- home

- Tuning

Winch for plowing land with a plow.

Homemade winch for plowing the land How to make a winch for plowing A homemade winch is designed to facilitate heavy manual labor when cultivating the soil and can replace any walk-behind tractor or cultivator. With its help, you can plow the soil under the beds, plant, harrow, hill, dig up potatoes.

The agricultural winch allows you to carry out a full cycle of soil cultivation when growing potatoes. The unit helps preserve and maintain soil fertility, which leads to maximum yield.

In the distant 90s, a plowing winch was created based on the engine from the Ural, Druzhba chainsaw, and it still serves faithfully to this day. Changes and improvements concerned mainly the plow. The video below clearly shows these changes. Gradually the idea came to create an electric analogue. And this is what happened, see the video and photos below.

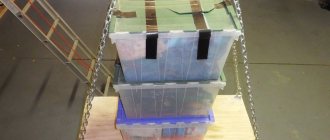

A winch was made - a walk-behind tractor from scrap materials using standard publicly available parts and ordinary materials (electric motor 2.2 kW 1500 rpm, pipes, angles, sprockets and chains from motor vehicles).

Electric plowing winch

The motor is three-phase and connected to a single-phase 220 V network. This power is enough for plowing, hilling, and digging up potatoes. If you buy a motor for a single-phase network, you can plow virgin soil. And in my modification for plowing virgin soil, I used a block that reduces the plowing speed by half, but also increases the effort.

A single-phase motor costs more than 10,000 rubles. We are talking about the city of Smolensk, so a 3-phase one was installed. In addition, people who were faced with rewinding a single-phase motor faced big problems. A 3-phase motor is in practice more reliable - it can operate continuously for years.

The principle of operation of an agricultural winch is to sequentially plow the land with the plow returning to the beginning of the furrow. It is advisable to carry out the work together, but if necessary, it is possible to do it alone. In this case, it is possible to apply fertilizer (humus) directly into the furrow.

Even the turf (virgin soil) can be plowed. At first, a classic homemade plow with handles was used, which required basic plowman skills and weighed a couple of kilograms more than the modernized one.

Electric and petrol winch

(the wheels on the winch are used only for transportation around the site)

Parts that need to be turned on a lathe or purchased at a motorcycle parts store.

For personal plots, it has become popular to use a homemade winch when plowing. Do-it-yourself homemade products are preferable. Let's consider a winch for plowing as a donor, which was the Minsk motorcycle. The engine with a displacement of 125 cm3 is not too heavy and the power is quite enough. Anyone who has used a Minsk motorcycle knows that the engine starts very easily and without fail. Reliable in operation, repairs are not expensive. Spare parts are available and there are no problems with them.

DIY electric plowing winch

A homemade winch is designed to facilitate heavy manual labor when cultivating the soil and can replace any walk-behind tractor or cultivator.

With its help, you can plow the soil under the beds, plant, harrow, hill, dig up potatoes. The agricultural winch allows you to carry out a full cycle of soil cultivation when growing potatoes. The unit helps preserve and maintain soil fertility, which leads to maximum yield.

In the distant 90s, a plowing winch was created based on the engine from the Ural, Druzhba chainsaw, and it still serves faithfully to this day. Changes and improvements concerned mainly the plow. The video below clearly shows these changes. See winch drawings here. Gradually the idea came to create an electric analogue. And this is what happened, see the video and photos below.

A winch was made - a walk-behind tractor from scrap materials using standard publicly available parts and ordinary materials (electric motor 2.2 kW 1500 rpm, pipes, angles, sprockets and chains from motor vehicles).

Electric plowing winch

The motor is three-phase and connected to a single-phase 220 V network. This power is enough for plowing, hilling, and digging up potatoes. If you buy a motor for a single-phase network, you can plow virgin soil. And in my modification for plowing virgin soil, I used a block that reduces the plowing speed by half, but also increases the effort.

A single-phase motor costs more than 10,000 rubles. We are talking about the city of Smolensk, so a 3-phase one was installed. In addition, people who were faced with rewinding a single-phase motor faced big problems. A 3-phase motor is in practice more reliable - it can operate continuously for years.

The principle of working with an agricultural winch is to sequentially plow the land with the plow returning to the beginning of the furrow. It is advisable to carry out the work together, but if necessary, it is possible to do it alone. In this case, it is possible to apply fertilizer (humus) directly into the furrow.

Even the turf (virgin soil) can be plowed. At first, a classic homemade plow with handles was used, which required basic plowman skills and weighed a couple of kilograms more than the modernized one.

Electric and petrol winch

(the wheels on the winch are used only for transportation around the site)

Parts that need to be turned on a lathe or purchased at a motorcycle parts store.

Description

The winch turned out to be compact and easy to use. Fuel consumption of a small 2-3 liters is enough for a fairly large plot of land. The fuel tank was borrowed from a chainsaw. The chassis is made of a drive sprocket (mounted on the engine), a chain and a driven sprocket (mounted on the drum) all from a motorcycle.

