Pipe flaring: subtleties of technology and basic tools

Specialists often have to change both the configuration and other geometric parameters of pipe rolling to solve various problems. Most often, to change the shape and size of a tubular product, a technological operation such as flaring is used. It should be borne in mind that this operation is fundamentally different from what is called rolling, and these differences are significant.

The ends of these copper pipes are flared: expanded to a specific shape and prepared for connection

Flaring and Rolling

First of all, it should be understood that pipe flaring cannot be called rolling, since the essence of these technological operations is completely different.

- Rolling, for which a special rolling machine is used (a machine equipped with work rolls), is a technological operation during which rolled sheet metal or a metal pipe is deformed in the radial direction. Using this operation, in particular, products of cylindrical or conical shape are formed from sheet metal, and products with a different cross-sectional shape are also made from round rolled pipes.

- The flaring tool does not contain work rolls in its design, and the essence of the procedure itself is that only the end of the pipe is subjected to plastic deformation, while its internal and external diameters increase to the required parameters. The need to perform such an operation most often arises in cases where two sections of pipe need to be securely connected to each other.

Types of tube flaring

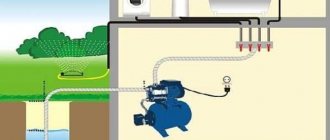

To obtain a reliable and tight connection between two pipes, various methods are used - soldering, the use of union couplings and other fitting elements, etc. In some of these cases (particularly when soldering and using slip-on couplings), the ends of the tubular products need to be widened. To perform this procedure, a flaring machine is required.

Many home craftsmen also mean by flaring other technological operations, the purpose of which is also the plastic deformation of a separate section of a pipe product. This includes, for example, rolling and bending.

- Rolling is a procedure that does not imply expansion, but narrowing of the edge of the pipe. In this case, a simple crimping method is used, for which ordinary pliers or miniature rollers are used. The need to perform such an operation arises in cases where it is necessary to cut a thread at the end of a pipe using a hand tool.

- Bending is a technological operation for which special devices with working rollers are used and which is often also called flaring, although this is fundamentally incorrect. The purpose of bending, which can be applied to both soft copper tubes and rolled pipes made of steel and other metals, is not to expand, but to bend a separate part of the product at the required angle.

Thus, rolling and flaring should be understood as completely different technological operations.

Flaring tubes during air conditioner installation

Making a homemade rolling tool

It is not always necessary to purchase a factory machine for pipe flaring, especially if the operation is a single one. In this case, you can use a regular cone and a hammer, but for greater accuracy of the result, it is better to make a simple homemade tool. Main parts of the device:

- Bed. It is made from a steel angle 200 mm long, a shelf width of 32 mm and a wall thickness of 5 mm.

- There are two M8 bolts. With their help they tighten the frame.

- Vise. The frame is clamped into them.

- Conical mandrels (flaring cone). They order it from a turner, or they grind it themselves from a steel blank.

Tool for work:

- Electric emery;

- Drill;

- Grinder with cutting wheel for metal.

- The blank from the steel angle is cut into two sections 100 mm long.

- The workpieces are connected (to form the letter “T” at the end) and clamped in a vice.

- Drill two holes in the corners for an M8 bolt.

- The workpieces are tightened together with bolts.

- Drill holes for different diameters of copper tubes (no more than 8 mm in diameter) along the line of contact of the two corners.

- Small chamfers are selected in each hole.

The resulting tool is ready for use, it is used in the same way as the factory one.

How to flare a pipe

When wondering how to flare a pipe, you should keep in mind that only products made from a sufficiently plastic material can undergo such a procedure. This, in particular, includes soft tubes made of copper and aluminum alloys, as well as certain grades of stainless steel. To perform such a technological operation, either a commercially produced flaring machine or a home-made device can be used. Meanwhile, flaring of large-diameter steel pipes or products made of other metals must be carried out using professional equipment.

Pipe flaring device

How to flare pipes at home? In such situations, tubes made of copper and other soft metals are most often subjected to flaring, but regardless of the material used to make the products, this technological operation is performed in the following sequence:

- The end of the pipe is thoroughly cleaned, and burrs are removed from its surface.

- Then a special coupling is installed on it and placed in a flaring device.

- If a manual flaring machine is used to perform flaring, then the process of doing it is as follows: when screwing in the screw, the cone of the flaring device, exerting a mechanical effect on the inner surface of the pipe, deforms it.

- Once the end of the tube has taken a funnel shape with a bevel angle of approximately 45°, the flaring tool is removed.

- The detachable coupling, which was previously put on the tube, is moved to its end and the nut is tightened.

