The volumes of sunflower oil shipped for export reach new highs every autumn, increasing by 300 thousand tons per year. At the same time, prices for raw materials (about $300 per ton of sunflower seeds versus $780 per ton of oil on the world market) make it profitable not only to supply abroad, but also to produce vegetable oils for the domestic market. The features of the technology make it possible to organize a mini-churn at home or in an outbuilding, but a full-cycle enterprise will require large premises and significant capital investments.

This article discusses the intricacies of organizing an oil milling business both at home and with a full production cycle. Calculations show that any of the options has economic efficiency and high profitability, and the amount of profit depends only on the volume of production and investment.

Making vegetable oil at home

Oil production at home differs from industrial production not only in the volume of products, but also in the range. Tabletop oil presses made of stainless steel weigh no more than 15 kg, are easy to clean and allow you to squeeze oils from 37 types of oilseeds. The most profitable way to order such a device is on Aliexpress.

In this case, you can provide oil for a large family and sell the excess at farmers markets and friends. The efficiency of production for sale remains high only when pressing rare crops, the oils from which are not produced by large enterprises and home oil mills.

The maximum operating time of the device is 12 hours per day, which, with a load of 3 kg per hour, will allow you to get 14 kg of almond oil or 9 kg of coconut oil per day. The cost of a liter of rare cold-pressed edible oils in health food stores reaches up to 2000 rubles/kg, so selling surpluses can become a source of additional income.

Equipment for the production of oil in small volumes (mini-oil mill)

If you want to turn oil extraction in the kitchen into a full-fledged waste-free production, you can consider organizing a mini-oil mill. To start the line, it is enough to purchase two pieces of equipment: a screw press for oil and a filter for cleaning the finished product. Such a mini-plant produces three final products:

- unrefined vegetable oil for sale;

- cake for agricultural needs;

- liquid sediment from filtration.

For household models of oil press, a power of 220 V is enough, that is, such production can be started even in a small garage of about 30 square meters. m. The productivity of such a machine is low and limited to 30 liters of oil per hour; the budget representative of this category of equipment is the MG-30 press.

| Name of equipment | MG-30 |

| Country of origin | Ukraine |

| Voltage, V | 220 |

| Productivity, l/hour | 30 |

| Weight, kg | 100 |

| price, rub. VAT included | 80 000 |

If you have access to a voltage of 380 V, then to start a business it is better to consider a model with higher productivity - the MG-100 screw press.

| Name of equipment | MG-100 |

| Country of origin | Ukraine |

| Voltage, V | 380 |

| Productivity, l/hour | 100 |

| Weight, kg | 180 |

| price, rub. VAT included | 130 000 |

The oil after the press is settled, and mechanical impurities are deposited under the influence of gravity. An alternative is cleaning with a plate filter. A simple filter model for viscous liquids, Professional FCP 20 OLIO, purifies 100 l/oil per hour.

| Name of equipment | FCP 20 OLIO |

| Country of origin | Italy |

| Number of plates, pcs. | 20 |

| Productivity, l/hour | 100 |

| Voltage, V | 220 |

| price, rub. VAT included | 105 000 |

In the future, home production can be expanded by adding fried oil and charcoal from ash to the assortment. To do this you will need to purchase additional equipment:

- winnower for oilseeds cleans raw materials from light impurities – from RUB 150,000;

- a gas fryer dries and fries raw materials - from RUB 86,000;

- liquid product bottling installation for filling pet containers with oil – from RUB 72,000.

Filling the finished product at the initial stage can also be done manually using a plastic funnel.

Technology for the production of vegetable oil by pressing

The technological process at home has a shortened cycle. Unlike large-scale production with a large load, a mini-churn, as a rule, does not involve cleaning the raw material from husks, heat treatment to increase the percentage of yield, refining and deodorization.

- The cycle begins with coarse and fine cleaning of raw materials from impurities. Coarse impurities are large debris that can damage equipment: iron particles, wires, stones. Subtle impurities affect the quality of the final product - weed seeds, sand, dust.

- The next two stages are implemented sequentially in modern oil presses: the raw materials are ground by screws in a bowl, after which the pressing occurs directly. As a result, two semi-finished products are obtained: crude oil and cake, which is called makukha. If the cake is sold in briquettes, that is, it is supposed to be pressed, then it is carried out immediately after this stage, while the cake is still warm.

- Next, the oil is filtered or settled. During the filtration process, the product passes under pressure through cellulose cardboards, purifying not only foreign impurities and aromas, but also free fatty acids and phospholipids.

- The resulting unrefined product is ready for bottling and packaging.

