At home in the workshop, a press is simply necessary. Over the years, a large amount of used newspapers and papers accumulate. They take up a lot of space. The room is cluttered. The device for pressing waste paper is usually made with low power. It is compact, runs on mains power, and absorbs a minimum of electricity. Such equipment will become indispensable when compressing unnecessary waste paper, newspapers, and cardboard.

With this device you can easily reduce the size of a large pile of paper. This unit operates under pressure . With its help you can press not only paper, but also plastic bottles and tin cans.

Today, industry produces devices for pressing paper, cardboard, and cans of various types and capacities. Such a device is not cheap, so it is more profitable to make it at home with your own hands. You can install the equipment yourself using the materials needed for the job. This device will not take up much space. It is installed in a place convenient for work. A workshop, garage, or other premises are suitable for this. To press waste paper, a device is used that operates with a pressure force of 10 tons. When assembling, you should take into account the main characteristics of the press:

- dimensions;

- his weight;

- piston stroke;

- pressure gauge;

- bed dimensions.

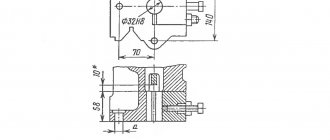

To pressurize the cylinder, manual or built-in hydraulic pump This directly depends on the type of equipment for assembling the press. The simplest and lightest design is a press mounted using a hydraulic jack. This device is shaped like a bottle. The design of which has a built-in hand pump.

Before starting work, you need to decide on the type of device. How hard should it work? Then we select a suitable type of jack for it. To correctly make a press with your own hands, you need to use drawings. They can be found on the websites. Each device is accompanied by detailed product drawings. They are calculated taking into account the materials and equipment used.

Features of use

Solid waste presses are versatile and are used for processing solid waste of almost any type. This could be, for example, waste paper, aluminum cans, plastic bottles, disposable tableware, textiles, etc.

The scope of use of such equipment is quite wide. Waste paper presses can be used:

- in regular supermarkets and self-service stores;

- on the territory of markets of different specializations;

- in office premises and warehouses;

- at industrial enterprises.

Equipment design

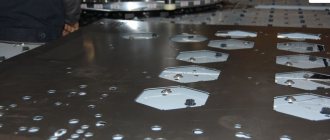

A cardboard press is a special hydraulic machine that turns waste into bales of standard sizes 70 x 50 x 60 cm. Subsequently, enterprises hand them over to companies involved in recycling recyclable materials, thus receiving additional income (provided they are sorted before pressing) .

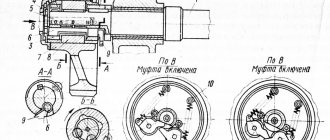

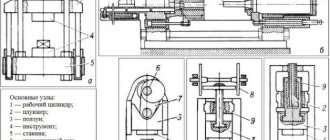

This type of machine is a large box for receiving waste with a piston-press descending from above. Also, the design elements of this type of equipment are:

- electric hydraulic pump;

- bed;

- pressure distributor;

- locking mechanism;

- magnetic switch;

- limit switch.

The functional part of such a machine consists of hydraulic cylinders and sliders. The press is controlled using a special handle. The pressure inside the device is monitored using a pressure gauge. Industrial installations of this type have a more complex design.

Types of cardboard presses

Machines of this type differ mainly only in power, average pressure mass, dimensions and productivity. In this regard, there are two main types of cardboard presses:

- mini installations;

- "standard" series;

- industrial models.

Mini presses for cardboard and paper are usually used in offices, shops, small industries, etc. Large industrial enterprises use presses of high power and productivity. Such equipment can process not only relatively soft materials such as cardboard or plastic, but also waste remaining after processing metal and wooden blanks. Models of the “standard” series have slightly higher productivity than the mini, but less than the pro.

