Quick release couplings (QRC) or breakaway couplings are a mechanism that allows you to quickly connect two hydraulic units to each other or to high-pressure hoses.

Breakaway couplings (quick-disconnect couplings) are used in road construction, oil or gas production, and are widely used in the chemical industry, as well as in various other industries. The use of quick-release connections does not require special skills and can be carried out by low-skilled personnel. The use of the coupling system does not require the use of any special tool.

Contrary to popular belief, quick-release couplings are not recommended for use as swivels (swivels) - rotation of quick-release couplings, especially under pressure, can lead to premature and very severe wear and leakage.

The basic design of breakaway couplings (BRC) is as follows:

1. socket (female)

2. nipple (male)

Quick release couplings (breakaway couplings) are made to different standards and from different materials, depending on where they will be used.

The following basic BRS standards are mainly used:

ISO-7241, ISO 16028 (Flat Face, FIRG or Flat End), Parker 3000 Series, Gromelle 6000 Series and many others.

Breakaway couplings (quick release couplings) are mainly made of carbon steel, aluminum, bronze or stainless steel, and, depending on the environment in which they are used, various types of sealing materials are used - NBR (nitrile butadiene rubber), Viton (FKM) , fluorine rubber), EPDM (ethylene propylene rubber).

Couplings and nipples, depending on the type of quick-release coupling, standard or series, can have different types of fastenings: internal thread, external thread, brush type fastening for a flexible hose, fastening for a plastic tube.

Device, dimensions and types

The quick release fitting consists of two main elements.

They are called by different names, but most often they are “coupling” and “nipple”. The coupling has the following components:

- Frame.

- Check valve.

- Fixing clamp. It, in turn, has clamping balls and locking bushings.

- A sealing rubber gasket designed to seal the joint.

- Connecting adapter.

The nipple has the following parts:

- Frame.

- Connection adapter.

- Sealing ring.

- Check valve.

The most popular are connections with a diameter of 50−150 mm. For domestic needs, products up to 50 mm are usually used. Most companies can produce quick couplings according to individual orders. In some cases, the cross-section reaches 540 mm.

All quick-release connections are divided into 3 main types:

- Without check valve.

- With one valve.

- With two valves.

Fittings for pipelines can be manufactured in different variations. There are straight and angular couplings, tees, and crosses.

The following advantages of the BRS can be noted:

- Wide use.

- Low cost.

- Reusable.

- Easy installation and dismantling.

- There is no loss of technical characteristics during use.

Quick-release connections reduce power and time costs. With their help, you can connect a watering device without stopping the work process. Couplers allow you to connect, extend or dock a hose with pumping equipment.

What does it consist of?

A classic hose connector consists of the following elements:

- Tube holder with housing. A watering hose is inserted directly into it. After tightening the cap, it is tightly and airtightly attached inside the connector.

- Release mechanism. It is this that makes it possible to remove the device in one motion.

- Screw cap. Using it, the hose is secured to the connector. It has an internal thread that screws onto the tube holder. As a result, the structure is fixed and compression is ensured.

- Stop valve. Installed in connectors with automatic closing. It is a plastic or metal piston with rubber bands that provide a tight seal. The essence of its work is that when the connector is connected to the nipple, the latter presses on the piston. When connected, the valve is always open, and after disconnection, the pressure in the pipe closes it. This allows you to stop the flow of water without turning off the tap.

- Rubber bands for sealing. They are located inside the quick connect and prevent water from escaping through the threads.

Industrial Applications

Automotive industry

- power distribution systems

- changing tools for robots - tool changers

- connection of pneumatic tools (bolt guns, blow guns, paint guns, sanders, drills, etc.)

- refilling process fluids (brake fluid, coolant)

- refilling air conditioning units (refrigerant refilling)

- bench and test tests of components and assemblies

Defense and aviation industry

- electronics cooling

- supply of breathable air

- hydraulic fluid supply

- contours of crew life support systems

- pressure measurement circuits

Alternative energy sources

- refueling vehicles with natural or liquefied petroleum gas

- filling with liquid or gaseous hydrogen

- connectors for photovoltaic solar cells

- cooling and hydraulic systems for wind farm drives

Railway transport

- connection systems for trains, metro and trams

- connection of bogies, wagons and locomotives

- pressure measurements

- emptying and filling tank cars

- braking systems

- hydraulic systems

- engine electronics cooling

- emptying and filling oil tanks

Chemical industry

- sampling and sampling

- emptying and filling drums

- intake of fuel and energy resources

- supply and transportation of clean gases

- compressed air in process plants

Medical equipment

- connection of circuits with medical gases: oxygen, nitrous oxide, air in ambulances, in intensive care wards

- supply of solutions in hemodialysis units, in artificial kidney devices

- CT scanner cooling circuits

Metallurgical industry

- connecting gases to casting ladles

- connection of gases to the cutting unit of the continuous caster

- hydraulics for jacks

- connecting hydraulics on calibration stands

- high pressure supply to hydraulic cylinders of rolling mills

- chock lubrication supply in rolling mills

Polymer industry

- connection of thermal control circuits of injection molds

- connection of pneumatic and hydraulic pushers for molds

Mining industry

In mines and quarries, BRS quick-release connections are used for quick connection and disconnection of steel pipelines with a nominal diameter of 50 to 400 mm with a working pressure of up to 32 MPa.