Technology for producing vegetable oil at home

This cycle can be extended through additional waste processing. For example, after filtration, the cardboards are left with fuz, a sediment that is added to livestock feed to increase nutritional value. Before sale, the fuses are additionally pressed, which makes it possible to obtain technical oil for the production of drying oil.

Storage of unrefined vegetable oil does not require special conditions for 5 months. The storage should be dry, with a temperature of plus 5-15 degrees Celsius, protected from sunlight.

Raw materials for production

Various oilseeds are used in production: sunflower seeds, flax seeds, pumpkin seeds, mustard seeds, soy nuts, peanuts, etc. If necessary, this allows the production process to be repurposed without additional costs. For example, the production of cosmetic oil will require the same equipment.

The main suppliers of raw materials are farms that sell seeds both in small volumes and in industrial quantities.

When purchasing raw materials, it is important to pay attention to the degree of contamination, contamination, presence of impurities and weed seeds.

Cloudy and dusty seeds impart a bitterness to the final product that filtration cannot cope with. The resulting oil can subsequently only be sold as technical oil.

With a full production cycle, the initial quality is not so important, since the seeds are pre-cleaned, including the removal of husks.

Features of the use of waste from production

The efficiency of a butter churn increases with increasing output volumes. But in home production, waste disposal is also of great importance. Rational management of resources and the creation of a waste-free cycle reduces the payback period of a business.

The cake is sold to producers of feed for farm animals. 100g of sunflower seed contains 30g of protein, which makes it more nutritious than cereal feed. However, its storage requires a supply ventilation system and protection from flour mites.

Sunflower top

The oil is pressed out again from the unprocessed liquor - the content of direct waste in it is only 20%. Special fuel presses produce not only oil, but also completely dried biofuel for boilers.

Pressed sunflower fuze

Uncompressed waste is also used as a valuable additive for livestock food, but in this case its sale serves to dispose of waste more than to obtain additional benefits.

Search for a sales market

Limited volumes of the product and the lack of certificates for home production limit the sales market to small retail outlets. Cold-pressed oils are popular in health food stores, farmers' markets and food shows. Buyers are particularly interested in oils made from flax seeds, grape seed and pumpkin.

By-products of production: technical oil, flour, fumed biocoal - are sold in small volumes to resellers or farms.

Creamery profitability

The minimum amount of investment in production is determined by the cost of the equipment. If you have your own utility room, the starting capital is 235 thousand rubles.

Equipment productivity is 100 kg per hour, non-stop operating time is about 3 hours. In an eight-hour working day, 600 kg of oil is squeezed out and filtered. With a five-day working week, the annual production volume will be: 600 kg/day * 247 working days = 148,200 kg/year.

Efficiency of home vegetable oil production in figures per year

The retail price of good quality unrefined oil is 60 rubles/kg, which allows us to estimate the gross annual revenue from its sale at 148,200 kg*60 rubles/kg=8.892 million rubles.

The yield of the finished product after filtration is 35%, that is, to obtain the planned annual volume, you will need to purchase 148,200 kg * 100% / 35% = 423,429 kg of raw materials with an average cost of 17,000 rubles. per ton. Thus, the purchase of raw materials for a year will cost 423.429 tons * 17,000 rubles / t = 7.198 million rubles. Another 500 thousand rubles. It will cost you a year's supply of plastic bottles with a lid.

From 420 tons of raw materials, 50% mash and 15% fuses are obtained - 210 tons and 63 tons per year, respectively. With a selling price of 12 thousand rubles. and 25 thousand rubles. per ton this will increase annual income by 210t * 12,000 rubles + 63t * 25,000 rubles = 4.095 million rubles.

Costs for electricity and transport do not exceed 100 thousand rubles/year, advertising and promotion – 240 thousand rubles/year. Hired employee with a salary of 30 thousand rubles. per month will cost the business another 360 thousand rubles. per year salary and 65 thousand rubles. deductions, total 425 thousand rubles. in year.

Thus, net profit for the year will be 8.892+4.095-7.198-0.5-0.1-0.24-0.425=4.524 million rubles. per year (377 thousand rubles per month). The costs of purchasing equipment are recouped in the first month of operation, subject to 100% sales of products.

About profitability and wastelessness

Sunflower oil is waste-free. This means that by-products resulting from the production of a product are used in other areas. Related components are sold to third parties.

The husks are used to make pellets - pet food. They are pre-pressed into briquettes and delivered to customers. The husk is sold to brick factories, and the cake is sold to farms. The sale of waste can be taken into account as additional profit, but most often sales are reflected in the cost price, reducing the price of the output product.

Production of vegetable oil in large volumes (production workshop)

The next step in expanding home oil production is the organization of a full production cycle workshop. This type of business requires large investments, and the sale of the finished product requires quality certificates, which in the Russian market is almost impossible without registering a legal entity.

