Metal stamping is the shaping of a material under the influence of an external force in order to obtain the desired part. Processing a workpiece in this way requires a lot of force. For this purpose, there is equipment that is produced with a force of 16 to 500 tons. The equipment installed in the press is called a stamp. In it there is direct contact of the working tool with the metal. In 1 stroke of the machine, a part with a high degree of accuracy is obtained.

Metal stamping process

History of the process

Stamping of metal products first began in the 16th century. This was due to the development of weapons production, which required the production of a large number of identical parts. In the 19th century, the rapid development of stamping production began. Household items are produced. There is a need to manufacture high-quality serial products.

With the advent of the automotive and shipbuilding industries, metal forming has taken a key position in the development of these industries. Dimensional parts began to be produced using stamping.

Automatic stamping lines

The high productivity of forging and stamping production technologies requires the mandatory use of mechanization and automation. For this purpose, flow-mechanized and automated lines are created and used. These lines include:

- Automatic shelving (mainly for separation equipment);

- Hopper-loading devices for piece workpieces (used in heating devices and sheet stamping complexes);

- Feeds - roller, roller, pincer, wedge, which are built into the equipment operation scheme;

- Transfer bars that are used for multi-position hot or cold stamping.

The highest degree of automation of forging and stamping production is the use of automatic lines, the control of which is programmed and carried out from a centralized console. Industrial robots often operate as part of such lines.

Areas of use

Industrial production is not complete without cold and hot stamping. Using these methods, you can create both small and large parts in a short period of time. Hot stamping is used where three-dimensional parts are needed.

When stamping flanges, 2 methods are used:

- Hydraulic presses are used in the forging process. Here, under the influence of pressure, the metal flows into the cavity, which is made in the striker. This space corresponds to the shape of the resulting part.

- When using sheet metal as a workpiece, crank presses are used. A stamp is inserted into them and sheet metal is fed. The flange is drawn out under pressure.

Making molds from scratch

To create a mold, you need 2 sheets or bars of steel, depending on the shape of the product. One part will be responsible for the moving part of the structure (punch), and the second for the matrix.

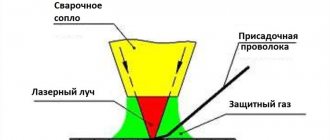

Having selected materials for the workpieces and tools, you can create a form for stamping. Having the drawings of the part, the equipment is designed. Using a laser or lathe, holes and recesses are cut into the blanks for the mold. For reliability, you need to tightly fasten the two plates and fix them until the work is completed. Carefully debug the gating system. To make some parts of complex terrain, a milling machine and subsequent manual work with a file may be required.

The finished product is checked in operation on test products. This makes it possible to find out the result and adjust the mold in case of any inaccuracies. The gating system must be adjusted for best results.

Making a mold is a complex process, but necessary for mass production of parts.

Punching technology

The technology for manufacturing parts by stamping, both hot and cold, requires the presence of tooling. For both types, stamps are made, which have certain differences. They are used for metal that has varying degrees of thickness.

Large sized workpieces are preheated and then the forging process takes place. When cold, the sheet thickness rarely exceeds 1 mm. Various operations are carried out with such material, for example, stamping badges.

Stamping technology

Cold stamping

During the cold stamping process of sheet metal, no heating is applied. The force of the press is enough to carry out separation or shaping operations. As a result, the resulting part is not subject to the shrinkage process. To save material, stamping is carried out according to the rules for cutting sheets, which are regulated by GOST.

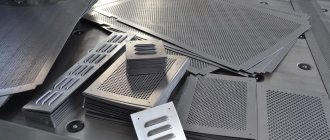

Cold stamping includes the following operations:

- Punching. During the cutting process, the finished part falls into a container, leaving waste outside. When punching, on the contrary, the waste falls into the container, and the part is formed from the outside. The design of the stamps is the same. During the work process, a separation operation is carried out, which involves a punch and a die matrix.

- Flexible. Refers to a simple operation. The part is placed between the stops on the matrix and pressed from above with a punch.

