We will advise you on any questions!

Have a question?

Our services

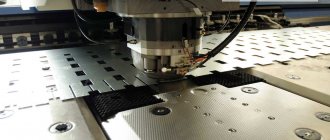

Cold forging (CF) is considered the most advanced metal forming technology. Its skillful use makes it possible to obtain products of various shapes and sizes. What is important is that products made using this technology are distinguished by the accuracy of their geometric parameters and the high quality of the formed surface, and therefore do not require additional modification. The cold stamping process is easy to automate, which allows it to produce products with high productivity.

Subtleties of technology

Stamping, or stamping, as this technological operation is often called, is a process in which a metal workpiece undergoes plastic deformation under pressure. As a result of such an impact, for which special equipment is used, a finished product of the required size and shape is formed from the workpiece. Deformation of a metal workpiece can be carried out with its preheating, then this process is called hot stamping. If there is no preliminary thermal effect on the workpiece, then cold stamping of the metal is performed.

Classification of basic stamping operations

We will advise you on any questions!

Have a question?

Our services

When performing cold metal stamping, special technological equipment is used. In this case, the metal from which the workpiece is made is subjected to additional hardening. Meanwhile, when cold stamping of metal is performed, its ductility deteriorates. Increasing the strength of the workpiece during cold stamping leads to an increase in the fragility of the metal, which is a rather negative factor. To avoid this, between the technological operations that comprise cold stamping of parts, the workpiece is heat treated—recrystallization annealing. In finished products that were subjected to such heat treatment during the production process, the parameters of strength and ductility are optimally combined.

Types of cold stamping

In order to change the original geometric parameters of a metal sheet in several directions, cold die stamping is used. In order not to increase the resistance of the metal and, accordingly, not to reduce its fluidity, such a technological operation is performed at a temperature that does not exceed forging.

Using this technology, which requires the use of special equipment, products are manufactured with increased precision, without such defects as hot cracks, scratches, burrs and risks, areas subject to metal shrinkage. However, due to the fact that the stamping press used to perform volumetric stamping is forced to overcome the enormous resistance of unheated metal, it is problematic to obtain parts of complex configurations with its help. In such cases, it is better to use hot rather than cold stamping.

Another type of metal forming, during which the workpieces are not preheated, is cold sheet stamping. When performing processing using this method, the workpiece can be a sheet, tape or strip made of metal. The thickness of the walls of the workpiece when using this technology practically does not change, and spatial products can only be obtained from ductile metals.

Tools and equipment

Main types of forging and stamping equipment:

- Shears – long, combined (for cutting various rolled profiles) or sheet. They use the principle of the well-known guillotine, when, due to the difference in the angle of inclination of the movable knife, metal is sequentially separated. The actuator mechanism of the scissors is of the crank type.

- Steam-air, pneumatic and hydraulic stamping hammers, in which the energy carrier is steam, compressed air or high-pressure liquid, respectively. They are impact equipment; they deform the metal not by pressing force, but by the energy acting on the forging.

- Crank presses, divided into equipment for hot stamping (HSE), universal presses for sheet stamping and hydraulic presses. The change in shape occurs due to the force developed by the actuator.

- Rotary machines, the tools of which perform a rotational movement - rollers, disc shears. This type of equipment deforms metal using torque.

- Screw machines with mechanical, electromechanical or hydromechanical drive. Their energy characteristics are intermediate between presses and hammers.

- Hydro- and gasostats are machines that develop extremely high static pressures, which are sufficient to compact metal powders.

Stamping technology involves the use of specialized tools - stamps. They are distinguished:

- By number of positions: single- and multi-position;

- Time of execution of stamping transitions: dies of sequential, combined and series-parallel action;

- By relative location; into vertical and horizontal;

- Design of guides and fixing units;

- According to the degree of accuracy - ordinary or precision.

Dies of automatic presses are usually called a set of deforming tools. For some types of stamping (for example, for explosive or electromagnetic forming), there are no stamps as a tool.

Modern die designs must include units for feeding, removing or moving the workpieces being processed.

Stages of stamp manufacturing

A major role in ensuring the required quality of the finished product is played by the design of dies for cold stamping, due to which the part is formed with the required geometric parameters. Working drawings of such working tools installed on stamping presses can be made in both two- and three-dimensional formats. To solve this problem, appropriate knowledge and skills are required.

