To decorate the interior of premises and local areas, curls made of metal rods are often used . A snail cold forging machine is a device that creates rounded patterns (curls, volutes). You make templates from metal sheets with your own hands for future use.

This article is devoted to the purpose of snail machines, their structure and scope of application in general, without dividing them into homemade and industrial ones. There is a separate article on homemade devices of this type on the site.

Step-by-step manufacturing of a small-sized manual machine for making curls

A small machine is designed for the production of curls from rolled strip with a width of 20...30 mm. It's easy to make it yourself.

Center

First the center is made. To do this, a small fragment of round timber is sawed off. The workpiece is fixed in a vice and the cutting line is marked. Using a cutting disc and an angle grinder, the workpiece is sawed off.

It has a diameter of 38 mm. The side surface is not further processed.

The center length is 28 mm. A little more is possible, but this is enough to bend a strip 30 mm wide.

A hole Ø 8 mm is drilled on a drilling machine. It is placed eccentrically. This situation is due to the fact that it is necessary to make a clamp for the end of the workpiece.

A profile is drawn, which should be removed using cutting and cleaning discs installed on the grinder. The workpiece is secured in a vice and excess metal is removed.

The flap discs protect the surface so that there is a smooth transition between different surfaces of the clamp.

To make it easier to fix the end of the workpiece in the future, you need to drill a hole. It is placed on the radial surface of the center. A hole is drilled for an M10 thread.

Using a set of taps, the internal thread is cut. A headless screw will be used here. After fixing the workpiece, it will hide inside the metal of the center.

The center is welded to the 4 mm thick base plate. This completes the work of its production.

Making a fixture

To make it easier to work with the device, a shaft is welded to the back side of the plate. By rotating it in a special mandrel, the snail will rotate.

The outer surface must be ground so that the welds do not interfere with the free fit of future workpieces.

The future spiral is drawn on the plate. A contour is created where it will be welded later.

A spiral is bent from a strip 4 mm thick. It must correspond to the project.

After checking the spiral against the template, the excess is cut off, and the spiral itself is welded to the plate and to the center.

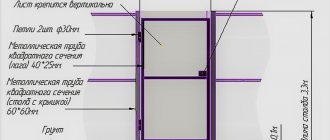

A 40×40 mm profile pipe with a 3 mm wall is used as a stand. Holes are drilled on it for attaching machine elements. Using support platforms, the prepared parts are fixed.

The handle is visible on the reverse side. It was secured to the shaft using a bearing. The prepared “Snail” can rotate.

A performance check is being carried out. The handle turns the spiral around the center axis.

This is interesting: Cyclones for air purification from dust - types, DIY production

"Globe" device

Such a device is similar in appearance to a school protractor and is designed for making arcs with a large bending radius from a strip, square, circle or hexagon. First, one end of the workpiece is fixed with a bend, then it is bent along its entire length according to the template. The principle of operation is somewhat similar to the operation of a canning machine.

Appearance of the device

Video of work at Globus

Using purely muscle power, a large diameter arc can be made on a template screwed or welded to a workbench. It is good for bending strips, thin-walled pipes, etc.

Sample

Video: homemade electric cold forging machine

Spiral like a spiral

Device for winding spirals manually

In some cases, ordinary smooth, straight, ascending spirals are used as an element of artistic forging. Making a spring twister machine for this on your own is absolutely unrealistic. But remember: the spirals in a forged pattern do not need to be springy and can be wound from ordinary ductile steel using a simple device (see figure on the right). The pitch (ascent) of the spiral is determined by the horn of the gate (filled in red); By bending the horn up and down, you can get thinner and thicker spirals. A square bar is taken onto the workpiece or a round one, it doesn’t matter. You can also twist spirals from a rod twisted on a torsion bar.

Flashlight device

This machine produces blanks for “Lanterns” or “Pine Cones” elements, which can consist of 4, 6, 8 or more rods. According to the principle of operation, the machine is similar to the “Twister”, but here the workpieces are bent around the guide shaft, which forms a more correct and accurate configuration of the product.

Flashlight device

Operation of the device for making “Flashlight”

Making a guide for the conductor

For these purposes, you will need an ordinary lathe of type 1K62 or 16K20, which is capable of cutting an Archimedean spiral, and, of course, an experienced turner. The “Archimedean spiral” function in lathes is intended for cutting special threads, but it is also quite suitable for obtaining a groove in the base plate, where the jig guide itself will then be located.

