Laser welding is fusion welding in which the energy source is a laser. The main feature is the high concentration of energy. This type of welding is used to join similar and dissimilar metals.

Laser radiation is focused using guide mirrors. The converted reduced beam of energy heats and melts the parts being welded.

The following types of laser welding are distinguished:

- microwelding – melts parts no thicker than 100 microns;

- mini-welding – used at a depth of 0.1 to 1 mm;

- macro welding – works with thicknesses over 1 mm.

Technical feature

Laser welding arose according to the developments of N.G. Basov, H. Towns, A.M. Prokhorov.

Specialists managed to obtain pulsed and continuous action devices. Their advantages include an increased concentration of the energy beam. The melting process is carried out at high power, which makes it possible to process dissimilar metals up to several centimeters thick.

Technical features:

- high melting rate;

- saving properties and geometry;

- minimum residual stress indicator;

- no need for filler materials or special chambers with a protected environment.

The precision of laser welding makes it possible to process products of complex configurations.

These nuances make this type of welding one of the most advanced in modern enterprises. The disadvantages include the cost of installation; for some manufacturers the purchase is unprofitable.

Fixed standards

In 2022, the following state standards that impose requirements for laser welding will be in effect:

- GOST ISO 15609-4-2017 – contains technical requirements for the certification of welding procedures for metallic materials. Part 4 of this document covers laser welding;

- GOST 28915-91 - describes the main types of laser pulse welding, structural elements and dimensions.

Classification by characteristics

By energy

Laser welding methods are classified according to several criteria. The varieties differ in technical characteristics and economic aspects. These features are taken into account when choosing a specific installation.

Each type differs in power density. The process is carried out at E=1-10 MW/cm2. If you reduce this indicator, then another type of welding will be more economically suitable, one of which is electric arc. Three main modes are used, which differ in several parameters:

- t>10-2 s, E=1-10 MW/cm2 . This mode involves the use of continuous lasers. It is suitable for machining structural steels.

- t<10-3 s, E=1-10 MW/cm2 . This type uses pulse-periodic installations. The combination of high power and process duration acts on metals with less energy consumption compared to the previous type.

- t=10-3 -10-2 s, E=1-10 MW/cm2 . The mode also uses a pulse-periodic installation; it is suitable for processing material of small thickness.

The workspace layout includes several important elements. The laser beam exits the nozzle, the filler wire provides strength to the weld, and the shielding gas resists adverse environmental conditions.

A rational method is selected according to specific conditions, which will allow obtaining the desired result with minimal economic costs.

Important! Laser welding modes for structural steels are selected individually; this directly depends on the specific conditions and tasks assigned.

According to economic

The first economic aspect is the welding speed. It regulates performance. Continuous laser systems are used at speeds that are 15 times more intense than simple types of welding.

The next economic factor is reducing metal costs. For example, processing of a part with a thickness of 30 mm is carried out in 1 pass without preparatory measures and the use of additives. Manual welding requires a couple of passes.

A concentrated laser beam with local action is the last factor. Thanks to this action, it is possible to obtain welded fastening in areas with a small area and difficult to reach places.

According to technological

According to the first, laser welding is divided into a method of small thicknesses and deep processing.

The latter type, as a rule, is used without additives, although to improve the degree of penetration and improve the quality of weldability, filler material is supplied to the affected zone. Deep penetration is carried out in a protected environment .

Objects of minor thickness are welded using continuous and pulse-periodic installations. The former have proven themselves well in seam welding, and the latter - for spot welding.

It is not necessary to use additives and special media, since they do not have much effect on the penetration of small thicknesses. The treatment is carried out in a gas environment if it is necessary to reduce the likelihood of oxidation of the seams.

Design and types of equipment used

The structure of the unit depends on the type of emitter included in its composition.

Solid state devices

The design includes elements made of ruby and neodymium-doped glass. They are activated by the luminous flux emitted by powerful arc lamps. The units operate in constant radiation mode. They are characterized by high frequency, low power and efficiency. Solid-state machines are used for welding small-sized parts.

