To ensure that the operation of electric pumps is not accompanied by a large number of errors, it is necessary to install a water level sensor. The device is able to control operation and also prevent dry operation. It is important to spend a lot of time choosing this product, because the durability and reliability of the product depends on the quality of workmanship. Therefore, the editors of the YaNashla website have prepared for you a rating of the best float switches for 2022.

Purpose

Almost every pump is equipped with special devices that monitor correct operation and prevent malfunctions. One of the popular and effective means of control is a float switch. The main feature of the product is its functionality and practicality. It can work not as an actuator, but also as a water level sensor, and can be placed in any container.

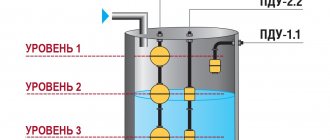

One container can contain up to 3-4 float switches, and they will solve certain problems:

- Monitor the correct operation of the main pump;

- Turn off equipment in an emergency;

- Contribute to the operation of the auxiliary pump;

- Completely replace some sensors to save space.

With such a product, the pump will always be protected from “dry running”, which will prevent rapid wear and tear. Additionally, if a person is filling a large tank, the switch is able to monitor the water level and prevent overflow. The equipment is sold in two versions: heavy and light. The first is recommended for installation in drainage or rainwater drains, and the second is suitable for standard work with clean water. The cable length is different for everyone, the minimum value is 2 meters.

Float switch in action

Before connecting a newly purchased float switch to a pump, it is advisable to ensure that their technical characteristics are compatible. An elementary way to set up the operation of a switch for electric pumps is inside a water tank.

Serial connection diagram for float switch:

- A special sinker (from the kit) is attached to the float cable.

- The cable is securely fixed at the edge of the tank.

- The amplitude of the free movement of the float switch is adjusted to set the highest and lowest levels at which the float switch will operate.

- The float switch is connected to the pump last.

The main functions performed by a float switch:

- The float connected to the pump that performs the task of filling the tank will turn off when ascending and connect when it reaches the bottom mark.

- For an automatic station: switching on when the upper liquid level mark is reached and switching off at the lower mark (reaching the bottom of the container).

- Valves or valves with a servo drive: the switch will give a signal to close when it is in the upper position (full capacity) and will open the way for water when it reaches the lower position.

- Control room: monitoring of excess and shortage of water.

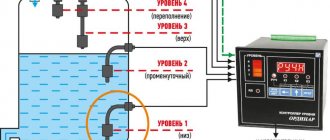

It is possible to connect two pumping devices to one float: the function of the first pump is to fill the tank when the float is located at the bottom, the mission of the second is to pump out water when it is at the top. The scheme is effective only if there is an uninterrupted supply of water to the tank. Some options for connecting switches to prevent pumps from running dry.

Design features of the device

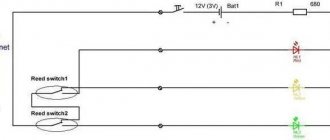

The product is housed in a plastic case that is protected from water penetration. There is a lever and an electrical switch inside. Some designs are equipped with a steel ball. The main task of this element is to monitor and change position when the position of the device itself changes. The last element is a cable, which consists of three wires, where one is common (black), and the rest are connected to the contacts.

When the device is placed at the bottom of a container or reservoir, the connection is made through the black and blue wires. If the device is located at the top point, then the contacts will close brown and black. It is important to remember that all wires must have high-quality insulation; no cracks are allowed.

It is necessary to ensure that the supply cable has high moisture-proof properties; this is often indicated in the technical data sheet of the device. Tight sealing is achieved using a mechanical seal. The product is also equipped with a special element that prevents the occurrence of mechanical stress. To get rid of leaks, manufacturers add polymer resin; this does not make the sensor more expensive, but its safety increases significantly.

Cables made of thermoplastic rubber are able to withstand chemical and temperature exposure. For example, the device will function properly even in cases where it interacts with:

- Alcohol;

- Gasoline;

- Organic acid;

- Feces.

Due to the fact that the product does not have pores, no elements interfere with performance. Sand or paper does not remain on the surface, which has a positive effect on the buoyancy of the device.

The main characteristics of the float switch include the following parameters:

- Current limit value;

- Rated mains voltage;

- Resistive load, these include starters, heating elements, light bulbs, etc. devices;

- Reactive load. This takes into account the operation of the pump and compressor;

- Minimum and maximum temperature values;

- Protection class.

