not depend on such random factors as bad weather or improper care of painted elements.

In conclusion, we note that one of the main advantages of most types of channels is the ability to construct metal structures without the use of welding. This allows you to create collapsible structures that can be moved to another location in whole or in part. For example, this technology is used to create a variety of seasonal structures, temporary buildings or warehouses. A channel, the dimensions of which are proportional to its weight, is a modern building material that is in no hurry to give up its position to plastic or concrete. In general, an aluminum channel is much more profitable than a profile pipe of the same size, since it allows you to further reduce the weight of the future structure.

Features of this range of channels

Grouping information

Each table displays only part of the information: 10 lines, between which you can switch using the buttons located in the lower right corner of each table.

Data filtering

The assortment tables provide data filtering, which allows you to display only the necessary lines. To do this, just enter the unique value of the channel parameter into the search, after which the table will display only its values. It is recommended to enter values for moments of resistance or moment of inertia, since these values are unique parameters for each channel.

Adaptability of assortment

All assortment tables are adaptive and automatically adjust to any screen size. For mobile devices with a small screen width, horizontal scrolling is provided: under each table there is a special slider.

Table with dimensions of channels with parallel flange edges.

| Series P channel number | h | b | s | t | R | r | Cross-sectional area F cm2 | Weight 1m/kg | Reference values for axes | X0 cm | ||||||

| no more | XX | YY | ||||||||||||||

| mm | Ix cm4 | Wx cm3 | Ix cm | Sx cm3 | Iy cm4 | Wy cm3 | Iy cm | |||||||||

| 5P | 50 | 32 | 4.4 | 7.0 | 6.0 | 3.5 | 6.16 | 4.84 | 22.8 | 9.1 | 1.92 | 5.61 | 5.95 | 2.99 | 0.98 | 1.21 |

| 6.5P | 65 | 36 | 4.4 | 7.2 | 6.0 | 3.5 | 7.51 | 5.90 | 48.8 | 15.0 | 2.55 | 9.02 | 9.35 | 4.06 | 1.12 | 1.29 |

| 8P | 80 | 40 | 4.5 | 7.4 | 6.5 | 3.5 | 8.98 | 7.05 | 89.8 | 22.5 | 3.16 | 13.30 | 13.90 | 5.31 | 1.24 | 1.38 |

| 10P | 100 | 46 | 4.5 | 7.6 | 7.0 | 4.0 | 10.90 | 8.59 | 175.0 | 34.9 | 3.99 | 20.50 | 22.60 | 7.37 | 1.44 | 1.53 |

| 12P | 120 | 52 | 4.8 | 7.8 | 7.5 | 4.5 | 13.30 | 10.40 | 305.0 | 50.8 | 4.79 | 29.70 | 34.90 | 9.84 | 1.62 | 1.66 |

| 14P | 140 | 58 | 4.9 | 8.1 | 8.0 | 4.5 | 15.60 | 12.30 | 493.0 | 70.4 | 5.61 | 40.90 | 51.50 | 12.90 | 1.81 | 1.82 |

| 16P | 160 | 64 | 5.0 | 8.4 | 8.5 | 5.0 | 18.10 | 14.20 | 750.0 | 93.8 | 6.44 | 54.30 | 72.80 | 16.40 | 2.00 | 1.97 |

| 16aP | 160 | 68 | 5.0 | 9.0 | 8.5 | 5.0 | 19.50 | 15.30 | 827.0 | 103.0 | 6.51 | 59.50 | 90.50 | 19.60 | 2.15 | 2.19 |

| 18P | 180 | 70 | 5.1 | 8.7 | 9.0 | 5.0 | 20.70 | 16.30 | 1090.0 | 121.0 | 7.26 | 70.00 | 100.00 | 20.60 | 2.20 | 2.14 |

| 18aP | 180 | 74 | 5.1 | 9.3 | 9.0 | 5.0 | 22.20 | 17.40 | 1200.0 | 133.0 | 7.34 | 76.30 | 123.00 | 24.30 | 2.35 | 2.36 |

| 20P | 200 | 76 | 5.2 | 9.0 | 9.5 | 5.5 | 23.40 | 18.40 | 1530.0 | 153.0 | 8.08 | 88.00 | 134.00 | 25.20 | 2.39 | 2.30 |