The development of a drawing and the subsequent production of a stamp used for cold stamping are carried out in several stages:

- drawing up a sketch of the future stamp;

- studying the scheme according to which the material will be cut, checking such a scheme using a special computer program;

- editing the sketch, if necessary;

- final verification of the dimensions of the developed stamp;

- designation of the position and exact dimensions of the holes that will be made on the working surface of the stamp.

When developing dies, you often have to choose between the quality of the future part and the cost of production.

When developing dies for cold stamping, it is necessary to break the drawing of the finished product into separate parts and carefully study them. After this procedure is completed, the production of stamps is carried out. In this case, it is necessary to pay special attention to the requirements for the parameters of the finished product. For each stage of the cold stamping technological process, a route map is developed, which takes into account both the execution time of individual operations and the characteristics of forgings at individual processing stages.

Most dies are made of carbon or alloy steel, but aluminum and copper alloys are sometimes used

In such a matter as cold stamping of a metal workpiece, many parameters are important, which, in particular, include the sequence of technological operations, the distribution of material in the cavity of the working tool, the equipment used and processing modes.

The process of manufacturing dies for cold stamping also imposes serious requirements, since the quality of the formed product depends on the accuracy of this tool.

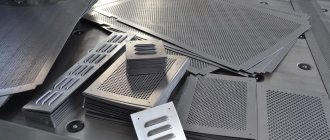

Stamping of parts, in which sheet metal is used as a workpiece, can include a whole list of mechanical operations. Such operations include, but are not limited to, cutting, punching, extruding, bending, cold heading, forming, crimping and drawing. In this case, cutting, punching and a number of other technological operations are classified as separation operations, and cold heading, molding, bending, etc. are classified as shape-changing operations.

Types of Sheet Forming Separation Operations

Types of sheet metal forming operations

Types of stamping technologies

The initial assortment for deformation is always rolled products. sheets, strips, tapes, rods, wire. Profile products are also often used - angles, channels, sometimes even I-beams. Ingots are not used, firstly, due to the smaller dimensions of the final product compared to forging. secondly, due to the low initial accuracy of this type of workpiece.

The classification of stamping technological processes can be carried out on the following principles:

- According to the nature of the flow of the deformed metal. There are separation and shape-changing processes;

- Based on the relative movement of the workpiece and the tool, a distinction is made between stamping of metal that is stationary during the operation, and stamping on machining centers, when during each working stroke the workpiece moves according to a certain program;

- According to processing temperature. Stamping can be hot, semi-hot (warm) or cold. The division criteria are the same as for forging: a stamping operation is considered cold if the temperature of deformation of the workpiece at which does not exceed 25% of the melting temperature of the metal. In this case, semi-hot deformation will be one in which the temperature of the workpiece does not reach the values necessary for the onset of irreversible processes of microstructural restructuring;

- According to the geometric relationships of the cross section, stamping can be sheet or volumetric. In particular, sheet stamping includes all pressure processing operations performed with metal, one of the dimensions of which (most often the height/thickness of the rolled product) is much smaller than the other two - length and width;

- Based on the nature of the movement of the moving parts of the stamp, stamping is performed with a tool that moves back and forth or rotates. In the latter case, a further distinction is made between continuous or cyclic processes. A stamping operation is considered continuous when the entire workpiece is first subjected to deformation and then cut into several finished parts/semi-finished products. During cyclic stamping, only piece workpieces are always subject to processing;

- Depending on the number of transitions, stamping can be single- or multi-position. To achieve proper productivity in the latter case, the die design provides for appropriate means of mechanization or automation;

- According to the type of forging and stamping equipment used, which can be conventional, with automation of individual operations (forging and stamping machines) or automatic (complexes or automatic production lines).

Specialized metal stamping has its own gradation of operations, which is determined by the design of the executive components of the equipment and tools.

Sheet metal stamping

Sheet stamping transitions can be dividing or form-changing. Separation operations include:

- Cutting – complete separation of parts of the workpiece along an open contour;

- Notching – incomplete separation of parts of the workpiece along an open contour;

- Trimming – separating a part from waste;

- Cutting is the separation of a part of metal from the main workpiece, while the resulting product is a part;

- Punching is the separation of part of the metal from the main workpiece, while the resulting product is waste;

- Cutting is the separation of adjacent parts of a workpiece.

