This is how furniture is created from a profile pipe for each specific product.

The instructions provided may be clarified in detail; some points may be omitted. The instructions for a chair and for a hanging shelf will be different, but it is advisable to create such instructions before starting work.

All these designs will have something in common, namely incredibly high strength and resistance to any aggressive mechanical influences.

Brief introduction

Before making furniture from a profile pipe with your own hands, you need to get acquainted with the material.

A profile pipe is a hollow metal product that can have different types of cross-sections, except round. The main materials of manufacture are low-alloy and carbon steel. Stainless steel is used much less frequently.

All kinds of crafts and full-fledged structures are assembled from it, which are subject to serious loads.

The shape, as well as the properties of metal pipes, have allowed the material to gain enormous popularity in the construction industry and beyond. This pipe is ideal for performing a large number of tasks. You can get a variety of designs from it.

The main types of sections are:

- square;

- oval;

- triangular;

- hexagonal;

- flat oval, etc.

rectangular;

Products with right angles in cross-section are in great demand. Oval and flat-oval are less common. And non-standard forms are even used in individual projects.

Simplicity of the loft

Calculate the exact cost of repairs using an online calculator

and receive a free detailed estimate for repairs

Calculate

Loft style is free and rough. And interiors in this style are often not fully finished. All electrical and pipes remain on the surface. The latter may well look good if you pay attention to their appearance, for example, paint them white or leave the clean metal ennobled.

Photo: housessive.com

Drawings of tables made of profile pipes

An example of how you can make a full-fledged, very beautiful table from a thin profiled pipe can be seen in the photo and diagram below.

The frame can be surprisingly elegant and beautiful The frame can be surprisingly elegant and beautiful

In order to bend a profiled pipe with a 10 mm edge, you can use a manual pipe bender, and assemble part of the decor from a round profile and fittings. Using wooden boards lined with plastic as a coating material will turn out beautifully and aesthetically.

Of all the designs for a durable metal frame for a home table, the most preferable would be the one with the back facing, this allows you to significantly improve rigidity without the use of heavy profile pipes measuring more than 30 mm.

For the main country table, for the garage and repair shop, choose the classic version of the table with legs tied at the lower level. The design is quite rigid, so if necessary it can be used as a cutting surface.

The height of the working surface must be selected individually. Universal frame

For small welding work, a mobile tray shown in the drawing below is suitable.

The tabletop can be covered with a sheet of metal or made of a combination, with a backing made of wooden boards. In this case, the wooden planks must be recessed under the metal covering.

Separately, it is worth mentioning the non-standard version of the frame with X-shaped side posts.

This design has several serious advantages:

- You can use relatively thin profiled pipes, the table is durable and light at the same time;

- The X-shaped pattern of fastening the legs allows you to make the table foldable;

- The absence of a lower profile trim, such as in welding workbenches, opens up free space for the legs and makes the furniture very comfortable to use.

Of all the above projects and schemes, this option is best suited for using a dining table on a veranda or open terrace.

Table functions

A small beautiful table can be made from an ordinary block of wood and a pipe base. It will, of course, look rustic, but if used correctly in the interior, it will be a nice little decoration for your apartment.

Photo: timbangharga.com

Advantages and disadvantages

To characterize future possible furniture made from a profile pipe with your own hands, it is worth looking at the strengths and weaknesses of the material.

Benefits include:

- thin-walled material is light in weight;

- stiffening ribs provide high strength indicators;

- withstand heavy loads at a smaller size than wood or timber;

- square and rectangular sections provide compact storage and convenient transportation;

- corners create a perfect fit to other elements;

- the stability of structures increases;

- the price is relatively low;

- there are no difficulties during installation and assembly;

- not afraid of wear, temperature changes, precipitation, etc.;

- can be used outdoors;

- pipes have a long service life.

Now it’s easy to buy the material and make furniture from a profile pipe with your own hands.

But you need to take into account the disadvantages.

The main disadvantage is the tendency to corrosion. But this disadvantage can be minimized through special processing, as well as painting.

Another weak point is the difficulty of creating a bend. Let me start by saying that not all drawings require bending pipes. Plus it can be done. You just need to fill the cavity with sand, and then set the desired bending angle on the machine.

Pros of using metal pipes as a frame

For profiled pipes, low-alloy carbon steel is used, which has good elasticity. It has high performance characteristics and is used for both industrial and private construction.