Typical baller sizes

Generally, the model or name of the bale will refer to the bale volume that the model produces. For example, 60-inch balers produce a bale that is 60 inches (wide). Of course, height and depth are the other two measurements needed to determine the actual size in cubic yards or feet. A 30-inch baler would most likely produce a bale volume that was close to 0.50 cu. yards or 13.5 cu. ft. For example, bale volume 30H X 30W X 24D = 21,600 cubic meters. inches, which is about half a cubic meter. tiers.

Typical vertical balers can vary in bale size, producing up to 80 wide or even higher. So if some base sizes are used on a Baler of that size (eg 40H X 80W X 40D), bale sizes can go up to 2.7 cubic yards or higher . By multiplying the three measurements it is easy to calculate the actual bale size.

When considering bales, it is important to try to determine the size of the PP so that workers or users do not have to do too much prep before putting the material into the baler (such as bendable cardboard). Therefore, before deciding on the size of bales, it is important to evaluate the typical size of items in the overall waste stream to be baled, combined with the hopper door opening and available space.

Additional space must be allocated to not only remove the bales, but also any maintenance requirements that may be required (typically about one mortar from the wall on the back and sides of the BCP). Also the ceiling height is very important, since the movement of the cylinder requires additional height beyond the normal "resting height" of the device.

Some of the other typical PCB sizes are:

- 42 l;

- 48 l;

- 60 l;

- 72 l;

- 84 liter PP.

There are also special pressings, such as:

- bales;

- foam;

- film PP;

- with core;

- PP of metal-cutting machines.

Main technical characteristics

Models of the “standard” series have relatively small dimensions and an average pressure weight of 8-10 tons. The performance of such machines depends, among other things, on power. For example, using a 2-2.5 kW mini-installation allows you to produce 4-5 briquettes of standard sizes per hour. Industrial models can exert 30-40 tons of pressure on waste. Their productivity is much higher.

Mini waste compaction plants operate with a force of 2-9 tons. Their main distinguishing feature is their small size (from 2000x645x420 cm). This model can be installed, for example, in a small office or store. Any waste paper press works from the mains. Mini-installations are connected to a network of 220 V, industrial and “standard” - 380 V.

The main technical characteristics that you should pay attention to when purchasing equipment of this type are power, average pressure mass, productivity and dimensions. Of course, when choosing equipment of this type, it is worth looking at the manufacturer’s brand.

Preparing for assembly

When pressing any paper products, you will need to construct a powerful unit. Those who make a paper press with their own hands need to consider the following parameters:

- device dimensions;

- total weight;

- presence of a pressure gauge;

- piston stroke;

- the size of the bed.

Before you start working on your future creation, you need to learn how to design a waste paper press with your own hands and what you may need to make it correctly. Usually, the master has everything he needs at hand and only needs to purchase a minimum set of items. To work you will need:

- ordinary jack;

- several springs;

- control elements;

- frame for the bed;

- metal pipe;

- wires through which current will flow.

Technical characteristics of the machine PGP-15M

Next, as an example, we will consider what parameters the popular domestic press for cardboard PGP-15M has. The main technical characteristics of this model are shown in the table below.

| Parameter | Meaning |

| Average pressure mass | 15 tons |

| Dimensions | 300x150x90 cm |

| Weight | 900 kg |

| Bale size | 900x1000x750 mm |

| Number of binding threads | 3 |

Classification by loading method

Depending on the loading method, press models can be horizontal or vertical.

Horizontal

Horizontal loading is typical for powerful stationary devices with a continuous operating cycle. The market offers small horizontal waste paper presses with hydraulic drive and low productivity. Such devices are suitable for small businesses, institutions and retail outlets.

The small press is easy to use and only needs one person to operate it. The cost of the device is 60,000 rubles.

Vertical

Small and standard presses, mainly with a vertical loading method. In terms of characteristics, such units are more powerful. They are used to press waste paper, plastic and metal up to 1.5 mm thick.

One person can operate a vertical cardboard press. The price of the press is 70,000 rubles.

Principle of operation

Recycling waste using equipment such as a hydraulic cardboard press is extremely simple. This procedure looks like this:

- the collected waste is placed in a chamber box;

- the machine is connected to the network;

- the press lowers onto the waste and presses on it with a certain force;

- as a result, a bale is formed;

- the resulting bale is tied with threads and unloaded from the container.

