Manufacturing food products in Russia is one of the most profitable businesses. But the wide range of available products means that not every product finds its buyer. Before choosing a type of business, you should find out how profitable it is. Sunflower oil production is an interesting business that attracts many entrepreneurs. This type of product is in demand and is in great demand among the population. Before you start creating a business, you need to familiarize yourself with some subtleties.

Profitable or not?

It is worth knowing that the production of sunflower oil and its sale is the prerogative of many small and medium-sized enterprises. This is due to the low investment required to start a business. Also, the activity pays off very quickly. There is a high level of competition in this segment, but with competent management, a well-thought-out business plan for the production of sunflower oil and a clear marketing policy, the entrepreneur will not be left without good revenue.

Sales volumes of oil exported annually set new records at 300,000 tons per year. Prices for seeds versus oil on the world market are $300 and $790 per ton. This makes oil production profitable not only for sale abroad, but also for supply to the domestic market.

Validity of choice

Every day a person necessarily consumes meat, dairy, bakery products, as well as products of plant origin in one form or another.

It is impossible to imagine a normal diet without them. Consequently, these products are most in demand on store shelves.

Even for the smallest enterprise, the main thing is the ability to sell the goods produced. Otherwise, the company will be forced to work “for the warehouse”, and this, as we know, does not bring profit.

Such companies end up in bankruptcy and liquidation. This is exactly what awaits entrepreneurs who have not thought through the possibility of marketing and ways to sell their own products in a timely manner. The marketing department should do a good job here.

She will have to carefully study the market (demand and supply), as well as pricing policy. After this, you can decide on the product. If you can somehow manage without meat, then people must consume products of plant origin.

It's not always bread. Every day a person uses vegetable oil for food. It is used for temperature treatment when preparing food or simply for dressing salads. Therefore, people will buy this product. From this we can conclude that a modest mini-dairy could be a good option for a business.

Sunflower oil production technology

Oil production technology includes several stages, each of which is worth getting acquainted with. First you need to rid the raw materials of husks. Processing of seeds is carried out using the following methods:

- by sifting through a sieve with different holes in shape and size;

- by blowing raw materials with air;

- by separating seeds according to ferrimagnetic properties.

The shell can be removed in several ways:

- by splitting the husk with a blow;

- compression of seeds;

- cutting in half;

- by peeling off the husks on a rough surface.

The sequence of actions is as follows - first perform a spin cycle. The seeds are placed in a roasting pan and heated to a temperature of 100º C, gradually pouring in water and stirring constantly. Then the oil is squeezed out through a press. The stronger the unit, the more oil it will squeeze out. But the seeds are of no small importance.

Important! In addition to oil, cake and husks appear at this stage. They are subsequently sold as cattle or pig feed. From 1 ton of raw materials, 422 kg of oil, 356 kg of cake, 172 kg of skins are obtained.

Refining is the second stage. The output is a special type of oil, which is characterized by a pleasant smell and yellowish color. Refining technology is divided into 4 stages:

- Removal of mechanical substances. The product undergoes settling, filtration, and centrifugation procedures. At this stage, the oil is sold as unrefined. It is characterized by a dark color and a pungent odor.

- Treatment takes place in hot water at a temperature of 65-70ºС. The process removes phosphatides. Due to this, the oil becomes lighter.

- Deodorization - getting rid of fatty acids. This will help remove the unpleasant smell and taste. The oil becomes marketable.

- Freezing is necessary to obtain a colorless and viscous oil.

Packaging the products in containers is the last step. Thanks to the complete line, the process of filling oil into bottles is simplified and occurs automatically. If it is a mini-factory, then you can bottle it manually.

Rare product

Some manufacturers take on the production of rather rare products. Take, for example, the production of pumpkin seed oil. The preparation of raw materials in this case is carried out as follows:

- drying at a temperature not lower than 50 degrees;

- grinding;

- hydration;

- frying the raw material until the moisture has completely evaporated.

The raw material obtained in this way is fed to a hydraulic seed press, from where an unusual blackish-green oil comes out. After bottling, the product reaches store shelves. Previously, it was produced mainly in Austria and some other Central European countries.

But in recent years, scientists have become very interested in its beneficial properties and have concluded that this product is truly unique for the prevention and prevention of quite serious diseases. An amazing amount of vitamins and microelements puts pumpkin seed oil on par even with some medications. Such information can make novice businessmen think.