When preparing the machine, the following transitions are performed:

- The small handle of the machine feed box is moved to the “Archimedes Spiral” position.

- The required spiral pitch, which will determine the dimensions of the conductor, is set using a large handle.

- The feed step is fixed by a lever, and the feed amount is determined by the depth of the groove in the plate (how to set this parameter will be discussed later).

- After turning on the machine, the feed lever remains in the same position, and cutting is performed during the reciprocating movements of the spindle.

- After each pass, the support is moved away from the end of the workpiece.

An example of obtaining an Archimedean spiral is presented in this video:

The fact that the frames show not metal, but plastic, does not fundamentally change anything: the spiral is obtained as a result of several successive passes of the cutter, which moves along a given path.

The dimensions of the spiral groove are determined based on the desired dimensions of the conductor and the height of its supporting surface. If in the first case everything depends on the size of the initial workpiece for the plate and the capabilities of the machine, then the depth of the groove should be calculated based on the height and thickness of the guide matrix.

Since in a cold state any metal has increased mechanical strength, then to make a guide matrix with your own hands you should use tool steel: for example, grade U7 steel according to GOST 1435-84. It is not recommended to use high- or medium-carbon structural steel such as steel 45 or steel 60G, since for tall volutes they may crack under the influence of a bending moment.

The dimensions of the guide matrix in plan are selected based on the available range of strip tool steel in accordance with GOST 4405-75. Since the jig must be compact, it is advisable to choose profiles 3×20, 3×25 or 3×30 with a maximum thickness deviation of 0.4 mm. When fitting the guide into the plate according to H11, the width of the spiral groove should be 0.5-0.7 mm greater than the width of the strip. The groove depth must be at least 1.5 times the strip height, i.e. 4.5 mm or slightly more. This parameter, by the way, will determine the thickness of the slab itself: it should be at least 6 mm.

The total length of the guide is determined from the cut groove in the slab (you can use a flexible tape measure or even regular thread to measure). Then they cut the required length of the strip “to size”, insert it into the groove and scald it along the contour (if the jig will produce only flat snails, then along the outer generatrix, and if three-dimensional, then along the inner one).

A support hook is bolted to the center of the conductor. It must have a lead-in section with which the workpiece is fixed at the initial moment of spiral formation (see Fig. 3).

Types and purpose of forging machines

A machine for any purpose is used to facilitate manual labor. For cold forging, various equipment can be used, minimizing the physical effort of the master and allowing the following basic operations to be performed:

Machine for creating a shaped profile using cold forging

- bending the profile at the desired angle or radius;

- making spirals or curls;

- longitudinal twisting of workpieces.

The variety of parts obtained allows you to arrange them in combinations and intricate designs, create a neat artistic canvas for fences and gazebos, symmetrical decor for park benches, as well as other items for various purposes.

Industrial bending machine, which allows you to obtain a workpiece with a given radius

Cold forging machines can be specialized (perform only one operation) or universal. There are the following types of special machines:

- bending machines (bending machines) – allow you to bend a workpiece at an angle or a given radius (wave);

- snails - twist the blanks into spirals and curls;

- torsion bars - help to longitudinally twist a workpiece or several such parts at the same time;

- stamping machines - they are used to make decorative clamps, shaped ends, and waves with fine pitches.

Universal machines include components of special equipment in various combinations.

Devices for cold forging are driven mechanically (manual machines) or by electric drive. Electrically driven equipment is characterized by speed and ease of processing workpieces. A cold forging machine, the price of which can be quite high, is characterized by high productivity. When there is no need for productivity and speed, then a manual machine will be quite sufficient to complete the work, especially if blacksmithing is a hobby.

Bent machine designed for processing pipes using cold forging

Is it possible to make a cold forging machine with your own hands?

You can buy a manual machine for cold forging in a specialized store that sells tools or order it online. The question is the price and solvency of the buyer. An alternative option is to assemble it yourself. The principle of operation will be no different from a product purchased in a retail chain, and the functions performed are absolutely identical to the factory ones. Additional advantages are a reduction in price, confidence that the design will not fail after the first use.

To begin with, it is worth familiarizing yourself with the design features of each type of machine in order to assess the possibility of its self-assembly.