Business registration

Depending on the number of founders, the form of their responsibility and the procedure for obtaining the expected profit, the organizational and legal form of the enterprise is selected. When registering, you will need to decide on the main and additional classifiers of the type of economic activity, the tax regime and the possibility of introducing simplified tax regimes.

Choice of legal form

From the point of view of the possibility of selling products in large retail chains, the availability of a bank loan and the possibility of expanding or reselling a business, the form of a limited liability company is more suitable.

The founder can be either one person or partners who share profits in proportion to the size of participation in the company. The state fee for registration is 4,000 rubles, the minimum authorized capital is 10,000 rubles. Registration takes 5 working days.

OKVED codes

The production of oils, like other food products, falls under class 10 of the OKVED-2 system, subclass 10.4. Codes relevant for this type of production are presented in the table.

OKVED classification codes for the production of vegetable oils

Production technology and necessary equipment

The full production cycle allows us to produce about ten types of products, not counting the possibility of expanding the range through the use of seeds of various plants: raw unrefined oil, from roasted seeds, refined oil, technical oil, fuel briquettes from husks, rounds of husks, pressed fuses, etc.

Technological process of industrial production of vegetable oil

The most complete technological process includes the following stages and equipment:

- Sifting and calibrating seeds on a separator. Depending on the quality and purity of the raw materials used, seeds can be contaminated not only with small stones, sand and weeds. Corn grains, oilseed seeds, oxidized open sunflower seeds, when pressed, give the oil a sour and bitter taste. In the case of storing raw materials, this also reduces its shelf life, increases humidity and leads to self-heating of the seeds.

The aerodynamic separator carefully sorts raw materials using air flows created by a pressurized fan inside the machine. The SAD-15 separator calibrates up to 7 tons of seeds per hour, requires loading by an operator; one person is enough to work on the line.

| Name of equipment | Aerodynamic separator SAD-15 |

| Fine cleaning performance | 7 t/hour |

| Power consumption | 7.8 kW |

| Weight | 538 kg |

| Number of staff | 1 person |

- Cleaning of shells and peeling of seeds is carried out using a seed huller. The continuous rotary mechanism can operate three shifts per day. HPX-4-01 machines with a capacity of 80 tons/day are produced for oil production enterprises.

| Name of equipment | Seed crusher NRKh-4-01 |

| Performance | 80 t/day |

| Power consumption | 11 kW |

| Weight | 1750 kg |

| Number of staff | 1 person |

The result is husks and kernels for grinding.

Briquetting of seed husks is carried out using a screw extruder press; the technology for manufacturing biofuel briquettes does not imply the use of any fastening substances other than water. The PBE-325 screw press is suitable for the productivity of the seed grinder.

| Name of equipment | Screw press PBE-325 |

| Performance | 5 t/hour |

| Power consumption | 30 kW |

| Weight | 1250 kg |

| Number of staff | 1 person |

Biofuel briquettes from husks

- The grinding of hulled seeds is carried out in roller machines. Oil from crushed seeds is extracted more easily and with less energy. A seed roller mill differs from a flour mill by the ability to adjust the gap to grind crops of various sizes. The SV-400/4 machine allows you to grind from 50 tons of raw materials per day. The output is a semi-finished product in the form of a flattened seed - mint.

| Name of equipment | Roller machine SV-400/4 |

| Performance | From 50 t/day |

| Power consumption | 30 kW |

| Weight | 9800 kg |

| Number of staff | 1 person |

- Warming up the mint with steam or frying. To save money from purchasing a fryer, in some industries this link is removed from the technological chain. The seeds are steamed if cold pressing is planned. The oil from the roasted seeds is extracted more efficiently and has a bright aroma and color. To roast 60 tons of mint per day, you can consider the Zh-60 roaster.

| Name of equipment | Roaster for seeds Zh-60 |

| Performance | Up to 60 t/day |

| Power consumption | 30 kW |

| Weight | 11600 kg |

| Number of staff | 1 person |

- Spin. The oil press squeezes out the flattened dry mint, resulting in crude oil and pulp. There are machines that automatically send the crop for repeated compression, but this function significantly affects the price of the unit. Screw press for processing 40 tons of seeds per day MP-1500.

| Name of equipment | Screw press MP-1500 |

| Performance | 40 t/day |

| Power consumption | 30 kW |

| Weight | 4200 kg |

| Number of staff | 1 person |

The waste from this stage - the waste - should be processed while the temperature from the pressure is maintained.