This material is easy to bend, weld or cut; structures of any level of complexity can be made from it, if you have an idea about the correct construction of frames and have knowledge of the basics of working with metal.

In private construction, such pipes are usually used for the manufacture of gazebos, arches, canopies, frame sheds, fences, gates, stairs, greenhouses, garden swings, and so on.

The products have the following characteristics:

- Low overall weight due to the frame structure of the structure - this parameter depends on the size of the profile pipe and the thickness of its walls.

- The dimensions of metal garden furniture can be any, the main thing is to accurately calculate the possible loads.

- They are much cheaper than analogues made from other materials.

- The structures are durable and resistant to high mechanical loads.

- With proper care and regular renewal of the protective coating, metal pipes have a long service life.

Profiled pipes come in different sections: diamond-shaped, round, rectangular and square.

For frame construction, the last two options are usually used, since the process of joining parts is significantly simplified - they can be connected at different angles, making only precise and even cuts.

Welded frame for future country furniture

This material is easy to work with if you have the necessary tools at hand.

The connections were made using a welding machine, which means you need to know how to work with it. This process requires compliance with safety precautions, and includes many subtleties that make it possible to obtain products with the correct geometry and reliable connections.

For frames of garden furniture, they mainly use a rectangular pipe with a cross section of 20*40 mm. Its average price per linear meter is 70-80 rubles, with a metal thickness of 2-3 mm.

For a powerful and durable frame you will have to pay no more than 1500-2000 rubles. A finished bench in a good quality store will cost at least 10,000 rubles.

Many people prefer to make garden benches from wood; step-by-step manufacturing instructions with drawings and photos can be found on our website.

What do you need for work?

If your goal is furniture made from a profile pipe with your own hands, then you will need to prepare tools.

The main set includes the following components:

- circular saw for cutting;

- hand saw with blade for metal;

- welding machine;

- electric drill;

- metal drills;

- hammer;

- roulette;

- bit;

- screwdriver or screwdriver;

- sandpaper.

A rust converter, metal primer, as well as paint or varnishes will not hurt.

For those who are going to make furniture with curves, a profile pipe bender will also be useful.

Making a bed

To tell the truth, sitting on metal is not very pleasant, because it is hard and cold. For this reason, a rocking chair made with your own hands from metal must have additional finishing. There are several options for making a stock:

- made of wooden blocks, each of which is attached to the frame with bolts;

- made of thick cotton fabric stretched over the top and bottom posts;

- of pillows attached to the back and seat and covered with a removable cover;

- made of willow wicker, which is woven around a metal frame.

Regarding the last option, it would be a good idea to first watch a video teaching the basics of weaving. This design looks very elegant and graceful.

Making a simple frame

Before work you need to prepare the following materials and tools:

- profile pipe 20x40;

- welding machine, electrodes (No. 3);

- Bulgarian;

- file, sandpaper, drill with attachment or grinder;

- measuring instrument: meter, square.

Drawing of a metal bench.

The dimensions of the bench are selected based on personal preferences. The pipe is cut according to the measurements: you will need 4 parts for the frame, 1 for the cross brace and 4 identical pieces for the legs. The frame parts are paired, 2 of them should be equal to the width of the bench, and 2 should be equal to its desired length. The length of the legs is determined by the height of the bench.

- Clean the surfaces where welding will be done with a file to fresh metal. Lay out the frame parts on a flat surface in the same way as they will be welded and make the connection, constantly checking that the angles correspond to a value of 900 using a square.

- Mark the middle of the long sides of the frame and weld a piece of pipe intended for cross bracing.

- Weld the legs in the inner corners of the frame so that they are strictly perpendicular to the plane of the frame.

The bench seat can be made from boards, thick plywood or MDF. If you want to have a product made entirely of metal, the required number of identical pieces of pipe or strip steel are cut for the seat and welded or bolted to the frame.

Based on the model of the bench frame, you can also make a frame for a table, stool or chair.

To do this, you only need to change its dimensions and provide additional details (back, legs, etc.) or decor.

Step-by-step instruction

There are several types of interior items made in this way:

- All metal chairs made using artistic forging.

- Tubular products created from aluminum or steel rods by welding.

- A combination of two materials, for example, metal and plastic.