| 22P | 220 | 82 | 5.4 | 9.5 | 10.0 | 6.0 | 26.70 | 21.00 | 2120.0 | 193.0 | 8.90 | 111.00 | 178.00 | 31.00 | 2.58 | 2.47 |

| 24P | 240 | 90 | 5.6 | 10.0 | 10.5 | 6.0 | 30.60 | 24.00 | 2910.0 | 243.0 | 9.75 | 139.00 | 248.00 | 39.50 | 2.85 | 2.72 |

| 27P | 270 | 95 | 6.0 | 10.5 | 11.0 | 6.5 | 35.20 | 27.70 | 4180.0 | 310.0 | 10.90 | 178.00 | 314.00 | 46.70 | 2.99 | 2.78 |

| 30P | 300 | 100 | 6.5 | 11.0 | 12.0 | 7.0 | 40.50 | 31.80 | 5830.0 | 389.0 | 12.00 | 224.00 | 393.00 | 54.80 | 3.12 | 2.83 |

| 33P | 330 | 105 | 7.0 | 11.7 | 13.0 | 7.5 | 46.50 | 36.50 | 8010.0 | 486.0 | 13.10 | 281.00 | 491.00 | 64.60 | 3.25 | 2.90 |

| 36P | 360 | 110 | 7.5 | 12.6 | 14.0 | 8.5 | 53.40 | 41.90 | 10850.0 | 603.0 | 14.30 | 350.00 | 611.00 | 76.30 | 3.38 | 2.99 |

| 40P | 400 | 115 | 8.0 | 13.5 | 15.0 | 9.0 | 61.50 | 48.30 | 15260.0 | 763.0 | 15.80 | 445.00 | 760.00 | 89.90 | 3.51 | 3.05 |

For channels of the U and P series there is a size that is not subject to control - this is the maximum deviation in wall thickness.

Weight of channels, their markings and symbols

To designate different types of channels, special markings are used.

The letter indicates the type of profile, characterizing the structural features and arrangement of the edges:

- “P” – indicates parallelism;

- “U” – indicates the presence of a slope on the edges;

- “E” – indicates efficiency;

- “L” – implies lightness;

- “C” indicates the special purpose of the profile.

On a note! The numerical indicator next to the letter indicates the size of the product; it corresponds to the height given in the GOST table. It should be noted that channels are usually marked with numerical values in centimeters, and their height in the table is indicated in millimeters. Visually it looks like this: channel 8, channel weight 12 or channel dimensions 16P.

To determine the types of channels, as well as their characteristics, special symbols are used.

In addition to the height of the product, other size indicators are also used. In the tables they have special designations:

- h is the profile height, which is the main quantity that determines the size of rolled metal products;

- b – indicates the width of the shelves;

- S – indicator of the thickness of the main wall;

- R – determines the radius of the rounded inner part of the shelf;

- t – indicates the thickness of the shelves;

- r is the value of the total radius of curvature of the shelves.

An important indicator in the choice of material (when designing construction) is the weight of the channel. Correct calculation of data allows you to accurately calculate the quantity of required products and, thus, save on their purchase. There are several methods for calculating the weight of a linear meter. They depend on the method of production of rolled products. For example, to determine the specific gravity of a hot-rolled channel, the indicators of the radii of internal curvature and flange curvature are taken into account.

Drawing of a hot-rolled steel channel with a slope and parallel flanges.

Table with dimensions of channels for economical shelves with parallel edges.