- Filtration by settling or centrifugation. To obtain a high-quality product, as well as to reduce the volume of fuses, it is recommended to leave the oil for at least a day. Next, filtering is performed. Continuous cleaning in large industries is carried out using centrifugal self-cleaning filters. The result is unrefined oil and fuzz. The U10-FC centrifuge removes up to 4 tons of oil per hour from mechanical impurities.

| Name of equipment | Centrifugal filter U10-FC |

| Performance | 4 t/hour |

| Power consumption | 18.5 kW |

| Weight | 1800 kg |

| Number of staff | 1 person |

Sunflower fuses

The fuses are boosted in a drum-type fusodushka, the result is technical oil, which can be sent for further purification, but it is more rational to make drying oil from it or sell it to a paint shop. The Danker sludge crusher allows you to process up to 600 kg of sludge per hour and is equipped with a control panel.

| Name of equipment | Danker drum press |

| Performance | 600 kg/hour |

| Power consumption | 1.5 kW |

| Weight | 175 kg |

| Number of staff | 1 person |

- Oil refining is carried out in stages. To begin with, the product after filtration is treated with hot water at a temperature of 65-70 degrees Celsius. This process is called hydration and serves to remove phosphatides from the product and improve its clarity. Phosphatides in the product cause it to become cloudy and precipitate.

Next, the product is neutralized: the heated oil reacts with alkali, which clears it of free fatty acids that affect the taste. The result is refined oil.

- Deodorization. The process of removing pigment from a product, which often enters a refining line. The result is deodorized refined oil. It is light, transparent, without carotenoids.

The equipment for the refining and deodorization workshop with a capacity of 45 tons/day consists of the following components.

| 1. Refining column with a volume of 9000 l with a stirrer | 1 PC. |

| 2. Refining column volume 11000 l with stirrer | 1 PC. |

| 3. Pump NSh-100 | 2 pcs. |

| 4. Stainless steel plate heat exchanger (refining) | 2 pcs. |

| 5. Drying column 9000 l with stirrer. | 2 pcs. |

| 6. Heat exchanger (to the dryer) stainless steel plate | 1 PC. |

| 7. Water ring vacuum pump (to the dryer) VN1 | 1 PC. |

| 8. Frame filter (after dryers) | 1 PC. |

| 9. Pump NSh-100 (for frame filter) | 2 pcs. |

| 10. Deodorization unit with a capacity of up to 50 tons per day Stroypischemash | 1 PC. |

| 11. Washing filters - 2 pcs. 1 ton and 1 piece - 3 tons AMO | 3 pcs. |

| 12. Gas-diesel boiler Booster 3t/h steam | 1 PC. |

| 13. Grease traps | 2 pcs. |

| 14. Soap container | 1 PC. |

| 15. Overpasses, stairs, pipelines, cranes | |

| 16. Automatic control panel for the Stroypischmash installation | 1 PC. |

| 17. Flow meters | 3 pcs. |

| 18. Oil freezing tanks with water jacket 4 m3, 8 m3 | 2 pcs. |

| 19. Capacity of citric acid solution | 1 PC. |

The number of personnel on the line is 6 people.

Refining and deodorization workshop

- Filling into polyethylene bottles is automated and allows you to fill containers with a capacity of 0.5 to 1.5 liters.

- The labeling machine is combined with an inkjet printer to print and apply labels to bottles. For packaging, a conveyor and an automatic packer are required. All this is part of a bottling line with a capacity of 6 thousand bottles per hour.

| Water cooler | 1 PC. |

| Blowing machine 3000 b/h | 2 pcs. |

| Compressor station 30 atm. | 1 PC. |

| Mold 0.5 – 1.5l | 2 pcs. |

| Monoblock filling with capping | 1 PC. |

| Labeling machine 6000 b/h | 1 PC. |

| Dating inkjet printer with a productivity of 8000 bph | 1 PC. |

| Automatic packer with thermal tunnel up to 1000 packs/h | 1 PC. |

| Conveyor 10 m | 1 PC. |

| Oil and moisture separating filter | 1 PC. |

The line is serviced by 6 people per shift.

Automatic oil filling line

Cost of equipment

Equipment is selected after designing the production line. At this stage, it is advisable to imagine the initial assortment of the enterprise, the degree of automation of production and the procedure for disposal or recycling of waste.

