A water well on your property is the best long-lasting source of clean water in your home. However, so that during the drilling process, as well as during operation, it does not become clogged with rock and does not collapse, it is necessary to strengthen its walls using a special pipe column. Let's consider which casing pipe is best suited for a water well - plastic, steel or asbestos-cement, what advantages, disadvantages and application features each type has, what are the general rules for choosing, how to correctly calculate its diameter, what are the main stages of casing technology.

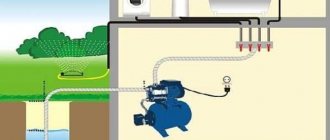

Option for arranging a private water intake with a casing pipe Source scvazina.ru

Plastic pipes

Considering the requirements for casing strings, it can be understood that an ideal material does not exist. Each type is designed for use in certain conditions.

In wells that are shallow, an excellent option is to use plastic elements: PVC, HDPE.

They are harmless to health, do not corrode, have sealed joints, are easy to install, cheap in material and assembly, and do not accumulate dirt on the walls.

- Frost-resistant polypropylene can withstand temperatures down to -60 degrees Celsius.

- The service life is at least 50 years.

All types of plastic have two disadvantages: due to their low strength, the depth of use is no more than 60 meters; unplasticized polyvinyl chloride (UPVC) can be lowered to a depth of up to 300 m, but it is a very fragile material.

Fastening wells during drilling

Well casing is one of the most important processes during oil production, as it affects:

- Well performance;

- Well lifespan;

- The strength and tightness of the channel through which the extracted product will flow from the horizon to the surface;

- Protection of the operating channel from corrosion;

- The strength of the well walls in places where the rocks are not stable enough;

- Tightness of separation of all permeable horizons from each other.

Securing oil wells involves the use of special columns or packers. The use of columns is the most popular method, which allows you to make the well strong, durable, and also isolate permeable horizons. Such columns are made up of special pipes called casing.

Fiberglass pipes

Few people have heard of fiberglass casings, the production of which was recently organized by a private company.

- A glass thread is wound onto a steel base and filled with synthetic resin.

- The inner surface is covered with polyethylene film.

Such an element has all the properties of plastic pipes, but has greater strength (withstands 25 tons along the axis), and is 5 times lighter than steel. Can be used repeatedly as casing.

Drilling technology

The drilling rig is installed with your own hands only on a site prepared for work. The homemade device is installed in a small hole - a pit. It should have a depth of 2 m and dimensions of 5x1.5 m. This will prevent the collapse of loose soil, which is usually located on the surface itself. The walls of the pit are reinforced with plank boards.

A tower operating on the UKB principle is installed only on a prepared site. At the same time, the vertical installation of the main structural elements is carefully checked. The slightest curvature of the driving tool’s trajectory will make it impossible to install the casing pipe and further operate the created structure.

The destruction of the soil begins with the help of a homemade glass from a piece of pipe. Using a shock rod, it is sharply lowered to the surface from a height of 1.5 m. Using a cable with a winch, the glass is removed out and the process is repeated from the beginning. If necessary, change the driving tool to a bailer or chisel, moisten the soil or add some dry rock.

Video: Cable-percussion drilling

Selection of questions

- Mikhail, Lipetsk — What discs should I use for cutting metal?

- Ivan, Moscow - What is the GOST for rolled sheet steel?

- Maxim, Tver - Which racks for storing rolled metal products are better?

- Vladimir, Novosibirsk — What does ultrasonic processing of metals without the use of abrasives mean?

- Valery, Moscow - How to forge a knife from a bearing with your own hands?

- Stanislav, Voronezh — What equipment is used for the production of galvanized steel air ducts?

Joining of casing pipes

- Connections using threads are made on thick-walled structures. One pipe has an internal thread and the other has an external thread. They curl up and fall into the well.

- The coupling method of connection is more complex. It consists in screwing a coupling with an internal thread onto both pipes, while the pipes are cut from the outside.

- The welding method is more economical, but has one drawback - the lack of qualified welders in this industry.

Wells are divided into three types - Abyssinian, sand and artesian.

Advantages and disadvantages of the method

The technology of percussion-rope drilling of wells has many advantages over other methods:

- Using this method, it is possible to qualitatively open the aquifer and exploit it. The service life of the well exceeds 50 years;

- When drilling using the percussion method, you do not need to use water or special drilling fluid. It's very practical;

- using this method to form a well, you can even drill into rock that very easily absorbs the flushing liquid;

- You can start operating the well immediately after completing the entire range of work;

- The impact drilling method does not pose a danger to the aquifer. After carrying out the entire complex of work, its clogging is excluded;

- Do-it-yourself impact drilling of wells is carried out with the formation of a hole with a large initial diameter;

- With the help of this drilling rig it is possible to carry out geological exploration work. The rock is excavated throughout its entire depth.

