A light gray metal with very high hardness, refractoriness and heaviness is tungsten. In addition to this, it has very high chemical resistance.

- Lighting

- Place of Birth

History of discovery and study

The metal gets its name from the mineral wolframite. It began to be mined in the 16th century. Back then it was called "wolf's foam." Tungsten was often found in tin ores and interfered with the smelting of this metal. He converted it into a foam of slag.

The first scientific mention of the discovery of a new chemical element appeared in 1781. Then the famous chemist from Sweden Karl Scheele worked with the mineral scheelite. He treated it with nitric acid, during which he obtained a new chemical element with a yellow tint. He called it "heavy stone." Two years later, the Eluard brothers obtained a new metal from the Saxon mineral.

If we compare protection against ionizing radiation from lead or tungsten, the second type of metal wins. The finished protective layer will trap more particles with less weight.

Wolframite

Areas of implementation

Tungsten wire is used in various fields of production and the national economy. It is used to produce spirals and spring parts created for incandescent light bulbs.

Tungsten-rhenium variety (TRN) is used for the production of traverses.

Tungsten is a refractory alloy, therefore wire products based on it are irreplaceable when developing resistance parts in heating devices. It is contained in thermoelectric converters and loop heaters.

The process of producing tungsten rolled metal is quite complicated, involving powder metallurgy techniques. It is very popular in the electrical and radio engineering industries. It is intensively used in the development of LCD television screens. More needed are wire products, which are tungsten anhydride and obtained from salts of this alloy.

It is used to make parts of X-ray equipment, which during operation are subject to vibrations and strong heating. Meshes and filter mechanisms based on it are used in the chemical industry.

Extraction from ore and deposits

In nature, tungsten can be found as oxidized deposits. They are formed from the trioxide of this metal, which combines with calcium, manganese, and iron. Sometimes you can find copper, lead, thorium, and some rare earth elements in the composition.

Minerals saturated with tungsten are more often found in small inclusions in ground rocks. In this case, the average concentration of heavy metal is up to 2%.

The largest tungsten deposits are located in the USA, China, and Canada. The average global production per year is 50 thousand tons.

The critical temperature for this metal is 13610°C. When heated to such levels, it turns into gas.

Individualities

For the production of tungsten wire - GOST 18903-73 - forged rods are used. During the drawing process, a gradual decrease in temperature is carried out. After this, the product is cleaned by annealing and electrolytic polishing.

The raw material for the production of this type of wire product is the most refractory alloy. This material is heat-resistant and durable, it is not resistant to acidic and alkaline environments. Such properties make it possible to use tungsten wire to produce parts designed for operation in heating conditions, as a result of which they do not lose their initial parameters.

The mechanical characteristics appropriate for this type of wire product (high hardness, resistance to wear during heating, low thermal expansion), superior to almost all similar materials, make tungsten products very necessary.

This type of rolled metal is distinguished by the highest modulus of elasticity, excellent ohmic resistance, and excellent thermal conductivity. This is a durable and reliable material that can withstand extreme operating conditions, which makes it irreplaceable in various industrial sectors.

There are several brands of such wire. Systematization is done in accordance with the cross-sectional diameter and the percentage of tungsten in the composition of the material.

The diameter of the wire can be from 12.5 to 500 microns.

The VA brand is more needed. The VRN brand is used for the production of cathodes for electrical devices.

The VM and VT tungsten metal grades are also in demand.

Specifically, the brand describes the scope of implementation of the material.

Industrial production

The production of tungsten by industrial enterprises begins with the extraction of ore and its delivery to production. The next stage is the separation of trioxide from the consumable material. It then goes through a reduction process to produce purified metal powder. The recovery procedure is carried out under the influence of hydrogen. In this case, the raw material is heated to 700°C. The finished powder is pressed and sintered at a temperature of 1300°C in a protective atmosphere of hydrogen.

Biological role of tungsten

limited. Its neighbor in the group, molybdenum, is indispensable in enzymes that ensure the fixation of atmospheric nitrogen. Previously, tungsten was used in biochemical studies only as an antagonist of molybdenum, i.e. replacing molybdenum with tungsten in the active site of the enzyme led to its deactivation. On the contrary, enzymes that are deactivated when replacing tungsten with molybdenum are found in thermophilic microorganisms. Among them are formate dehydrogenases, aldehyde ferredoxin oxidoreductases; formaldehyde ferredo-xyn oxidoreductase; acetylene hydratase; carboxylic acid reductase. The structures of some of these enzymes, such as aldehyde ferredoxin oxidoreductase, have now been determined.

Severe consequences of exposure to tungsten and its compounds on humans have not been identified. Long-term exposure to large doses of tungsten dust can cause pneumoconiosis, a disease caused by all heavy powders entering the lungs. The most common symptoms of this syndrome are cough, breathing problems, atopic asthma, changes in the lungs, the manifestation of which decreases after cessation of contact with metal.