With a planned capacity of about 800 tons/month, it is rational to purchase an automated line, fully equipped for the extraction and refining process. For smaller production volumes, it is more profitable to purchase equipment separately.

| No. | Technological process | Name of equipment | Cost, thousand rubles | Output product |

| 1 | Initial purification of raw materials | Separator SAD-15 | 150 | Seeds cleaned of dust and impurities |

| 2 | Peeling | Seed crusher NRKh-4-01 | 750 | Seed kernels, husks |

| Screw press PBE-325 | 778 | Biofuel briquette | ||

| 3 | Seed grinding | Roller machine SV-400/4 | 2000 | Mint - flattened seed |

| 4 | Heat treatment | Roaster Zh-60 | 900 | Roasted sunflower seed |

| 5 | Oil extraction | Screw press MP-1500 | 2500 | Unrefined butter, flour |

| 6 | Cleaning oil from impurities | Centrifugal filter U10-FC | 200 | Unrefined oil, fuz |

| Danker drum press | 50 | Technical oil, shovel fuzz | ||

| 7 | Refining | Refining and deodorization line | 20000 | Refined oil, not deodorized |

| 8 | Deodorization | Refined deodorized oil | ||

| 9 | Bottling | Filling and labeling line | 2500 | Oil poured into bottles with label |

| 10 | Label sticker | |||

| Helper Processes | Pneumatic loader | 1500 | ||

| Scales, buckets, shovels | 300 | |||

| Total: | 32378 | thousand roubles. | ||

Selecting a raw material supplier

When choosing a supplier, you need to focus not only on the low price, but also on the quality of raw materials and delivery conditions. If heavy transport is not available at the production site, the supplier must ensure an uninterrupted supply of seeds on its own or through a transport company.

For each item there must be at least three suppliers to provide insurance in case of a bad harvest, quality or transport problems with the seller.

With a daily loading of 75 tons of unpeeled seeds into the separator, the volume of purchased raw materials will be more than 1800 tons per month, which allows you to purchase directly from farms, bypassing distributors.

When purchasing, you should pay attention to such indicators as impurities of litter and oil, acidity, moisture, and oil content. The average market price per ton of sunflower seeds is 15 thousand rubles, the minimum is 13 thousand rubles. The bulk of suppliers are located in the Krasnodar region and the Volga region.

Selection of production premises

Since the oil and fat industry is a food industry, the premises of the enterprise must meet the strict requirements of the SES and fire departments. The workshop must be clean, bright, with a correctly calculated electrical load, clean water supply and sewage system. Standardly, for daily processing of 75 tons of raw materials, 1200 sq.m of workshop area and at least 2500 sq.m of warehouse space are required. Seeds are stored in bulk, with a supply for 1.5 months of uninterrupted operation, so storage areas must be dry and covered.

Separate premises are also needed for storing finished products - both the oil itself and waste products. Household premises must comply with labor protection requirements.

Recruitment and payroll

Production requires both highly qualified personnel, workers and craftsmen. The number of management personnel and technologists is constantly 10 people or more. Workers are hired based on production capacity. The work schedule is variable.

| Job title | Number of persons | Salary, thousand rubles | Total, thousand rubles |

| Office | 4 | 70 | 280 |

| Technologists | 6 | 50 | 300 |

| Storekeepers | 10 | 25 | 250 |

| Masters | 14 | 45 | 630 |

| Workers | 68 | 35 | 2380 |

| Total | 100 | 3840 |

Personnel can be recruited gradually, as production volumes increase and the most optimal operating mode is established based on market needs.

Use of production waste

Income from the sale of produced oil is not the only component of the profit of a large enterprise.

Selling waste products makes the creamery more efficient and profitable. Typically, the cost of the final product is reduced by the amount of sales of production by-products, thereby reducing its price for the consumer.

Briquettes made from husks are environmentally friendly fuel, due to which you can organize the economical operation of a fryer, and also sell them to other industries, for example, brick factories.

Highly purified sunflower cake is sold to confectionery shops for the production of halva and sweets. If this product is not sufficiently purified, it is hot pressed and sold to animal feed manufacturers.

Tank sludge is passed through a fuel press, providing additional volumes of oil for production. Most often, such oil is not sent to the filtration line, but is sold as technical oil to paint factories and for the production of drying oil.

Sales market

Due to the opaque situation in the field of GOSTs for oil and fat production (especially in terms of squeezing raw oil), it is easier to develop your own specifications to confirm the quality of the products. Technical conditions are registered and samples are submitted to the laboratory according to them. If the samples meet the standards, the company receives a quality certificate for its products. If you have such a certificate, the oil can be sold in large retail chains, retail stores, and market pavilions.

It is also rational to organize a specialized retail store during production. Such a retail outlet should offer the most complete range of products. Consumers of maca and fuse products are large farms engaged in livestock breeding. You should pay attention not only to Russian enterprises, but also to non-CIS countries. Pure sunflower oil is in great demand in countries with little presence of this crop in crops.