A design feature of these quick-release connections is a hinged clamp that tightly connects the flanges welded to the ends of the pipes, as well as an elastic ring that self-seals against the influence of the working environment. Areas of use:

- supply of concrete, mortars

- cementation of watered rocks

- air supply to mines

- connecting pneumatic tools

- connection of equipment (hydraulic monitors, pumps, coal pumps), etc.

- pumping groundwater from flooded areas, mines, quarries.

Other watering fixtures

The connector for the irrigation hose is just one of the elements of the connecting fittings for irrigation. Other parts are required to make it work successfully.

- Nipple. It is a cone connecting two connectors. At its ends there are rubber bands that ensure the tightness of the connection. This element can be of two types: STANDARD and POWER JET. Depending on this, a fast connection is selected. Two elements of such reinforcement cannot be fastened using parts of different sizes.

- Tee. It is analogous to a nipple. The difference is that it has three connections to the connector.

- Clutch. Connects two flexible tubes. If the element is reducing, then it can be used to connect hoses of different diameters.

- Faucet adapter. This device is designed to connect a hose to a water supply. Depending on the thread of the faucet, it may have an external or internal thread. At the other end there is a nipple connector.

- Guns and sprinklers. There are a huge number of sprinklers of various modifications. At the end they have a nipple connector that fits into the connector.

All elements of watering connection fittings are necessary to ensure ease of operation. A variety of sizes and shapes allows you to select elements that provide high-quality watering in each specific situation.

When laying and using water pipes, you cannot do without special fasteners. Quick-release connections for hoses and pipes simplify the process of organizing and operating water supply and distribution systems and irrigation. Quick-release products for docking are available in various variations, which differ in size, functionality, and material of manufacture. Let's consider their main features.

Quick-release connections (QRC) are devices used for joining pipes, hoses, sleeves and other various parts in production. This type of connection is used in a wide variety of areas of modern life and is characterized by high levels of tightness and reliability in environments characterized by high pressure. Working with these products does not require any special tools, knowledge or skills.

Nowadays, quick-release couplings are constantly used in many areas of human activity and, thanks to their special characteristics and ease of operation, have firmly established themselves there. Let's list the areas where braces are used:

- auto industry;

- aircraft manufacturing;

- systems for water supply and water treatment;

- connection of various pneumatic units;

- defense industry

- alternative energy;

- shipbuilding;

- chemical production;

- Medical equipment;

- railway transport;

- construction;

- polymer production;

- mining production.

Helpful information! I would like to note that in mining activities a special quick-release connection is used, equipped with a hinged clamp. Using this device, steel pipelines with a nominal diameter of 50 to 400 mm are connected; the operating pressure in these lines can reach up to 32 MPa.

Operating principle and scope of use

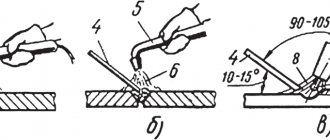

To connect the quick-release structure, you first need to press the locking sleeve of the product towards the adapter. Thus, the clamping balls move away, which is why the coupling can become attached to the connecting tube. This allows the previously prepared coupling to fit into the nipple.

Then you need to loosen the bushing. This completes the installation process of the quick-release device. The result is a reliable and durable connection.

There are also mechanisms that do not require a sleeve clamp. The coupling is inserted into the nipple automatically.

The scope of application of such structures is quite wide. They are used almost always when you need to quickly connect two elements into a single system. The following requirements are put forward for the BRS:

- Corrosion resistance. If rust forms, it will chip off after some time anyway. This may cause the nozzle to become clogged (when used on compressors).

- High level of tightness.

- Versatility. The most popular couplers are those that can be used on various equipment.

Often these connections are used to create trunk lines or quickly connect and disconnect hoses. For example, firefighters use only ballistic control systems.

Source

Additional accessories

Today, there are many devices in stores that are needed to connect the line to a paint sprayer, a compressor and a filter that will remove moisture and oil. As a rule, we are talking about quick-release connectors. Such devices are divided into two categories:

Their main difference will be, first of all, in diameter. Fittings will be smaller in size. The reason for this is the type of connection: inserting a fitting into a fitting. You should take into account that if you bought a moisture-oil separating filter that is not equipped with fittings, you will need to buy them separately.

Peculiarities

In addition to the irrigation system, quick-release couplings can be used in conjunction with compressor equipment. For example, during painting work, for air supply. All of these systems require certain hoses to be connected. The operational features of quick-release couplings are different. These hose connection parts have common characteristics.

- Compactness. The light weight of the connecting element greatly simplifies its operation.

- High corrosion resistance. Modern manufacturing materials provide this factor.

- Reliability of fastening. This is ensured by the shape of the product. By combining stepped parts and O-rings, the elements provide an increased degree of sealing.

- The geometric shape of the product allows you to quickly connect and disconnect the connection. Quick change of hoses allows you to expand the possibilities of using the equipment.

- Quick-release connections are convenient because their installation is accessible to anyone. You don't need any special skills or professional tools for this. Many modern connections are equipped with automation. To fasten the two parts of the hose, just apply a little pressure to the connector.