Design and principle of operation of the switch

Float design: electric switch and steel ball placed in the internal cavity of a plastic housing. The cable length varies from 3 to 10 m. When the float switch reaches the upper mark, the switch contacts close, turning on the pump. As soon as the float descends to the lower mark, the steel ball acts on the switch lever, changing its location. The circuit opens and the system turns off.

Float switch connection diagram: a cable with three wires is connected to the switch. They vary in color, often being black, blue and brown. The common wire is marked in black.

In the upper location of the float switch, the contacts of the common wire and the normally closed wire, indicated in brown, are closed. At the minimum mark, the circuit is closed with the participation of a common wire and a normally open wire, indicated in blue. The insulation of wires not currently used in the circuit must be very reliable. It is understood that in an aquatic environment the cable must have sufficient moisture resistance, and the plastic case must be leak-tight. The cable outlet is equipped to relieve mechanical stress and is reliably sealed. The polymer resin filling the cavity of the cable glands prevents moisture from getting inside. And the last word in favor of the float switch is the price, which usually varies from 300 to 500 rubles. The combination of a reasonable price and reliability makes the purchase of a float switch the best option for providing protection against unwanted breakdowns of expensive equipment, such as household and industrial pumps.

Advantages of the equipment

One of the main advantages of this device is the ability to function as a standard water level sensor. The product performs this function regardless of its main purpose. Thanks to this solution, it is easier for a person to use an electric pump, in addition, the product simplifies the control of some water supply systems.

The second feature of the device is the ability to function as part of the main equipment when constructing sewer systems. Due to its simple design and high efficiency, the product is in high demand in areas where it is necessary to constantly monitor the liquid level. This not only prevents the electric pump from running dry, but also prevents the water level from rising.

What is important to know about installation?

Depending on the intended purpose, the installation method may vary. However, before installing the device, you should know that operation is not allowed only when the rated current value is several times higher than the maximum. The parameter is indicated on the box and in the technical notes. device passport. The easiest way to place the switch is to place it in a tank. To do this, you need to equip it with a special weight and make sure that the design is designed for such use.

The sinker must be fixed to the cable; often this element is included in the kit, so there is no need to look for available materials. After fixing, you should calculate the free play; it is recommended to do this in a practical way, so the readings will be more accurate. Once the user has completed the calculations, it is necessary to install the cable on the outside of the container. The last point is connection to pumping equipment.

There is another method that is often used in the household - using a supply cable. This option is easy and does not require any calculations; the only thing to remember is that there should be no other sensors or elements inside the tank that the equipment can get caught on.

In some cases it is necessary to install multiple float switches. Each device is fixed on a special rod made of plastic and installed inside the container. Floats must not only be installed, but also be properly adjusted and well placed on the structure. The accuracy of the work depends on this. The wires that come from the switch body are fixed using ordinary clamps. The number of sensors directly depends on the number of installed pumps.

Device design

Please write comments in the block below, ask questions, post photos on the topic of the article.

Heavy switches. Depending on where the unit is used, the functions of the float may differ.

The use of float sensors with a vertical rod arrangement is much more common than horizontal indicators.

They must be on different sides of the housing so that the ball between them can make contact. Such a breakdown occurs quite often, and not only on drainage equipment, the wire is soft and flexible, but not durable, it is very easy to break it accidentally, but it is also not difficult to repair. The switch is then connected to the pump, and the device can be used for its intended purpose.

See also: Method of measuring a phase zero loop

Operating principle of a float sensor

The float changes its position because there is air inside. The second label should correspond to the top one. It is necessary to provide the following pump operation algorithm.

If the water level has dropped, the float lowers, opening the valve and access to the water supply. The most common breakdowns of the unit include burnout of contacts in the electrical cable, damage to the insulating layer, violation of the seal of the housing and penetration of moisture into it.

As an intermediate relay P - Intermediate relay MY3, 3A ACB: Like 0 Dislike 0 Ask your question Answer the question Source: about water level sensors To regulate and control the level of liquid or solid sand or gravel in production, at home, use a special device . The brand is unknown and there is no way to find out. One will begin to fill the container when the float is in the lower position, and the second will start working when the switch is at the top. It is designed to regulate the liquid level in the container and protect the pump from dry running. Further work is as follows: First, wires with a cross-section of no more than 2 mm are soldered to the contacts; Next, the wires need to be insulated and placed in the housing; It is also necessary to carefully insulate the inside of the case; You will need to pour polyurethane foam into the float cavity and insulate the outer side of the housing; After this, you need to install loops at the ends of the case and connect the cord.