Specialized oil store

Calculation of initial investment

It is impossible to calculate the profitability of production without assessing the initial investment in the business. The cost of organizing a production line with a loading of 75 tons of crude raw materials per day will amount to 43 million rubles.

| Capital Expenditures | Amount, thousand rubles |

| Equipment purchase | 3 2378 |

| Delivery, installation (30% of the cost of equipment) | 9 700 |

| Indoor work | 800 |

| Paperwork | 100 |

| Total | 43 000 |

To organize production in the first month of work, 37 million rubles will be needed.

| Turnover expenses | Amount, thousand rubles |

| Rent 3700 sq. m. | 1200 |

| Wage | 3840 |

| Taxes | 2000 |

| Raw materials | 30 000 |

| other expenses | 300 |

| Total | 37 340 |

Calculation of profitability and payback

When calculating payback, the situation with 100% sales of products is taken into account, excluding damage, defects, and loss as a result of improper storage or transportation.

Output per month is calculated from the percentage of yield per ton of sunflower and the daily rate of raw material loading.

| Name | % yield | Output, t/day | Output, t/month |

| Oil output | 42,21 | 31,66 | 949,8 |

| Cake yield | 35,55 | 26,66 | 799,88 |

| Husk output | 17,04 | 12,78 | 383,40 |

| Output of litter | 0,81 | 0,6 | 18,23 |

| Moisture loss | 4,39 | 3,29 | 98,78 |

| Total | 100 | 75 | 2250 |

Based on wholesale selling prices, the monthly revenue will be:

| Product type | Wholesale price, thousand rubles/t | Revenue, thousand rubles/month |

| Sunflower oil | 35 | 33 243 |

| Dry poppy seed | 8 | 6399 |

| Biofuel husk | 3,5. | 1342 |

| Total | 40 984 |

Then the net profit will be 40,984-37,340=3,644 thousand rubles, and the return on capital investments will be 43,000/3,644=11.8 months.

Profitable or not?

It is worth knowing that the production of sunflower oil and its sale is the prerogative of many small and medium-sized enterprises. This is due to the low investment required to start a business. Also, the activity pays off very quickly. There is a high level of competition in this segment, but with competent management, a well-thought-out business plan for the production of sunflower oil and a clear marketing policy, the entrepreneur will not be left without good revenue.

Sales volumes of oil exported annually set new records at 300,000 tons per year. Prices for seeds versus oil on the world market are $300 and $790 per ton. This makes oil production profitable not only for sale abroad, but also for supply to the domestic market.

Our main advantages:

- a wide range of;

- premium products;

- stable availability of assortment in warehouses;

- favorable rates;

- various forms of payment;

- delivery throughout Russia.

For a long time, it has maintained a professional approach to its business and a loyal policy towards its clients. We offer favorable terms of cooperation and payment, and do everything to ensure that everyone who contacts us is completely satisfied.

Recruitment

If the workshop has an automated line, the number of employees is reduced to a minimum. But if you hire people, they must be experienced workers who know how to operate machines.

Only specialists should work on the units. If the plant is medium-sized, then it is necessary to hire loaders, drivers and maintenance personnel. Statistics show that finding a professional with experience is not easy. In this case, you can hire young certified people and develop a scheme for them according to which they will work.

Assessing the feasibility of opening an oil shop for the production of refined sunflower oil

If you increase the production of guns from 0 to 30, for every 10 guns you produce, you will have to sacrifice a reduction in oil production by 15 tons. A further increase in the production of guns from 30 to 60 will increase the opportunity cost to 2 tons per gun. And finally, the last guns will cost 3 tons of oil each.

TASK 5.

Robinson and Friday can collect coconuts and fish. Robinson can catch 5 fish or collect 15 coconuts in one hour. Friday can catch 15 fish or collect 5 nuts in the same time.

Construct a production possibilities curve for this “team” if they cannot work together in such a way as to increase the labor productivity of any of them.

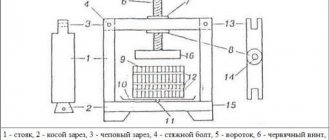

Homemade makukha press complete with butter churner

Circles of flour from roasted seeds can be pressed using equipment of our own production. To do this you will need a homemade crown press. A little imagination and desire and I assure you that everything will work out and you will save a lot of money.

And so, in order to press the top circles, you must build a homemade press. This equipment is very simple to manufacture and lasts a very long time. You need a small metal ring, maybe from a large piece of pipe or part of some kind of cylinder with a diameter of 50 cm, a car jack, a circle plate of durable metal with a diameter of 49.5 cm (this is the most difficult part that can be ordered from a turner). Next, assemble everything into a kit, as shown in the figure. I think it’s clear from the picture how a homemade crown press works. Such a homemade press does not have high productivity, but it will cost much less than an industrial press for mahogany, and it does not consume electricity. It’s just important to note that when you roasted a sunflower seed during production and want to press circles of flour from sunflower meal, this must be done while the meal is still warm, that is, immediately from under the churn. 1 circle of flour is obtained from approximately 1 bucket of meal.