If there is no automation in the connector, you need to perform the following actions. Press out the locking sleeve on the coupling. Push towards the adapter. The clamping balls will come off and the coupling will be inserted into the nipple. Next, open the bushing. This will ensure reliable fixation of the sleeve in the nipple. After fixing, the check valves will open, which ensures the free flow of liquid or air through the hoses. Quick connectors may not be equipped with valves. Also, this part can be located on one or both sides of the coupling system.

Features of the products include a wide selection of quick-release connections. The types are as follows:

- BRS with wedge-shaped retainer;

- cam type products;

- European connections that differ from the domestic standard;

- valve connectors.

Recommendations for selection

GOST 2.709-89 unified system of design documentation (ESKD). symbols of wires and contact connections of electrical elements, equipment and sections of circuits in electrical circuits

A wide range of quick-release products confuses the average person. Most connectors are interchangeable. If the product is selected for watering purposes in a garden, you can consider inexpensive items made of plastic or galvanized. The connection for water pressure hoses can be either threaded or crimped. The method of assembling the parts requires technical skills.

In order for the couplers to be truly high-quality, it is not necessary to purchase expensive stainless steel elements. Plastic products will also meet all safety requirements, especially if they turn out to be branded, factory-made. Makeshift adapters usually easily become unusable, which can lead to a spill, good, if only water

When assembling systems that transport toxic substances, it is important to prevent their depressurization, which can be caused by home-made connectors

To learn how to choose quick-release connections for hoses, see the following video.

Product characteristics

During installation, two types of fittings can be used:

- with threaded fasteners;

- collet.

The material used for their manufacture is stainless steel, various alloys (bronze, brass), technopolymers.

Fittings for any pneumatic systems are used in devices whose operating principle is based on the use of compressed air energy. In order to ensure complete tightness of the system and prevent loss of power of operating equipment, reliable pneumatic tubes and fittings are required.

Metal and polymer collet pneumatic fittings

Today, industrial enterprises specializing in the production and supply of pneumatic tubes and fittings offer a wide range of this type of product.

There are two main types of such products:

- Fittings whose purpose is to control the flow of compressed air (gas). They can change the physical characteristics of substances passing through the system in devices such as pneumatic throttles, mufflers, consumption (flow) regulators, etc.

- Push-in fittings, which require a minimum amount of time for installation (disassembly) and are used mainly for connecting individual parts of a system consisting of many tubes.

Application area

Pneumatic tubes and fittings are necessary for monitoring and reliable sealing in a variety of pneumatic systems. They are also installed in systems for transporting (pumping) air that has been previously filtered.

Using push-in fittings to connect a compressor

Their use is also possible in water supply systems, when it is necessary to create an absolutely tight connection.

In the latter case, special attention should be paid to the material from which the connectors are made, since the integrity of the entire system (its tightness) will depend on their wear resistance under various operating conditions. MV pneumatic fittings are used in systems that operate with filtered air. Such connectors can withstand internal pressure up to 12 bar, and do not lose their performance characteristics at temperatures from -10 to +70ºC

Such connectors can withstand internal pressure up to 12 bar, and do not lose their performance characteristics at temperatures from -10 to +70ºC

MV pneumatic fittings are used in systems that operate with filtered air. Such connectors can withstand internal pressure up to 12 bar, and do not lose their performance characteristics at temperatures from -10 to +70ºC.

The material used to manufacture such fittings is high-tech plastic, and the connection types are threaded or quick-release collet.

The plastic used in the manufacture of such products consists of an acetal polymer, whose properties far exceed the functional properties of conventional polymer or metal.

Such models are characterized by resistance to corrosion and have a high level of rigidity. Produced in various standard diameters.

Polymer pneumatic fittings are widely used in industry, where they can be installed in systems for the preparation, transportation, processing of compressed air or other gaseous substances.

Connecting pipes to the pneumatic system using collet fittings

The main devices on which such connectors are often used are regulators, pneumatic valves, pneumatic cylinders, filters, microfilters, lubricators and other similar mechanisms.

Functions

A modern compressor hose is an air line designed to supply compressed air from the element responsible for pumping it directly to the spray gun. In the vast majority of cases, the twisted version is used. Its distinguishing feature will be the highest efficiency in use. The hose is necessary when carrying out many works using a compressor:

- the compressor can become a power source for the impact wrench;

- it can also be used as a source of energy for riveting equipment, which allows for a fairly reliable fastening due to the pressure created during operation;

- spray guns can also be used to spray a variety of substances onto any surface;

- as well as compressor hoses are used to supply compressed air when used in various pistol-type equipment, which is intended for construction work.

It should be noted that not every compressor-type equipment receives lines included. In some cases you have to buy it separately. You also need to buy a compressor line if such equipment is made by yourself. In addition, in most cases, hoses for a spray gun or compressor have an internal cross-section that is insufficient for painting a car. Its figure is usually 5–6 mm, and the reliability of the hoses is often questioned due to too much susceptibility to fractures.

For this reason, they are not usually used for painting cars. But such solutions are perfect for inflating tires.

There are different categories of lines for compressor equipment. Like most spare parts, compressor hoses are classified according to a considerable number of aspects. The most common air solutions: rubber. The rubber version is very inexpensive. If we talk about such solutions, then there are several types of hoses that can be used for pneumatic tools or for a spray gun:

- twisted or spiral;

- straight for forming a pneumatic line.