| Series E channel number | h | b | s | t | R | r | Cross-sectional area F cm2 | Weight 1m/kg | Reference values for axes | X0 cm | ||||||

| no more | XX | YY | ||||||||||||||

| mm | Ix cm4 | Wx cm3 | Ix cm | Sx cm3 | Iy cm4 | Wy cm3 | Iy cm | |||||||||

| 5E | 50 | 32 | 4.2 | 7.0 | 6.5 | 2.5 | 6.10 | 4.79 | 22.9 | 9.17 | 1.94 | 5.62 | 6.02 | 3.05 | 0.993 | 1.23 |

| 6.5E | 65 | 36 | 4.2 | 7.2 | 6.5 | 2.5 | 7.41 | 5.82 | 48.9 | 15.05 | 2.57 | 9.02 | 9.42 | 4.13 | 1.127 | 1.32 |

| 8E | 80 | 40 | 4.2 | 7.4 | 7.5 | 2.5 | 8.82 | 6.92 | 90.0 | 22.50 | 3.19 | 13.31 | 13.93 | 5.38 | 1.257 | 1.41 |

| 10E | 100 | 46 | 4.2 | 7.6 | 9.0 | 3.0 | 10.79 | 8.47 | 175.9 | 35.17 | 4.04 | 20.55 | 22.68 | 7.47 | 1.450 | 1.56 |

| 12E | 120 | 52 | 4.5 | 7.8 | 9.5 | 3.0 | 13.09 | 10.24 | 307.0 | 51.17 | 4.84 | 29.75 | 35.12 | 10.03 | 1.638 | 1.70 |

| 14E | 140 | 58 | 4.6 | 8.1 | 10.0 | 3.0 | 15.41 | 12.15 | 495.7 | 70.81 | 5.67 | 40.96 | 51.76 | 13.13 | 1.833 | 1.86 |

| 16E | 160 | 64 | 4.7 | 8.4 | 11.0 | 3.5 | 17.85 | 14.01 | 755.5 | 94.43 | 6.50 | 54.41 | 73.17 | 16.70 | 2.024 | 2.02 |

| 18E | 180 | 70 | 4.8 | 8.7 | 11.5 | 3.5 | 20.40 | 16.01 | 1097.9 | 121.99 | 7.34 | 70.05 | 100.51 | 20.87 | 2.219 | 2.18 |

| 20E | 200 | 76 | 4.9 | 9.0 | 12.0 | 4.0 | 23.02 | 18.07 | 1537.1 | 153.71 | 8.17 | 88.03 | 134.07 | 25.54 | 2.413 | 2.35 |

| 22E | 220 | 82 | 5.1 | 9.5 | 13.0 | 4.0 | 26.36 | 20.69 | 2134.2 | 194.02 | 9.00 | 111.00 | 179.05 | 31.54 | 2.606 | 2.52 |

| 24E | 240 | 90 | 5.3 | 10.0 | 13.0 | 4.0 | 30.19 | 23.69 | 2927.0 | 243.92 | 9.85 | 139.08 | 249.03 | 40.07 | 2.872 | 2.78 |

| 27E | 270 | 95 | 5.8 | 10.5 | 13.0 | 4.5 | 34.87 | 27.37 | 4200.2 | 311.12 | 10.97 | 178.25 | 316.24 | 47.43 | 3.011 | 2.83 |

| 30E | 300 | 100 | 6.3 | 11.0 | 13.0 | 5.0 | 39.94 | 31.35 | 5837.1 | 389.14 | 12.09 | 224.00 | 395.57 | 55.58 | 3.147 | 2.88 |

| 33E | 330 | 105 | 6.9 | 11.7 | 13.0 | 5.0 | 46.15 | 36.14 | 8021.8 | 488.17 | 13.18 | 281.23 | 497.02 | 65.78 | 3.282 | 2.94 |

| 36E | 360 | 110 | 7.4 | 12.6 | 14.0 | 6.0 | 52.90 | 41.53 | 10864.5 | 603.58 | 14.33 | 350.05 | 618.92 | 77.76 | 3.420 | 3.04 |

| 40E | 400 | 115 | 7.9 | 13.5 | 15.5 | 6.0 | 61.11 | 47.97 | 15307.9 | 765.40 | 15.83 | 445.41 | 770.89 | 91.80 | 3.552 | 3.10 |

The dimensions of the economical channel (E series) are controlled according to GOST 8240-97 (the data in the tables corresponds).

Channel: dimensions affecting the scope of application

Summarizing the above, the conclusion suggests itself that a channel is a rolled metal product that is used for reinforcing reinforced concrete structures, for the production of crane products, electrical supports, bridges, oil rigs and other large-scale structures. The wide range of uses is due to the high level of strength and stability with a relatively small weight of the product. At the same time, different sizes of channels are applicable in specific areas or have a special purpose.