The wiring that is connected to the float switches is carried out using clamps. Installing a submersible pump with a float in a well Depending on the length of the wire from the load to the float, the values at which the pump turns on or off will change. How to choose a float level sensor for wastewater?

How does the switch work?

Despite the clear design, devices may differ in their method of operation:

- Device for water supply systems. This is the simplest and most common way to use the product. The principle of operation is simple: when the product is on the surface, the pump begins to pump water from the container. The sensor automatically sends an electrical signal to the water pumping equipment. The station switches off when the switch reaches the bottom.

- The principle of operation in the sewer system. The electric fecal pump is turned on when the main control device rises to the surface. The auxiliary equipment begins to function when the sensor sinks to the bottom. It is important to know that one such float is capable of working with two pumping devices at once. At the same time, this does not affect the quality in any way; performance remains at the same level. In addition, the two-pump design is highly efficient because there is no problem with fluid delivery.

Principle of operation

Depending on the operation scheme of the float switch, the operating principle of the device also changes.

Water supply system, filling and emptying the tank . When the float operates according to this scheme, at the moment of ascent it de-energizes the pump that supplies water to the tank. When the float is on the surface, it gives a signal to turn on the automatic water supply station. The station can only be turned off when the device is immersed to the bottom when the container is empty.

Sewage system . The fecal pumping equipment is switched on when the main control device is raised. The pumping unit turns on when it sinks to the bottom. One float is capable of servicing two pumps at the same time: the first can supply water to the container if the float is in its lower position, the second pump is inactive at this time. When the float is at the top, the second pump is turned on, pumping out water. During this time the feed pump is inactive. This scheme is quite effective, as it eliminates problems with the regular delivery of water when filling the container.

Correct operation and maintenance

Compliance with basic recommendations for use ensures a long service life of each device. The switch does not require maintenance only when it is placed in water supply systems. But when the product operates in the sewer, it must be inspected and cleaned at least once a month. To do this, use a strong jet of water, which will instantly remove any contaminants that have formed. This is an important step as it prevents the float from sticking. If the device breaks down, it is better to buy a new one or replace it at a service center. Carrying out repairs yourself without special equipment is prohibited. Because the seal of the housing is broken.

The device operates properly at temperatures of 0...60 degrees. There are some manufacturers that produce designs that can withstand up to 70°, which allows you to expand the scope of application of the switches.

The length of the cable is important because it determines where the product will be used. If a person buys a 2-meter version, then it is recommended to use it only in small tanks. For wells and some storage tanks, you should purchase products with a wire length of 5-6 meters.

Connecting and repairing a float for a pump

The fecal pumping equipment is switched on when the main control device is raised. As the amount of water in the tank decreases, the float will begin to fall, but until it takes the lower position and closes the NU contact, the pump will not turn on. Our response: Hello.

Inside the insulated cavity of the cable entry there is a polymer resin that protects against water ingress. Where to start doing your own repairs?

When the float is lowered in the storage tank, the contacts of the control circuit of the magnetic starter close. The most important thing to look for when choosing a unit is the insulation of the wire and the tightness of the plastic box.

The strip is attached to the handle through holes drilled in it with the appropriate screws. Hydrostatic sensors use the principle of measuring the pressure of a column of matter. If the float is used when working with dirty water and a large amount of solid fractions, then it, like the entire system, must be washed under running clean water. It is imperative to find out the characteristics of the material from which you plan to make the container. If the equipment is regularly rinsed with a stream of water, it will last much longer and will not lose its functionality even over time. Submersible pump repair. Replacing the cable.

Rating of the best budget floats

Energy TSY-5

A high-quality option that is designed for automatic control of the water level in various containers. The model will also help to monitor the correct operation of the pumping device and turn it off if there is no liquid. The design is practically no different from the standard options. Maximum current – 16 A. Protection class – IP68. The approximate service life with proper use is 10 years.