Abyssinian

This type of well has a shallow depth of up to 30 meters. Water is lifted using surface pumps from a depth of 8 - 9 m. Therefore, the diameter of the casing pipe is of little importance.

A polyethylene pipeline from a coil is used as casing, which does not require docking. You can combine the casing and the supply pipe of the electric pump.

Well on site

- the presence of aquifers accessible for drilling;

- physical properties of soil rocks;

- type of drilling tool;

- the length of the casing, depending on the depth and direction of the well shaft.

After a geological survey of the area, the owner makes one of the following decisions:

- rent a UKB cable drilling rig and carry out the work on your own;

- hire a specialized team.

For independent actions, you can make a tripod of your own design. The triangular pyramid is made from available materials - wooden beams or metal profiles. You will need to stock up on a lifting mechanism to lower the casing pipe into the well and manipulate the projectile. The height of the drilling tower is determined by the size of a single casing fragment.

Artesian

Artesian springs are the deepest - the depth reaches 200 meters. The casing string experiences enormous mechanical loads at such depths. The choice of material for a well water supply is obvious: only steel can be used.

There is no need to worry about corrosion, since artesian water has a significant percentage of all kinds of dissolved metals. Treatment plants are used for such water.

You can place a plastic one inside a steel pipe, then rust will not mix with clean water, and the steel will protect the plastic from stress.

- It is important to choose the right casing pipes. If you buy polymer structures, you should pay special attention to the fact that they are not made from recycled materials and are absolutely safe for health.

- A significant step in selecting the casing will be calculating the diameter. If you intend to install a deep-well pump, you should remember that the distance between the pump and the walls of the well should not be less than 5 mm.

Purpose

When drilling wells, a casing is always made of special pipes, which performs the following functions:

- The main purpose of the casing is to protect the mine from soil shedding and clogging of the borehole channel.

- The presence of a column makes it possible for the water column to rise upward without being absorbed into the ground, and prevents water pollution.

- Due to the tightness of the connection of the pipe sections, the casing protects the well source from the penetration of contaminated surface and ground water into its channel.

- It is convenient to immerse a deep-well electric pump that sucks up water into a smooth and rigid round trunk.

- A cap or cover is attached to the top of the column, which prevents external precipitation and dirt from penetrating into the channel and serves as a support for the safety cable of the deep-well electric pump.

- When connecting an adapter water supply, the casing pipe is a support for attaching the adapter, which is cut from the side into its wall at a depth below the freezing point.

- The filter, located at the bottom of the column, filters out large and small particles of gravel, sand, limestone, clay, making the water more suitable for drinking and household needs.

Rice. 2 Designs of casing steel pipes according to GOST 632-80

Photos of casing pipes

Pressure or non-pressure pipeline?

The only correct option is to use pressure pipes. Only such products can withstand double-sided pressure. From the outside, the walls of the column are affected by the buoyancy of the soil, and from the inside by water pressure.

The construction of a pressure main will protect the aquifer system from premature failure. When choosing a water pipe, compare its operating pressure with the expected flow rate of the well

The video reviews below will help you decide on the most optimal well casing option.

How to mount and install an iron box for a cellar at a high groundwater level

It is not necessary to make a container the entire height of the cellar. It can be made in the form of a trough with low sides, the dimensions of which depend on specific conditions and the extent of flooding. On the sides of such a container there must be fastening wings, by which the “trough” can be removed from the cellar and lowered into it.

Construction of a cellar in places with a high ground level: 1- trough-type box made of sheet steel; 2 – a piece of half-inch pipe; 3 – tap; 4 – mounting wings; 5 – fastening the box to the ground.

At the bottom of the box, in one of its corners, you need to weld a pipe with a tap built into it. This locking element of the structure must be located at the end of the pipe, the height of which must be at least half a meter. Next, they begin to disinfect and paint the box. To do this, it is first treated with orthophosphoric acid, then coated with red lead for iron.

On the outside, additional waterproofing is carried out to prevent rust: a layer of bitumen is applied to the surface of the box. If everything is done correctly and carefully, such a container will last for many years and will not give a single leak.

Upon completion of the work, they begin to lower the box into the pit that was dug to construct the cellar. In conditions of high water and high groundwater level, the pit will always be filled with water. If formwork was not installed along the walls of the pit, the height of the iron container should be greater than the depth of the pit. Otherwise, if the groundwater level is high, the walls of the pit will quickly be washed away by water. The box is lowered into it after opening the tap. It will gradually sink and sink to the bottom, as water will flow into its interior.

After the container is firmly in place, its position is fixed by concreting the outer wings. After this, the water is pumped out using any powerful pump. Upon completion, close the tap. All that remains is to complete the simplest work: make a cellar lid and install a staircase. In a similar way, you can make a viewing hole for a car if the garage is located in an area with a high groundwater level.

https://youtube.com/watch?v=eKg24j5LKg8