Thus, due to its compact dimensions, channel 8 is widely used in individual construction as concrete lintels, and is also used for making foundations for the construction of door and window openings. Channel 10, made by hot rolling, is widely used due to its universal size and strength.

The scope of use of the channel directly depends on its size and steel thickness.

Channel 12 is also produced in the same way. Its main positive feature is excellent weldability. It is used to increase the load-bearing capacity of a structure and as reinforcement for structures. Channel 14 is produced using rolling machines. Increased rigidity suggests its use as load-bearing beams in floors during the construction of high-rise buildings, as well as in carriage building.

On a note! When choosing rolled metal products, you should remember that there are different series of channels. Profiles in which the edges of the shelves are placed parallel are marked with the letter “P”; special channels are marked “C”. Models with inclined inner edges of the shelves are designated by the letter “U”; economical profiles correspond to; the sign “L” implies lightweight versions of the channels.

Channel 16, made by hot rolling, is widely used in the construction of high-rise buildings, as well as in the construction of metal supports for bridges. The dimensions of channel 18 allow it to be used as reinforcement in high-rise buildings and in structures with a high degree of load.

Profiles marked 20 and above can be used for the construction of bridges and other large objects with high loads.

Profiles marked 20, 22, 24 belong to the high-strength category. They are used in the construction of highly loaded buildings and structures that move. For example, the dimensions of a channel 24 suggest its use in the construction of sliding bridges, as well as cranes with high lifting capacity.

Channel 40, having maximum rigidity, is used in heavy industry, where enormous loads are required, in shipbuilding, as well as for the construction of oil platforms.

Rolled metal assortment: popular types of products and algorithms for calculating weight (read more)

Thus, channels are of great importance in construction, and therefore are widely used in various fields. When choosing products, you need to navigate the range of sizes and know the main characteristics of each type of channel. This will allow you to select the desired series and use this type of rolled metal products as efficiently as possible.

Table with dimensions of light series channels with parallel flange edges.

| Series L channel number | h | b | s | t | R | r | Cross-sectional area F cm2 | Weight 1m/kg | Reference values for axes | X0cm | ||||||

| no more | X–X | Y–Y | ||||||||||||||

| mm | Ix cm4 | Wx cm3 | Ix cm | Sx cm3 | Iy cm4 | Wy cm3 | i0 cm | |||||||||

| 12L | 120 | 30 | 3.0 | 4.8 | 7 | – | 6.39 | 5.02 | 135.26 | 22.54 | 4.60 | 13.43 | 5.02 | 2.24 | 0.89 | 0.76 |

| 14L | 140 | 32 | 3.2 | 5.6 | 7 | – | 7.57 | 5.94 | 212.94 | 30.42 | 5.31 | 18.23 | 6.55 | 2.70 | 0.93 | 0.78 |

| 16L | 160 | 35 | 3.4 | 5.3 | 8 | – | 9.04 | 7.10 | 331.96 | 41.49 | 6.06 | 24.84 | 9.23 | 3.46 | 1.01 | 0.83 |

| 18L | 180 | 40 | 3.6 | 5.6 | 8 | – | 10.81 | 8.49 | 503.87 | 55.98 | 6.83 | 33.49 | 14.64 | 4.10 | 1.16 | 0.94 |

| 20L | 200 | 45 | 3.8 | 6.0 | 9 | – | 12.89 | 10.12 | 748.17 | 74.82 | 7.62 | 44.59 | 22.37 | 6.51 | 1.32 | 1.06 |

| 22L | 220 | 50 | 4.0 | 6.4 | 10 | – | 15.11 | 11.86 | 1070.97 | 97.36 | 8.42 | 57.82 | 32.85 | 8.61 | 1.47 | 1.19 |

| 24L | 240 | 55 | 4.2 | 6.8 | 10 | – | 17.41 | 13.66 | 1476.39 | 123.03 | 9.21 | 72.90 | 46.25 | 11.04 | 1.63 | 1.31 |

| 27L | 270 | 60 | 4.5 | 7.3 | 11 | – | 20.77 | 16.30 | 2218.16 | 164.31 | 10.33 | 97.48 | 65.10 | 14.17 | 1.77 | 1.40 |

| 30L | 300 | 65 | 4.8 | 7.8 | 11 | – | 24.30 | 19.07 | 3186.74 | 212.45 | 11.45 | 126.24 | 89.08 | 17.84 | 1.91 | 1.51 |

Series L channels must have a wall deflection size of no more than 0.15s.