Gas welding devices

Such units are suitable for welding thick workpieces made of steel and other metals. Radiation generated in a gas environment is characterized by high power. The installation is capable of connecting parts up to 2 cm thick. It has a fairly high efficiency. The operation of the device is complicated due to the introduction of a fragile glass tube into the design.

Hybrid installations

Such devices were created for joining metal workpieces of large thickness. Together with the laser head, the device circuit includes an electric arc torch. Additionally, a feeding mechanism is installed that removes consumables into the weld pool.

Manual models

Small devices operate on the principle of standard units. The need to use compact parts when assembling makes the devices expensive. They are used to create miniature metal structures and solder microcircuits.

Application area

The greatest welding efficiency is observed in products with a thickness of up to 10 mm . The method is not widely used for economic reasons, since the cost of installation and additional equipment is high.

This processing is used in cases where other types of welding cannot be used and precise preservation of the structure of the part is required after all manipulations. The concentrated impact of the energy beam guarantees minimal changes in the properties and geometry of the product. This is an excellent solution for joining difficult-to-weld metals, without the need for additives, vacuum chambers and other additional elements.

Types of welding

Laser welding comes in two types:

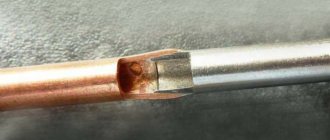

- Butt joint - in this case additives and flux are not used. A minimum joint between metals is allowed, no more than 0.2 mm. The same value is the maximum for focusing the laser beam on the joint. Welding is carried out by means of “dagger” penetration of the metal over the entire thickness with a laser radiation intensity of up to 1 mW/cm2. In this case, the seam must be protected from oxidation by argon or nitrogen, and helium will protect it from breakdown of laser radiation;

- Lap - metal sheets are superimposed on each other, they are connected through powerful radiation. Welding is carried out with local clamping of parts. The maximum permissible gap between metal surfaces during operation is 0.2 mm. If it is necessary to improve the quality of the parts being joined, a double seam is used.

Technology

The essence of the method is to direct the laser beam to a focus, where the beam cross-section decreases. When concentrated energy hits a part, it changes the structure of the metal, the temperature rises instantly, which leads to melting and the formation of a weld. The process is realized by partial and complete penetration, regardless of the position in space. To process products with small thickness, the beam is defocused.

Pulsed radiation is characterized by the formation of a weld in the form of dots. The units are equipped with solid-state lasers; due to their high technical characteristics, the welding speed is 5 mm/s. Additionally, filler materials are used, which can be tape, wire, or special powder. They improve the quality of adhesion by increasing the cross-section of the seam.

Physical properties of the process

The laser method differs from other methods in its increased energy density at the heating site - 1 MW per cm². This helps to speed up the process of formation of the welded joint and reduce the duration of the thermal effect on the areas adjacent to the seam. When laser welding of metal, deformations, foreign inclusions or cracks rarely occur.

The size of the area of influence of the welding installation lies in the range of 0.2-13 mm. The penetration depth depends on the laser radiation power and the location of the focal plane of the flow. The molten metal moves with the beam, forming a welded joint.

It turns out to be deep and narrow, so it is very different from the seams formed when using other technologies.

Advantages and disadvantages

The relevance of this technique lies in the presence of a large number of advantages. These include:

- Precise concentration of energy, due to which it is possible to obtain high-quality products, and the size of the parts can be insignificant in radius.

- High-performance gas units allow the melting of narrow seams, which reduces the area of thermal action and reduces the degree of deformation and surface stress.

- Welding work is carried out with a laser located at some distance from the working area, which is a cost-effective solution.

- Optical fiber and a system of mirrors make it possible to adjust the position, which allows welding work of any complexity, for example, for large diameter pipes.

- You can simultaneously fasten several parts using splitting prisms.

The negative qualities of the laser include the high cost of the equipment, so this option is only suitable for large enterprises.

Conditions and methods of the process

High beam concentration is achieved through a series of reflections from mirrors that have a hemispherical shape. When the critical value is reached, the beam overcomes the central zone of the first mirror and penetrates through the prisms directly into the working area.