Due to the specific design of the die, several transitions in one working stroke can be combined, for example, this happens during punching, punching, cutting, etc.

Nomenclature of forming operations:

- It is flexible when the axis of the workpiece or part of it changes. In turn, bending is divided into V-shaped and U-shaped;

- Drawing, in which a spatial product is formed from a flat workpiece;

- Molding, which is the drawing of part of the original workpiece. Variations of this operation are considered to be relief molding and embossing, as a result of which local extrusions or depressions are obtained on a flat surface;

- Flanging, which consists in local expansion of one of the circular sections. Performed in relation to tubular semi-finished products. The same operation that is performed with workpieces of non-circular cross-section is called dispensing;

- Crimping is a transition opposite to distribution;

- Rolling is a forming performed by a tool that moves not reciprocatingly, but rotationally.

Some of the molding transitions can be performed in one working stroke of the equipment.

Volumetric

The main operations of cold die forging are upsetting and extrusion. The difference between them is that for extrusion they use a piece blank, usually obtained from a rod. Planting is carried out from wire using automated equipment - cold heading and rolling machines.

Extrusion (the terms pressing or extrusion are less commonly used) can be direct, reverse or combined. With direct extrusion, the direction of metal flow coincides with the movement of the deforming tool. Accordingly, during reverse extrusion, it is opposite to the movement of the moving part of the stamp. Combined extrusion is also often implemented.

Upsetting or extrusion are direct competitors of metal processing operations on machine tools. They significantly exceed the capabilities of mechanical processing in terms of productivity and quality of finished products. In particular, using technological hardening of the metal, achieved by creating a favorable microstructure, a significantly higher durability of finished products is ensured. A limitation is considered to be the high specific energy intensity of cold die forging operations, so it should be provided primarily for conditions of serial and mass production of products.

The operation of stamping bulk products, performed in a cold state, also involves rolling threads and profiles.

hot

During hot die forging, the same transitions are used as during forging, for example, upsetting, piercing, flattening, etc., which, however, are carried out in dies. In many cases, the nature of metal forming is similar to the corresponding transitions of cold stamping. For example, this can be said about cutting, upsetting, extruding, flanging, rolling.

Separately distinguished are hot sheet stamping operations performed with thick sheet or rolled profiles of significant cross sections. To do this, the workpieces are heated in a furnace to temperatures 100...1500C lower than the temperature at which structural transformations begin in the material. The temperature range of hot sheet stamping is selected from the condition of minimizing the resulting scale, the presence of which will lead to a decrease in the durability of the dies. After heating, the vast majority of the plastic deformation transitions discussed above can be performed with the workpiece.

The terminology of the main stamping transitions is set out in GOST 18970-84.

Cold

The main positive features of cold stamping:

- The presence of strain hardening of the metal, as a result of which cheaper low-carbon steel with lower initial strength values can be used for processing;

- Increased dimensional accuracy. It is believed that the surface quality of the finished part is only 1 class lower than the accuracy class of the deforming tool;

- High productivity tens of times higher than the corresponding indicators of metal-cutting equipment, including automatic machines.

At the same time, the increased complexity of design, production and operation of stamping tools, as well as its non-versatility, limit the use of stamping processes only to mass production of similar products, for example, in the automotive industry, hardware production, and the production of radio-electronic and electrical products.

Characteristics of sheet stamping

Cold sheet stamping is today one of the most widespread technologies for processing metals, plastics and some other materials. The range of application of the technology is from large structures in shipbuilding to thin-walled parts of household appliances

The technology is characterized by the following undeniable advantages:

- Exceptional opportunities for mechanization and automation of production processes.

- Reducing the cost of manufacturing mass products.

- High utilization rate of sheet metal.

- The ability to accurately manufacture thin-walled but durable products of almost any shape.

- Minimal need for subsequent machining.

However, in addition to obvious advantages, cold sheet metal stamping also has disadvantages. This is, first of all:

- High complexity of technological process design.

- High cost of preparation for production of molds.

- Highly qualified press equipment debuggers.

It should be noted that with large series of manufactured products, these disadvantages are leveled out due to the economies of scale known from economics, and the cost of manufactured products turns out to be lower than with alternative methods of metal processing.