Oil mill premises

The main requirements for the workshop are directly related to production volumes. The territory for the oil mill must meet the following conditions:

- have an area of 150 sq. m.;

- divided into several zones - production, warehouse for raw materials, warehouse for finished products;

- be equipped with communications - electricity, water supply, sewerage;

- fully comply with safety conditions - be protected from spontaneous combustion;

- comply with sanitary standards.

Important! If production will be carried out at home, then one room is enough.

The workshop area should include the following premises:

- the area where the equipment will be located must be 60 m2;

- warehouse for storing raw materials – 50 m2;

- room for storing finished products – from 30 m2;

- waste storage area – 40 m2;

- room for administration and workers - 25 m2.

Depending on the condition of the structure, repairs, distance from the center or city, you need to pay about 150,000 rubles for rent. You also need to pay 80,000 for utilities. It is better to choose a building that has convenient access for cars to make it convenient to load goods and unload raw materials.

The waste storage room must be equipped with a fire protection system, since the cake has the property of spontaneous combustion. The temperature in the warehouse must be constantly monitored and checked. You can do this in the old proven way. A wooden twig is stuck into the cake. When it gets hot, the by-products need to be removed.

The storage for raw materials should be spacious, sunflower seeds will be scattered in it. The thinner the layer of product, the longer it will last. In such a warehouse, 20 to 40 tons of raw materials are scattered.

To store finished products you will need containers with a capacity of 10-15 cubic meters. They are placed in a room with an area of 20-30 square meters. m. 5-7 pieces each. It is recommended to choose barrels made of stainless steel.

If you use containers made of a different material, problems with SES will arise. When storing sunflower oil in rusting steel, the taste and beneficial properties of the product will deteriorate. But in order to save money, it is allowed to use standard aluminum milk cans.

Important! The devices and equipment for producing the product are quite powerful, so it is necessary to have at least 380 W of wiring in the workshop.

For production workshops for the production of food products, the SES imposes certain requirements. Mini-dairy with an area of 40 sq. m. must meet the following conditions:

- The concrete floor has been poured.

- Suspended panels and ceilings are prohibited. The walls must be tiled or plastered to a height of more than 2 meters.

- Purchase lamps and chandeliers only with explosion-proof characteristics.

- Availability of fire alarms and fire extinguishers.

- A ventilation system, hot and cold water, sewerage, and treatment buildings must be present.

A squeezing and regenerative unit can be located in the same area. If the area is large, it is recommended to equip two separate zones.

Filtration

To speed up the process and not crowd the room with different containers, the oil can simply be filtered. Pre-filtration is carried out after the oil has cooled to 60 degrees. When it cools to 20 degrees, it is filtered more thoroughly. This is called "fine" filtration.

Filters used in food production are also suitable for expressing oil. The most common, so-called frame filters, consist of several layers of filtered cotton fabric, through which oil is pressed. Which material naturally gets used up over time. You can purchase it from suppliers of similar equipment or in various other places; it is not in short supply.

There is another method of filtration - vacuum. In this case, the oil is pulled through the layers of filtered material by vacuum force, leaving various specks and excess on it; after such filtration, the oil is light and has a longer shelf life.

Video: The process of cold pressing vegetable oil

About profitability and wastelessness

Sunflower oil is waste-free. This means that by-products resulting from the production of a product are used in other areas. Related components are sold to third parties.

The husks are used to make pellets - pet food. They are pre-pressed into briquettes and delivered to customers. The husk is sold to brick factories, and the cake is sold to farms. The sale of waste can be taken into account as additional profit, but most often sales are reflected in the cost price, reducing the price of the output product.

Oil suppliers and market

When creating a business for the production of sunflower oil, it is necessary to resolve the most important issues: where to sell the products and where to purchase raw materials. It is recommended to find a permanent supplier; it will be easier to plan profits there.

If an entrepreneur is engaged in trade, then it will be easier for him - he will connect to his network of customers who constantly purchase goods from him. The oil will be poured into a ready-made sales scheme.

It is recommended to find a supplier in the fall that is located geographically close to the enterprise. If he enters into an agreement for regular supplies of oil in small quantities and with deferred payment, this will be an ideal option. This scheme will help to minimize the cost of seeds, thereby increasing profitability.