Waste can be loaded into the chamber several times during the pressing process.

Cardboard press: equipment price

The cost of this type of equipment directly depends on its technical characteristics. Mini-installations designed for waste processing are estimated at approximately 75-112 thousand rubles. The price for “standard” series presses is about 92-150 thousand rubles. For professional equipment of this type you will have to pay about 140-400 thousand rubles. In addition to new waste presses, used models are also sold on the modern domestic market, the cost of which depends not only on the technical characteristics, but also on the condition of the components and mechanisms. But, of course, the price of such equipment will be lower in any case.

Mechanical models

In addition to this type of hydraulic equipment, mechanical presses can be used to process waste. The advantage of such equipment is that it can be installed even outdoors. Such machines are small in size and weight (within 100-150 kg). Very often, mechanical units are installed in the bodies of cars that collect recyclable materials.

Mechanical presses operate on the principle of conventional screw pressure. The force in them can range from 4 to 32 tons.

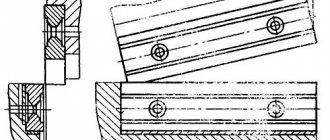

Types of press designs

Then calculations of the bed parameters are made. This is a frame inside which a jack is installed. It produces pressing movements on the waste paper. The frame is made of thick metal. Its strength should be sufficient to withstand the pressing movement of the jack. Thick metal is used to make the frame. When moving, the press presses up and down on the frame, as if it is trying to tear it apart .

The base of the frame must also be strong. It becomes sustainable. The frame, made in the form of a platform, has good stability. The width of the frame must be calculated based on the size of the jack. It must exceed the dimensions of the equipment installed on it for pressing waste paper. The height of the product is determined depending on the size of the jack. During operation, its free movement must be ensured. When determining the height of the structure, the thickness of the working surface of the table is taken into account. It is movable and is used to process objects.

Depending on the design and operating mode, the jack is attached to the base . The top of the frame will be a stop for the parts. The force from the movement of the rod is transmitted through the work table and then to the object being processed. The work table is mounted above the jack on the bed. It should move up and down freely.

Benefits of use

It is worth installing a cardboard press in a store, warehouse or office space, if only because in this case you can:

- Save on waste removal. Recycling costs are usually much less than the cost of transporting recyclables to a disposal site. To store a ton of compressed waste, only 1.5-3 m2 of space is needed.

- Free up part of the production space. Bales take up much less space than solid waste itself.

Bales can be stored indoors, according to regulations, for an unlimited time. The standard sizes of bales allow them to be transported with maximum convenience both by rail and by car. The press is extremely simple to operate and does not require the operator to have any special knowledge or skills. This type of equipment can be operated by one person.

Waste classification

Let's see what common weights and measures are taken in waste treatment:

- 1 cube of space consists of 46,656 cubic meters. inches;

- 1 cu. a yard is equal to 27 cubic meters. feet;

- 1 bale (measured in cubic kernels) = LXWXH (in inches) divided by 46,656;

- 1 Bale (measured in cubic Ft) = LXWXH (in inches) divided by 46,656 X 27;

- 1 bale measuring 36L X 36W X 36H equals 1 cubic yard.

Lost balance sheets

Typical bulk densities and other characteristics of waste streams vary from industry to industry and from location to location within an industry. It makes sense that waste streams or waste profiles with the highest air content benefit the most from compaction. Since debris profiles can vary significantly within the same industry (and even within the same market segment), the strength of compaction or benefits derived from Balers will also vary accordingly.

Unallocated or non-compact

Bulk or oil-free materials require a huge amount of space compared to a dump. One of the main benefits of baling as much recycling waste (such as bulky cardboard) as possible is that materials are removed from the waste stream. Even when there is no recycling program, this can significantly reduce waste transportation requirements since even small amounts of packaged waste are likely to be loaded free of charge by the recycler.