Hot metal stamping

The peculiarity of the method is the deformation of the workpiece after heating it to a certain temperature. Form formation occurs as a result of forced redistribution of heated metal along the recesses of the inner surface of the die.

Features of hot stamping

The process is based on the use of metal plasticity, which increases when heated. Before forming, the blanks are evenly heated in special automatic control units. They ensure maintenance of the required temperature throughout the entire volume of workpieces and eliminate the formation of oxide films.

Equipment used for heat treatment:

- Electrical contact installations. Heating is carried out by electric current passing through the workpiece.

- Induction systems. The heating of the blank occurs due to eddy currents arising in the surface layer of the blank.

- Gas ovens. The temperature of the workpieces increases in an insulated chamber filled with inert gas.

Hot metal stamping is carried out by trained personnel with practical skills and experience in this type of production.

This method produces two types of parts:

- Elongated. These can be: levers, shafts, knobs and others. The work is carried out flat and ends with shaping in blank forging rolls.

- Disk. These include: rings, discs, gears, covers. In this case, the method of upsetting to the end of the workpiece using stamping transitions is used.

Closed method

To obtain products of the required shape, presses with a protrusion at the top and voids at the bottom are used. There is a minimum gap between the fixed and moving parts. The connector cavities are located at an angle of 90° relative to each other. The method is used in cases where the dimensions of the finished product and the forging match the parameters.

Open way

In this case, there is a larger gap between the working parts to allow excess metal to drain. Trimming and punching dies and crank presses are used to remove flash. The technology can be used for stamping products of any size. A flawless surface, a uniform structure and metal savings are the advantages of the open method.

Stamping streams

The creation of complex shapes with differences in thickness and height, protrusions and bends is carried out thanks to surfaces that have special depressions, blanking and stamping grooves.

They come in several types:

- Drawing. They are used to increase the length of individual sections by applying frequent blows while simultaneously turning the part.

- Procurement. Necessary for shaping the workpiece and giving the finished product a shape with minimal metal waste.

- Pinch. They are used to reduce the height while simultaneously increasing the width of a separate section of the workpiece.

- Roll-on. They ensure uniform distribution of metal along the axis of the workpiece with an increase in the diameter of individual parts.

- Bending. They are used to form forgings with a bending angle of 90°.

The final necessary shaping of the part occurs in the stamping strands. They are:

- Rough ones. To bring the dimensions of the workpiece closer to the required dimensions of the part and reduce wear on the finishing groove.

- Finishing. They are installed in the middle of the die, and are used for final molding of products. During its manufacture, allowances for shrinkage are taken into account. The extruded metal flows out through the cladding groove.

Additional operations

At the final stage, after removing excess material in the finishing stream, the shape of the part is corrected. This is required to correct its curved axes. Products made of alloy steels and large sizes are processed in a hot state. Small caliber products are adjusted after heat treatment and cooling.

The physical properties are brought to the required values during the final heating. Heat treatment relieves residual stress, reduces grain size and increases ductility.

Cleaning from scale is carried out by mechanical processing. The procedure for large products takes place in shot blasting complexes. Small parts are cleaned in tumbling drums.

Product calibration is used to reduce roughness and obtain accurate dimensions. After this, there is no need to carry out finishing processing; it is enough to sand the resulting parts. For the work, special dies with particularly precise grooves that repeat the configuration of the forging are used.

Advantages and disadvantages of hot stamping

Advantages:

- Saving metal by reducing losses.

- Possibility of manufacturing parts of complex shapes.

- Reduced labor intensity.

- Obtaining products of precise shape and configuration.

- High level of productivity.

The disadvantages of the method include:

- High cost of design and manufacturing of equipment.

- Complexity and energy intensity of the process.

- The maximum weight does not exceed 4 tons.

The hot method is used to produce large series and in cases where the complexity of the shapes and thickness of the products does not allow cold stamping.

Types of sheet metal stamping equipment

A wide range of equipment is used for different types of sheet metal stamping operations.

Thus, vibration or guillotine shears are used for cutting operations.

To perform forming operations, the main stamping equipment is used - a sheet stamping machine or a press. By type they differ in:

- Crank-rod.

- Hydraulic.

- Radial forging.

- electromagnetic.

The simplest to set up and maintain is a press with a crank drive. It is suitable for simple sheet stamping—thin-walled, small and medium-sized parts of simple shape.