The engine is mounted on the frame in one position and does not move along the frame. The drum is installed on the frame using four bolts and nuts. Special longitudinal holes are cut for it so that the drum moves along the frame and with this the chain tension is adjusted. To create a homemade winch for plowing, not only parts from various motorcycles were used, but also parts made by hand.

Operating the plowing winch is very simple; anyone driving a motorcycle will figure it out very quickly. Controls like those on a motorcycle. On the left side is the clutch control lever, on the right is the throttle control handle and the ignition switch. The speed can be switched on either with your foot or with your hand. It's even more convenient to use your hand. It is advisable to plow at first speed. The homemade plowing machine starts up like a motorcycle.

How to make a plow-electric winch

At home I had an old, dusty and oily 4-40 worm gearbox with a reduction ratio of 1:40, which served as the basis for the winch. This, by the way, can be found at a flea market for a low price and in good condition.

Having completely disassembled it and washed it in gasoline to remove oil deposits, which looked more like black plasticine, I decided to immediately change the seals. As a replacement, I used oil seals from a VAZ family car. I changed all the gaskets (replacement ones were cut out of paronite 0.6 mm thick), and adjusted the gap between the worm and the gear. I filled in the transmission oil and the gearbox was like new.

To determine what size drum would be needed, I first welded a frame from a 40x40x4 mm angle piece measuring 75x30 cm.

At first I thought that the cable from the drum would be unwound using the engine reverse, but this turned out to be very time-consuming and inconvenient; manually it is much easier. But for this it was necessary to come up with a coupling with which it would be possible to separate the gearbox shaft from the drum shaft and thereby unwind the cable effortlessly to the required length of the garden. And while the winch is operating, I connect the gearbox to the drum, and both shafts work together.

EVERYTHING YOU NEED FOR THIS ARTICLE IS HERE >>>

The coupling was made from the front CV joints (constant velocity joints) and the front hub of the VAZ 2108. The CV joint shafts have external splines identical to the internal splines of the hub. They will engage with each other. I purchased used CV joints and a hub at a scrap metal collection point (the nearest auto repair shop did not have them at that moment). I immediately cut off two parts of the shaft from the CV joint - these are what are needed to make the winch shaft (Fig. 3).

Then I started making a drum on which the cable would be wound. From a piece of pipe with an outer diameter of 114 mm I made two flanges 5 mm thick. At a metal depot I bought round steel (round timber) with a diameter of 35 mm - it served as a blank for the shaft. A round piece with a diameter of 90 mm became a blank for the drum bearing housings. By the way, keep in mind: when buying metal at a metal depot (if they cut it for you with a propane cutter), do not immediately throw it into a container of water. This metal is difficult to turn. I also had to buy a pair of 306 series bearings - these will withstand the load created by the plow.

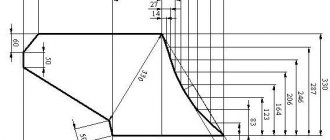

Arriving home and drawing a drawing of the future shaft on a piece of paper (Fig. 1), I went to the turner. The time has come to collect all this into a single mechanism. I’ll say right away that winch housings can be found both ready-made and used. But there are no such stores in my city, so I asked the turner to also turn out the housing for the unit (Fig. 2).

Taking flanges with holes cut in the center for the outer diameter of the shaft, I welded them to a piece of pipe with a diameter of 114 mm. Then, passing the machined shaft through the flanges of the drum, centered it so that there was a small gap between the flange and the bearing housing, and welded the drum to the shaft. The splined shaft of the CV joint was inserted into a machined hole in the end of the drum shaft and carefully welded. I made the same slots on the gearbox. This required a second splined CV joint shaft - it was fixed to the gearbox through a machined bushing.

I made the fastenings of the gearbox and drum to the frame from a 50x50x5 mm corner. I fixed everything with tacks, because it all needs to be aligned. I welded a 50x50 mm angle to the turned bearing housings (Fig. 5): now they can be secured to the frame with bolts and easily removed if repairs or replacement of bearings is needed.

Electric plow - purpose and principle of operation

Often, a plow is used in tandem with an electric winch, which significantly increases its performance. Its principle of operation is quite simple: a traction structure is installed on one edge of the site, and a cultivator or plow attached to it on the other. Switching on: the trailing mechanism begins to pull towards it, switching off – it moves to a new row and the process repeats.

You can buy a plow for a winch in almost any specialized store, but you can also make it yourself. To do this, it will be enough to correctly measure the angles of the share (the optimal indicator relative to the field board is 20°-25° and 45° relative to the center line) and take a solid base (channel, for example). Often, for the stability of the structure, a 4 mm metal strip is welded into the middle, which will protect the plow from damage when it hits boulders.

