Published on May 18, 2022 Category: Heat engineering | 34 comments

How much heat does the riser or deck of the heating system give off to the air in the room? How many degrees does the water cool in an insulated air heating system? How to properly and economically insulate a pipeline? Using the following…

...a program in Excel, you can quickly get accurate answers to these and other questions!

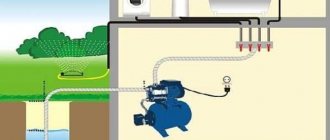

The object of research is a pipe with a coolant - water, surrounded by air space.

The next user functions (PF) of Vyacheslav Leonidovich Polkovov perform automatic calculation of the heat transfer of a pipe with and without surface insulation in any spatial position.

Let me remind you that a user-defined function (PF function, UDF function) in Excel is a program (macro) written in VBA in a program module of a file, and has the form:

y=f (x1, x2, x3, …, xn) , where:

- y – function value (the desired design parameter);

- x 1 , x 2 , x 3 , …, xn – values of the function arguments (initial data).

You can see a little more detail about working with custom functions in the previous blog article and read on the Internet.

What systems require calculations?

The heat transfer coefficient is calculated for heated floors. This system is made less and less often from steel pipes, but if products made from this material are chosen as coolants, then calculations must be made. The coil is another system, when installing which it is necessary to take into account the heat transfer coefficient.

Radiator made of steel pipes

Registers are presented in the form of thick pipes connected by jumpers. The average heat output of 1 meter of this design is 550 W. The diameter ranges from 32 to 219 mm. The structure is welded so that there is no mutual heating of the elements. Then heat transfer increases. If you assemble the registers correctly, you can get a good room heating device - reliable and durable.

Making a heating battery from a profile pipe

A heating radiator is a device that can be manufactured not only by industrial companies, but also by home owners, including those new to this business. True, the latter will have to spend a lot of time. The easiest way is to make a battery from a profile pipe with a square or rectangular cross-section. This is because it does not spin and is easy to lock into place, allowing you to concentrate on all your welding and metal cutting work.

The design of a heating radiator made from a profile pipe is as follows:

- 3 horizontal pipes;

- 4 vertical jumpers;

- 6 plugs;

- couplings with internal threads welded to the ends of the upper and lower pipes.

Vertical bridges are placed at the ends of the pipes and allow water to flow from the top pipe to the bottom pipe.

How to optimize the heat transfer of a steel pipe?

During the design process, specialists are faced with the question of how to reduce or increase the heat transfer of 1 m of steel pipe. To increase, you need to change the infrared radiation upward. This is done with paint. Red color increases heat transfer. It is better if the paint is matte.

Calculation

Another approach is to install fins. It is mounted outside. This will increase the heat transfer area.

In what cases does it need to be reduced? The need arises when optimizing a pipeline section located outside a residential area. Then experts recommend insulating the area - isolating it from the external environment. This is done using polystyrene foam, special shells that are made from special foamed polyethylene. Mineral wool is also often used.

Application of thermal insulation materials

Probably the first thing that comes to mind when it is necessary to retain maximum heat inside a pipe is to wrap it with heat-insulating material. At the end of the last century, fiberglass insulation with additional winding with non-flammable fabric was used for these purposes (this method is recommended by the regulatory framework). A little earlier, solutions of gypsum or cement were actively used, that is, the thermal insulation was solid. In reality, careless plumbers often simply wrapped the pipes with old rags, hoping that no one would check.

The abundance of modern materials, such as foam pipe linings, split polyethylene shells, mineral wool and others, allows for much better thermal insulation of heating pipes. And in new buildings such materials are successfully used. However, the backwardness of housing and communal services often leads to the fact that pipes are wrapped in rags the old fashioned way.

We make a calculation

The formula by which heat transfer is calculated is as follows:

Q = K*F*dT, where

- K – thermal conductivity coefficient of steel;

- Q – heat transfer coefficient, W;

- F – area of the pipe section for which the calculation is being made, m2 dT – temperature pressure value (the sum of the primary and final temperatures, taking into account room temperature), ° C.