Forging such products requires special skills and equipment. It is almost impossible to do this without skill. The connecting points in the second type are provided by welding or screwing the bolts with a drill.

Structural diagram of a metal rocking chair.

The first stage of design is to develop a drawing. To do this, you need to take the parameters of a regular chair and display them on a piece of paper. Manually draw an oval line at the base of the future chair. This way you can easily calculate the size of this semicircle. The larger radius ensures maximum safety. Then cut out such diagrams and attach these outlines to the original materials.

Then you will need steel rods measuring 20x20 mm. Cut them into 1 m sections each and weld them to the base, following the drawings exactly. Bend the steel following an oval and use a welding machine to connect it to the legs. The frame pitch should be about 6 mm.

Next, you need to place a metal seat with a back on the frame base. It is secured by welding or screw fixation.

What can you collect

See also Wardrobe transformable bed: design options, which one to buy

Now let’s get down to manufacturing. What kind of furniture you will assemble from a profile pipe with your own hands depends on you.

You can look at photos, as well as videos, highlight interesting ideas and original solutions for yourself.

Since we have a furniture site, the main emphasis will be on furniture for an apartment, house or cottage. We have already made a chair from plywood. Now you can try out profile pipes in action.

The following options are possible:

- table;

- chair;

- armchair;

- stool;

- couch;

- banquette;

- bar stool;

- massage table, etc.

Obviously, the profile pipe will not be used as the only material. Otherwise, it will be impossible to sit on such furniture.

Usually this is a combination of metal and wood, foam rubber, upholstery materials, etc.

Basically, the profile pipe is used as a base or frame for furniture. Next, it is decorated and sheathed to create a complete composition.

Also, profile pipes are excellent for tasks such as garden furniture and garden structures:

- sunbeds;

- tables and chairs;

- gazebos;

- greenhouses;

- greenhouses;

- grills and barbecues;

- awnings;

- Garden swing;

- summer shower, etc.

Yes, I agree. Not all of the above is furniture. But the fact remains a fact. Profile pipe is a universal material with wide application possibilities.

Additional materials for the bench

If we talk about the full production of a bench, then you won’t be limited to just metal and wood. There is also a small list of materials and consumables that will be needed. They are listed in the following table.

| Materials, photos: | Description: |

| Primer paint for metal | The final coating of the metal may vary. Primer enamels are often used, which do not require surface preparation, apart from cleaning it. This paint is applied in several layers. You can even cover rusty areas with it, but we do not recommend doing this, since the service life of the protective layer will be reduced. |

Grinder circle for cutting metal | For frame structures, the metal always has to be cut to the design dimensions. For cutting, abrasive wheels are used, mounted on a grinder or similar tools. Wheels made of the same material are used for grinding metal and processing welds. |

Wire brush | Before painting, the metal must be cleaned. The task is to remove all the rust and expose its shiny surface. On this basis, even primer paint will adhere much better. |

Degreaser | Before painting, the metal is degreased. This will seriously increase the adhesion of the material and promote even application of paint layers. As a degreaser, you can use universal compounds, which are ordinary kerosene, or its light varieties, for example, white spirit. |

Electrodes for welding | Electrodes are also consumables. Without them, the benches definitely cannot be assembled. |

| Set of metal drills | You will need to drill a little, but you should always have several drills of the required diameter in stock. Holes are made for bolted and screw connections. The wooden part of the bench is fastened in this manner. |

Bolts and screws | Again, necessary to secure the wooden parts of the frame. Sometimes they are used to connect metal parts, although welding is the preferred method. |

Wood processing materials | We have combined them into one line because different options may apply. Let us note antiseptic impregnations, which significantly increase the service life of wood in the open air, impregnations for changing the color of boards (this includes oils, stains, glazes, waxes, etc.), protective compounds and paintwork materials that create a waterproof film on the surface. These properties may be combined in some materials. For example, oil from water qualitatively protects and transforms the color of wood, making it more saturated. |

Sandpaper for random orbital sander | The surface of the wood must be carefully treated to make it smooth, safe and pleasant to the touch. To do this, it is polished with abrasives of different fractions. |

This variety is accompanied by the following set of tools:

- Bulgarian.

- Carpenter's square.

- Electric drill.

- Sander.

- A hammer for knocking down scale after welding, and indeed this tool is always required.

