What are abrasives

Abrasives

- these are materials characterized by hardness that is superior to other types of materials (even metals). These are solid small particles used in free or bound form (for example, in the form of some form, fixed on a surface, etc.).

Abrasives are designed for mechanical processing of various materials, removing the thinnest layer from them with sharp protrusions of their particles. In fact, any hard structure has abrasive properties in relation to a less hard one. However, only specific types of abrasive materials are used on an industrial scale.

Abrasive processing of materials

Special abrasive tools are made from abrasives. They, unlike blade (metal) ones, do not have a continuous cutting edge. This function is performed by a solid grain structure, each of the grains is a cutter in it. These abrasive particles are bonded to each other with a binder or combined into some kind of product (it can be a wheel, a stone, sandpaper, a brush), and collectively act on the working surface with their cutting edges, removing the finest chips with them (this layer can be as little as several microns).

Abrasive materials are in demand for different types of processing:

- grinding - can be round, flat, circles, tape, and also preliminary and finishing;

- lapping;

- water jet treatment;

- ultrasonic;

- sandblasting;

- polishing (sometimes preliminary, mirror);

- honing (this is the finishing treatment of internal cylindrical parts, such as automobile cylinders);

- superfinishing (involves minimal material removal);

- tumbling (this is the cleaning of small parts from scale, corrosion, burrs, etc.);

- cutting, cutting;

- sharpening

Types of abrasives

Abrasive materials differ in different parameters. Thus, they are classified according to their hardness (there are soft, hard, super-hard), their chemical composition, and grain size (they can be large, medium, fine, extra fine).

Based on their origin, abrasives are classified into three types.

1. Natural (or natural) origin. These are sand, garnet, zirconium, etc.

2. Artificial (or synthetic, industrial) origin. These materials are manufactured specifically for abrasive processing. The most common are artificial diamond, silicon carbide, boron, electrocorundum, cubic boron nitrite.

3. Abrasives from production by-products: agricultural residues, slags from metal smelting (for example, nickel slag), from the operation of power plant boilers. These materials are available, have a variety of particle sizes, and are low in cost.

Natural abrasives

Let's look at some of the natural abrasives.

Diamond is the hardest of natural materials, consisting of pure carbon. In nature, it is found, as a rule, in the form of a scattering of crystals. Diamonds can be either jewelry or technical (they are used as abrasives).

Pomegranate

is a mineral consisting of aluminosilicates of lime, magnesia and other impurities. It can be painted in different colors, with the exception of blue. It is used in crushed form: the particles are applied to sandpaper for grinding.

Corundum

consists of crystalline aluminum oxide with impurities, differs in color from bluish to brown. In this case, the hardness of the material decreases with increasing content of iron oxide in it.

Emery

- a mixture of corundum grains with magnesite and other minerals.

Quartz

is silicon oxide in crystalline form. A variety of quartz is flint: it consists of silica and is found in nature in the form of massive rocks.

Pumice

- This is a porous structure of volcanic origin, consisting of silica and alumina.

Chalk

— calcium carbonate, with which fine types of processing (polishing, lapping) are possible.

Choosing the type of cutting tool for metalworking

To place the correct order, you need:

- Determine what tasks it should solve - with the help of the same cutter you can perform a wide, but still limited range of work; it will not be suitable where a drill is required.

- Take into account which machine it will be installed on - it is simply necessary that it is compatible and can receive and transmit rotation force without unnecessary losses.

- Make sure that he can maintain the required cutting parameters - carry out calculations, draw up a technological map, and compare the passport data (and other indicators) of the devices he likes with it.

- Consider the efficiency of use - all other things being equal, it is better to buy the option whose wear resistance is higher, because it will last longer, this is true even for mass production, under conditions of high loads.

Artificial abrasives

The artificial abrasive carborundum was first synthesized in 1891 by scientist-inventor Edward Acheson (USA). Today, there are a lot of abrasives of industrial origin, they are used more widely than natural ones. Let's look at the features of the most common of them.

Electrocorundum is produced by reduction smelting from bauxite in electric furnaces. The color of the abrasive varies from gray to red-brown. The material is used to produce a hard abrasive tool.

Silicon carbide is obtained by reducing silicic acid with carbon. The material is highly brittle and is used in powder form or as a tool for processing glass, porcelain and other fragile structures.

Boron carbide

- the hardest synthetic abrasive, used as a paste for grinding very hard surfaces.

Classification of metal-cutting tools

There are a number of key parameters - let's take a look at each.