Laser cutting and welding of metals are carried out with different localization of workpieces . The melting depth can be adjusted in a wide range, from surface to through. Treatment is carried out with a constant or intermittent beam. The efficiency of laser technology is low and requires high qualifications from the worker.

The process is divided into several types:

- Butt. It is used without additives and powders, but a protective environment is required for processing.

- Overlapping. The joined edges are installed one on top of the other. It is necessary to ensure reliable fastening of the workpieces.

There are compact models for home use that allow you to weld metal products with your own hands.

Devices

The equipment is presented in the form of large-sized machines or mobile devices:

- LAT-S is a machine designed for surfacing and welding of metal products. The device shows high technical characteristics; it is equipped with automatic coordinate machines, which increases the processing speed of complex structures.

- CLW120 is a laser welding machine that has pinpoint accuracy. Used for processing ferrous and non-ferrous alloys, stainless steel and titanium. The device operates on 220 V, so it is suitable for domestic use from an electrical panel.

Welder of the highest category Ivleev A.V.: “The vast majority of models for laser welding are equipped with a binocular; the element protects vision from the negative effects of a bright beam and improves the visibility of the part.”

With solid active element

The operating principle is based on the following aspects:

- A solid rod-shaped element is the source of the beam, it is located in a special chamber.

- The pumping lamp generates flashes of light that activate the working fluid.

Solid state laser circuit

The solid part is made from ruby; this material has shown high technical characteristics, safety and impeccable efficiency.

With elements based on a gaseous medium

These are high-performance machines that work in combination with gas protection . The active medium is a mixture of nitrogen, oxygen, and helium; it is supplied under high pressure, reaching more than 10 kPa. The working gases are excited by an electrical discharge. The efficiency of the device does not exceed 15%.

Nitrogen and helium transfer energy to carbon dioxide, which creates ideal conditions for obtaining a discharge.

Classification of gas lasers

Based on the cooling method, installations are divided into two large groups: with convective (intensive) and diffuse (slow) pumping. The latter is used in low-power single-beam lasers. It is advisable to install convective in powerful devices.

On the side of gas movement relative to the electrodes of the resonator mirrors and the gas chamber, convective lasers are divided into transverse and longitudinal pumping. The mixture is excited by a high-frequency or direct current discharge. A dual-circuit cooling system is responsible for cooling the resonator and optical elements; the working mixture is cooled by a water-gas heat exchanger.

Beam transport and focusing systems

This system includes protective beam guides, a mirror and a focusing element. The mirror is designed to change the trajectory of the beam and moves it into the working area. Low-power solid-state lasers are equipped with special prisms and refractive mirrors, which consist of a multilayer dielectric coating. Gas lasers have copper mirrors; more powerful devices use mirrors with a water cooling system.

The focusing element (tube) makes movements relative to the workpiece. The lens is fixed in it. Solid-state lasers are equipped with glass optical lenses; gas lasers use prisms made of zinc selenide or potassium chloride. Air curtains protect lenses from melting products.

The focal length to obtain high power should be about 100-150 mm. a decrease in this indicator leads to difficulty in removing harmful products.

When laser welding of carbide metal, the distance from the energy source to the working area is determined by the tabular method.

Gas protection

The purpose of a gas protection system is to reduce the likelihood of oxidation in and around the weld. It includes nozzles of different designs. These elements eliminate spatter and fumes that appear during welding. The nozzle is selected depending on the level of chemical activity of the materials, power, and melting depth. The gas with the most suitable composition is supplied to the working area.

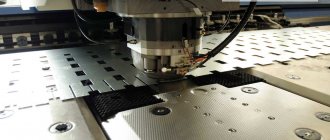

Moving the beam and product

The welded products and the energy beam are moved by a CNC manipulator, which has several degrees of freedom, this indicator depends on the complexity of the process. Travel speed can reach 400 m/h.

When processing large parts with a large mass, it is more advisable to move the beam rather than the part. This process is realized through movable mirrors. The most promising system is to secure the tool in an automatic manipulator.

Hybrid installations

Hybrid arc welding is great for creating straight welds.