- Clamps for preliminary fixation of parts.

- Brushes or a small roller for a more even application of paint.

- Welding machine.

- Tape measure, pencil, marker.

- To create curved parts, a pipe bending machine is required

Pipe bending machine Other

small things can also come in handy, which you will find out for yourself when you start assembling your bench.

Is forging cold or hot?

This is a starting question that needs to be dealt with right away. Forging can be hot or cold. Classic hot forging will allow you to make anything - right down to thin metal lace. But it is only possible with a furnace or forge for high-temperature heating of metals.

Various forging processes.

The most democratic way of manufacturing metal products is, without a doubt, welding. Forged chairs, for example, can be made even in your own apartment, just don’t forget about safety. They will turn out to be strong and cheap, but you will have to forget about aesthetics and sophistication.

There is only one way in which you can make real artistic furniture without much expense or skill. This is cold forging. The best solution would be a combination of welding and cold forging; these technologies combine well with each other.

Required Tools

To work, you need to prepare a basic set of carpentry tools. It is simply impossible to make any wooden furniture without carpentry tools. Professional furniture manufacturers have fully equipped workshops with expensive, specialized equipment. But in order to prove yourself as a carpenter, of course, you shouldn’t immediately buy professional equipment, but you still need to prepare some tools.

How to assemble

See also Modular bedroom furniture: pros and cons, which one to choose

To assemble furniture from a profile pipe with your own hands, you do not have to be a qualified specialist in this field.

The manufacturing process involves several stages. Moreover, this is true for any type of furniture, as well as other products.

Step by step it looks like this:

- study the drawing, or draw up your own plan with detailed dimensions;

- mark the pipes and make a cut;

- remove all burrs;

- drill holes for bolted connections;

- if necessary, bend the elements;

- perform the welding step to connect the parts;

- supplement the welded joints with a tie of bolts and nuts;

- prepare and install fittings;

- complement the product with components made of plastic, wood and other materials;

- Finish the job with primer, paint or topcoat.

I can't say it's incredibly difficult. It all depends on what kind of furniture design you decide to create. All in your hands.

Let's sum it up

Profile pipes are a universal and multifunctional material.

Factory furniture is assembled on their basis. It is done with your own hands, as well as with the help of partners.

The material has a lot of advantages. And the shortcomings are minor and easily eliminated. Protecting against the same corrosion is not a problem. In this case, metal will last longer than wood. Especially in a garden, vegetable garden or backyard of a private house.

Your task is to come up with a project, or take a ready-made idea as a basis, and bring it to life.

By the way, this article describes in detail how profile pipes can be bent, and what is required for this. Moreover, the instructions do not provide for the use of special machines or professional equipment. Only what can be used at home or in the garage.

What do you think about this option for assembling furniture? How do you assess the potential of the material? Do you have any experience working with it? What kind of furniture or structures were made?

A do-it-yourself bed made of metal.

You can make your own very stylish double bed with a fairly easy-to-make frame.

To make the frame you will need:

- profile pipe 20 x 20 mm for the manufacture of crossbars for load-bearing backs and uprights;

- channel 65 x 32 mm and corner 40 x 40 mm for making a frame.

The frame dimensions are selected depending on the size of the mattress you choose. They have standard sizes:

- length – 1.9 m, 1.95 m, 2 m;

- width – 0.8 m, 0.9 m, 1.20 m, 1.40 m, 1.8 m, 2 m.

The design of the bed allows for quick disassembly if necessary. Two sub-mattress frames and two backrests make the product somewhat heavier, but this design is highly durable.

Handrails for stairs

Owners of homes with stairs are faced with the need to use handrails, especially if there are elderly people in the family. A stylish and easy-to-implement solution is to use several pipes screwed to the wall. Painted black, they will not look rough; on the contrary, they will add style to the room.

Photo: my.carousell.com

How to make a garden bench from a profile pipe with your own hands

It is impossible to imagine simple country life without benches or simple furniture for sitting and relaxing. You can, of course, bring plastic or wooden furniture, but such furniture is enough for a couple of summer seasons at most. It is well known that garden benches need to be made of metal, especially since a simple bench from a profile pipe can be built with your own hands in a few hours with a budget of 800-900 rubles.