Yuri Krutyakov

Stamps

Tungsten grades:

- VR is a compound of tungsten and rhenium.

- VT, VI, VL - an additive of lanthanum, thorium, and yttrium oxide is added to the base.

- VRN is a metal without additives. The presence of a small amount of different impurities is allowed.

- VM - various additives are added to the base. The main ones are silica-alkaline, aluminum.

- MV is a compound of molybdenum and tungsten. Plasticity is maintained while strength is increased.

- HF is pure metal without impurities or additives.

- VA - combination of base with aluminum, silicon-alkaline additives.

Incandescent lamps have a sealed glass capsule for a reason. Since tungsten quickly oxidizes in open air, the capsule is filled with an inert gas.

Incandescent lamp

Where can I get it at home?

Almost everyone is interested in where to find tungsten wire at home. This is a component of all heating parts of household devices.

It is found in old modifications of irons and electronic kettles. If you have an old fan heater at home, remove the wire strands from the heaters. It's not hard to get it out of broken toasters. It is also found in the heating elements of washstands. To remove the wire, the heating elements are carefully opened with a grinder. It will only be necessary to clean the wire products from the insulation.

Tungsten rolled metal, resistant to wear and adverse external influences, has proven itself to be excellent. Its supplies are made not only in reels, but also in coils.

How to find out what tungsten wire is and where it is used, see the following video.

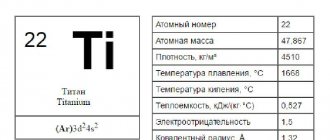

Properties

To understand where it is best to use tungsten, you need to know the properties of this metal. Now enough information is known about this material to determine the scope of its application.

Chemical

Properties:

- The valency of a pure metal is 6. For compounds based on it, it can vary from 2 to 5.

- The molar mass of the chemical element is 183.84.

- The element has an orbit consisting of two tiers.

Tungsten is a reactive metal. It reacts with various substances to form complex, simple compounds. When heated, reactions proceed faster. To further speed up the reaction, water vapor can be added.

Physical

Properties:

- Color: grey.

- Transparency - none.

- There is a metallic sheen.

- Hardness - 7.5 (indicated according to the Mohs scale).

- Density - 19.3 g/cm3.

- Radioactivity - 0.

- Thermal conductivity - 173 W/(m K).

- Electrical conductivity - 55·10−9 Ohm m.

- The Brinell hardness index is 488 kgf/mm².

- Heat capacity - 134.4 J/(kg deg).

- Melting point - 3380 °C (the indicator depends on the amount of impurities).

- Electrical resistance - 55·10−9 Ohm·m (subject to a temperature regime of 20°C).

- Boiling point is about 5555 °C.

The metal is best forged when heated to 1600°C.

Heavy alloys are made based on tungsten. The total base content can reach 97%. Ready-made alloys are used for the manufacture of containers in which radioactive substances will be stored and transported. The main feature of the container is the ability to absorb part of the gamma radiation.

Application of tungsten.

The use of pure metal and tungsten-containing alloys is based mainly on their refractoriness, hardness and chemical resistance. Pure tungsten is used for the manufacture of filaments of electric incandescent lamps and cathode ray tubes, in the production of crucibles for the evaporation of metals, in the contacts of automobile ignition distributors, in the targets of X-ray tubes; as windings and heating elements of electric furnaces and as a structural material for space and other vehicles operated at high temperatures. High-speed steels (17.5–18.5% tungsten), stellite (cobalt-based with the addition of Cr, W, C), hastalloy (Ni-based stainless steel) and many other alloys contain tungsten. The basis for the production of tool and heat-resistant alloys is ferrotungsten (68–86% W, up to 7% Mo and iron), easily obtained by direct reduction of wolframite or scheelite con - a very hard alloy containing 80–87% tungsten, 6–15% cobalt, 5–7% carbon, indispensable in metal processing, mining and oil production.

Calcium and magnesium tungstates are widely used in fluorescent devices, and other tungsten salts are used in the chemical and tanning industries. Tungsten disulfide is a dry high-temperature lubricant, stable up to 500° C. Tungsten bronzes and other compounds of the element are used in the manufacture of paints. Many tungsten compounds are excellent catalysts.

For many years after its discovery, tungsten remained a laboratory rarity; only in 1847 did Oxland receive a patent for the production of sodium tungstate, tungstic acid and tungsten from cassiterite (tin stone). The second patent, obtained by Oxland in 1857, described the production of iron-tungsten alloys, which form the basis of modern high-speed steels.

In the middle of the 19th century. The first attempts were made to use tungsten in steel production, but for a long time it was not possible to introduce these developments into industry due to the high price of the metal. The increased demand for alloy and high-strength steels led to the launch of the production of high-speed steels at Bethlehem Steel. Samples of these alloys were first presented in 1900 at the World Exhibition in Paris.