A snail cold forging machine that allows you to create spiral elements

The torsion bar must twist metal rods, so its design assumes the presence of two elements that hold the workpiece. One of them serves as a clamp, and the other contains a rotating spindle, which, in fact, will twist the rod to the desired frequency of the helical wave. The device is quite easy to build yourself, and some craftsmen even make do with a vice and a simple hand crank.

The design of the bending machine is also simple, but it contains several mandatory elements, the assembly of which is impossible without specialized tools. The base is a massive metal plate with a groove in the middle into which a movable stop is inserted, moved by a worm mechanism. The other two cylindrical stops are stationary and are attached to the base on both sides symmetrically relative to the groove. It is the installation of stops that can cause difficulty, since holes for fasteners are drilled only on a specialized machine; such a workpiece made of high-strength steel will not yield to the influence of a drill.

Creating elements using the cold forging method on a homemade gnutik machine

A snail metal forging machine can have two types: with a collar or a lever type. The first option allows you to vary the shape of the bend during operation, however, it has a number of weak points in the design and is very demanding on the strength of the manufacturing materials. The second type is more stable, but less productive. Craftsmen consider the snail to be the simplest machine, the self-assembly of which will not cause difficulties.

Device "Gnutik"

Purchased or made independently, the “Gnutik” is a universal device that allows you to obtain an arc or angle from a rod. It consists of a base with a slider, on which a stop with an angle (90° or another as necessary) and two cylindrical fixed stops are fixed. By moving the slider and the angle stop, the rod bends at an angle. To obtain an arc, a third cylinder is provided, rotating on the side opposite to the angle stop.

The device can be made on a horizontal or vertical platform.

Axonometry of the "Gnutik" device - vertical arrangement

To scale the dimensions, here is a drawing of the bottom bar of this “Gnutik”.

Bottom bar

This device is universal. With the help of attachments you can not only bend, but also cut and punch holes. But this will be the next step.

Getting an arc on "Gnutik"

Getting an angle on "Gnutik"

This is what a homemade “Gnutik” looks like:

Types and purpose of forging machines

A machine for any purpose is used to facilitate manual labor. For cold forging, various equipment can be used, minimizing the physical effort of the master and allowing the following basic operations to be performed:

Machine for creating a shaped profile using cold forging

- bending the profile at the desired angle or radius;

- making spirals or curls;

- longitudinal twisting of workpieces.

The variety of parts obtained allows you to arrange them in combinations and intricate designs, create a neat artistic canvas for fences and gazebos, symmetrical decor for park benches, as well as other items for various purposes.

Industrial bending machine, which allows you to obtain a workpiece with a given radius

Cold forging machines can be specialized (perform only one operation) or universal. There are the following types of special machines:

- bending machines (bending machines) – allow you to bend a workpiece at an angle or a given radius (wave);

- snails - twist the blanks into spirals and curls;

- torsion bars - help to longitudinally twist a workpiece or several such parts at the same time;

- stamping machines - they are used to make decorative clamps, shaped ends, and waves with fine pitches.

Universal machines include components of special equipment in various combinations.

Devices for cold forging are driven mechanically (manual machines) or by electric drive. Electrically driven equipment is characterized by speed and ease of processing workpieces. A cold forging machine, the price of which can be quite high, is characterized by high productivity. When there is no need for productivity and speed, then a manual machine will be quite sufficient to complete the work, especially if blacksmithing is a hobby.

Bent machine designed for processing pipes using cold forging

Is it possible to make a cold forging machine with your own hands?

You can buy a manual machine for cold forging in a specialized store that sells tools or order it online. The question is the price and solvency of the buyer. An alternative option is to assemble it yourself. The principle of operation will be no different from a product purchased in a retail chain, and the functions performed are absolutely identical to the factory ones. Additional advantages are a reduction in price, confidence that the design will not fail after the first use.

To begin with, it is worth familiarizing yourself with the design features of each type of machine in order to assess the possibility of its self-assembly.

A snail cold forging machine that allows you to create spiral elements

The torsion bar must twist metal rods, so its design assumes the presence of two elements that hold the workpiece. One of them serves as a clamp, and the other contains a rotating spindle, which, in fact, will twist the rod to the desired frequency of the helical wave. The device is quite easy to build yourself, and some craftsmen even make do with a vice and a simple hand crank.