If the flaring machine is used to prepare tubes for soldering, a threaded detachable coupling is not used.

Obtaining a conical socket

To understand the technology of the process, we can take the example of flaring copper tubes. The work order is as follows:

- The pipe is carefully trimmed. For high-quality flaring, the angle between the end and the plane must be strictly 90 degrees.

- Metal processing of the working part consists of cleaning and removing burrs and oxides.

- A threaded coupling is placed on the tube.

- The workpiece is clamped in the frame in a mounting hole of the appropriate diameter. The end of the pipe (working part) should protrude a few millimeters above the frame.

- When screwing in the screw, press the flaring cone against the end and apply pressure until the deformation of the area reaches the limit - a skirt is formed, beveled at an angle of 45 degrees.

- The workpiece is removed from the bed, the coupling is moved to the machined edge.

To make it easier to apply the cone to the workpiece, it is better to cover the working surface with a lubricant. Move the screw back and forth, gradually achieving the desired result - this will help avoid possible rupture of the metal in the deformation area.

Working with a manual expander has its own algorithm of actions:

- The end of the workpiece is pushed onto the appropriate diameter of the head until it stops (there are several diameters available).

- While holding the stationary handle, the movable handle is moved around the circumference, thereby spreading the jaws of the head. The work is carried out without violence, so as not to rupture the pipe.

- After obtaining an expansion of the diameter, remove the workpiece from the tool.

- Check the ease of entry of the second pipe into the resulting socket.

Communities › Kulibin Club › Blog › Zig machine. Machine for flaring (creating a side) of pipes

When installing intercoolers, you often have to cut aluminum pipes and connect them with silicone. At the same time, to prevent the silicone from jumping off, the pipe must be flared.

You can flare a pipe in various ways; in the Drive search you will find many options. But the most convenient, correct, high-quality and fastest option is to use a pipe flaring machine

Such machines are available for sale, but their price tag is very inhumane. 8000 rub.

I use this exact machine when I work with pipes in one of the workshops. Convenient and useful thing.

I am constantly adding to my personal arsenal of tools and have had my eye on such a machine for a long time. But the toad said that he would not give money and I had to make the machine myself.

And this is what I got.

The machine is completely made of stainless steel. It turned out to be heavier and larger than the machine that can be found on sale, but it’s worth it)

And now in more detail.

The advantage of my machine is that it can be mounted on the edge of a table or in a vice. The machine from the store can only be mounted in a vice. I made the clamp with which the machine is attached to the table removable, so that if necessary it would be easier to secure it in a vice.

From rotation on the axis, the rollers are fixed with cotter pins and tightened with bolts

Well, now the fun part! Machine test!

We take an aluminum pipe and clamp it between the rollers

By turning the rollers and gradually tightening the pressure screw, we form a bead on the pipe.

The result is a neat, even side

But that is not all!

Sometimes you come across cars where stainless steel pipes are used when installing the intercooler. Often they are not flared. We have to fix this.

I tried to flare stainless steel pipes on a machine for 8000. It’s clearly not for these purposes. Too flimsy.

Not like my machine!

Without much effort, my machine makes an excellent rim on stainless steel pipes!

If you sit down and think through the design of the machine more carefully, then of course you can make a more compact version. During the creation process, thoughts already appeared about what could be done more successfully, but for this we need to do everything from the beginning. There is neither time nor desire for this.

Another not unimportant point. On a machine from a store you can flare a pipe with a diameter of at least about 20 mm; on my machine it is not possible to flare such a pipe. The minimum internal pipe size for my machine is 28 mm. But for my purposes this is enough.

Thank you for your attention!

Cost of services

| Sheet thickness | D=500 rub. VAT included | D=1000 rub. VAT included | D=1500 rub. with ND | D=2000 rub. VAT included | D=2500 rub. VAT included | D=3000 rub. VAT included |

| 4 mm | 3 325,00 | 5 500,00 | 8 200,00 | 10 450,00 | 13 437,50 | 15 850,00 |

| 5 mm | 3 914,00 | 6 640,00 | 10 024,00 | 13 844,00 | 15 274,00 | 20 612,00 |

| 6 mm | 3 903,00 | 8 780,00 | 12 816,00 | 15 238,00 | 19 110,50 | 24 308,00 |

| 8 mm | 6 650,00 | 11 000,00 | 16 432,00 | 30 900,00 | 25 844,50 | 33 766,00 |

| 10 mm | 6 828,00 | 12 280,00 | 20 048,00 | 25 688,00 | 30 548,00 | 39 224,00 |

| 12 mm | 8 006,00 | 13 560,00 | 21 664,00 | 28 476,00 | 34 251,50 | 44 682,00 |

| 14 mm | 9 153,00 | 15 780,00 | 25 280,00 | 33 138,00 | 39 955,00 | 52 140,00 |

| 16 mm | 10 331,00 | 18 060,00 | 28 896,00 | 37 926,00 | 45 658,50 | 59 598,00 |