Table with sizes of special channels.

| Series C channel number | h | b | s | t | R | r | Shelf slope % | Cross-sectional area F cm2 | Weight 1m/kg | Reference values for axes | X0 cm | |||||

| no more | X–X | Y–Y | ||||||||||||||

| mm | Ix cm4 | Wx cm3 | ix cm | Iy cm4 | Wy cm3 | Iy cm | ||||||||||

| 8C | 80 | 45 | 5.5 | 9.0 | 9.0 | 1.5 | 6 | 11.80 | 9.26 | 115.82 | 28.95 | 3.13 | 22.24 | 7.63 | 1.38 | 1.57 |

| 14C | 140 | 58 | 6.0 | 9.5 | 9.5 | 4.75 | – | 18.51 | 14.53 | 563.70 | 80.50 | 5.52 | 53.20 | 13.01 | 1.70 | 1.71 |

| 14Ca | 140 | 60 | 8.0 | 9.5 | 9.5 | 5.0 | 10 | 21.30 | 16.72 | 609.10 | 87.01 | 5.35 | 61.02 | 14.09 | 1.69 | 1.67 |

| 16C | 160 | 63 | 6.5 | 10.0 | 10.0 | 5.0 | – | 21.95 | 17.53 | 866.20 | 108.30 | 6.28 | 73.30 | 16.30 | 1.83 | 1.80 |

| 16Ca | 160 | 65 | 8.5 | 10.0 | 10.0 | 5.0 | – | 25.15 | 19.74 | 934.50 | 116.80 | 6.10 | 83.40 | 17.55 | 1.82 | 1.75 |

| 18C | 180 | 68 | 7.0 | 10.5 | 10.5 | 5.3 | – | 25.70 | 20.20 | 1272.00 | 141.00 | 7.04 | 98.50 | 20.10 | 1.96 | 1.88 |

| 18Ca | 180 | 70 | 9.0 | 10.5 | 10.5 | 5.3 | – | 29.30 | 23.00 | 1370.00 | 152.00 | 6.84 | 111.00 | 21.30 | 1.95 | 1.84 |

| 18Sat | 180 | 100 | 8.0 | 10.5 | 10.5 | 5.0 | 6 | 34.04 | 26.72 | 1791.01 | 199.00 | 7.25 | 305.48 | 43.58 | 3.00 | 2.99 |

| 20C | 200 | 73 | 7.0 | 11.0 | 11.0 | 5.5 | 10 | 28.83 | 22.63 | 1780.37 | 178.04 | 7.86 | 128.04 | 24.19 | 2.11 | 2.02 |

| 20Ca | 200 | 75 | 9.0 | 11.0 | 11.0 | 5.5 | 10 | 32.83 | 25.77 | 1913.71 | 191.37 | 7.64 | 143.63 | 25.88 | 2.09 | 1.95 |

| 20Sat | 200 | 100 | 8.0 | 11.0 | 11.0 | 5.5 | 6 | 36.58 | 28.71 | 2360.88 | 236.09 | 8.03 | 327.23 | 46.30 | 2.99 | 2.93 |

| 24C | 240 | 85 | 9.5 | 14.0 | 14.0 | 7.0 | – | 44.46 | 34.90 | 3841.35 | 320.11 | 9.29 | 268.89 | 43.70 | 2.46 | 2.35 |

| 26C | 260 | 65 | 10.0 | 16.0 | 15.0 | 3.0 | – | 44.09 | 34.61 | 4088.00 | 314.50 | 9.63 | 1115.60 | 171.60 | 5.03 | 3.91 |

| 26Ca | 260 | 90 | 10.0 | 15.0 | 15.0 | 7.5 | 8 | 50.60 | 39.72 | 5130.83 | 394.68 | 10.07 | 343.15 | 52.62 | 2.60 | 2.48 |