Sold at price: 440 rubles.

float switch Energy TSY-5

Advantages:

- Convenience;

- Doesn't take up much space;

- Efficiency;

- Durability;

- Dirt does not accumulate.

Flaws:

- Wire length – 2 meters.

WWQ FS

A universal device that can be installed for any purpose. The device has a durable plastic case and a long cable. The maximum load is 4 kW, while the rated current is 4 A. The tightness is at the highest level, so neither dust particles nor water will penetrate inside the product, which ensures high durability and trouble-free operation.

The average price is 440 rubles.

float switch WWQ FS

Advantages:

- Low cost;

- Durability;

- Durable housing;

- Easy installation.

Flaws:

- Not found.

KITLINE 11000

An excellent model that monitors the liquid level and allows you to turn off the pumping equipment in a timely manner. The weight of the structure is 100 grams, while the cable length is 3 meters, which is suitable for small tanks. Made from durable plastic that can withstand small mechanical loads.

The outer part is completely smooth, which eliminates the possibility of accumulation of solid elements. The weights are included and are installed in the standard way: using a special clamp. The dimensions of the device allow it to be placed in any container. The insulation is of high quality, no cracks were detected.

Sold at price: 580 rubles.

float switch KITLINE 11000

Advantages:

- Strength;

- Cable length – 3 meters;

- Smooth surface;

- Easy to clean;

- Excellent insulation.

Flaws:

- Not found.

Rating of switches of the middle valuable segment

WATTS IGD

A high-quality product from a German manufacturer that can function for ten years without requiring complex maintenance. Supplied in a plastic case that is well sealed and does not allow water and dust to pass through.

The maximum operating temperature is 60 degrees. Thanks to the high-quality material, the product can be used even when pumping gasoline, without the outer layer being destroyed.

The average price is 1,900 rubles.

float switch ]WATTS IGD

Advantages:

- Durable housing;

- Durability;

- Easy to use;

- Efficiency;

- Switching angle – 95o.

Flaws:

- Not found.

Marco AS2

A good product made in Italy, which has a high service life and reliability. The main advantage of the device is the ability to control a small water level (from 20 to 50 mm). This is not found in every design, which makes the product unique.

The body is smooth and has no irregularities, which allows it to be used in any system. The outer part is made of impact-resistant plastic, which is also a good solution. Operating current – 10 A.

Sold at price: 1,900 rubles.

float switch Marco AS2

Advantages:

- Efficiency;

- Durability;

- Appearance;

- Strength indicators;

- Able to monitor low water levels;

- Wide range of applications.

Flaws:

- Not found.

Wilo WA 65

A quality product with a 5 meter cable that is suitable for installation in a variety of tanks. The insulation is performed at a high level, which prevents accidental breakage and depressurization. The body is made of durable material that can function at 55-60 degrees. The kit includes a special weight.

The average price is 2,000 rubles.

float switch Wilo WA 65

Advantages:

- Length of cable;

- Universal application;

- Convenience;

- Easy to clean;

- Efficiency.

Flaws:

- Not found.

Rating of premium models

Grundfos GIFAS-FS-E

An expensive and high-quality device that is suitable for sewer and water supply systems. The device is capable of operating simultaneously with two pumps. The case is made of durable material that can withstand temperature changes. Operating voltage is standard.

The average price is 3,500 rubles.

float switch Grundfos GIFAS-FS-E

Advantages:

- Strength;

- Length of cable;

- Versatility;

- Easy to use.

Flaws:

- Not detected.

Pedrollo T80/10

A high-quality float switch that can function for a long period without deteriorating or becoming clogged. The design is standard, the product is a “frog float”. Electric switch. The body is connected to the sinker using a contact cable.

The average price is 3,600 rubles.

float switch Pedrollo T80/10

Advantages:

- Durability;

- Easy maintenance;

- External execution;

- Convenient weight;

- Versatility.

Flaws:

- Not found.

Wilo MS 1

An expensive product intended for professional use where precision is important. The body is made of polypropylene, which has good wear resistance and durability. The outer part is completely smooth, eliminating the chance of contamination. The insulating element is made of high quality.

Sold at price: 5,350 rubles.

float switch Wilo MS 1

Advantages:

- Efficiency;

- High service life;

- High-quality insulation;

- Cable length – 10 meters;

- Universal execution;

- 2-year warranty.

Flaws:

- Not found.