The main advantage of such installations is the complete fusion of all kinds of profiles without special preparation. The peculiarity of the method is the combination of an electric arc with an energy beam . It is used for fastening parts of large thickness at high speed in automatic mode and low heat transfer. The quality of the seams is at a high level.

Equipment for laser welding

Diagram of a laser welding machine.

There are two types of laser welding devices: solid-state and gas machines. To make the right choice of such a device, you need to know the features of each of them.

As noted earlier, a laser welding machine can operate pulsed or continuously. A hand-held solid-state laser system belongs to devices operating according to the second principle. Such devices are based on a solid rod; pink ruby is most often used.

Currents are supplied to the external circuit and the lamp. The lamp generates high-frequency, short-term pulses of light. As a result of the described processes, an ionized laser beam is formed inside the rod. Under the influence of a magnetic field, it is released in the desired direction.

This laser formation technology is characterized by low power. In this regard, it is used for small products, allowing the formation of high-quality seams. This method has become widespread in microelectronics.

Features of working with thin-walled materials

Welding of parts of medium and large dimensions is carried out by melting throughout the entire thickness. For these purposes, high concentration sources are used. The main nuance when processing thin-walled products is the risk of burning through the sheet. To avoid such a result, it is necessary to control the following indicators:

- power;

- focusing;

- speed of movement of the energy beam.

To connect thin-walled workpieces, the installation should be set to the minimum power setting . A continuous type installation must have an increased speed of movement of the contact spot.

In pulse mode, the pulse duration is reduced and the duty cycle is increased. If the flux density is too high, then they resort to defocusing the beam, which reduces the useful effect, but eliminates the possibility of burning and splashing of liquid metal.

Differences in technology

The technology of joining parts by welding for each metal and alloy has a number of distinctive features. For example, processing parameters for steel products of grade 30KhGSA require preliminary cleaning from scale and traces of corrosion. The part must be dried, which will reduce the likelihood of the appearance of an oxide film, porous structure and seam cracks. The contact area must be treated with degreasing agents.

Steel

Processing of steel products is carried out only after careful preparation ; it consists of removing dirt and moisture. Otherwise, there is a high risk of defects forming in the area that was exposed to thermal stress. The distortion and gap between the welded edges of the products should be minimal. The gap size is no more than 7% of the melting thickness.

It is recommended to use potholders only in case of emergency. For steel parts, it is better to use the butt welding method. The locking and lap varieties are highly sensitive to concentrated stress. The process is carried out in an argon atmosphere with carbon dioxide in a ratio of 3:1. Low-carbon steels are processed without a special protective environment.

Aluminum and magnesium alloys

Melting of magnesium, aluminum and alloys of these metals is complicated by their activity; they come into contact with the environment and various alloying elements. Plus, the welded edges are covered with an oxide film. These nuances can be overcome due to a concentrated energy beam.

Preparatory activities do not differ from those that must be carried out before arc welding . These include mechanical processing with cleaning, etching, hot water washing and stripping, which reduces the risk of oxide film formation. Welding is carried out in a protective environment of helium or argon.

Titanium and titanium alloys

At elevated temperatures, titanium and alloys based on it, for example, titanium technology VT1 VT20, exhibit excessive activity. Heating above 300 degrees provokes grain growth, and there is a tendency for cold cracks to form if the hydrogen level increases. The edges are prepared by mechanical or shot blasting with etching with chemical reagents, brightening, and cleaning. The protective medium is purified helium, and it is advisable to cool the products in argon.

Manual

The connection of products can be carried out using manual laser welding. A small-sized machine can be easily purchased even for domestic use. Moreover, at an affordable price with high technical characteristics. Such equipment is intended for:

- repair of products with small overall dimensions, for example, jewelry, eyeglass frames;

- surfacing;

- polymers;

- butt spot welding;

- carrying out welding work in the field of microelectronics;

- mold corrections;

- processing of medical devices.

Laser welding is a method of joining products made of various materials, which has become widespread in various fields. Non-contact technology allows interaction with metals of various electromechanical properties . The work is carried out in a small area with high power, which allows you to penetrate hard-to-reach places. The application of the method is limited by economic aspects due to the high cost of installation.