The design of the bending machine is also simple, but it contains several mandatory elements, the assembly of which is impossible without specialized tools. The base is a massive metal plate with a groove in the middle into which a movable stop is inserted, moved by a worm mechanism. The other two cylindrical stops are stationary and are attached to the base on both sides symmetrically relative to the groove. It is the installation of stops that can cause difficulty, since holes for fasteners are drilled only on a specialized machine; such a workpiece made of high-strength steel will not yield to the influence of a drill.

Creating elements using the cold forging method on a homemade gnutik machine

A snail metal forging machine can have two types: with a collar or a lever type. The first option allows you to vary the shape of the bend during operation, however, it has a number of weak points in the design and is very demanding on the strength of the manufacturing materials. The second type is more stable, but less productive. Craftsmen consider the snail to be the simplest machine, the self-assembly of which will not cause difficulties.

Twister device

“Twister” is a tool for twisting rods, mostly square, along the longitudinal axis. This simple device can be manual or electric. Operating principle: both ends of the rod are secured, then one fastening begins to rotate, twisting the metal to the required shape.

Appearance of a purchased manual “Twister”

Look at the photo of a homemade “Twister” with an electric drive, assembled using used electrical equipment:

There is a special machine for making “Lanterns” and “Cones”, but for starters you can also use a “Twister”, as shown in the video (English, but everything is very clear).

Read also: How to connect a float to a water pump

Video: how to make a blank for “Flashlight” on “Twister”

Making a simple part on a machine

The strip steel workpiece is cut to the required size. This size is usually clarified by drawing the finished product and its component elements.

The free end is placed in the center of the spiral. The workpiece is secured using an internal screw.

The “Snail” rotation is performed. The workpiece is pressed tightly against the guides. This requires some effort to obtain the desired product profile.

By turning the device further, a curl is made. If necessary, insert the other end of the workpiece and make a closed or open curl.

Usually the other end does not stay straight. It is also bent. Therefore, a distinction is made between internal and external reverse curls. Marks are made on the device itself using a marker or chalk. They are used as a guide when making curls with the required parameters.

As you can see from the step-by-step guide, using a simple set of tools, a homemade curl maker is easy to make. How much does it cost? Its price is determined by the cost of the blanks. Often the price is minimal.

Buy

If opportunities do not allow you to make a machine with your own hands, you can easily purchase it in a store. On our website there is a special section with a selection of reliable companies selling ready-made devices.

In addition to the snail-type device that is so popular among customers, manufacturers also offer to buy other cold forging machines: manual and electric.

Purchasing the devices will allow you to complete cold forging projects yourself.

Making a snail

Several devices are shown in the figure. This is roughly how it should turn out (basically).

Assembling a snail with your own hands is one of the options for independent design, when it makes no sense to give recommendations indicating the exact parameters of all components. Here you need to focus on your own idea of what will bend and how (radii, number of spiral turns, and so on). But if the essence of the manufacturing process becomes clear, then the assembly itself will not cause any difficulties.

Desktop device

The cold forging process requires a lot of effort. If you already have a ready-made workbench, you may have to strengthen it. When making a snail from scratch, the table frame is made only of metal - a channel, a corner, a thick-walled pipe.

It is clear that the tabletop should also be metal. During the operation of the snail, it will be subjected to both static and dynamic loads. Therefore, ordinary iron sheet is not suitable. Only a plate, and not less than 4 mm.

Marking and installation of “attached” equipment

Perhaps the most creative stage of work. You can do everything with your own hands. But how, taking into account the future or limiting ourselves to the production of similar samples?

Option 1. The simplest. The meaning of the operation is that the outline of a spiral is drawn on the tabletop.

Essentially, this is a sketch of future shaped parts, for example, from a rod. After this, it is enough to cut out several segments from a thick strip of iron, bent along a radius. They are welded to the tabletop, and the bending mechanism is basically ready.

Some may find this design more attractive - with a solid stripe.

But practice shows that it is more difficult to work with such a snail. For example, when removing the finished product from it, certain difficulties will arise.

Option 2. The same, but several contours are drawn. Holes are drilled along each one and threads are cut into them. All that remains is to prepare the templates for the stop segments. They are usually made with your own hands from thick cardboard or plywood.