The oil can be sold to shops, supermarkets, and private enterprises that order products as the main raw material for creating their goods. The component is used in various fields - soap making, food preservation, paint and varnish production, cosmetics and medical industries.

Important! If you can’t find a customer, the oil can be supplied to Turkey. It is in great demand there.

Required Equipment

The technological process for producing oil is quite labor-intensive and complex. It will take time to set up and automate. It is important to correctly calculate the indicators.

The main thing is to purchase a unit that will produce oil. The price is very high - about $20,000, but the enterprise cannot manage without it. It is recommended to find trusted, good suppliers who will sell an excellent quality machine at an affordable price.

If the scale of oil production is small, then in order to save money, you can purchase a manually controlled unit. To make a good profit, it is necessary to purchase large volumes of raw materials, and to process them, the plant must have an automatic line.

To produce sunflower oil, you need to purchase a number of machines:

- oil press;

- filter;

- fryer;

- separator

Approximate costs for units:

- a separator for initial seed cleaning costs about 50,000;

- a crusher-winter unit, which will separate the peel from the seeds, will cost about 60,000;

- machine for grinding raw materials – 500,000;

- fryer - 300,000;

- oil press – 600,000;

- refining apparatus – 600,000;

- automatic bottling line – 300,000.

When starting a business, you can get by with a mini-factory. When a sales market is found and the technological side is established, then they expand.

Advantages of screw presses

The oil screw press has a number of undeniable advantages compared to other units designed for extraction. Such machines have high wear resistance of components. They are reliable and quite easy to use. Having very small sizes, they make it possible to organize production in a room with a relatively small area.

These presses allow, if necessary, to plan the output of finished products by regulating their productivity. Scientists have long paid attention to promising equipment and periodically improve it, modernizing individual areas. As a result, models with a high level of energy consumption have been developed, which is also important for organizing the work process.

Different types of presses allow one-, two- and three-stage cold pressing to produce vegetable oil of fairly high quality. Some of them can even replace an entire production line.

Recruitment

If the workshop has an automated line, the number of employees is reduced to a minimum. But if you hire people, they must be experienced workers who know how to operate machines.

Only specialists should work on the units. If the plant is medium-sized, then it is necessary to hire loaders, drivers and maintenance personnel. Statistics show that finding a professional with experience is not easy. In this case, you can hire young certified people and develop a scheme for them according to which they will work.

Revenue and profit

An important section of a business project is the calculation of projected income. To do this, the upcoming costs and possible profits are summed up. Costs that an entrepreneur will face:

- equipment and machinery – 2,000,000 rubles;

- carrying out preparatory work in the workshop – 300,000;

- obtaining documents for carrying out activities – 50,000.

The total is about 2,350,000 rubles. The entrepreneur will also spend money monthly on the following needs:

- workshop rental from 500 sq. m. – 100,000;

- issuance of salaries to staff for 3 people – 60,000;

- payment of taxes – 70,000;

- marketing activities, payment for utilities, transportation costs - 100,000;

- purchase and delivery of raw materials for oil production – 700,000.

As a result, the cost of the finished product is 1,030,000 rubles. To calculate income, take the work of equipment for 1 shift daily. Oil production per month will be:

- (5 tons per day: 3 shifts) * 30 days = 50 tons;

- oil is sold on average for 40 rubles per 1 liter, therefore, the income will be equal to: 40 * 50,000 = 2,000,000;

- profit will be: 2,000,000 – 1,030,000 = 970,000 rubles.

Capital costs will pay off in 2.5 months: 2,350,000/970,000=2.4

The essence of the production process

The process of purifying sunflower oil

Thinking through all the details of the production cycle, it is necessary to decide what type of sunflower oil - unrefined, refined - will be produced. They differ in the degree of purification.

The cycle for the production of refined oil is more labor-intensive, since it includes chemical-technological methods of purification, which allows removing unnecessary odors and foreign tastes. If the goal is the unrefined form, then the process stops at the mechanical filtration phase, and the product retains the specific taste and rather expressive smell of natural vegetable oil.

How is sunflower oil produced?

A novice businessman should take into account that, despite lower costs, profits from the sale of unrefined oil are reduced, since its cost is lower and demand is less.

The technological chain for producing vegetable oil is quite branched; on average, it consists of the following steps:

- Sifting seeds.