| 20 mm | 13 656,00 | 22 560,00 | 36 160,00 | 47 376,00 | 57 096,00 | 74 580,00 |

| 25 mm | 15 601,00 | 28 260,00 | 45 184,00 | 59 346,00 | 71 370,00 | 93 192,00 |

| 30 mm | 18 515,00 | 33 900,00 | 54 208,00 | 71 190,00 | 85 644,00 | 111 804,00 |

| 35 mm | 25 343,00 | 45 120,00 | 72 288,00 | 94 752,00 | 114 192,00 | 149 094,00 |

Flaring of copper, steel and stainless steel tubes

Flaring, with a simple mechanism, RIDGID 345 is designed for professional use. Ensures smooth and uniform production of 45 degree sockets. The simple handle of the lead screw makes it possible to rotate without any effort. The flaring cone is made of hardened steel and easily allows the production of bells at an angle of 45 degrees. Main applications: installation of air conditioners, installation of refrigeration units, installation of hydraulic systems, etc. It is recommended to flare aluminum, copper, mild steel and brass pipes.

Teleinspection of pipes. Video diagnostics of the internal condition of sewerage pipelines, air ducts, wells. Recording an image.

Pipe routing. Searching for pipes and cables underground at great depths. Determination of depth and location.

Cleaning and rinsing. Cleaning and washing of pipes of various diameters from fatty deposits, growths, roots, rags, sand, clay, wood.

Examples of work execution

Video inspection of pipelines - video diagnostics of pipes, television inspection of the internal condition of the sewerage system.

Cleaning the toilet drain pipe - clearing the blockage.

Flushing and cleaning of pipelines with a hydrodynamic machine.

Tracing and searching for pipelines and cables underground.

Cleaning drains in sinks, showers and bathrooms.

Pipe wrenches, chain wrenches, pipe pliers.

Professional hand tools for installation and repair work of any complexity. Wide choose.

Pipe and metalwork vices, workbenches, work tables.

A number of models of pipe and bench vices, work tables for performing various types of work.

Threading tools, manual and electric.

Pipe clamps, ratchets, combs, electrical clamps for cutting various threads.

Threading machines, stands, pipe supports.

Threading equipment for cutting threads on construction sites and factories.

Press tools, press pliers, cable cutters.

Hand press tool for crimping press fittings, cutting cables, cutting holes in steel.

Manual and electric pipe cutters, countersinks, bolt cutters.

A huge selection of pipe cutters for cutting metal and plastic pipes, wire cutters for cutting fittings.

Manual and electric pipe benders, pipe bender shoes.

A number of models of pipe benders for bending steel, copper, stainless and aluminum pipes of various diameters.

Electric and hand saws, drilling machines.

Tools and equipment for cutting and drilling in metal, tapping into pipelines under pressure.

Hydropress, pipe freezing, pipe flaring.

Manual and electric hydraulic press for crimping pipes under pressure, flaring pipes.

Laser levels, current clamps, thermometer, range finder.

Measuring tool for construction work, as well as maintenance of utilities.

Diamond drills, diamond core bits, vacuum cleaner.

Hand drills – drilling in walls and ceilings, drilling reinforced concrete, granite, brickwork.

Diamond machines, bits, extensions, water pump.

Diamond machines for drilling holes of different diameters when installing pipelines.

Video systems for pipeline inspection, mini cameras.

Video diagnostics, inspection, telemetry of the internal condition of sewer pipes, air ducts, wells.

Locators, probes, generators for searching pipes.

Searching for pipes and cables underground at great depths, detecting utility lines.

Rolling: what does it mean?

The term is used to refer to the following processes.

- Rolling - the main technological operation in the production of a seamless pipeline is the formation of a product from a round billet. The workpiece is stretched, thinned and calibrated on the appropriate equipment - rollers. Hence the name.

- Flaring does not require the participation of rollers and can be done by hand. Its essence is to increase the diameter of the pipe edge using mechanical action. This need often arises when connecting straight segments.

A high-quality joint involves inserting one section into the sleeve - expanding, another and sealing the gap. But since not all products have such a sleeve, you have to do the operation yourself. In everyday life, flaring is usually understood as this process.

- Rolling is the reverse operation: crimping the edge of the pipe before inserting it into the sleeve. If manual threading involves cutting the thread, the edge of the pipeline also needs to be reduced in volume - rolled. Conventional pliers or miniature rollers are used for this.