Buy only high-quality traction mechanisms from trusted manufacturers. Basically, for self-assembly, electric plows are used from the Polish companies Dragon Winch and Husar. They are quite resistant to loads and do not require significant maintenance. However, during operation it should be remembered that the traction force directly depends on the length of the cable: the more turns there are on the drum, the less weight the winch can pull and vice versa.

Preparing for work

At the beginning of the row, in the middle, we install a winch, driving in two metal rods for fixation. An assistant manually unwinds the cable to the required length. Using the hub, two shafts are connected, then we turn on the grinder - and the unit begins to work.

When hilling, you only need to slightly direct the plow to the left or right, adjusting the position of the hiller in the row. The plow also needs to be adjusted when plowing, although most of the work is done for you by the wheel in the furrow in front of the plow.

Now hilling and plowing takes much less time and effort, although, making the same winch again, I would correct a few things, making the design smaller. And so the plans include painting and modification of this winch, but even now it copes with its task perfectly.

HARNESS..WINCH

A winch working in tandem with a plow is not new.

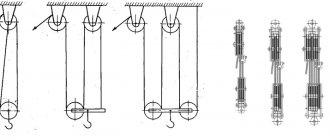

Especially for owners of small plots of land, on which these fairly simple and reliable nonstrings have already proven themselves to be excellent. Unlike a mini-tractor, the winch does not compact the soil. And it doesn’t slip like a walk-behind tractor. And almost all the traction power of the motor here goes to useful work - plowing the nursery land with a towed plow. The winch itself is securely held in place by an anchor, the arms of which, having the appearance of bayonet shovels, easily penetrate into the ground. Plowing is carried out by two people, making furrow after furrow. Moreover, the partner, whose duties include returning the plow to the beginning of the furrow, can be a 10-year-old child. High plowing quality is guaranteed even on extremely inconvenient sites (slopes with a “washboard” profile) and heavy soils. The proposed homemade plow-electric winch (see illustration) has a number of additional advantages associated with the relative cheapness of electricity, ease of acquisition and long life (over 30 years) of trouble-free operation of the electric motor, ease of start-up and operation of the entire structure. The gearbox speed control lever is located in close proximity to the unit with electrical equipment (capacitors, magnetic starter, “Start” and “Stop” buttons). Next to it is a coil of cable on a reel. So the electric winch can be anchored anywhere on the land plot at a distance of up to 100 m from its connection to the power grid (with a longer cable length, line losses increase). And the built-in remote control with a “Stop” button allows you to control and plow, even working together with a disabled person.

When a boulder or tree roots get under the plow, the force on the rope increases sharply. And when it becomes the maximum permissible (330 kgf), the winch electric motor stops, preventing the rope from breaking (as well as breaking the chain transmission mechanism).

And one more feature. Thanks to the modular design, if necessary, you can easily remove the engine and the unit with electrical equipment from the electric winch (it is enough to unscrew 4 M10 bolts) and, installing them on an electric sawing machine, start preparing firewood, slats, timber, etc. By rearranging these same block units onto the grass cutter, we obtain valuable, vitamin-rich feed for livestock and poultry. Well, having replaced the plow with a towed cultivator-hiller, the same electric winch can be used not only for weeding and hilling, cultivating row spacing, but also, say, for digging potatoes.

Kinematics? The proposed home-made design is so elementary (and therefore reliable) that it is unlikely to cause anyone any difficulties when “incarnating it in metal.” From the electric motor shaft, the torque is transmitted (a sleeve coupling is used for this) to the gearbox (taken from the Riga moped with subsequent minor modifications). And from there (thanks to a chain drive with a pitch of 12.7 mm) - onto a drum with a 10-mm nylon rope wound onto the last one, to the end of which a towed plow or cultivator-hiller (aka potato digger) is connected.

The frame is based on a welded structure made from sections of 34x50 mm steel angle with a tubular spar and brackets for mounting the electric motor, gearbox and drum. Moreover, the rope guide, made from a suitably bent section of 22×3 steel water and gas pipe, is welded after installing the drum. And in the brackets of the latter, boring holes are provided for the shaft with the possibility of some movement of the shaft to ensure proper tension of the PR-12.7 drive roller chain.

Structure and types of plows

To make a plow with your own hands, you need to have information about its structure and the purpose of its parts. General purpose arable implements are most often used. It consists of several parts, which can be divided into working and auxiliary:

- workers:

- body - consists of a stand to which a ploughshare with a blade and a field board are attached;

- knife - the main cutting part;

- skimmer - an additional cutting part that cuts the turf layer of soil;

General purpose plow design

How does this plow work? The skimmer removes the top layer of soil with plants growing on it, turns it over and places it at the bottom of the furrow, which is the result of the work of the body. The body with the equipment cuts off part of the soil from the side of the furrow, loosens it, turns it around a certain angle (depending on the design), and lays it on top of an inverted layer of turf (laid with a skimmer). To level the furrow wall, a knife is placed in front of the last plow body.

General purpose plows can provide a plowing depth of 20 cm to 30 cm, plowshares - from 16 cm (they also do not have a knife and skimmer).