The process of preparing sunflower oil - Cleaning them from husks.

- Grinding

- Heat treatment.

- Spin.

- Filtering operation.

- Refining.

- Spilling of the finished product.

- Package.

If sunflower oil is produced from a line of unrefined varieties, then there will be no refining operation in the cycle. Sometimes the heat treatment stage is eliminated in order to save on the purchase of equipment.

Heat treatment in the presence of a full cycle before pressing involves heating the raw materials in braziers. The optimal temperature for this operation is set between 100 and 110°C.

The completeness of subsequent extraction in presses depends on a number of indicators - viscosity, pressure, density. The next stage involves filtration (settling, centrifugation), the purpose of which is to remove mechanical impurities. After this operation, unrefined oil is obtained, which can be sold.

Refining involves going through several stages:

- To remove phosphatides and make the oil transparent, it is treated with hot (65-70°C) water (hydration process).

- A neutralization procedure may be carried out, in which preheated oil is exposed to alkali. The reaction removes free fatty acids.

Classic continuous refining process

The oil after these stages is called refined, not deodorized. Deodorization completely removes pigments and volatile compounds, giving the resulting deodorized refined oil a light straw color.

How to organize a mini strike

To open a small workshop for producing sunflower oil, you will need minimal investment. The price for a churn that will produce 10-17 liters per hour ranges from $200 to $450. Other units required for operation:

- a filter to clean the product will cost $100-200;

- the cost of additional tools, products, and kits will be about $100.

Capital investments are small, so agricultural producers often open private mini-dairies.

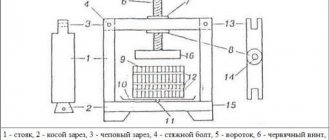

The modern design for producing oil is a press extruder. It is visually similar to a meat grinder. Equipment for the production of sunflower oil

consists of three parts:

- bunker for supplying seeds;

- auger compartment where raw materials are crushed;

- nozzle for squeezing oil.

After receiving the product, it will need to be filtered. For small production volumes, canvas bags are used for filtration. After the process, the oil must be kept in a cool room for some time. Then it is poured into barrels.

If sediment forms at the bottom, the oil is filtered again. For larger oil mills, it is better to purchase special filters that will quickly clean the product.

It is better to open a small production when the owner plans to grow sunflowers on his own. Due to this, he will save a significant amount on the purchase of seeds and their delivery.

As the practice of entrepreneurs shows, the profitability of a mini-enterprise can reach 25%. The first investment pays off within six months. Here it is important to find consumers and establish the technological process.

To open your own creamery, you do not need to obtain permits or licenses. The business owner must register as a sole proprietor. Since the activity is related to food, sanitary and epidemiological stations will regularly visit the owner to check the quality. It is also impossible to do without control of the fire service.

Important! When opening a small plant for the production of sunflower oil, it is recommended during registration to ensure that the owner is recognized as a manufacturer of agricultural products. In this case, he will pay taxes at reduced rates.

How many cars do you need?

If, as a result of much deliberation, an oil mill has become the choice for your own business, the equipment should be selected based on the desired productivity and financial capabilities. Out of questionable savings, you shouldn’t buy one powerful machine and install it in a small room.

The savings on rent are not that significant. It is much more practical to purchase several small presses and install them in a spacious workshop. Initially, the costs will be significant. But they will definitely pay off in the coming months. In any case, the size of the room must comply with certain sanitary standards.

The fire service will measure the explosion hazard index, and in a small area it is problematic to meet the required limits. Having several presses, you can set up simultaneous production of different types of products.

Thus, you can significantly expand your range and increase your competitiveness in the market. As a result of an accidental breakdown of one of the machines during the repair period, the workshop will not stop its work, but will continue to produce products on the remaining presses.

Some modifications of screw presses can easily be adapted to produce feed in granular form. This is very convenient in case the equipment is idle due to a possible lack of raw materials.

conclusions

From the point of view of investing money, the business idea of creating your own creamery has not lost its relevance. The business is still characterized by fast payback periods, profitability and demand. In addition to the oil, the owner will receive by-products that can easily be sold and receive additional profit. Sunflower oil production breaks even. When creating a small workshop, the owner may not need to obtain licenses; it is enough to register with the tax service as an individual entrepreneur and remit taxes on time.