Press with crank drive

Hydraulic presses allow you to develop much greater force (up to 2 thousand tons) and more accurately regulate the press stroke. This type of equipment is used for bending or die stamping operations from thick sheets.

Radial forging complexes are used for sheet stamping of parts having the shape of a body of rotation.

Electromagnetic presses are a fairly new type of equipment. The pressure on the workpiece is produced by the mass of the electromagnetic core, directed to the punch by an electromagnetic pulse. A pulse of opposite polarity returns the core to its original position. Such a drive is much simpler to manufacture and maintain than a hydraulic one, but does not yet reach its power.

Classification of equipment for stamping metal products

In the most general case, it is a press machine with a certain type of drive (about which below), as well as various characteristics of strength, productivity, number of operations performed, maximum size of processed objects, and so on.

The choice must be made depending on the characteristics of production and on what kind of final product should be obtained: taking into account that relatively soft materials do not require significant power, that high speed is required for serial production, and other nuances of a particular case.

It is simply necessary that the machine model complies with the recommendations of current interstate standards. In addition to the operating parameters of equipment for sheet metal stamping, GOSTs also determine consumption, labor safety standards, design rules and other related issues.

Crank presses

The principle of operation of the equipment is based on the conversion of torque by a crank mechanism into reciprocating movement of the slider.

Such equipment is classified as simple type mechanisms. They can be double or triple acting.

Hydraulic presses

The most powerful equipment, capable of developing a force of up to 2 thousand tons. The operating principle is based on the movement of two hydraulic cylinders of different diameters. The magnitude of the difference in size determines the degree of impact on the surface. The liquid is driven by special electrically driven pumps.

Radial forging presses

They are a molding press for the production of cylindrical parts. The machine is equipped with an induction furnace for preheating the ingots.

The equipment is used to produce forgings of square, round or rectangular cross-section.

Electromagnetic presses

A product of modern technology. The driving force is the energy of the electromagnetic field, which presses on the core with the wire winding. During the movement, it affects the executive part of the machine.

Principle of operation

The physical principle of operation of stamping equipment is the plastic deformation of a sheet blank under pressure. The shape of the future part is determined by two parts - a matrix and a punch, which are pressed against the sheet blank from both sides under great pressure. Where there is a convexity at the matrix, the punch has a depression corresponding to it in shape and size. When deformed, the sheet blank repeats the shape of the matrix and punch.

Along with this, holes can be drilled and individual parts can be cut out of the sheet material. When designing a technological process for cold stamping of sheet metal parts, the tooling designer and technologist combine and, if possible, combine form-changing separation operations in order to make do with a minimum number of workers passing the die and thus reduce the cost of manufacturing the product.

In the case of thin sheets, cold sheet stamping is carried out. When working with thick sheets or low-ductility alloys, the workpiece is preheated to increase its ductility.

History of the process

Mechanization of the process began in the 1850s. Then machines began to be connected to the metal stamping process, which significantly speeded up the production process and improved the quality of products.

And in the 19th century there was a new upsurge in the production of metal parts by stamping, which gave rise to the era of automobile manufacturing. Using this method, car bodies and some mechanical parts began to be created.

Car parts

Since the 1930s stamping of sheet metal parts began to be used in factories for the production of aircraft and ships. And after 20 years it was introduced into the rocket science industry.

The metal stamping method has become popular due to a number of reasons:

- the production process is mechanized and automated using rotary conveyor lines, which makes it possible to speed up production as much as possible;

- it is possible to manufacture parts of any shape and parameters, which can be either a blank or a finished product;

- there is a high precision of manufactured parts, allowing them to be replaced with each other without modification with tools or equipment;

- It is possible to produce lightweight, high-strength products.

Stamping of metal parts is used for massive products that are used as blanks in the construction of cars, ships, aircraft, and for small lightweight parts like clock hands. Stamping owes its popularity to the high speed of production of such products and the almost limitless possibilities for producing non-separable parts of any size, which is so important in the construction of ships and trains.

Let's consider how some separation operations are carried out.

cutting

When cutting, a certain part is separated from a part by cutting it along a curly or straight line. This separation operation is performed using a press made in the form of scissors of different designs.

This operation is intended mainly to prepare the workpiece for other processing methods.

