How to age metal yourself?

The choice of method for creating an interior style, which assumes the presence of traces of antiquity in the design, is quite wide. For connoisseurs of this style, it is not always affordable to purchase real old items. The way out of this situation is to imitate ancient metals. How to properly paint antique metal with your own hands? Coloring is carried out in stages:

- Preparing the surface for painting. We get rid of dirt, rust and traces of grease by grinding and solvent treatment.

- Metal priming. In this way we achieve the formation of roughness on the surface for better adhesion of the paint. We choose a primer special for metal.

- Application of selected metallic paint. Experts advise performing the process using a regular brush, this way aging is achieved in the best possible way.

- Aging stage. When the paint has dried, coat the surface with a special craquelure varnish. It is after this step that the metal object becomes covered with cracks, which create the effect of an old product.

Important! If non-metallic surfaces are being processed, then it is necessary to take a responsible approach to the choice of primer composition to achieve reliable adhesion with metallized paints.

On video: master class on applying patina to forged metal.

Design errors

Unfortunately, it is not uncommon for a product to have a significant amount of time and money spent on aging, but it has an unfinished, and often contradictory, look to the era of imitation. The reasons include poor training of the person who carried out this work, violation of recommendations on the methodology and sequence of work, and may only consist of a careless attitude to detail. For example, painstaking work was carried out and the metal doors were painted in an antique style, but the frame did not undergo any changes, the fittings and small door parts have a modern design. The overall picture is not original, but rather unpleasant.

If we consider the issue more deeply, then it is important to involve several elements of the overall interior of the room in the architectural group to create the effect of an ancient component. A variant of the method for making an antique door leaf is demonstrated in the following video.

Making an antique metal door.

Additional Information:

- The surface of the object being processed is cleaned. Varnish, old paint, and any other coating are removed from wood. Do-it-yourself putty on external walls for painting video? Those parts and fittings that are not planned to be painted are dismantled.

- The surface is polished and then cleaned from dirt and dust.

- The surface is primed with antiseptic compounds to avoid subsequent rotting or mold damage. Do-it-yourself puttying of walls for painting step by step video? The primer will also ensure the paint adheres better.

First you need to prepare the wooden surface. Preparation consists of removing the old layer of paint or varnish. In addition, the surface needs to be leveled, which can be done with wood putty. After leveling, the entire surface is sanded, for which you need to use a grinding machine or sandpaper.

The choice of method for creating an interior style, which assumes the presence of traces of antiquity in the design, is quite wide. For connoisseurs of this style, it is not always affordable to purchase real old items. The way out of this situation is to imitate ancient metals.

How to properly paint antique metal with your own hands? Coloring is carried out in stages:

Painting is traditionally carried out at positive values of the mercury column and experts call the borderline permissible temperature +5 degrees. But in life all sorts of situations arise that explain the urgency of finishing here and now. If you follow the recommendations, the probability of successfully painting the metal structure will be quite high. There are two main differences between painting at sub-zero temperatures and similar work in warm conditions:

When the paint has completely dried on the surface, apply a primer layer of craquelure in accordance with the manufacturer's instructions for the specific composition. The coating should be applied in an even layer without smudges. When the coating dries, a transparent and somewhat sticky surface should appear.

- Applies to all types of surface painting. It is necessary to prepare surfaces for painting by removing old paint, rust, etc. using suitable equipment.

- Mandatory degreasing is carried out.

- To improve the quality of adhesion and create additional anti-corrosion protection for the material, the surface is primed.

- After drying, apply a layer of bronze paint. After drying, the procedure is repeated until the desired visual effect.

Bronze painting

In the old days, many objects were made of bronze. Therefore, painting products in bronze will help to decorate the interior of the house in an old style. There are several technologies for coating metal with bronze. Let's consider the simplest options.

Giving a monochromatic effect

You can perform a single-color coating of metal with bronze as follows:

- First of all, we clean the old surface from dirt and rust. To do this, you need to clean it with sandpaper and then degrease it.

- To increase the adhesion of the dye to the surface, we perform a metal priming process. In addition to adhesion, the primer will help further protect the product from corrosion.

- At the final stage, we begin painting with bronze paint. It is necessary to apply 2-3 layers evenly. But each subsequent layer is applied only after the previous one has completely dried.

Achieving the effect of antique bronze

Decorative antique painting with a bronze effect is suitable for lovers of rare things. To do this, follow these steps:

- Preliminary preparation of the old surface is carried out according to the same rules as in the previous case. Also, do not forget to coat the product with a primer.