- Hood. Often obtained in several transitions. Separate stamps are made for this purpose. In the process of working, a glass, cone or hemisphere is obtained from a round blank. This is achieved due to the redistribution of metal in the original workpiece.

- Beading. The punch catches the hole in the part with a clamp and expands it, beading the walls.

An important point is the correct choice of the gap between the punch and the matrix. This value depends on the thickness and type of material. The thicker the metal, the larger the gap. For aluminum and other soft materials this size is reduced. Otherwise, burrs will form.

Hot stamping

In the process of manufacturing metal parts by hot pressing, the workpieces enter a heating chamber. Hot metal stamping begins after they reach a temperature of 1200°C. Heated products are placed in a stamp, where there are special grooves for preliminary and final stamping.

If you need to upset a heated forging, then it is placed in the space between two flat strikers. The equipment starts up and the workpiece is settled to the required size.

Heated metal (Photo: pixabay.com)

Alternative stamping methods

Metal stamping can also occur under the influence of other forces:

- Explosion. The process is carried out in water. The material is placed on a matrix in which a recess of the desired shape is made. There is an explosion from above. As a result, the workpiece fills the stream and takes on the desired shape.

- Electrohydraulic. Voltage is applied in the aquatic environment. The water is heating up. Under the influence of high temperature, a shock wave occurs, which forms the workpiece.

- Pulling metal through rolls. This method allows you to give the workpiece the desired shape.

Stamped badges are made in a die, where enamel is placed in the recess of the punch.

Manufacturing methods

There are three ways to make a stamping mold:

- Remaking an existing mold;

- Manufacturing from scratch;

- Assembly from ready-made materials.

The first option is extremely rare due to the costs; it’s easier to do it yourself. In the CIS countries they create forms from columns to form-building ones. There is a trend towards specialization of molds. All parts of the mold are made in different factories, and finally they are assembled into the finished product.

The production of molds for stamping aluminum parts is reduced in cost by reusing, without repairs, molds that have already served their purpose on more high-precision parts. Aluminum parts do not have tight tolerances, so this option is acceptable.

Making metal stamps

To make stampings from a workpiece, metal dies are constructed. At the first stage, drawings with specifications and details are developed.

Stamps consist of the following parts:

- The working parts are a punch and a matrix. Manufactured from tool steel U8a, U10a, X12M. After heat treatment, they are hardened to 60 Rockwell units.

- Punch holder. Material - Art. 3

- Gaskets. Manufactured from structural steel with a hardening grade of 45 Rockwell.

- Puller. Made from Art. 3

- Top and bottom plates. Their thickness depends on the force expended on stamping.

- Columns and bushings. The material is Steel 20. The surface is carburized to a depth of 1–1.5 mm. This layer is then hardened.

- Shank. Inserted into the press slide.

Parts for making a stamp

Material selection

High-strength steels that can withstand impact loads are used for molds. These steels are highly hardenable and have high toughness. The most commonly used are 40Х13 and 5ХНМ. For dies, durable steels St45, St40X, U8 are chosen.

For cold stamping, a hydraulic press is used due to the variety of its configurations and low metal consumption. For cutting and punching, choose a tool with a large washer stroke.

IMPORTANT! U8A and 8HF steels are not used for the manufacture of mold parts. U10A steel is hard after heat treatment, but parts manufactured with it will have to be subjected to additional machining.

Equipment and tools

To form metal products, dies are made that are inserted in presses, which are of 2 types:

- Crank-rod. The main element in them is a slider moving along guides. An electric motor is located on top, which gives impetus to the movement of the crank mechanism. There is a plate at the bottom on which the stamp is placed. The equipment is high-speed. The disadvantages include the high impact force when the punch comes into contact with the metal. As a result, the tool becomes chipped.

- Hydraulic presses. They have great power. The advantages include the smooth movement of the slider. Thanks to this, there is no mechanical shock during operation, which leads to long service life of the tool. The amount of travel of the slider provides a large open height of the press space. This makes it possible to perform deep drawing or bending operations on workpieces with high sides.

Metal forming allows you to produce a large number of parts in a short time. In this case, they will all have the same shape. The accuracy of their manufacture is regulated by GOST.