Flexible air hoses can also be divided according to the category of material from which they are made. A number of performance qualities, including the duration of operation, will depend on this moment. According to this criterion, there are three categories of hoses:

- reinforced;

- spiral polyurethane;

- rilsan;

- rubber;

- oxygen

A straight pneumatic hose for creating a pneumatic line has become quite widespread. Its main features will be its large diameter and high throughput. Such solutions are used in high pressure systems. Often this option can be reinforced, which can significantly increase its resistance to temperature changes. Typically such solutions are found in industry. This sleeve can be called a universal solution that is suitable for various areas.

A twisted spiral hose is found in almost any auto repair shop. Its application is characterized by the following features:

- as a rule, this version of the hose is mounted as the main part of pneumatic equipment, where one of the components is a compressor;

- the twisted spiral is made using technology that does not allow the hose to straighten at the time of its use;

- Thanks to self-twisting, maximum compactness of the hose is ensured, which simplifies its use and storage;

- Since this type of painting hose does not need to be constantly twisted, it saves time.

However, this type has a certain drawback: small diameter. At the same time, straight trunk-type tubes are cheaper and have greater throughput capacity.

Coiled hoses are also widely in demand. Rilsan hoses can generally be used to connect to various pneumatic tools because they can withstand high pressure: up to 20 bar. By the way, this is why they are often used with a pressure gauge. For this reason, as it is also called, polyurethane hose is used in almost every field of industry.

Flexible lines for spiral-type paint sprayers will most often be in demand when a pneumatic tool operates at a considerable distance from compressor equipment or the main fitting. This can be explained by the ability of such products to increase their own length due to stretching. If they are in a relaxed state, they immediately acquire their normal dimensions. Such solutions are not greatly deformed even with too active use.

Reinforced painting hoses are durable and flexible, making them highly resistant to wear. The products in question also have a fairly high transmission capacity. They are also resistant to abrasive substances and weather conditions.

If we are talking about garage conditions, then two types of reinforced lines are usually used there: plastic and rubber. Sometimes a polyurethane or silicone hose is also used. The main disadvantage of such hoses will be their greater mass than conventional options. Such solutions are usually professional and can be used great for painting a car. These can be used with oxygen cylinders.

There are also reinforced plastic solutions for spray guns that cost significantly less than the options mentioned. This will be their main advantage. But it should be taken into account that they have a very high sensitivity to temperature changes to which the natural environment is subject. If the weather is cold outside, they freeze, losing their elasticity.

And if it’s hot outside, they soften too much, which can cause a rupture under pressure when the wire is used. For example, if we are talking about painting a car. For this reason, work in the hot season when using a paint sprayer equipped with a device of this type must be carried out indoors or in the shade.

Features and types of quick-release connectors

Most of the quick release or quick release connections are designs made in accordance with ISO standards. Quick-release connections have a very useful quality - interchangeability. This suggests that parts of the same design can be manufactured by different manufacturers from different countries around the world.

The materials from which coupling rods are made are very diverse:

- stainless steel;

- alloy steel;

- aluminum;

- bronze alloy;

- titanium and its alloys;

- alloys of other metals;

- various polymers.

The service life of the coupling system is influenced by a number of factors that must be taken into account when selecting a product:

- type of working medium (water, oil, acid);

- line pressure;

- maximum and minimum media temperatures;

- environment (humidity, precipitation, low or high air temperatures).

To improve the quality of the structure, it is usually additionally treated with an anti-corrosion coating. There are the following methods of applying protection to parts:

- chrome plating;

- nickel plating;

- galvanization;

- a variety of solid applications.

A wide range of identical fittings makes it possible to connect not only identical pipes, but also products made from different materials.

Types of couplings by pressure:

- ISO-A quick release hose connections. Fits perfectly into hose systems with low operating pressure. At the same time, it does not create obstacles to circulation within the system. The valves in it are made in the shape of a cone.

- FIRG. These valves will fit perfectly into a wide range of systems. When closed, this structure has no protruding parts. Valves in a disc-shaped design. Thanks to them, no unnecessary resistance is created in the system, and they also eliminate the possibility of air entering the system and leakage of working fluid.

- T.G.W. Such connections are ideal for systems whose operating pressure ranges from 300 to 1100 Bar. Like other quick-release couplings, they help prevent air from entering the system and fluid leakage. They can be supplied with protection plugs made of metal and plastic as components. Such connections can withstand water hammer and impulse loads.

- NRA. These connections are used for domestic mobile hydraulic tools. They can withstand pressures up to 700 bar. Just like EPU type couplings, they are resistant to water hammer and impulse loads.

Based on the number and location of valves, couplings are divided into three main groups:

- with free passage (not equipped with valves);

- with valve on one side;

- with valve on both sides.

Products with quick-release sleeves have a convenient snap mechanism. Installation of such couplings is simple, and this connection perfectly secures the tubes.

Nowadays, these products are distinguished by a fairly wide range of assortments, which makes it possible to choose a coupler for a specific situation. Now you can purchase several types of quick-release couplings:

- Quick couplings equipped with a locking wedge;

- cam devices (Camlock);

- designs made in Europe (BAUER and Perrot);

- ISO connections that have a conical valve in their design.

Couplers can connect flexible hoses or plastic and metal pipelines. Quick-release fittings for a variety of pipelines are made in various designs: couplings, tees, crosses, etc. Such a connection is made using a special clamping device - a collet.