Marking of tungsten electrodes

Fundamentally! Marking of tungsten electrodes is needed by specialists, as it contains the entire list of features and metals used both in the manufacture of the electrode and those suitable for welding.

The established and accepted markings, for convenience, differ in designation and color.

The following markings apply to tungsten electrodes:

Color marking of tungsten electrodes.

- WP (greenish color) - here the electrode actually consists entirely of tungsten. Its content is 99.5%. Used for welding magnesium and aluminum. The probable implementation of the electrode of the presented marking is welding with sinusoidal current. For protection, two types of gas are used: argon and helium.

- WC-20 (greyish) – 2% cerium oxide. They are considered universal electrodes, as they are used in welding with alternating current and using positive polarity. They are used in connecting pipelines in non-rotating joints.

- WL-15, WL-20 (dove) - there is an admixture of lanthanum, which allows you to achieve a stable arc and re-ignition, which makes the electrode of this brand often used in industry. In addition, the use of lanthanum in the electrode can increase the operating current and reduce wear by half. Seams made using this type of electrode are durable and least dirty. To work, the electrode must be given a spherical end shape.

- WT-20 (reddish) – this contains thorium. As already described above, its dust during operation is somewhat unsafe for human health. Despite this fact, the presented markings are sometimes used more often than electrodes, which are actually entirely made of tungsten. This highlight is explained by the good qualities of thorium, which is capable of connecting the most “fastidious” alloys in a matter of seconds. When working, it is recommended to use a constant current, since when the current is used sinusoidally, the acquired arc can jump along the surface being welded. Such problems cannot be allowed to happen.

- WZ-8 (snow-white) - there is less than a percentage of zirconium oxide. When working, you need to pay close attention to cleanliness. It is recommended to use alternating current. Before insertion, the electrode should be given a spherical end shape. Best used for welding aluminum.

- WY-20 (blue) - tungsten electrodes with a narrow yttrium coating. They are considered to be the most stable electrodes, which is why they are often used for welding critical and fundamental structures.

When choosing electrodes, you need to decide on the welding method and the qualities of the alloy being welded, therefore, to connect one structure, several types and markings of tungsten electrodes may be required.

Interesting read: Plaster casting at home

Trait alloys

The most important compound is tungsten carbide. It has a very high melting point - 2780 °C. It is used to create parts of electronic circuits, cutting tools, cermets and “cemented” carbide.

Ceramic metal is a material made of ceramic and alloy. Ceramics is a clay material. Metal ceramics are used where very high temperatures last for a long time. For example, parts of a rocket or jet engine are made specifically from it.

"Cemented" carbide is made by bonding tungsten carbide to another alloy. The product is very durable and remains strong in high temperatures . Specifically, “cemented” carbides are used for drilling tunnels. Tools made from this material can operate at speeds 100 times faster than similar tools made from steel (for example, drills made from this material can withstand higher temperatures than drills made from steel, and, consequently, the intensity of their use can be maybe higher).

Tungsten steel

The meaning of the word Tungsten steel according to the Brockhaus and Efron dictionary: Tungsten steel

— The tungsten content in steel gives it significant hardness and significantly increases the melting point. It is used for springs, projectiles, currency slates, for cutting tools (with a molybdenum additive - “self-hardening” steel), etc. In general, two classes of high-grade steel can be distinguished: poor and rich in tungsten. With a tungsten content of up to 10%, steel with 0.2% C is close in microstructure to ordinary steel; at a higher tungsten content, a number of crystalline inclusions appear in the steel, preventing, for example. rolling. At 0.8% C, these crystals appear already at 5% W. In composition, they are possibly C + W. Tungsten-poor steel is pearlitic in microstructure, has qualities similar to ordinary steel, only, with the same C content, temporary resistance, elastic limit and hardness are greater, and elongation, reduction in cross-sectional area at break and impact resistance are less, the greater W; This difference is sometimes quite significant. This type of steel can withstand hardening and annealing more strongly than usual. Tungsten-rich steel with carbide inclusions has, with the same C content, the lowest tensile strength and elastic limit than the previous one. Impact resistance is practically independent of the C and W content. Quenching at 850° causes a very fine formation of martensite; it greatly increases the tensile strength, elastic limit and hardness of steel. A.M.

Tungsten Bronze Tungsten Steel Wolfsbergite

Interesting read: How to vulcanize a camera at home

Manufacturing of posts

We have already found out what kind of metal tungsten is, and now we will find out in what range it is manufactured. Compact ingots - bars - are made from the powder compound. For this, only powder that has been reduced with hydrogen is used. They are made by pressing and sintering. The resulting ingots are quite strong, but fragile. In other words, they are difficult to forge. To improve this technological property, the bars are subjected to high-temperature treatment. A different assortment is made from this product.