Required Equipment

The technological process for producing oil is quite labor-intensive and complex. It will take time to set up and automate. It is important to correctly calculate the indicators.

The main thing is to purchase a unit that will produce oil. The price is very high - about $20,000, but the enterprise cannot manage without it. It is recommended to find trusted, good suppliers who will sell an excellent quality machine at an affordable price.

If the scale of oil production is small, then in order to save money, you can purchase a manually controlled unit. To make a good profit, it is necessary to purchase large volumes of raw materials, and to process them, the plant must have an automatic line.

To produce sunflower oil, you need to purchase a number of machines:

- oil press;

- filter;

- fryer;

- separator

Approximate costs for units:

- a separator for initial seed cleaning costs about 50,000;

- a crusher-winter unit, which will separate the peel from the seeds, will cost about 60,000;

- machine for grinding raw materials – 500,000;

- fryer - 300,000;

- oil press – 600,000;

- refining apparatus – 600,000;

- automatic bottling line – 300,000.

When starting a business, you can get by with a mini-factory. When a sales market is found and the technological side is established, then they expand.

Oil suppliers and market

When creating a business for the production of sunflower oil, it is necessary to resolve the most important issues: where to sell the products and where to purchase raw materials. It is recommended to find a permanent supplier; it will be easier to plan profits there.

If an entrepreneur is engaged in trade, then it will be easier for him - he will connect to his network of customers who constantly purchase goods from him. The oil will be poured into a ready-made sales scheme.

It is recommended to find a supplier in the fall that is located geographically close to the enterprise. If he enters into an agreement for regular supplies of oil in small quantities and with deferred payment, this will be an ideal option. This scheme will help to minimize the cost of seeds, thereby increasing profitability.

The oil can be sold to shops, supermarkets, and private enterprises that order products as the main raw material for creating their goods. The component is used in various fields - soap making, food preservation, paint and varnish production, cosmetics and medical industries.

Important! If you can’t find a customer, the oil can be supplied to Turkey. It is in great demand there.

conclusions

From the point of view of investing money, the business idea of creating your own creamery has not lost its relevance. The business is still characterized by fast payback periods, profitability and demand. In addition to the oil, the owner will receive by-products that can easily be sold and receive additional profit. Sunflower oil production breaks even. When creating a small workshop, the owner may not need to obtain licenses; it is enough to register with the tax service as an individual entrepreneur and remit taxes on time.

Sunflower kernel price for 2016 harvest per ton

Ours is one of the leading suppliers on the Russian wholesale market of agricultural crops. We accept orders every day, process them in the shortest possible time and ship them the same day anywhere in the country. We only have this year’s fresh harvest at a favorable price, for example, the price of a ton of sunflower kernels harvested in 2016 is one of the most attractive, since we do not work with intermediary organizations, but collect, process and deliver ourselves.

To ensure complete preservation of all beneficial properties, we carry out stable quality control. All our products are stored in warehouses with a certain temperature regime so that the content of all minerals and vitamins in them does not decrease. By choosing us, you get an improved selection and storage system, a multi-stage purification process and delivery of only high-quality products in a short time!

Korepanova Production Possibility Curve Practice 2003

PRODUCTION POSSIBILITY CURVE

TASK 1.

The medieval blacksmith specializes in spears and ploughs. Can its alternative production possibilities be described by the following data?

Spears, pcs. 36 30 24 18 12 6 0

Plows, pcs. 0 2 5 9 12 15 17

TASK 2.

In one field, a farmer can produce 500 tons of potatoes or 100 tons of wheat, and in another field, the opportunity cost of growing 2 tons of wheat is equal to 5 tons of potatoes, with a maximum potato production of 1000 tons.

Draw a farmer's production possibility curve.

TASK 3.

120

100

Here is the production possibility curve for a farmer who grows wheat and potatoes in two fields.

- What is the opportunity cost of producing one ton of potatoes if 75 tons are grown? 150? What is the opportunity cost of one ton of wheat?

- Determine the opportunity cost of growing the first 50 tons of wheat.

- Calculate the average yield of wheat and potatoes using the best use of resources, if the area of each field is 100 hectares and 70 tons of potatoes are grown.

- 50 tons of potatoes were grown, and 100 tons of wheat. How much can the wheat harvest be increased next year? What about potatoes?

TASK 4.