Quick-release collet connections help to quickly install and dismantle the pipeline. One of the main features of this connection is that thanks to it it is possible to make the transition to threading.

General information about connections

Hoses connect pneumatic tools

They are also widely used in hydraulic structures. This connection speeds up the work much faster. The installation work of this type of device is very simple and allows operations to be carried out without shutting off the water during semi-automatic irrigation. All you need is a main connector and a special element for tightening the appropriate size.

Using this type of connection, you can arrange garden watering with the possibility of adjustment directly during operation. There is no need to create any additional portable devices. The only condition is the presence of a central water supply to create pressure in the hose.

Features of quick connectors

Basically, quick release or quick release couplings are devices made according to the ISO standard. They are interchangeable and product designs are produced in different countries. Quick-release connectors are made from stainless or alloy steel, aluminum, bronze, titanium, and polymer materials.

Factors influencing the service life of connections are identified

- in what environment the work takes place;

- what is the system pressure;

- at what temperature;

- under what natural conditions?

To improve quality, anti-corrosion treatment of products is carried out. For this purpose, parts are subjected to chrome plating, nickel plating, galvanization, etc.

Advantages and disadvantages

Quick-release connections have a number of advantages:

- Wide distribution and availability;

- Not a big cost;

- Easy installation and disassembly;

- Reusable;

- They are not capable of losing their characteristics during operation.

This is very convenient and does not require much effort or time. Using this method, you can assemble a watering device during the working process, with the possibility of adjusting it. Using a quick-release hose fitting, you can connect a hose, extend it, or connect it to pumping equipment. They come in sizes 12-150 millimeters in diameter.

Disadvantages include:

- When using components of a compound from different manufacturers, the warranty period of the products is void;

- More than twenty percent of these devices are not interchangeable.

Areas of application

Currently, this type of connection is used in many areas, all thanks to the presence of good characteristics and easy operation. The main areas include automotive production, aviation, pneumatics, defense industry, medical equipment, energy consumption, etc.

Quick release devices can be used for seams; for semi-automatic machines; for pipe and locking clutches; for camlock American; for a variety of containers for liquids, powders, gas or chemicals; for distillation of petroleum products.

Advantages

The quick-release pipe connection has its advantages and disadvantages. The benefits include:

- Choice. It is extensive, the variety of coupling systems that the market offers will solve any problem.

- Price. They have a low price, so they are used both in production, in public utilities, and for domestic needs.

- Tightness. There are no complaints, pipe systems with such connections can withstand high pressure, so you don’t have to worry about leaks for a long time.

- Installation. You can make a connection with a quick-release connection in a short time; installation is not difficult and can be performed by an ordinary person without special knowledge and skills.

- Reusable. The product can be reused an unlimited number of times.

- Reliability. Thanks to the use of high-strength materials, the connections do not lose their performance characteristics for a long time.

- Interchangeability. Most of the parts on the market are interchangeable with units from other brands. That is, you can easily install a nipple from one manufacturer into a coupling from another.

There are few shortcomings, they exist, but they are not significant. If you replace parts from one brand with another, the product's warranty will be voided. Even if it is a small percentage, only a fifth, there are non-interchangeable devices on the market.

Pros and cons of mechanisms

Quick-release couplings have quite a few pros and cons that need to be taken into account. Let's call the following points as advantages:

- It is possible to quickly change the nozzle. There is often a situation when the need to change a nozzle or hose appears while the work is being completed.

- The required connection tightness is ensured. Excessively high system pressure determines that ordinary connection elements do not give the desired result. If the system allows air to pass through, the pressure will drop significantly.

- Can be used to restore the highway. The very large length of the highway turns out to be the basis for the emergence of a variety of shortcomings. In this case, it is necessary to cut the hose and remove the damaged part. To connect individual elements, very different quick-release connections are used.

- The mechanisms are light in weight. This simplifies the process of transferring the highway and its use.

- High mechanical resistance. Connecting products must guarantee good fixation during system operation. If significant pressure is applied to the interface between two products, in other words, the likelihood of a decrease in throughput.

In addition, during long-term use, the reliability of fixation of connected components can significantly decrease. However, in many cases it is hardly possible to do without wedge joints.

Quick-release couplings for pipes (QRC).

Despite the fact that the topic of quick-release couplings is considered “innovative” in the pipeline parts industry, quick release couplings have been known for quite a long time. The fact is that historically, the main domain of these connections were technological pipelines of machines and equipment, hydraulic and pneumatic lines, and elements of water supply and heat supply pipelines in the housing and communal services sector. It must be said right away that, as a rule, these are pipelines of small diameter up to Dy10. The use of coupling systems in these areas is quite understandable and understandable, because Many of the listed connections are often subject to assembly and disassembly procedures for the purpose of repair, connection and switching of equipment, or installation and dismantling of various devices (for example, hydraulic lines of various construction equipment tools, or equipment for loading/unloading tank trucks). At the same time, couplings not only allow you to quickly disassemble and reassemble pipelines, but also do this without the use of special devices and tools.