Based on the nature of processing (action), they are divided into:

- blade - cut off excess material;

- abrasive - abrade the surface, bringing it to the desired geometry by grinding.

By design they can be:

- solid - completely made from one piece;

- composite - made of several parts, all connections of which are permanent;

- prefabricated - their elements are fastened so that they are easy to separate if necessary.

According to the mounting option, there are top-mounted and tail-mounted ones. There are also options for drives (manual, machine or combined) and shape (plate, cylindrical, disk, conical), and each of them is in demand in its niche.

Abrasive liquids

The percentage of solids in different abrasive products can vary significantly. Sometimes they are included in a liquid medium - in this case we are talking about an abrasive liquid. Examples are liquid cleaning products (household chemicals), paints containing quartz sand, sand suspensions, caustic sludge, food products (sugar suspensions, chocolate spreads with pieces of nuts), cosmetology (scrubs, abrasive toothpastes), etc. Of course, not all of them are used for surface treatment. Nevertheless, these media have abrasive properties, which must be taken into account when selecting equipment that works with them.

Read more about pumping abrasive liquids

can be read here:

https://www.arkronix.ru/fluid-types/abrazivnye-zhidkosti/

Properties of abrasive materials

Abrasives have a number of important characteristics, or properties. So, their important parameter is hardness. It is determined by the resistance of the material whose surface is subjected to grinding. Thus, the hardest abrasive material on the Mohs scale (named after the German mineral scientist) is diamond (10 points), boron carbide has 9.5 points, corundum, silicon carbide and electrocorundum - 9, quartz - 8, gypsum - 2, talc - 1 point.

Other properties of abrasives are strength, brittleness, and grain size (this is the size and shape of the grinding grain). Thus, the shape of the grains can be isometric (their height, width, thickness are approximately the same), xiphoid, lamellar - this indicator depends on the nature of the abrasive material and the degree of grinding of the original grain.

The abrasive ability of these substances (that is, their performance qualities) is determined by the mass of the layer of material removed during grinding.

Abrasives have the property of self-sharpening: they remain operational due to the formation of new protrusions, cutting edges near the grains during processing.

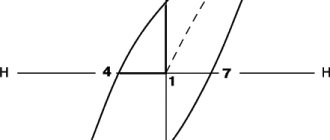

Types of grinding wheels:

The following types of grinding wheels are distinguished:

Grinding wheel with intermittent working surface.

Reinforced wheel is a grinding wheel containing reinforcing elements. Reinforcing elements can be, for example, a steel ring or fiberglass mesh.

A highly porous wheel is a grinding wheel with a specified size and number of pores.

High-speed wheel is a grinding wheel designed for high-speed grinding.

High-speed wheel is a grinding wheel designed for high-speed grinding.

Roughing wheel (roughing wheel) is a grinding wheel designed for rough grinding.

Ball grinding wheel (ball grinding wheel) is a grinding wheel designed for ball grinding.

A profile wheel is a grinding wheel whose working surface shape differs from cylindrical.

A worm wheel is a profile grinding wheel with a helical working surface, designed for gear grinding by rolling.

Flap grinding wheel (flap wheel) is a grinding wheel consisting of radially located grinding sheets rigidly fixed to one of the end sides.

Grinding head (head) – a grinding wheel with a blind hole for fastening.

Assembled grinding wheel – a grinding wheel with a detachable connection of its parts.

Composite grinding wheel is a grinding wheel with a permanent connection of its parts.

Cutting wheel (cutting disc, grinding disc, cutting wheel) – a grinding wheel designed for abrasive cutting and abrasive cutting.

Application of abrasives

People have used abrasives since ancient times. For example, the Mayans in the 9th century. BC e. They decorated their teeth with precious stones, and they drilled holes in them with tubes onto which crushed quartz was applied.

Today, the scope of application of abrasive materials is very wide.

For example, they are indispensable in metal and woodworking, construction. Abrasives are also used in everyday life. So, in every home there is sandpaper, pumice, and nail files (they are also covered with very fine polishing particles). #FORM#

Areas of use

We looked at what cutting tools there are, but where and when are they in demand? They are virtually indispensable in all major industries, but they can only be used effectively if certain requirements are met:

- the material they are made must be harder and stronger than the metal they process;

- the workpiece must be securely fastened;

- It is necessary to strictly observe safety precautions and the parts production scheme.

If all these conditions are met, you can count on long-term and cost-effective operation.

Another important niche is small private and home workshops. They require manual devices - all kinds of machines and machines designed for piece operations, at low speeds and with low feeds.