Draw a production possibilities curve using the following information. The maximum oil production is 135 tons.

How to organize a mini strike

To open a small workshop for producing sunflower oil, you will need minimal investment. The price for a churn that will produce 10-17 liters per hour ranges from $200 to $450. Other units required for operation:

- a filter to clean the product will cost $100-200;

- the cost of additional tools, products, and kits will be about $100.

Capital investments are small, so agricultural producers often open private mini-dairies.

The modern design for producing oil is a press extruder. It is visually similar to a meat grinder. Equipment for the production of sunflower oil

consists of three parts:

- bunker for supplying seeds;

- auger compartment where raw materials are crushed;

- nozzle for squeezing oil.

After receiving the product, it will need to be filtered. For small production volumes, canvas bags are used for filtration. After the process, the oil must be kept in a cool room for some time. Then it is poured into barrels.

If sediment forms at the bottom, the oil is filtered again. For larger oil mills, it is better to purchase special filters that will quickly clean the product.

It is better to open a small production when the owner plans to grow sunflowers on his own. Due to this, he will save a significant amount on the purchase of seeds and their delivery.

As the practice of entrepreneurs shows, the profitability of a mini-enterprise can reach 25%. The first investment pays off within six months. Here it is important to find consumers and establish the technological process.

To open your own creamery, you do not need to obtain permits or licenses. The business owner must register as a sole proprietor. Since the activity is related to food, sanitary and epidemiological stations will regularly visit the owner to check the quality. It is also impossible to do without control of the fire service.

Important! When opening a small plant for the production of sunflower oil, it is recommended during registration to ensure that the owner is recognized as a manufacturer of agricultural products. In this case, he will pay taxes at reduced rates.

Revenue and profit

An important section of a business project is the calculation of projected income. To do this, the upcoming costs and possible profits are summed up. Costs that an entrepreneur will face:

- equipment and machinery – 2,000,000 rubles;

- carrying out preparatory work in the workshop – 300,000;

- obtaining documents for carrying out activities – 50,000.

The total is about 2,350,000 rubles. The entrepreneur will also spend money monthly on the following needs:

- workshop rental from 500 sq. m. – 100,000;

- issuance of salaries to staff for 3 people – 60,000;

- payment of taxes – 70,000;

- marketing activities, payment for utilities, transportation costs - 100,000;

- purchase and delivery of raw materials for oil production – 700,000.

As a result, the cost of the finished product is 1,030,000 rubles. To calculate income, take the work of equipment for 1 shift daily. Oil production per month will be:

- (5 tons per day: 3 shifts) * 30 days = 50 tons;

- oil is sold on average for 40 rubles per 1 liter, therefore, the income will be equal to: 40 * 50,000 = 2,000,000;

- profit will be: 2,000,000 – 1,030,000 = 970,000 rubles.

Capital costs will pay off in 2.5 months: 2,350,000/970,000=2.4

Documentation

An entrepreneur can organize a business in the form of an individual entrepreneur or a legal entity (LLC). It all depends on the volume of production and sales of goods. It is better to choose an LLC - this form will allow you to cooperate with large wholesale and retail companies and stores.

It is not necessary to obtain a mandatory certificate of conformity for the production of oil. Go through the verification process and issue a voluntary certificate - this will simplify your work with buyers and intermediaries.

Table 3. Regulatory documents.

| Name | Content |

| GOST 22391-77 “Sunflower. Industrial raw materials. Technical conditions". | On the standards governing the quality of sunflower seeds supplied to the plant. |

| GOST 1129-73 “Sunflower oil. Technical conditions". | About the standards governing the quality of the product. |

| GOST 22391-89 “Sunflower. Requirements for procurement and supply." | On the standards governing the storage of oilseed raw materials. |

Seed preparation

Enterprises for the production of oil and fat products are built where the sunflower harvest is high. These are the southern regions of the Russian Federation and the Black Earth Region. Why is long-distance transportation unprofitable? Because the raw material weighs too little compared to the finished product. This is a costly undertaking. Large volume and low mass negate the economic benefits.

Sunflower seeds

The production process begins next to the laboratory, where trucks are lined up. Experts check the quality of seeds:

- Humidity.

- Rejection rate.

- Oil content.

- Dirtyness.

If at least one parameter does not coincide with the control one, the machine with the raw materials is sent back to the procurer. The car then drives onto a massive scale. After weighing, the driver goes to unload. The seeds fall into the waste pit and move along conveyors to other areas:

- Cleaning section.

- Dryer.

After these procedures, bulk cargo enters silos - reinforced concrete, prefabricated or metal storage containers. The former remain only at old enterprises. New generation of businessmen choose metal. It is reliable and practical.