Thanks to these advantages, quick-release connections are gradually expanding the scope of their application, and today couplings with Dy 350 and Ru 63 are commercially produced. Of course, such connections are used where justified and necessary, in industrial systems, petrochemicals, housing and communal services, small-scale energy, mining, etc. By purpose, these are temporary pipelines, pipelines with frequent changes of equipment or configuration, and other pipelines in which assembly and disassembly of the system may be required. In particular, couplings have been widely used in the mining industry and construction. It is in these industries that temporary pipelines for various purposes are most common. Despite the fact that, thanks to the use of coupling systems, installation is significantly simplified and accelerated, their use on conventional pipelines is not advisable, since it reduces the reliability of the system and increases its cost.

Quick release couplings BRS

Quick-release connections of the BRS series (TU 34-23-5854-77) for welding are intended for interfacing hydraulic pipelines. They are also used for connecting and quickly disconnecting concrete pipes at construction sites and facilities during concreting work using injection units and concrete pumps.

Structurally, couplings consist of a pair of pipes connected to the pipes, a seal installed between them, paired half-clamps and a fixing wedge.

Quick-release connections of domestic production are manufactured in accordance with TU 34-23-5854-77 (for welding) and are sold in a standard size line consisting of 5 models: BRS-50, -80, -100, -150, -200. Can be considered as corresponding to the inch ruler designations: BRS-2, BRS-3, BRS-4, BRS-6. The guaranteed operating time of quick-release connections used in concrete pipelines is at least 1000 cubic meters of concrete placement.

Technical parameters of quick release couplings, prices

:

| Characteristics, dimensions | BPC-50 | BRS-80 | BRS-100 | BRS-150 | BRS-200 |

| Outer diameter of the nozzle pipe, mm | 63,5 (60) | 89 | 108 | 159 | 219 |

| Conventional passage Dy, mm | 50 | 80 | 100 | 150 | 200 |

| Working pressure up to, kgf/cm2, (MPa) | 25 (2,45) | 25 (2,45) | 20 (1,96) | 20 (1,96) | 16 (1,57) |

| Weight, kg | 2,87 | 3,74 | 4,42 | 7,57 | 11,1 |

| Price, rub (including VAT) | 1269 | 1497 | 1876 | 2446 | 3556 |

The quick-release connection is installed at the joints of the pipes by welding the pipes to the ends of the pipes, tightening the opposing pipes with half-clamps and fixing them with a wedge. The tightness of the connection is ensured by installing an elastic ring seal between the flanges of the pipes.

Pipelines and concrete pipelines connected using BRS products can be operated when supplying liquid materials such as concrete mixtures, cement and lime mortars, clay and silted groundwater - at an ambient temperature of at least 1 degree. They can also be used to supply compressed air.

We sell both complete sets of quick-release connections and individual elements (clamps, pipes, gaskets). Upon delivery of products, a product passport is issued for each batch.

We deliver the couplings to the customer or send them by transport company to their destination anywhere in the Russian Federation.

Source

Varieties and their characteristics

A normal connector has differences in the type of connector. They are as follows. Camlocks are a self-locking cam action mechanism. This is a versatile quick-release connection that allows you to quickly connect a sleeve to a container or several flexible connections together. The cam mechanism provides vibration resistance without any additional fastening elements.

DRYLOK – quick connector for connecting flexible hoses pumping dry substances. The connection includes a lever valve that opens or closes the line in one motion. The element is used in highways through which harmful substances are transmitted: acid, solvents, oil. DRYLOK prevents unexpected spills and reduces the risk of losses due to unexpectedly high pressure in pipes. KAMVALOK is an industrial type of connector, used for transporting varnishes, adhesives, paints, and various acids.

The coupling and nipple are the two main components of the product. The parts are also called “mother” and “father”. Design features of the “mother” include:

- frame;

- clamp;

- rotary valve;

- butt ring;

- sealing ring;

- connection adapter.

The design of a regular “dad” looks like this:

- frame;

- half turn valve;

- connecting part;

- sealing ring.

The product range comes in a variety of sizes. Adapters, fittings, clamps are divided according to the material of manufacture:

- different versions of BS 1/2" made of PVC;

- made of PVC with galvanization;

- brass;

- brass with rubberized surface.

If quick releases for water pipes consist of several parts, then the elements for pneumatics are a single solid piece. The installation of such fittings consists of placing the hose into the device, a springy and split sleeve grips it inside, which seals the liner. To remove the hose, simply press the locking ring. Even if the one-piece fittings are plastic, they do not lose their tightness even with numerous connections.

Elements are not only straight, but also corner, as well as three- and four-sided. A nipple for pneumatic systems is a connecting tubular element with a one-way valve and a thread, which can be either internal or external. The products are distinguished by a herringbone, which is only on one side, as well as a coupling, which is available on the other side. The pneumatic connector can be two-component. This is a unique new generation design. The part has a special fuse. It releases oxygen as the air tool stops. The latch is activated by a regular key.

The product is two-component - the fitting is metal, and the body is made of composite material. This solution ensures a long service life of the product and increases the comfort of use. Most modern quick-release couplings are affordable and have positive characteristics. Correctly selected connectors can withstand the necessary loads and ensure safety during operation.

How to choose?

There are a considerable number of compressor hoses, which differ in properties, purpose, and also in their characteristics. And in order to choose the most suitable solution for a particular model, you should better understand many important points. If you know all the necessary features, then you can easily select an excellent solution for a specific compressor, which will not only allow you to use this type of equipment as efficiently as possible, but will also make it possible to perform the required amount of work with minimal consumption of materials. Great attention must be paid to the selection of a hose for the compressor, since an incorrectly selected hose can greatly reduce the functionality of the system.