| 30C | 300 | 85 | 7.5 | 13.5 | 13.5 | 7.0 | 10 | 43.88 | 34.44 | 6045.43 | 403.03 | 11.74 | 260.74 | 41.41 | 2.44 | 2.20 |

| 30Ca | 300 | 87 | 9.5 | 13.5 | 13.5 | 7.0 | 10 | 49.88 | 39.15 | 6495.43 | 433.03 | 11.41 | 288.78 | 43.93 | 2.41 | 2.13 |

| 30Sat | 300 | 89 | 11.5 | 13.5 | 13.5 | 7.0 | 10 | 55.88 | 43.86 | 6945.43 | 463.03 | 11.15 | 315.35 | 46.29 | 2.38 | 2.09 |

Series C channels are hot-rolled steel channels, which come in general and special purposes and can have the following dimensions: height 50 - 400 mm, shelf width 32 - 15 mm. The dimensions of the C series channel are controlled according to GOST 8240-97.

Features of channel 16: dimensions, weight and cost

Channel 16 is widely used for strengthening large-sized structures such as bridges, supports, as well as when pouring the foundations of high-rise buildings. The technical features of a special series of rolled metal products provide for its use in mechanical engineering, carriage building and shipbuilding.

The main feature is the slope of the edges in the middle of the products, which gives increased bending strength and torsional stability. This product type has three series:

- 16P - used in installation work due to ease of installation;

- 16U – is resistant to vertical loads, which suggests its use in areas with increased seismic activity;

- 16L - due to its low weight, it is used for the construction of monolithic structures and in shipbuilding.

All products comply with specific GOST:

- 8240-97 – hot-rolled channels;

- 8278-83 – cold-formed channels with equal flanges;

- 8281-80 – bent with unequal flanges.

The standard dimensions of channel 16 correspond to the following values:

- height – 160 mm;

- shelf width – 64 mm;

- wall thickness – 5 mm;

- shelf thickness – 8.4 mm.

The weight of channel 16 corresponds to 14.2 kg. There are about 70 m of rolled products in one ton. These indicators directly proportionally affect the pricing of steel profiles. For example, the average price of channel 16 per meter is 520 rubles. Products are produced in lengths from 2 to 12 m.

Helpful advice! The length of the product affects the ease of its transportation. That is why it is not practiced to produce channels longer than 12 m. At the same time, this is the length that is most popular, and special vehicle platforms are designed just for it.

Maximum deviations of parameters (channel sizes) in the table.

| Parameter | Parameter value range | Maximum deviation |

| Height h | Up to 80 | ±1.5 |

| Over 80 to 200 | ±2.0 | |

| Over 200 to 400 | ±3.0 | |

| Shelf width b | Up to 40 | ±1.5 |

| Over 40 to 89 | ±2.0 | |

| Over 89 | ±3.0 | |

| Shelf thickness t | To 10 | -0.5 |

| Over 10 to 11 | -0.8 | |

| Over 11 | -1.0 | |

| Wall thickness s | Up to 5.1 | ±0.5 |

| Over 5.1 to 6.0 | ±0.6 | |

| Over 6.0 | ±0.7 | |

| Warp of shelf D with shelf width b, no more | Up to 95 | 1.0 |

| Over 95 | 0.015b | |

| Wall deflection ƒ along the height h of the profile section, no more | Up to 100 | 0.5 |

| Over 100 to 200 | 1.0 | |

| Over 200 to 400 | 1.5 |

Advantages of hot rolled channel

The main advantage of this product is its shape. Thanks to this, it is used where high rigidity values are needed. Advantages of this type of rolled metal:

- Ability to withstand heavy loads.

- Resistance to deformation.

- Resistance to mechanical damage.

But this metal product has another advantage - the channel is resistant to corrosion.

But there are also disadvantages. Hot-rolled channel is difficult to weld. Therefore, in prefabricated structures, where elements are connected by welding, a product produced by cold rolling is used.