The thermal conductivity coefficient K is selected taking into account the area of the product. Its size also depends on the number of threads laid in the premises. On average, the coefficient is in the range of 8-12.5.

dT is also called temperature difference. To calculate the parameter, you need to add the temperature that was at the outlet of the boiler with the temperature that was recorded at the entrance to the boiler. The resulting value is multiplied by 0.5 (or divided by 2). The room temperature is subtracted from this value.

dT = (0.5*(T1 + T2)) - Tk

If the steel pipe is insulated, then the resulting value is multiplied by the efficiency of the insulating material. It reflects the percentage of heat that was given off during the passage of the coolant.

Registers

The simplest design of heating radiators is registers. These are medium- or large-diameter pipes welded at the ends, single or connected in sections by jumper tubes. They can be seen in entrances, at industrial facilities or in private houses with individual heating.

Steel pipelines are considered traditional for the installation of water supply, sewerage and underground gas supply systems

To increase their thermal power, they use a method of increasing the area - thin metal plates are welded. This improves the heat transfer of the battery by almost one and a half times. Compact radiators, the closest relatives of cast iron accordion batteries, have approximately the same heat transfer. Although they are, of course, far from panel bimetallic devices.

To ensure maximum heat transfer from heating radiators, a simple and inexpensive convection method is used. This method involves hanging the device correctly. It is installed as close to the floor as possible, where cold air accumulates, but the gaps necessary for circulation are left, including near the wall itself.

With this installation, the battery sections come into contact with a medium that has the lowest possible temperature under the given conditions, that is, the thermal pressure increases. And the air heated by the registers, thanks to the gaps left, rises freely, and the room is heated faster.

An excellent method is to increase the heat transfer surface area. They do this in different ways:

- By increasing the total length of the heating pipes by forming them into U-shaped registers.

- With fins - strictly speaking, this method increases not specifically the thermal conductivity of the steel pipe, but of the entire radiator, but the power increases by 50%.

- Increasing the number of sections.

Black surfaces have the best heat transfer, but not every interior will fit such a dark battery, which is why this method has not found application. Registers traditionally continue to be painted white.

Using cross-linked polyethylene for heated floors

Metal-plastic is very convenient as a material for a pipeline that will be hidden under your floor and will have to warm the feet of you and your family. Metal-plastic is multi-layered, so it is not susceptible or minimally susceptible to corrosion, lasts more than fifty years, the pipes have a large footage (from 50 to 500 meters), in addition, they have low linear elongation when heated.

Connections can be detachable, conditionally detachable and permanent. Detachable fittings include threaded and collet fittings; for conditionally detachable ones - compression ones, and for non-detachable ones - press fittings. Of course, it is necessary to buy both the pipes themselves and fittings only from reliable and trusted manufacturers.

Metal-plastic floor pipes have many advantages, but they also have some disadvantages. These disadvantages can be very significant if you are not warned about them in advance.

So, firstly, due to the different expansion coefficients of the polymer and aluminum, spontaneous expansion may occur and/or the pipes may crack (a phenomenon that professionals call pipe delamination will occur). Secondly, if you use threaded fittings for installation, then scale may form on their inside. Therefore, it is better to use exclusively press fittings (of course, when possible).

Despite a number of significant disadvantages, today metal-plastic pipes for floor heating are the best and most used option for those who value comfort, long service life of the product, as well as their own safety and the safety of their family. They have good thermal conductivity and have multiple advantages.

Advantages and disadvantages

The advantages include simple design and simple calculations, availability of materials. All this together allows you to make heating registers with your own hands.

The next positive point is that most of the heat is transferred using radiant energy, and it is perceived by a person as more pleasant.

Heating registers are usually located in utility, production, and auxiliary rooms

The next plus is the smooth surface, which makes cleaning easy.

Excellent quality - compatibility with any systems - both natural and forced circulation.

There are also disadvantages: low heat transfer, susceptibility to corrosion, not the most attractive appearance, the need for regular painting (read how to choose paint here).

Why is this necessary?

Impeccable aesthetics, deadly performance

In general, it is necessary to calculate the heat transfer coefficient of a pipe in two categories of cases:

- When calculating heating devices;

- To estimate the amount of heat loss in pipelines transporting coolant.

Heating devices

What kind of heaters are used as heat-transmitting pipe elements?

The most common ones worth mentioning are:

- Warm floor;

- Heated towel rails and various coils;

- Registers.

Warm floor

The heating element for a water heated floor (there is also an electrically heated floor) is almost always pipes; however, the use of steel pipes for heating has recently become rare.

The reasons are obvious: a steel pipe is subject to corrosion and a decrease in clearance over time; installation of a pipe without threaded connections requires welding; Installing a steel pipe on pipe threads always means potential leaks. What are leaks in the floor, under the screed? Wet ceiling on the lower floor or in the basement and gradual destruction of the ceiling.

That is why, quite recently, it was preferred to use coils made of metal-plastic pipes (with the obligatory installation of fittings outside the screed) as a heating element for a heated floor, but now reinforced polypropylene is increasingly being installed in the screed.

It has a low coefficient of thermal expansion and, if installed correctly, does not require repair or maintenance for many decades. Other plastics are also used.

Now they do it like this

Tip: be sure to leave small gaps for thermal deformation of the pipe. Reinforced polypropylene stretches less when heated than non-reinforced polypropylene, but still stretches.

Heated towel rails

Steel heated towel rails are very common in Soviet-built houses. Until quite recently, they were part of the standard design of any house under construction, and until the 80s they were always mounted on threaded connections.

Circulation taps in elevator units, providing constantly hot heating risers, also appeared relatively recently.

If so, the operating mode of the heated towel rail was repeated cooling and heating. Expansion - compression. How did the threaded connections react to this? Right. They started to leak.

Later, when heated towel rails became part of the heating risers and were heated around the clock, the problem of leaks faded into the background. The very size of the dryer (and, accordingly, the effective heat transfer area) has sharply decreased. The reason is a change in the average daily temperature.

If previously the coil in the bathroom only heated up when the owners of the bathroom used hot water, now it heated constantly.

Extreme people now install steel dryers in bathrooms

Registers

In many industrial premises, warehouses and even some shops that have not been renovated for a long time, attention is drawn to several rows of thick pipes under the window, from which there is noticeable heat. Before us is one of the cheapest heating devices of the era of developed socialism - a register.

It consists of several thick pipes with welded ends and jumpers made of thin tubes. In the simplest version, it can generally be one thick pipe running along the perimeter of the room.

It’s funny to compare the heat transfer of a steel register with a modern aluminum battery occupying a comparable volume in the room. The differences in heat transfer are significant.

Both due to the greater thermal conductivity of aluminum and due to the huge heat exchange surface with air of the modern solution. You understand, there is no need to talk about aesthetics in the case of register at all.

However, the register was a cheap and accessible solution. In addition, it extremely rarely required repair or maintenance: a pipe that was even half-clogged continued to heat up, and the electric-welded seam began to leak after about the five-hundredth blow with a sledgehammer.

Really, what's there to break?

Possible installation errors

In order to avoid any technical difficulties after installation, it is necessary to provide for common errors that are often made during operation. So, if you install batteries less than 7 centimeters from the floor surface, then in the future we will be faced with the difficulty of not only cleaning underneath them, but also with heat exchange in the room. On the contrary, if you install the batteries higher than 15 centimeters, then, most likely, significant temperature changes will occur.

In addition, heat transfer may deteriorate if the radiator is installed close to the wall. Also, do not forget that you should not cover homemade pipe heating radiators with decorative grilles - this will lead to a decrease in their power.

Replacing batteries

If radiators need to be replaced, then it is advisable to start work in the warm season. The fact is that the heating is turned off during this period, so dismantling/installation can be carried out without any difficulties. Often, replacement is required if the equipment wears out or, alternatively, if it is necessary to reduce the number of sections. By the way, we prepare not only the batteries for replacement, but also the wall surfaces located behind them.

Note! We putty, level and paint the walls before installation, since after installation, as noted above, this will not be possible. Video - Replacing radiators

Video - Replacing radiators

Comparison of types of heating batteries - looking for the best

Previously, we reviewed and compared different types of heating radiators, thereby identifying their positive and negative sides; in addition to this article, we advise you to read this information