A budget option made from a profile and water pipe will cost several hundred rubles, no more

Bathroom decoration

The bathroom is a place where there are a lot of pipes. Usually they are simply hidden in a wall or in a box. But if you make copper-colored pipes and give them a beautiful shape, you can easily leave them outside as an interior decoration. This solution looks good on a dark background.

Photo: antiquers.com

Options for benches made of profile pipes

The choice of a specific furniture scheme directly depends on its purpose. Benches made of metal pipes have a similar structure in many respects, but there are slight differences in the design and assembly of the frame. You have to take into account the design features and method of its use. For example, if this is a place to relax under the canopy of trees, then it is best to make a bench on the street with your own hands from a massive corrugated pipe, with a cross-sectional edge of at least 50 mm. Often such furniture serves not only for relaxation, but also replaces a stepladder when harvesting fruit. But many people simply like the design in the Loft style.

Despite their unsightly appearance, garden benches made of reinforced profiled pipe are popular among summer residents

Most summer residents prefer making a bench with their own hands from a profile pipe in one of the most popular options:

- A classic version of a long-length country bench without a back;

- Garden bench on a metal frame;

- Bench for relaxing on the veranda or terrace;

- A simple bench with a backrest.

A classic country bench is assembled on a profile frame with a long and narrow seat. To prevent the board from sagging, a beam is sewn onto the frame at the bottom, acting as a stiffener. This bench is used primarily for gazebos or canopies, complementing a large dining table under a canopy with a summer kitchen.

For an open terrace or veranda, people traditionally look for options for a beautiful bench made from a profile pipe. Such designs use elegant curved side rails and racks with a curved back.

Bench for veranda

For gatherings in the backyard of a dacha around a lit fire or at a table, corner benches are often used. The L-shape is considered the most convenient and practical.

It is not necessary to try to make a frame from a square profile; it is difficult to bend, and not everyone likes square shapes. You can make an elegant bent bench with a canopy; it looks more interesting and at the same time safer for children’s games.

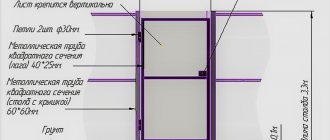

A tall frame made of profile pipe will need to be attached to the ground base

In addition to design and purpose, you have to take into account that a bench from a profile pipe for a dacha is made with your own hands, taking into account the covering on which the furniture will be located. For example, if a bench made from a profile pipe in the garden will stand on soft ground, then it will have to be made with “ski” or solid supports.

Otherwise, the bench will constantly sag and sink in soft soil. For compacted soil areas, you can use ordinary metal “spots”.

Advice! If there are no specific preferences, then the best solution would be to make an ordinary homemade bench with a back from a profile pipe. Simple and reliable.

Bench model with correct seat angle and front edge hemming

Features of the design

Despite the fact that these structures are called metal, in fact, metal is used to create only the support, while the rest of the structure is made of wood.

Metal is not the only material from which a support for a garden bench can be created. In addition, you can choose the following options:

- concrete;

- tree;

- cast iron;

- stone.

If we consider cast iron supports, we should note their greater weight and they are most often used in parks. A similar picture is observed with concrete products. Due to their massiveness and difficulties with transportation, they can be found extremely rarely in residential areas.

Article on the topic: DIY forged furniture

If you decide to opt for stone supports, then immediately get ready for the large costs of purchasing them. In addition to this, such structures are limited in terms of design.

As for wooden supports, they seem to be an excellent solution, since they not only have an attractive appearance and low weight, but also provide a large number of processing options.

But the tree has certain disadvantages, the main of which is difficulty in care, the need for protection due to low resistance to parasites and fungi. It also does not tolerate various natural disasters well. For example, if a tree interacts with moisture for a long time, this will cause it to swell and rot. Thus, the likelihood increases that the service life of such a bench will noticeably decrease.

Metal supports can be a rational option for summer cottages or a country house. The drawing attached to such designs is quite understandable for most owners. Also, these structures are resistant to corrosion processes and destruction, and, in addition, provide many opportunities for the implementation of various design ideas, which is largely achieved through the use of forged parts.

As a rule, such garden benches last at least 15 years. At the same time, they differ in their affordable price. There are no particular difficulties in terms of their manufacture, and therefore even a non-specialist can produce a similar design of the product.

Schemes, drawings and dimensions of garden benches from profile pipes

Of course, a simple universal bench can be purchased without any problems at a construction or garden center. But those Chinese benches made of thin profiles and plastic are not practical enough, and branded garden furniture will cost an order of magnitude more.

The meaning of making a bench from a profile pipe with your own hands is formulated in two points:

- It will turn out to be much cheaper, the frame assembled by yourself will withstand the most extreme loads;

- You can always choose with your own hands the drawings of a bench made from a profile pipe of exactly the shape of the seat or backrest design that best meets the needs of the family and your own preferences.

Advice! When choosing a suitable design, you need to pay attention to the way the frame is assembled. It is quite difficult to assemble a full-fledged garden bench from a profile pipe without welding.

You can, of course, use a bolted connection, but from experience it is known that garden benches and benches, the frame of which is made of a profile pipe with bolts, last no more than two or three seasons. A bolted connection is perfect for attaching wooden cladding, but the metal will still have to be welded using an inverter or semi-automatic machine. There is practically no alternative to using welding for a profile pipe. A bench made from a profile pipe, made without welding, can at best be used for a veranda or terrace.

Drawing and diagram of a bench with a back made of profile pipe

For relaxation in a relatively quiet place in a summer cottage, we can recommend the diagram shown in the drawing below.

A special feature of the design is the construction of side posts made of profile pipes; they are assembled from curved arcs and connected to each other in the form of a semi-arch. To ensure lateral stability, a spacer is welded between the sidewalls. This is one of the most successful models of all the options for a bench made of a square pipe. It is beautiful and interesting in its own way, but the bench can only be installed on a hard surface or on a wooden floor. If you are looking for drawings of benches from a profile pipe for a veranda, then perhaps this scheme will be the best solution.

For a situation where the simplest and at the same time inexpensive and reliable design is required, you can give preference to the two-post model shown in the diagram below.

The consumption of materials is minimal, and most importantly, making a bench from a profile pipe yourself will not be difficult even for a person who is encountering a similar problem for the first time. Each side post is assembled from 4 parts; for reinforcement we use an additional cross member, and any board or beam can be used for the seat and back trim.

Despite the relatively weak frame at first glance, the bench is quite rigid and can easily support the weight of 3-4 adults. At the same time, the weight of the bench is relatively small, and it can be easily carried independently within the site.

The following is a drawing of a universal garden bench for a summer residence for all occasions.

Bench - universal

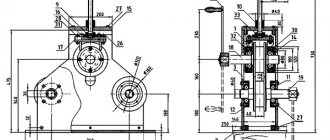

This is the most complex option; it will have to be manufactured in a metalworking workshop using a workbench, clamps and special welding equipment.

Pipes on the walls of the living room

A modern-style living room is often filled with all sorts of technical elements, which naturally require a network connection. To prevent a huge number of wires from bothering you, we offer an interesting option: run them through pipes. They will fit perfectly into an interior with loft elements.

Photo: archilovers.com

What tools and materials will be needed

To make a bench or bench of a standard model, you only need a square pipe with a cross-section of 25x25 mm, an edged board with rounded chamfers and ends, M8 bolts and nuts and small metal plates from which you can cut cards for welding the racks.

The tool is somewhat more complicated; to work with a profile pipe you will need at least:

- Grinder with a set of cutting discs;

- Drilling machine or hand-held electric drill with a set of drills;

- Bench's ruler and caliper;

- Set of clamps;

- Hand grinder;

- Welding inverter or carbon dioxide automatic machine.

The wall thickness of a square pipe is only 1.5 mm, so it is best to perform welding using a semi-automatic machine. If you have some experience, you can weld parts using an inverter, having previously practiced on scraps to select the welding mode.

The metal of the profile pipe is thin, so it is better to cook it with a semi-automatic

Selection of materials for manufacturing

When making a bench with your own hands, it is important to choose durable materials for making its frame. The ideal option would be a profile pipe of rectangular, round or square cross-section. The base of the bench can be made of wood. Coniferous and deciduous species are suitable for this.

Attention: before you start working with the corrugated pipe, it must be carefully inspected for defects and various damages. If there are any, you will need to immediately treat the problem areas, otherwise the product will soon begin to rust and lose its aesthetic appearance.

In addition, to make a bench you will also need materials such as:

- paints and varnishes;

- antiseptic;

- anti-corrosion composition;

- special deep penetration primer;

- wooden beams;

- self-tapping screws;

- screws.

Important: since the thickness of the square-section corrugated pipe is 1.5 mm, it is better to carry out welding using a semi-automatic machine.

How to make and weld a bench from a professional pipe with your own hands

The best option for the first experiment would be a simple bench with a backrest of 75 cm and a seat height of 42 cm. You can use the drawing shown in the photo, or draw up a sketch at your own discretion.

Its short length and low number of welding points make it ideal as a prototype. In theory, such a bench can be easily assembled directly at the dacha, provided that there is electricity and you managed to bring all the necessary materials and tools.

How to make a corner garden bench with a back from a profile pipe with your own hands

First of all, we cut out the blanks. The most difficult part will be making the rear side pillars. To sit and lean on the back comfortably, its surface should be slightly tilted back.

Therefore, we cut out blanks 85 cm long and make cuts with a grinder at a height of 40 cm from the floor level. The cuts allow the square pipe to be bent without deformation. The line will need to be welded using electric welding.

To assemble, we assemble all the sidewall parts on a workbench and secure them with clamps.

After welding, let the part cool and clean the surface with an angle grinder. On the bottom of the racks we weld support patches cut from 5 mm thick steel.

Finished boards must be sanded to remove burrs and round the edges.

All that remains is to drill a hole for the bolted connection and assemble the bench.

Simple benches made of profile pipe and wood without a back

This is a more complex version of garden furniture, since you have to use three supports at once, each of which is a rectangle made of a profile pipe measuring 60x40 cm.

All racks must be absolutely identical in size, otherwise at the slightest deviation one of the supports will simply hang in the air. The wooden sheathing is connected to the rack system using ordinary M8x120 mm bolts.

Round pipe bench

One of the options for such a bench is shown in the sketch below. The peculiarity of this design is that the handrails and racks are made from one flexible piece on a pipe bending machine or device.

Two cross members made of a round pipe are welded between the sidewalls in the shape of arches. The back can also be bent from one piece or welded from a square profile. For cladding, a 50x40 mm strip is used.

How to make a bench from a profile pipe with a canopy with your own hands

It is not difficult to build a bench or bench equipped with a canopy; the technology and methods for manufacturing parts are no different from those used in previous cases. The only difference is that instead of a simple backrest covered with horizontal slats, you have to bend or weld the U-shaped frame of the canopy posts. The supports can be straight or curved, depending on the design of the furniture.

Separately, you will need to weld a roof rectangle from the profile. The flat or arched surface is usually covered with either polycarbonate or wooden slats.

When designing and drawing up a drawing, you need to pay attention to the position of the roof relative to the seat. The center of the canopy should coincide with the middle line of the bench seat. The design has a fairly large windage, a high center of gravity and can easily capsize even with a weak gust of wind.

Selecting a drawing or drawing it

Before you start work, you need to obtain an accurate drawing that will show the dimensions. If you couldn’t find it on the Internet, you can draw it yourself. True, without experience in furniture production or making accurate drawings with projections, you should not do this.

Limit yourself to what you can find on the Internet. This is due to the fact that the production of a chair requires knowledge of the anatomy of the human body, so that in the future the design will be comfortable and safe for sitting and swinging.

When the drawing has been selected, you need to enlarge it and transfer it to graph paper or thick cardboard. This will make it easier to cut out or complete individual elements.

When the stage is completed, you can proceed directly to cutting out the elements and assembling the complete structure.

Plywood construction

It is plywood that allows you to obtain complex curved shapes, and without much effort or skill. For such a rocking chair, you must perform the following steps:

- Glue together several layers of plywood and clamp them in a position that matches the radius of the runners. It is important to make two elements at once and clamp them equally and at the same time in order to obtain identical parts and eliminate unevenness.

- After this, complete all other structural elements in accordance with the drawing. This is usually done with a jigsaw. Sand them and soak them in drying oil.

- On the side elements there are 3 through holes for the footboard and the middle part of its headboard.

- The side elements are connected using a special beam - this is done using either self-tapping screws or additionally reinforced with glue.

- Then the remaining frame slats are also secured with self-tapping screws, assembling the structure in accordance with the drawing and maintaining the dimensions.

- At the final stage, everything must be decorated with a protective coating of a matching color or transparent varnish.