Advantages of bent channel

The production of this type of rolled metal takes place on a special profile bending machine. Paired pressing rollers act on the sheet metal workpiece on both sides, giving it a U-shape. With the help of modern equipment, this process occurs automatically and has a number of advantages: speed, the ability to create a profile of any shape, etc.

Unlike hot-rolled channel, its bent version has low weight. This makes it possible to use this type of channel in lightweight metal structures. The low weight of this product reduces the time for its installation and reduces the complexity of this process.

Bent profile is used:

- In the construction of buildings.

- During the reconstruction of buildings.

- During major repairs.

Lightweight versions of bent profiles can be used to assemble greenhouse frames and erect temporary structures. The scope of use of this product is not only construction, but also carriage building, machine tool building, shipbuilding, automotive industry, etc. It can be used to produce products that have high load resistance, but are light in weight.

Channel materials

According to the required characteristics of the finished product, it can be produced from steel of different grades.

If hot rolled steel is used, the main raw materials are the following types of steel St3 (quiet and semi-quiet): 09G2S, 17G1S, 10KHSND, 15KHSND. The last two names are lighter than the others and more resistant to corrosion.

Bending is carried out from the following varieties: St3ps5, 09G2S, 08ps, 1ps, 2ps.

Since all of the above alloys are sensitive to corrosion, galvanizing is used when necessary. Due to it, the service life of parts is increased, especially those used in open space, under conditions of high humidity.

I-beam or channel?

The choice in favor of one or another rolled metal product is based on the scope of its application. In terms of strength, the I-beam is significantly superior to the channel. Shelves protruding from both sides better distribute weight and are able to withstand significant loads. When heavy loads are placed on the channel, forces arise that tend to twist it. Which cannot happen when using an I-beam.

When comparing these types of rolled metal of the same standard size, wall thickness and shelf dimensions, with a load acting perpendicular to their axis, the U-shaped profile will be stronger. This is due to its shape. The shelves located in one direction make it so that the center of gravity extends beyond its cross section and is shifted towards the ends. While in an I-beam it is located exactly in the middle.

GOST standards

Weight, dimensions, profile configuration are regulated by GOST. Since products are produced for different industries, each type has its own standard for the manufacture.

GOST 8240-97 describes the assortment of hot-rolled channels, both general - for the construction and strengthening of floors and walls, and special. The profile obtained for automotive production is regulated by GOST 19425-74. Products for carriage building are described by GOST 5267.0-90 and 5267.1-90. Each of the standards describes not only the classic type of channel - equal-flange and with parallel flanges, but also wide-flange, bent, with different accuracy classes - GOST 8278-83B GOST 8281-80, GOST 5422-73. The U-shaped profile is made of both hot-rolled and cold-rolled steel. The material for the beams must also comply with GOST.

Main parameters of channel 12: dimensions, weight and cost

A metal product called channel 12 with parallel flanges has a body thickness of 7.8 mm and a wall thickness of 4.8 mm. Such products are produced in lengths from 2 to 12 m. Longer copies can be made to order. The popularity of this type of profile is due to its positive qualities, contained in the optimal ratio of weight, strength and relatively low cost.

Profiles made of low-alloy steel are subject to operation at high temperatures and under conditions of increased exposure to chemicals. Also, the products have excellent resistance to compression and bending, but at the same time have poor resistance to torsion.

The weight of 1 meter of channel 12 can be found using the table above or using an online calculator. The price of the product depends on this parameter. According to the table, the weight of channel 12 per 1 meter is 10.4 kg.

Like channels of other sizes, this type of product has additional markings with different characteristics. The most popular is the 12P channel, which has parallel flanges with edges without slope.

The dimensions of the 12P channel are given below:

- width – 52 mm;

- linear meter weight – 10.40 kg;

- length in ton – 95.94 m.

The channel with mark 12 also has other series. For example, 12L is a rolled metal product with dimensions of 120x30 mm, characterized by inclined shelves. The weight of 1 m of such a profile is 5.02 kg, and the footage of 1 ton is 199 m.

Helpful advice! The marking of the channel 12C indicates its special purpose, 12E - an economical series of products with shelves without slope. Their size is standard - 120x52 mm, and their weight is slightly lower - 10.24 kg. Accordingly, a ton of material contains almost 97 m.