Overlays are made from metal, in which, after the next marking, holes are also drilled, coinciding with the landing “sockets” in the slab. This design will make it possible to organize the production of spiral-shaped workpieces with different radii on one table. You will only have to, depending on the shape of the bend, install the appropriate segments in certain places. Their fastening to the base is bolted. You can do it differently. Instead of such stops, install cylindrical ones.

For fixation, they are attached with bolts (from the bottom of the slab) or are made immediately with legs (+ thread) and screwed into the tabletop. It's much more convenient with them. And if you have your own mini-lathe, then turning it yourself will take a couple of hours.

Option 3. Prepare several removable modules that can be changed as needed.

Snail assembly

The ploughshare is installed, the levers and the side stop are attached. All this is clearly visible in the pictures.

Everything that is in the shed (garage, attic) will be used - cuttings of pipes, rods, corners, and the like. If the principle of the snail’s operation is clear, then no further hints are required.

Functionality check

This is always implied, so no comment.

In principle, making a snail for cold forging is not so difficult. Moreover, there is no single standard for such devices. Someone will say – isn’t it easier to buy a factory model? Firstly, as already said, you will have to search for a long time. Secondly, it is not a fact that her capabilities will coincide with the fantasies of the master. Thirdly, you will have to lighten your wallet by about 19,000 (manual) and 62,000 (electric model) rubles, at a minimum.

Good luck in making your own snail!

Do-it-yourself “Snail” forging machine

according to drawings and technology

Before making any devices, hand tools or machines for artistic forging, it is necessary to complete graphic images, templates, sketches, and drawings of the future device.

To make markings more accurately, it is best to use graph paper. Draw a spiral on it, the radius of its turns gradually increasing. The same pitch must be observed between turns. It must be said that this condition must be observed only in cases where symmetry of patterns is required; as a rule, no more than 4 pieces are made.

Also take into account what kind of workpieces you need to work with. The distance between the turns must be made so that it is slightly larger than the diameter of the metal rods, otherwise it will be difficult to remove the finished product from the machine.

To create a full-fledged work process, it is necessary to securely fix one end of the product. Here you will need a piece of rod that is equal to the width of the strips. To fix the working platform you will need a workbench. Often a piece of thick-walled pipe is used as a stand. The main thing is to ensure maximum fixation, since during cold forging the forces applied are quite large.

https://youtube.com/watch?v=rUTdr5Cb9SE

Machine assembly

Along the length of the structure, small pieces of rods can be welded at a distance of 5-6 cm; special holes must be made for them in the working area. Do not forget to carefully secure the ends of the products that you will bend.

Cold forging is especially popular among beginners in blacksmithing. To manufacture products using this method, you do not need a well-equipped workshop (you can get by with a garage or shed), nor much experience, nor do you need special knowledge about the behavior of metals. As for devices, all the necessary machines and tools can be made with your own hands at home.

Devices for making crow's feet

“Crow's foot” - flattening with the application of beautiful notches at the ends of the workpieces to make the structure more elegant or to reduce the thickness for various joints.

The ends of the elements are decorated with “houndstooth”

This operation can be performed using a machine with a die or fixture and a heavy forging hammer on an anvil. We provide both options in the form of videos.

Machine for making houndstooth

Tools for forging crow's feet

Detailed stamp making process

Below is a rolling machine to perform the same operation.

Machine for rolling "crow's feet" (the distance between the rollers is adjustable). Materials for a rolling machine: gears and shafts - spare parts from a used combine

Operating principle

Making a simple snail with your own hands

If you settled on a simplified monolithic design, then you know that this device uses simple winding of a rod by hand or using a lever onto a form rigidly welded to the working surface. This machine can be used to create curls on rods of small cross-section (less than 12 mm).

Monolithic non-demountable snail

It is made like this:

- First, a diagram of the future template with the required dimensions is drawn on a sheet of paper (sometimes the template diagram is applied directly to the base of the conductor). This must be approached responsibly, because after welding the finished form, it will not be possible to correct errors. The thickness of the outline of the form in the drawing should be the same as the thickness of the metal strip used for its manufacture. It should be at least 3mm. The coils must be placed at a distance of 12–13 mm from each other, so that a 10 mm deformable rod fits into the groove between them.

- The base of the snail (preferably round) is cut out of a steel sheet with a thickness of at least 4 mm, the diameter of which is determined in proportion to the size of the template spiral and be larger than the size of the snail. Typically the diameter of the base is within 70 cm.

- In accordance with the drawing, the desired curl shape is made from a 3mm thick metal strip. To do this, it is better to calcinate the workpiece so that it is easier to machine. After making the mold, the excess end of the strip is cut off, and the edges of the snail are cut into a cone and cleaned.

- The finished form is welded to the base, which is mounted on the frame. Sometimes a template welded to the base is fixed to the frame using yews installed on it. To do this, a piece of timber is welded to the back side of the base of the form for gripping with a yew.

With the option of fixing the conductor in a yew clamp, you can easily change the templates and obtain different shapes of curls if you make several types, monolithically welded to the base of the devices.

Removable design

On the working base, first draw the contour of the snail with a mark along the contour of the holes for attaching the template.

Based on the sketch, a template is made from a thick steel strip and holes are drilled in it. It is attached to the base with bolts.

Forging a twisted shape should begin from the central curl. The end of the workpiece is inserted into the groove of the first curl of the form and pressed tightly against it. You can use a small clamping tool to secure the fixation. With force, the free part of the rod is screwed onto the template using a device - a lever. Advanced designs use a lever driven by a moving bearing mounted on it. The lever is made of a rod with a diameter of 20 mm.

You can watch the making of such a device in the video:

Assembling the device

This version of the machine is used as an example because of its simplicity. Knowing the basic principles and sequence of equipment design, you can upgrade it at will. To assemble all parts of the equipment into a single whole, you will need to use:

- drill with carbide type drills;

- welding machine;

- a saw cutting metal or a hacksaw;

- metal sheet of the selected size;

- round metal pipe;

- metal rod;

- bearings of different sizes;

- bolts size M8.

To assemble a cold forging machine with your own hands, you need to use a proven sequence of actions:

- Initially, you need to assemble a stand that will serve as a support. To do this, all its components (pipe sections of the same size and the joints between them at the top and bottom edges) must be connected into a single whole. The design may resemble a stool in appearance. The connection is made using a welding machine, and the sections are cut with a saw.

- The next step is cutting the metal sheets. You should get circles of equal diameters and four triangles with equal sides. Triangular-shaped elements must be welded to the bottom of the connected pipe structure in such a way that something similar to a pyramid is formed. The base, which has a wider area, must be welded at the central point of the cut circle.

- Four strips that are located horizontally must be attached to a circle with an already welded element. This should be done using bolts; for this you will need a drill to make the holes.

- The next step is the construction of the handle. To do this you need to use two rods of different lengths. Their sizes can be determined by correlating them with the diameter of the circle. One rod should be commensurate with the diameter, the other should slightly exceed its size. When bending the first rod, you should maintain an angle of 30 degrees. Then weld both rods to each other, and then weld another rod into the lower part. There should also be a jumper between the first two sections, to which a lever is attached by welding, which should maintain the direction towards the structure made of rods.

A bearing for future directional variability in the device must be attached to the end of the attached lever, as well as to the segment located at the bottom of the structure. The upper section serves as a mount for a metal coil, which must be installed horizontally - it makes it possible to bend the metal. On the lower side of the segment, where there is a free end, a hole should be made equal in diameter to the size of the pipe section.

The last step in the algorithm of actions when constructing a machine for cold forging with your own hands will be the connection of the designed handle with a part of the device similar to a “pyramid”. These elements are fixed after putting on the handle with a wide-diameter nut, to which it is first necessary to weld a metal circle, which will allow the template itself to be attached to the machine. Next, the “snail” template is attached by welding.

Anyone who decides to take up forging seriously and make a cold forging machine with their own hands should be very scrupulous at the stage of creating drawings and calculations. Otherwise, the creation process is quite simple, and once you understand the principle of equipment design, you can come up with various variations of it that will help improve the product.

One way to decorate areas is to use forged items. Fences, benches, gazebos, stair railings and other similar structures look very decorative. Moreover, in most cases, these products are not forging in its traditional sense. Most often, this is done not in a forge or with a hammer and anvil, but with the help of some devices that allow you to create a wide variety of patterns and products from metal strips and square rods. To make such products you will need cold forging machines. Some of them you can make with your own hands, others are easier to buy.