The most important characteristics to pay attention to are the following:

- diameter;

- category of connection being used;

- length;

- the material from which the hose is made;

- permissible operating pressure.

All the parameters mentioned are very important and none should be neglected. If, for example, the diameter is neglected, then the compressor will not be able to transfer the right amount of paint at the right time of operation. Other characteristics are no less important. Let's start with the length. This characteristic is, in general, probably the most important. If it is selected incorrectly, the pressure loss will be proportional. And also the negative consequences of choosing the wrong length are:

- serious or not very large reduction in pressure in the entire mechanism;

- increasing power will require a significant increase in the length of the compressor line;

- Too short a length leads to a decrease in the comfort of using the device.

Typically, the standard length of the line for an air gun or for an air impact wrench will be 5 m, 6 m, 12 and 15 m. During operation, the hose should not be over-tightened: this may cause a decrease in strength.

The next parameter is diameter. The specified size is no less important than the length. The larger the diameter, the greater the throughput of the product, which should be taken into account. Increasing the throughput increases the ability of the compressor to pump the volume of air masses. Among the features of selecting a hose according to this parameter, several important ones should be noted.

- Reducing the diameter will directly affect the decrease in efficiency.

- If the diameter is too large, this may cause a decrease in pressure.

- Standard sizes for twisted versions are 6 mm, 8 mm and 10 mm. But there are other, non-standard indicators.

To figure out what specific diameter is needed in a particular device, you can simply look at the operating instructions for a particular model. The next main parameter is the material. Hoses can be made from various materials. The most common materials for making hoses are:

This parameter has a significant impact on performance characteristics, because the service life and area of use will depend on it. The next point is the category of connection. The backbone can be connected to equipment using different devices. The most common are:

- Bayonet class connection;

- air seal solution.

Both solutions are suitable for compressor lines of different lengths and diameters. The material of manufacture will also be unimportant.

The last point that is considered extremely important is the working type pressure. Compressed air for an airbrush or for an aquarium compressor with a quick-release connection can be supplied at different pressures. And if the highway does not have the necessary strength indicators, then it will very quickly become unusable. Conventional high pressure compressor solutions are made using multilayer materials using reinforcement. In the case of the operating pressure parameter, it should be understood that:

- the most common solutions on the market are options that are designed for 6–8 bar;

- if it is not known what the operating pressure is for a particular device, it can be found in the operating instructions for that particular model;

- and you should also pay attention to the product labeling: after all, different hoses may have different properties, and if some can cope with a certain pressure, others may not, although they will be extremely similar in a number of parameters.

To learn how to choose a hose for a compressor, see the following video.

An irrigation system consists of a certain set of elements that ensure the supply of water from the source to the final point. The main ones are hoses and connecting elements. The sleeve is selected based on the material of manufacture. As a connecting element, the quick release for the hose has proven itself to be the best, as it is capable of performing a reliable and hermetically sealed connection of system elements without the use of tools.

In the organization of modern irrigation systems, quick-release couplings are indispensable

Operating principle

Pipeline quick-release connections are classified according to a variety of characteristics, including their operating principle. Among the features of the operating principle, we note the following points:

- As a rule, the device is represented by two elements, which together provide the required tightness. The connection principle is significantly different.

- Hoses or other elements are connected to both parts. Fixation is carried out in a variety of ways, in most cases using a clamp or wire.

Each type of quick-release coupling has its own specific advantages and disadvantages that must be taken into account. Let's take a closer look at the most common design options.

Material of manufacture and main types of connectors

All types of pneumatic fittings can be made of polyamide (nylon and rilsan), Teflon, polyethylene, polyurethane. Nickel-plated steel, copper, and stainless alloys are often used in production. Brass pneumatic fittings can be used provided there is no exposure to an aggressive environment.

Connectors that are designed for sealed pneumatic systems are divided into the following types:

- straight;

- corner;

- tees;

- splitters;

- adapters.

Metal, plastic and bronze collet fittings for pneumatic systems (tees, couplings, bends, splitters)

The following types are most in demand:

- a brush that has external and internal threads;

- adapter for connecting tubes of different diameters;

- corner with internal or external thread;

- combined angle (external and internal thread);

- tees with internal or external thread;

- combined tees;

- T and Y shaped tees with different thread locations;

- cruciform connections;

- transition couplings;

- external threaded adapters;

- plugs;

- hose connectors;

- quick release fittings;

Special tubes are used in combination with pneumatic fittings:

- Polyurethane. They are resistant to mechanical stress (twisting, squeezing, bending). When subjected to physical impact, they are quickly restored to their original form. Not subject to hydrolysis, resistant to oils, ozone, microorganisms, and different types of fuel. The only drawback is that they are susceptible to the influence of acids.

- Polyamide (rilsan). They are very flexible and durable at the same time. They do not lose their properties at temperatures from -10 to +70ºC. They withstand the effects of alkali, gas, fuel, and machine oil.

Wide selection of types of polyurethane tubes for connecting pneumatic systems

Installation of collet fittings

An example of connecting two metal-plastic pneumatic tubes using a collet-type pneumatic fitting:

- Cut two tubes to the required length using special scissors.