We will advise you on any questions!

Have a question?

Our services

Volume stamping is the process of processing metals using pressure in different planes. The original dimensions and shape of the material are deformed, which allows the workpiece to be given the desired configuration according to the drawing. To change the geometric parameters of a metal workpiece in several planes, it requires heating. This technological operation is called hot die forging (HOF).

Advantages and disadvantages of the process

Hot stamping has some advantages and disadvantages relative to forging.

Advantages of GOSH:

- high productivity exceeds forging hundreds of times;

- production of finished products of complex configuration;

- relative simplicity of a specialist’s work and faster training in the necessary skills;

- fewer tolerances and allowances, since only the contacting surfaces of the parts are machined, and the remaining surfaces have satisfactory geometric parameters and roughness. After calibration, tolerances are only 0.05 mm.

The disadvantages are:

- the weight of the finished product does not exceed 3.5 tons;

- the high cost of a special die tool in contrast to a forging tool. The die is made on the basis of high-quality steel and is used exclusively for a certain size of forging;

- the need to use more powerful equipment due to the deformation of the entire workpiece, and not part of it, which requires an increase in the impact force. And also the walls of the die cavity experience pressure during the flow of metal, which affects its wear resistance.

Horizontal forging machines.

These machines perform hot heading of various parts (such as a rod with a thickening, a through hole, a blind cavity, a complex configuration, etc.) from rod material or pipes in multi-strand dies. The design of the dies also allows for punching holes, cutting along a contour, cutting off a rod, etc. Horizontal forging machines are distinguished with dies being separated in the vertical and horizontal planes.

The general view and kinematic diagram of a horizontal forging machine with a vertical matrix split are shown in Fig. 48, a, b. Electric motor 1, through a V-belt drive 2, a flywheel 3 and a clutch 4, rotates the drive shaft 17. This shaft transmits rotation to the crankshaft 22 through the small 16 and large 21 gears. The crankshaft covers the connecting rod 20, which sets the main slider 19 in reciprocating motion. An eccentric 23 is mounted on the crankshaft, driving the side slider 5. The latter, moving forward, moves the system of levers 6, 7 and 8 associated with the clamping slider 9 .

Thus, rotation of the crankshaft causes translational movement of the side 5 and clamping 9 sliders; Almost simultaneously with them, the working movement (forward movement) of the landing or main slider 19 occurs.

The front stop 13 is connected to the upsetting slide through a system of levers and rollers. In the initial position of the slides 19 and 5 (this position is shown in the figure), the stop 13 is lowered into the stamping space and is located between the punch 14 and the halves 11 and 12 of the matrix. The heated workpiece fed forward comes into contact with the stop. As soon as the sliders begin to move forward (working stroke), the stop 13, using the lever 15, begins to rise and leaves the die space. The clamping slider 9, leading the upsetting slider 19, clamps the workpiece between the halves 11 and 12 of the matrix, after which the upsetting slider hits the end of the workpiece with a punch 14.

After landing, the sliders move back, the forging is released and the stamper removes it or transfers it to another stream.

The horizontal forging machine has idle and working strokes. Idling begins when the electric motor is turned on, when only pulley 3 rotates, but clutch 4 is turned off; brake 18, located on the right side of the drive shaft 17, keeps the drive shaft from rotating. When pedal 10 is pressed, compressed air enters the clutch and turns it on, which loosens the tightened brake bands and causes the drive shaft to rotate. At the same time, the air entering the brake 18 releases the tightened brake bands, and rotation from the drive shaft is transmitted to the crankshaft.

The productivity of horizontal forging machines is high (400-900 forgings per hour).

At domestic factories, horizontal forging machines are manufactured with a force of 1-31.5 MN (100-3150 tons) with a number of strokes of 95-21 per minute.

For stamping on horizontal forging machines, blanks with a diameter of 20-270 mm and a weight of up to 100 kg are used.

Date added: 2014-02-05; 6565; Does the published material violate copyright? | Personal data protection |

Didn't find what you were looking for? Use the search: