When landscaping a house on a summer cottage, the owners immediately sketch out the fences around it. Installing gates with a wicket is an important element of the enclosing structure. There are all sorts of options for implementing the plan. You can make a wicket built into the body of the frame or separate from the gate from various materials.

The only condition is that the material of the opening element must be durable and reliable. If we take these parameters as the main ones, then a metal gate has no equal, and in the process of making it yourself, you can show your imagination. There are many design methods, and forging elements welded to steel rods will give the entire structure a special charm.

It is easier to buy a ready-made structure than to make it yourself, but many owners like to do all the work on arranging their dacha on their own.

Types of gates made from corrugated pipes

Gates and wickets look seamless and harmonious when they are made of the same height in the same artistic style. According to the type of filling, products are forged, metal-welded, open and closed. The choice depends on the characteristics of the site, the architecture of the house, as well as the task performed by the fence.

All types of gates are united by the basic principle - professional pipe

Forged is a welded frame, the space in which is filled with openwork from forged elements and a metal rod. They are made in open and closed types. You can order a ready-made standard gate or one made according to an individual project. The price of typical forged products depends on the complexity of the design and ranges from 1100–3500 rubles. for 1 sq. m.

External view of the structure with forging elements

The price of a product made according to an individual project is more expensive, 12,000 rubles. for 1 sq. m depending on the complexity of the work. Advantages: appearance, service life, reliable fencing. Disadvantages: cost, heavy weight.

The structure made of corrugated sheets looks like a frame covered with corrugated sheets. The space is filled in two ways. The first is that the corrugated sheet is screwed on top of the frame. The second method is to insert the sheet inside the frame.

The frame is made from a 40x20 mm profile pipe; for rigidity, jumpers from a 20x20 mm profile are welded inside.

Option for a door made of profiled sheets

The design is rigid and convenient for attaching corrugated sheets. Pros: the product is lightweight, the price is low, installation is simple. Cons: careful handling is required so as not to damage the corrugated sheet; installation of a rubber seal is required so that the finished product closes silently.

Closed welded gate - a metal sheet 1.5 mm or 2 mm thick is welded to the frame, resulting in a durable structure, which is decorated with patterns of forged elements or creates strict shapes. Due to the metal sheet, the structure is heavy, the weight of the product 1x2.5 m is approximately 70 kg.

An example of creating a forged welded model

The manufacturer offers a finished product with a kit that includes bolts, canopies, and eyes; its cost is 13,000 rubles. Additionally, you can purchase pillars 80x80x3 mm, 3 m long, for 1,300 rubles. Pros: reliability, long service life. Cons: high price and heavy weight.

An open type of gate in which the space is filled with a 3–6 mm wire mesh curved for rigidity. The parts are painted in a special way in several layers, the product is guaranteed for 20 years. A 3D mesh gate is installed together with similar fencing systems.

The entrance group made of a three-dimensional mesh allows you to fence off the area from unauthorized entry

The price of foreign-made fencing is 10,000 rubles. per product 2x1 m. Pros: easy installation, light weight, modern look, long service life. Cons: high price.

Varieties

Depending on the location, there are two types of doors for the site:

- Garden gates. The canvases are not massive.

- Input. Massive door panels, the main task of which is to protect the territory from the penetration of strangers.

Depending on the design, gates are of two types:

- Arches. They can be decorated with metal elements - branches, leaves, bunches of grapes, birds, apples, etc.

- Classic rectangular designs.

The main division of wickets relates to the materials from which they are made:

- Wooden. The very first door blocks for private areas. Canvases can be made from individual bars, slats, solid wood, plywood, and particle boards.

- Made from corrugated sheets. A modern version of gates for a summer cottage. Corrugated sheeting is often used to make fences and gates.

- From chain-link. Gates, which are rarely installed at the entrance to the site. They are often placed between the vegetable garden and outbuildings.

- Forged. Massive gates that are suitable for protecting your own territory and decorative decoration. To prevent them from rusting due to rain, they are coated with an anti-corrosion compound.

A separate group includes designer gates, which can be made from different materials and old metal tools.

Wicket made of corrugated sheets (Photo: Instagram / a2aofhouse)

Building design

Gates are usually made swinging.

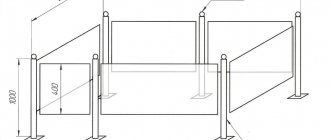

The gate consists of supports in the form of pillars and a door leaf on a frame, which is fixed to the posts using canopies. To close, locks are installed. The pillars are made of brick, steel, reinforced concrete or wood. Inside monolithic and stone supports, embedded parts made of thick metal, angles or rods are inserted in order to weld a gate frame made of corrugated pipe to them.

The door is made as a separate passage in the fence or combined with a gate. In this case, the frame of the gate is placed in one of the leaves. If there is a sidewalk in front of the yard, the opening is made inward so as not to disturb pedestrians. In this case, the size of the leaf is taken into account so that there is a distance for the sash to fully swing open.

Hinged or sliding

The first option is considered an inexpensive design that is easier to cook and install. Such a gate does not require a base to install guide beams; it does not need a counterweight or roller elements. The swing system is combined with the gate and saves space at the entrance. At the bottom, the canvas is cut to height in areas with heavy snowfall. This way, the resulting snowdrift does not affect the opening.

Sliding schemes are more complicated, since guide girders are often placed at the bottom and require a level foundation. There are options with a device for cantilever movement of the leaf, in which the beam is hung so that it does not limit the height of the span, and the rollers are placed inside the sash frame. Automation is installed on swing and sliding systems.

Decor, painting and care

Decorative elements are installed during the section assembly process. Among them may be sockets coated in bronze, pommels for peaks, or shaped forged or cast inserts that are welded to sections of rod (this way you can decoratively connect short trims, saving material).

All fence fittings must be painted with paint or bitumen varnish. The paint color can be any; sometimes a combination of contrasting colors is used (for example, black and white). Metallic sprays can be used. Bar fences can be partially painted with them.

Caring for a metal fence made of welded parts consists of annually updating the paint layer. If rust stains appear on the surface, sand the metal until it shines, cover it with a new layer of protective compounds and paint it.

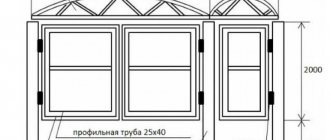

Preparatory work and drawing development

It is clear that any work begins with preparatory activities. During construction, the first thing that needs to be done is to develop a detailed drawing. It will be possible to calculate the amount of material required. As a basis, you can take ready-made projects that are freely available on various Internet resources, or you can make your own based on your preferences. It is important to take measurements exactly in millimeters, this will avoid errors when creating the design.

The drawing will not only help you make a gate from a profile pipe faster and easier, but will also make it possible to save money. A correctly developed diagram clearly shows how much material will be needed to make a structure from a profile pipe, and there will be no need to buy extra. Also, the presence of a detailed diagram reduces the time for manufacturing a gate from a corrugated pipe.

Below you can see several options for diagrams for the manufacture of this building. They can become the basis for a future structure, to which you can add your own details. In this matter, it all depends on personal preferences, and the drawing can be supplemented with other elements.

When the schematic design of the gate from the profile pipe has been made, the rolled metal pipe should be prepared for work. If these are not new products, then they should be cleaned of corrosive formations with a grinding disc.

If these are new products without rust, then before welding they must be degreased with a simple solvent used to dilute paint.

Then the rolled pipe for the gate from the profile pipe is cut into pieces of the intended length. For a rectangular inlet hole, it is recommended to cut metal professional material in pairs. So the blanks for a structure made from a profile pipe will have the same length.

Dimensions and shape

For a solid gate, a profiled pipe with a cross section of 60*60*3 mm is used as pillars. In this case, it is better to choose thicker walls, as this will affect the durability of the structure. For the frame, a rectangular pipe 40*20*2.5 mm is usually used. The strength of this pipe is sufficient for medium wind loads. For light wind loads, you can take a 2 mm wall, but it will be more difficult to weld. Anything thinner than 2.5-3 mm must be welded in a special mode, and this is far from easy. If the winds are stronger, you can either increase the wall thickness, or use a larger cross-section: 40*30 or 40*40, even 40*60.

Wicket - device, dimensions

The height of a gate with an upper crossbar is usually about two meters, without a crossbar - from 1.2 m. Low ones are usually made in internal fences that delimit a site or in translucent low fences. For solid high fences made of corrugated sheets, wood, or flat slate, the height at the fence level is more typical. The width of the gate is minimum 90 cm, optimal is 100-110 cm. These dimensions are based on practical considerations, since in winter or autumn it will be inconvenient to walk through a narrow gate with a width of 70-75 cm in outerwear, and it will also be difficult to carry any items if necessary. those are big things.

It’s also worth talking about how deep to bury the pillars. The standard solution is 15-20 cm below the freezing depth . Based on this value and adding the height of the gate to it, supports are made.

Additional jibs increase rigidity

Using a shovel or a drill, make a hole in the ground, at the bottom of which a bucket of medium-fraction crushed stone is poured. Then the pole is installed, set vertically, covered with crushed stone (or broken bricks) and filled with concrete mortar. When the solution has gained at least 50% strength (after 7 days at a temperature of +20°C), you can attach the gate frame.

Basic requirements for gates

Metal gates, which are produced by large enterprises, must meet a number of requirements:

- The optimal width of one leaf is 100 cm. This width is enough to carry large objects through the opening. If the sash is larger, this will negatively affect the condition of the fastenings - over time they will bend due to the weight, and the door will warp.

- The height of the doorway should not exceed 2.3 meters, and the door - 2 m. A plank is fixed on top of it. It allows you to visually equalize the height of the opening and the fence.

- The door must be installed so that it can be seen from the window.

- During manufacturing it is necessary to use only high-strength materials. They must be resistant to moisture and temperature changes.

Also, attention should be paid to the fastenings for the door. Their number depends on the severity of the door.

Metal gate (Photo: Instagram / pavel_mlechko)

Tools required for work

Tools for installing a gate

For excavation work, use a bayonet shovel or crowbar. Sand, crushed stone, and cement are transported using stretchers or buckets and mixed in a concrete mixer. A small volume of the mixture can be prepared manually in a trough, stirred with shovels. To weld a gate from a profile, welding is required; consumables are purchased for it.

Other tools:

- tamper for crushed stone, sand, electric vibrator for concrete;

- grinder with a grinding and cutting wheel for metal;

- electric screwdriver and drill;

- level, square, plumb line, 5 m tape measure, core.

An angle grinder (grinder) is used to cut off the parts of the frame and diagonals, and using a grinding wheel to clean the welds from scale. In different cases, you may need other tools, such as an ax, to cut roots in the ground.

Selection of material

The appearance of the entrance group determines the choice of building materials for support pillars and lining of the panels. You can weld a gate from a round pipe, but it is inconvenient to attach hinges to it, and difficulties arise when connecting the corners of the frame. The square section avoids such difficulties.

The internal filling is made of mesh, artistic forging, this structure looks openwork and opens up an overview of the internal space of the yard. Corrugated sheeting is used more often due to the wide choice of colors and patterns to resemble stone and wood.

For the canvas, cellular or monolithic polycarbonate is used, and sandwich panels are installed. Sometimes forged elements are combined with wooden filling.

Characteristics of professional pipes

All profile pipe products have the following main characteristics:

- affordable cost;

- reliability and durability in use;

- light weight;

- a significant degree of resistance to mechanical stress and corrosive processes.

Every home craftsman, if desired, can make a gate from a profile pipe with his own hands without the help of a craftsman, which does not require professional knowledge and skills. You just need to confidently use a drill, welding machine, or grinder. You will also need to draw a simple drawing.

For the designed structure, you should purchase high-quality building materials. But before you go shopping, they develop a detailed drawing of a gate made from a profile pipe with all dimensions.

Cost and weight

The price of the pipe depends on the size and wall thickness. Products are produced in square and rectangular shapes. The dimensions of the profile shelves are 10–180 mm. Wall thickness 1–14 mm. For private construction, a profile pipe with a thickness of 1 to 4 mm is used; it is durable, lightweight, and the round counterpart is 20% heavier.

Types of professional pipes for creating a frame

The most popular profile for building a gate from a profile pipe at home:

- For the posts and frame of 3D gates, a pipe of 60x30 and 60x40 mm with a wall thickness of 2 mm is used. The approximate cost is 128–140 rubles per linear meter.

- To make a large open-type frame, a 50x25x2 mm pipe is used. The price, depending on the region, averages 110 rubles.

- The 40x20x2 mm profile is the most common for products of this type. It is used for products made of corrugated sheets, as well as metal sheets. The price of a pipe per meter is 78 rubles.

- To facilitate the design, a 40x20 mm profile with a wall thickness of 1.5 mm is used. The price of one meter is 75 rubles. Jumpers for rigidity are made from a 20x20x1.5 mm profile, the cost is 40 rubles. per linear meter.

The rectangular shape allows for greater convenience in attaching the facing material.

Thanks to its rectangular shape, the pipe has natural stiffening ribs, which makes it durable and can withstand heavy loads; this is the advantage of profiles over their round counterparts.

How to make a gate from a profile pipe - do-it-yourself installation

When arranging a fence, many owners of summer cottages prefer to install gates with a wicket made from profile pipes. You can make such a metal structure yourself. In addition, a high-quality gate made from a profile pipe can become a decoration for your dacha.

Welding the gate frame

When preliminary calculations have been made and the material has been purchased, you can proceed to creating a frame for the gate.

- Before welding a gate from a profile pipe, prepare the place. A metal table with a flat surface is the best option for work. The table is set horizontally, all irregularities are smoothed out with a grinder. This is necessary to ensure that the product is level in the horizontal plane.

- The material is cleaned of rust and debris using a grinder with a grinding wheel. It is better to clean the workpieces separately, since this is more difficult to do in the finished product.

- The prepared material is cut to size. The blanks are cut at an angle of 45 degrees. Such welded seams look aesthetically pleasing, and moisture does not get inside.

- To get an evenly cut workpiece, use a stationary cutting angle grinder with a degree scale or manually mark it using a corner. When cutting, make sure that the workpiece lies flat and the grinder is perpendicular to the surface.

- Before assembly, all metal parts are primed. A gate made of a profile pipe must be treated on all sides so that rust does not appear when moisture gets in.

- The prepared frame blanks are placed on the work table, tightly joined, and the diagonals are checked.

- Make neat tacks in three places to fix the structure, check the dimensions again.

- If the dimensions and diagonals are normal, the structure is turned over to the other side and the blanks are welded together. This is done so that the structure does not go astray in the horizontal plane. Then they turn it over to its original position and finish scalding the joints. After the frame of the gate is ready, the welding areas are polished and filled with decorative elements or metal sheets.

The finished product is primed and then painted.

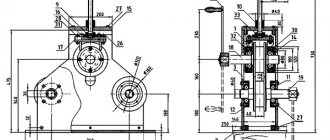

Lock mortise

The gate experiences temperature changes, exposure to humidity and atmosphere. A special feature of the lock is a narrowed bar and a short distance from it to the axis of the lock.

Every entrance gate needs a lock. There is a wide choice of locks: from padlocks to electronic ones. But most locks are mortise, they are reliable, and have many degrees of protection. When manufacturing the frame, a 40x20 mm profile pipe is used, which is suitable for installing a mortise lock.

For convenience, the lock is cut in when the frame is not yet welded and it is easy to work with the workpieces. On the 40th shelf, 90 cm from the bottom, mark the opening for the lock on the inside and outside.

Arranging a place for a mortise lock

For cutting, take a small grinder, set a circle of small diameter, usually used circles. The markings are made from the center of the profile with a margin of 1 mm on each side.

First, longitudinal cuts are made in the profiled pipe. Then small transverse cuts are made in a small circle at both ends and in the middle. The middle cut is made diagonally, this makes it easier to cut through the plank. Then use a screwdriver to pry the plate off in the middle. Clamp the edge with pliers and break the two halves in turn. Cut out on both sides, inside and outside. You can watch the video at the end of the article for more details.

When assembled, the structure should look like this:

Painting

Painting is an important part of the job. Paint protects the metal from corrosion and gives it an attractive appearance. Particular attention is paid to preparing the product for painting. The metal is cleaned of rust. It is better to do this at the preparatory stage of assembly, then you will not have to manually remove rust from hard-to-reach corners.

Coating metal surfaces with paint

The workpieces are wiped free of dust and degreased with a cloth soaked in solvent so that the painted surface is free of dust particles. To thin the paint and primer, use solvent 646 or 647. After dilution, begin priming the product.

This is a preliminary treatment of the metal with an alkyd primer, which smoothes the surface and ensures good adhesion to the paint. Now they produce 2 in 1 paints, which are used without a primer.

Painting with a spray gun significantly reduces the consumption of protective composition

It is better to paint the product with a spray gun, then the paint will spread evenly in a thin layer. You need to paint twice. The first layer is applied to level the surface, and then partially covers all unpainted areas. Paint the second time after the first layer has completely dried. The paint gives shine and lasting color.

The cost of the Russian primer GF-21 weighing one kg is 151 rubles. Finnish Tikkurila costs 500 rubles. per can weighing 0.9 kg. Primer consumption 70–100 g per 1 sq. m.

Appearance of the domestic primer GF-021

The cost of Russian-made paint is cheaper than its foreign counterpart. PF-115 enamel, 0.9 kg can, costs 200 rubles, and Finnish Tikkurila of the same weight costs 1100 rubles. Paint consumption 100–150 g per 1 square. m.

Note. Try not to let the paint drip. Apply the first thin layer, and after drying the second. Smudges and thickly applied paint do not look attractive on the finished structure.

Installation of a gate

We move on to the final work - installing the gate. Please note that at the welding stage, the loops that cover the paintwork are fixed. Before you begin installing the frame and gate, you need to install the support pillars. For this purpose, use a tube with a diameter of 60 x 60 mm. The element is buried into the ground up to 70 - 100 cm, this is enough to ensure the stability and strength of the structure.

Advice! At the bottom of the post, parts made of metal sheet are attached, like a sole. This will provide additional stability and simplify the leveling task.

Take measurements and dig holes to immerse the supports. Align the elements strictly level, checking the vertical position of all sides. Place temporary spacers, mix the concrete mixture and pour it into the recesses.

After the concrete solution has hardened, proceed to fixing the canopies. Take another person to help, since this is a critical stage, it is necessary to maintain clarity and coherence in the work. Attach the gate made of the profile pipe to the supports in the position in which it will hang on the gate. Make marks for the awnings and attach the missing elements using a welding machine. Sand the seams with a sanding wheel. At the end of the work, cover the pillars with primer and paint.

Cladding works

The wicket frame is covered at the final stage. Profiled sheet metal, which is used for wall decoration, is suitable for the design of the structure. The choice of corrugated sheets is presented in various colors.

Select durable fasteners - hardware. The color of the side for the rivet can also be very diverse, just like the profiled sheet.

Place the sheet against the metal frame, drill holes around the perimeter at intervals of 20 cm. After that, proceed to fixing the profile sheets to the frame. At the last stage, hang the gate on the frame and check the quality of opening and closing, install the lock and handle. Use forged parts as decoration. They can be purchased ready-made or made to order. A gate made from a forged profile looks very attractive against the background of the overall fence design.

It’s very easy to do the sheathing for the gate yourself. But there is no need to rush in this matter. Patience and accuracy should not be discounted. If you haven't had to do this work yourself, there's no need to be upset. Everything will work out correctly if you correctly measure the required sheets of material and act without undue haste.

Installation of swing gates with a wicket

Independent construction of this type of gate with a wicket is simple and is carried out in stages:

- First, draw a drawing and determine the amount of materials required.

- When using old pipes, they are cleaned with a grinder and a grinding wheel, or regular sandpaper can be used.

- If pipe products were purchased recently and have not yet rusted, then they must be degreased using gasoline or paint thinner. The products can also be painted.

- Cut and mark the purchased materials. If the gate has a rectangular shape, then the corrugated pipes are cut in pairs.

- Using a hole drill, they make recesses for installing support pillars.

- The bottom of the grooves is covered with crushed stone, which will become like a pillow for the supports. Then the entire structure is concreted with a mixture of cement, crushed stone and sand in a ratio of 1:4:2. Two days are allowed for the solution to harden.

- Next, you need to weld the gate frame from the profile pipe as accurately as possible with your own hands. This must be done in such a way that all the existing corners and diagonals of the structure are the same in size.

- Then you need to weld the hinges to the support posts, and then to the gate frame.

- When the cleaning of the welding effects is completed, they begin to grind the surface, after which it is treated with a primer and wait until it dries.

- Apply paint to metal.

- Profiled sheets are attached to the finished frame with self-tapping screws. They can be placed from the outside or from the inside of the frame - it depends on the personal preferences of the owners of the site. If you plan to decorate the gate using forged elements, then the sheets are fixed exclusively from the inside of the gate frame. When wooden boards are used for finishing, they are first coated with varnish. Forged products are welded to the gate frame.

What is a rebar fence?

The simplest version of a fence made of metal rods consists of vertical elements attached to 2 horizontal veins. Its design resembles a simple wooden picket fence and is just as easy to assemble.

Making an unusual decorative fence is a little more difficult. There can be many design options: it’s easy to come up with a design yourself or choose what you need from the illustrations. The basic principle of pattern formation is a combination of horizontal, vertical and inclined elements. Sometimes a complex pattern requires the creation of a section frame, but most often the veins are connected by structural parts, which themselves form the basis of the ornament.

The rod is easy to bend using a cold forging machine or hand tools. Using this technology, it will be possible to create a fence that resembles a forged product. Even an arched upper vein in combination with straight rods of different heights looks more decorative than the simplest option, although in terms of manufacturing complexity it is practically no different from it.

In addition to reinforcing bars, welded mesh is also used for decoration. Elements from it, beautifully integrated into the structure of the fence, will give it an unusual openwork look. In addition to its decorative function, a mesh strip at the bottom of the fence will help prevent street dogs from entering the area.

Advantages and disadvantages

1. Considering the budget pricing policy for profiled materials and their availability in stores, the first advantage can be called low cost. A gate made from a profile pipe will cost you little compared to products made from other materials.

2. With proper processing and subsequent care of such a door, the material will be resistant to corrosion.

3. The door is the most used place of the entire structure, so the fact that products made from profile pipes are durable and will serve you for a long time is no less important.

4. Profiled pipes are light in weight, which will lighten the structure frame and allow you to quickly and effortlessly install the gate.

5. To manufacture and install the structure, you do not need special knowledge and skills. It is enough to be able to handle tools such as an angle grinder and a welding machine and do a little drawing. You will also need knowledge of working with soil, which boils down to digging holes for supports.

6. Another factor why private sector owners prefer structures made from profile pipes will be their reliability.

7. Also, real aesthetes can create their own design using a variety of materials.

1. One of the disadvantages is the lack of sound insulation. Therefore, your yard will be protected from prying eyes, but not ears.

2. If you cannot guarantee that the gate will not be subject to any mechanical influences, then you must be prepared for the fact that any damage can lead to metal corrosion.

Among other things, the following advantages stand out:

- The cost of the source material is quite understandable for every summer resident.

- Long service life of the finished structure.

- Very easy to make and install.

- The profile pipe construction is quite reliable.

- There is always the opportunity to diversify the design, for example, to use forging elements.

Direct assignment

An integral part of a reinforced fence is the construction of a strip or columnar foundation. The first option costs a lot of labor and money. A trench is dug along the perimeter of the site, which is subsequently filled with solution. It is prepared from M200 concrete or a higher grade. The dimensions of the foundation ditch depend not only on the weight of the entire structure, but also on the characteristics of the soil. The main thing is that it is deeper than the frozen layer. Otherwise, when the soil freezes, it expands, swells and pushes the concrete base upward.

The bottom of the dug trench is covered with sand, which is generously moistened and compacted. Formwork is installed, which can be boards or sheets of any flat material. It is fixed with spacers. The supporting pillars are installed strictly vertically and secured with a reinforcing frame before pouring the solution.

The process of installing a fence from reinforcement

Then reinforcement is made: long horizontal rods are welded to short rods installed vertically along the entire length of the trench. This is where reinforcement is used for its functional purpose - to strengthen concrete. This role is performed more effectively if it is not smooth, but grooved, 8–14 mm in diameter. It is not always possible to fill a long tape without interruptions. Then this is done layer by layer.

Time intervals are needed for each horizontal layer to set. The concrete finally hardens in about a week.

The second type of foundation for fencing is pit-columnar. It is much cheaper than tape. Installation takes less time. Only the underground support of each pillar is concreted, and not the entire perimeter of the site. Here reinforcement is not used at all.

Return to contents

Photos of beautiful gates

Making a gate that is not ordinary, but beautiful is not so difficult. And this does not always require expensive materials. What is always needed is imagination. Then even a bicycle, a shovel, a knot or a pickaxe is a material for exclusive design.

For pets))

For houses in a modern style, gates need appropriate

From a variety of materials... even from knots

Wood and forged elements - a win-win combination

The main component is fantasy

A stencil changes even the simplest fence

Make a couple of cutouts in the boards... the original wooden gate is ready!

Visiting fairy tales

Bicycle, wheels, shovel - all materials for making gates

To the fence made of Euro picket fence

A small fragment - a cat made of plywood

Original design from the courtyard Sources

- https://ZaborSebe.ru/vorota/kalitka-iz-profilnoj-truby-svoimi-rukami.html

- https://StrojDvor.ru/krupnye-konstrukcii/kalitka-iz-profilnoy-truby/

- https://TrubaNet.ru/izdeliya-iz-trub/kak-svarit-kalitku-iz-profilnojj-truby.html

- https://zabor-pro.ru/kalitka-iz-profilnoj-truby.html

- https://domsdelat.ru/okna_i_dveri/kalitka-iz-profilnoj-truby-svoimi-rukami-osobennosti-sozdaniya-i-poshagovaya-insturkciya.html

- https://passaz-okna.ru/dveri/kak-sdelat-kalitku-iz-profil-noy-truby-shema-i-poshagovyy-montazh-svoimi-rukami.html

- https://ZaborStroj.ru/kalitki/delaem-kalitku-iz-proftruby

- https://stroy-okey.ru/house/zabor/kalitka-iz-profilnoj-truby-i-profnastila-svoimi-rukami/

- https://stroychik.ru/zabor/kalitka-svoimi-rukami