- Calibrate the tube opening using a calibrator.

- Remove the chamfer from the inner surface of the tube using a chamfer remover.

- Check the presence and quality of the dielectric gasket and two rubber sealing rings on the fitting shank.

- Place the union nut and then the collet onto the first tube.

- Insert the fitting shank into the hole in the tube until it stops.

- Hand tighten the union nut onto the fitting body.

- Repeat steps 5, 6 and 7 for the second tube.

- Tighten the union nuts on the fitting body using a spanner, leaving 1-1.5 threads free.

- Installation is complete.

Collet pneumatic parts (fittings) are designed for durable connections without leakage of air or other working media in pneumatic systems.

A wide range of products makes it possible to choose a wide variety of manufacturing materials and allows the use of collet pneumatic fittings in various equipment, ensuring reliable fastening and tightness of the connection.

Types of Hose Quick Connects

Generally, quick release hose couplings can be divided into three groups. Couplers for ISO A and ISO B hoses, Flat Face and threaded couplings. The division of products into groups is done on purpose - this allows the buyer to better navigate the range of connections and choose for themselves a coupling system that most accurately meets its requirements.

You can choose couplings for low or ultra-high pressure applications, made from carbon steel, stainless steel or brass.

Couplers for ISO A, ISO B hoses are the simplest type of quick-release couplings, most often found on agricultural machinery and in public utilities, designed for light operating conditions, as well as where there are no high pressures. Has a ball bearing seal and valve system.

PUSH-PULL (for agricultural machinery)

- ISO B – industrial applications

- IRB (carbon steel)

- IRBO (brass couplings)

- IRBX (stainless steel)

FLAT FACE couplings – connections with a flat connecting part. This design does not allow oil to leak out when disconnected; also, if the FF coupling falls on the ground, dirt will not get into the internal part.

FIRG – quick release coupling with locking pad (ISO 16028), used in hydraulic systems where it is necessary to eliminate the possibility of external oil leaks and there is a risk of fluid contamination. FIRG couplers provide a dry connector when disconnected.

- FIRG AX/FL (stainless steel) for aggressive environments

- FIRG Q (heat-treated carbon steel) for moderately aggressive media (e.g. distilled water, water-glycol mixtures)

- FIRG A (external connecting part - thread)

- APM - drain nipple, has a triple valve system (double internal relief valve and valve with locking platform), designed for residual pressure in the hydraulic system

- AHD – socket for APM nipple

- A-HP – special design of couplers for high pressure hoses that can withstand a pressure of 700 bar

Threaded couplings - this type of quick-release connections is used at very high and pulse pressures. Most often used on equipment working in quarries.

- IV-HP – threaded ball couplings, designed for high pressure systems up to 700 bar, used for cylinders, hydraulic hammers and hydraulic jacks

- VEP-P – used at high operating pressure and the need for connection with residual operating pressure in the system

- VP-P - this type is designed for residual pressure in the hydraulic system, has a safety ring that protects against arbitrary opening during strong vibrations

- VEP-HD - these quick-release couplings are designed for residual pressure in the hydraulic system, have a full connection indicator and a flanged connection part

- VLS – The VLS coupling has been specially designed for earthmoving equipment. Widely used when operating equipment with frequent pulse pressure, water hammer, and in systems with increased operating conditions

- VD – threaded and seat type couplings with seal, made of high temperature treated carbon steel, designed for pulse pressure systems

- VR – coupler with a special valve that reduces oil loss during disconnection (metric thread only)

Stucchi SpA's product range also includes SATURN blocks, multi-connectors (battery connection), valves for 5 and 65 bar, plugs, special couplings.

Types of quick-release elements depending on the operating pressure of the system

Features of parallel and serial LED connections

Based on the operating pressure, quick releases for hoses are divided into four types. ISO-A fittings are used to connect hoses in low operating pressure systems. Due to the presence of valves in the form of a cone, there are no obstacles to the circulation of the medium inside the line.

FIRG quick connectors for water or air hoses have a wide range of applications. When closed, the structure has no protruding parts. The valves have a disc design, as a result of which no unnecessary resistance is created in the system. This also eliminates the possibility of air getting inside the line or liquid leakage.

The low operating pressure system uses ISO-A fittings.

For systems with operating pressures of 110-300 Bar, TGW quick-release couplings are used. They are equipped with special protective plugs made of plastic and metal that prevent leakage of the working medium. Such quick releases for 1-inch hose and larger diameter products can withstand impulsive loads and water shocks. For domestic mobile hydraulic tools, it is advisable to use quick releases of the NRA type, designed for operating pressures up to 700 Bar.

Note! When choosing a quick coupler with a smaller power reserve, there is a high probability of a quick failure of the connection, and using a quick coupler with a higher power is an economically unjustified solution.

Scope of use

Today, quick-release couplings have penetrated into many areas of human activity and are firmly entrenched there, thanks to their unique qualities and ease of use. Let's consider the main operational areas of the coupling system:

- Automotive industry;

- aviation industry;

- connection of pneumatic devices;

- defense sector;

- alternative sources of energy supply;

- shipbuilding;

- chemical industry;

- medical equipment;

- railway transport;

- polymer industry;

- mining industry;

- construction sector.

Quick-release connections are used in many areas, including in everyday life