- Bending – Most pipe bending machines, both manual and hydraulic, include rollers. The product is inserted into the machine, the deforming roller is rolled along the length of the segment and gradually bent at the required angle. Since the operation involves rollers, this process is also often called flaring. Water pipelines made of stainless steel and aluminum are subject to bending.

Only the second option can be legitimately called this - increasing the diameter of the edge before joining. GOST regulates the qualitative and quantitative characteristics of the rolling result.

Profile products

Profile products are manufactured in the following sequence:

- Strips are flat-shaped steel blanks, cut into narrow strips.

- The strips are butt welded to form an endless strip, which is wound on top of the drum.

- When the tape is needed, it is run onto the machine and rolled into round blanks.

- The edge is cooked, in most cases using induction current.

- The rolling machine gives the desired shape. Mechanical rollers can make any shape, even the profile of a person if desired.

Rolling of round pipes is also possible. Such processes are cheap and easy to perform.

Advice: if the product has undergone cold deformation, after finishing the work it should be thoroughly heated and allowed to cool on its own. This way you will relieve the tension that has arisen in the middle of the product.

If you use a homemade profile pipe when building a water supply system, then it is better not to overdo it when heating. Take an ordinary soldering lamp or transformer welding.

Flaring: sequence of actions

The operation involves products made of stainless steel, aluminum and copper - that is, a material with a certain level of ductility. For this purpose, both home-made and special devices are used. To flare pipes with large diameters, professional equipment is required.

Flared edges can most often be found on medium- and large-diameter sewer lines. It is their dimensions and permissible error that are described by GOST.

At home, you often have to deal with copper pipes. But stainless steel products are subject to rolling. The process technology is the same for any tool.

- The end of the segment is cleaned and burrs are removed.

- A coupling is put on the edge.

- The pipe is installed in some kind of flaring device and clamped.

- If we are talking about a manual device, then it looks like this: the flaring cone, when the screw is screwed in, puts pressure on the inner surface of the water conduit and deforms it.

- The flaring tool is removed. The end of the segment should have a regular funnel shape with walls beveled at an angle of 45 degrees.

- Then the coupling is moved to the flared edge and the nut is tightened.

The video demonstrates the flaring of a copper pipe before joining.

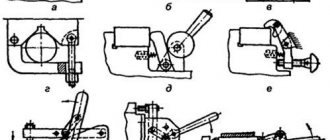

Flaring Tools

When installing a copper pipeline with your own hands, a hand-held device is sufficient. Copper is a ductile metal. Forming a funnel-shaped edge requires not so much effort as accuracy. The funnel should be completely symmetrical, without distortions or chips.

- The simplest mechanism consists of two parts: a clamp with standard diameters - a metal plate in which the product is held, and a cone with a screw. The photo shows a sample.

- An extender is a lever tool with a replaceable expansion head for different diameters. The extender is fixed to the edge, the levers are moved apart and the legs stretch the pipe.

You need to work with mechanical devices carefully, as there is a great danger of forming walls of unequal thickness.

- A professional flaring machine is usually equipped with an electric drive and belongs to the rolling apparatus. A cone-shaped head of the appropriate diameter is rolled along the edge of the product until the funnel reaches the required size and shape. Uniformity and symmetry in this case are much higher.

To work with stainless steel water pipes of large diameter, only this tool can be used. Otherwise, GOST requirements will not be met, and the pipeline connections will be of poor quality.

Methods

Depending on the temperature of the workpiece, the pipe rolling process can be divided into two large groups.

- Hot rolling. Used when working with materials that have high resistance to deformation. For example, heating is used when rolling plastic pipes along a radius.

- Cold rolling . Suitable for soft materials such as copper, aluminum, low-quality steel and the like.

Both types of processing are used in both manual and industrial pipe rolling methods. For independent work, you will need to purchase an expander or a special set, which includes the following items: a pipe cutter, stamps with holes of various diameters, a clamp and the pipe expander itself. It is equipped with a conical expander. If the cone is black and untreated, then the set is intended for plumbing pipes, otherwise the set can be used when working with air conditioners.

When flaring, there are three main types of funnel.

- An ordinary funnel. The simplest option, found everywhere.

- European standard mushroom. This type is often found on European-made cars. Externally it resembles a car tire.

- Funnel with double folded edge. Funnels of this type are common in American-made cars.

Often, to expand the pipe on your own, a conical blank with the required angle is used. But with this approach, there is a high probability that the pipe material will deform unevenly, and perhaps the pipe will rupture or bend.

In industry, the list of equipment and tools used is much wider, so let’s look at it in more detail.