Punching

An operation called punching is used to create holes of different shapes in a workpiece. During punching, part of the metal is completely removed from the workpiece, and its weight decreases.

The figure shows a diagram of the punching process.

Felling

Using the process of cutting out a metal part, a finished product has a closed contour.

The figure shows a diagram for manufacturing a part using cutting.

2. Form-forming deformations include changes in the shape and size of a product when its individual areas are moved, without leading to its general destruction. These include drawing, bending, relief molding, twisting, crimping and other operations.

Let's consider some types of operations that do not lead to physical destruction of the form.

Hood

Using drawing, hollow volumetric products are obtained from flat sheet blanks. For example, in this way parts are made in the shape of a hemisphere, cylinder, cone, cube and other types. The figure shows different hood options.

Bending

Using the bending operation, a sheet product is given a given bending shape. Depending on the type of bending, this operation makes it possible to obtain curved products of different configurations. Some of them are shown in the figure.

Relief molding

This type of operation involves modification of local parts of the product, its external configuration remains unchanged. The figure shows diagrams of some molding operations:

It is also possible to use combined operations, including separation and shaping of one part.

The technological process of cold stamping consists of stages that are associated with the nature of the deformation operation and depend on the type of stamping equipment used.

The development of the technical process is carried out in the following sequence:

- The structure of the main operations is indicated, including their nature, quantity and sequence of execution.

- The initial, intermediate and finished dimensions of the part are calculated, as well as the necessary deformation forces to achieve the desired result.

- Documentation of the technological process is carried out.

Additional operations can be introduced into the technical process, with the help of which the workpiece is brought to a form convenient for processing. These include cleaning, straightening sheets, applying lubricants and other operations.

After stamping, the product can be subjected to a number of auxiliary operations, which include annealing and etching. With the help of such operations, the required mechanical characteristics are given to the finished product. To increase the wear resistance of products obtained by cold stamping, various protective coatings are applied to their surface.

If a sheet metal workpiece needs to be subjected to volumetric stamping, then such an operation can be performed according to two technological schemes.

The first of them consists of three operations:

- preliminary heat treatment of the workpiece (this is necessary in order to reduce the strength of the metal);

- preparing the workpiece surface for stamping;

- directly from the stamping itself.

When performing cold stamping according to the second technological scheme, one more stage is added to the three above stages - preliminary preparation of dimensional blanks, from which finished products will be formed.

Equipment

Sheet metal stamping is done using a press and a stamp. The press is used to create pressure, that is, the stamping process itself, and the stamp gives the product the desired shape. The stamp is made of tool steel and consists of a punch and a matrix.

The deformation process occurs with the help of a punch and a matrix at the moment of their approach. The movable part is the upper half of the stamp, fixed on the press, namely on its slider.

The lower half remains motionless and is located on the working surface of the equipment. If it is not steel that is being stamped, but the material is soft, then the working parts of the stamp can be made of polymer alloys or wood.

When producing a single, particularly large-sized product by stamping, it is usually not a press that is used, but a special device made of a cast iron or concrete matrix and a container with liquid (usually water). A sheet of metal is placed on the matrix, and above it is a liquid punch.

Concrete matrix fixture

To create the pressure in the liquid necessary to deform the metal into the desired shape, a gunpowder-based charge is detonated in the container or an electric discharge of sufficient power is provided to the water.

For cutting sheet metal, scissors, rather than a press, are used. They come in several types:

- with parallel knives;

- disk;

- guillotine;

- vibration.

Vibrating type scissors are most often used.

For high-quality manufacturing of products, you need to carefully select a press for each type of operation and material being processed. There are several types of presses:

- Hammer (maximum speed up to 20 m/s).

- Hydraulic press (maximum speed up to 0.3 m/s);

- Crank machine (maximum speed up to 0.5 m/s);

- Rotary type machine (maximum speed 8 m/s);

- Pulse stamping machine (maximum speed up to 300 m/s).

Crank machines are suitable for most types of operations. They can have from one to four crank mechanisms. The operating principle of the crank mechanism can be described according to the following diagram:

- The drive electric motor transmits motion to the crank shaft through a kinematic chain, which consists of a friction clutch and a V-belt drive.

- An adjustable length connecting rod drives the crank slider.

- The foot pedal through the clutch starts the working stroke of the press.

Equipment for stamping products with complex configurations may have several sliders.