- After priming, one layer of bronze paint is applied to the surface. It is desirable that the composition be applied evenly, but for an antique effect it is better to use a brush.

- After drying, the bronze painted surface becomes covered with patina (paint of a darker color). It is applied to the recesses. Experts advise using a translucent patina. This allows you to adjust the shade of the bronze coating.

- The next stage is glazing, that is, processing with a brush that is barely moistened with light paint. The process is carried out on all protruding edges and corners. This aging method allows you to give the product the effect of wear and tear, which usually appears on metal over the years.

- Next, we wait a while, allowing the applied materials to dry completely, and finally we coat the product with transparent varnish.

Description of acrylic decorative paints

Most often, water-based acrylic compounds are used to decorate metal products, as they are easy to apply and safe. They can be used even by people prone to allergic reactions. It is also worth noting that these materials do not have a pungent odor characteristic of coloring compositions.

Any decoration of metal products requires special skills in working with coloring compounds. For example, you should know that when painting objects with acrylic paints, all devices should be washed only with warm water, immediately after finishing the work. Nowadays acrylic paints for decoration are available in a wide variety of shades, but gold and silver colors are best suited for applying decor on metal. Such solutions can be purchased in 100 ml tubes, in the form of sprayers or in standard jars of 50, 100, 150 and 200 ml.

If you are going to decorate metal products for the first time, then give preference to small sets of paints for decorating metal (often these types of products contain detailed instructions for mixing paints, as well as the required number of shades). It would be a good idea to purchase an additional tube of white paint, since this color is used up the fastest during the painting process.

Antique Brass Painting

Textured metallized compositions can transform a product, giving it an imitation of brass. The processing technology is almost no different from those provided above. The surface is pre-cleaned, sanded and degreased. For aging, a technique of decorative painting to imitate brass is used.

The application process is carried out as follows:

- Before applying decorative paint, the old coating is removed from the product. To do this, you can use a wire brush or sandpaper.

- The key to durability and reliability of painting is the primer. Use a compound specifically designed for metal.

- Brass paint is applied to the surface in one layer. You can age the resulting coating by painting it with craquelure. Burnt umber, which is applied very carefully using a dry cloth, will help enhance the effect. If excess is formed during the work, it must be removed before the substance dries.

- Finally, the surface of the painted and aged part is coated with a glossy acrylic-based varnish.

As you can see, designer antiquity is achieved in simple ways. When doing work with your own hands, paints that create the necessary effect of a bronze, brass, or copper surface help you get the desired result.

When painting metal products, two goals are pursued: protection against the formation of corrosive areas and giving the metal an aesthetic appearance. When implementing the last task, sometimes it is necessary to cover the surface in 2-3 layers. But the end result may not always be just painting. Sometimes metal products need to be given original decorative effects, for example, the appearance of an aged object. For this purpose special technologies are used. Let's try to figure out how to paint antique metal and what is required for this.

You can achieve the effect of aged metal by using the main method - aging through the creation of a patina and the formation of abrasions. Patina is applied with special paints, but for metal, acrylic-based metallic compounds are more often used. In stores today there is a wide range of such paints; in addition to their decorative function, they also perform a protective function.

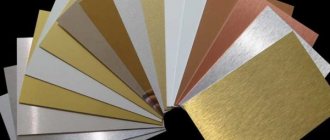

There is a choice of acrylic paints for aged metal, namely:

- brass;

- bronze;

- copper;

- gold.

Thanks to modern technologies, an aged effect can be given not only to metal surfaces. Often this painting is performed on plastic, wood and plaster products.

The aging process is completed by applying a final protective layer. For this they often use:

- acrylic-based varnish, which has a high degree of gloss;

- very durable polyurethane-based varnish with a gloss level of up to 50%;

- polyurethane-based varnish with a matte effect.

The choice of method for creating an interior style, which assumes the presence of traces of antiquity in the design, is quite wide. For connoisseurs of this style, it is not always affordable to purchase real old items. The way out of this situation is to imitate ancient metals. How to properly paint antique metal with your own hands? Coloring is carried out in stages:

- Preparing the surface for painting. We get rid of dirt, rust and traces of grease by grinding and solvent treatment.

- Metal priming. In this way we achieve the formation of roughness on the surface for better adhesion of the paint. We choose a primer special for metal.

- Application of selected metallic paint. Experts advise performing the process using a regular brush, this way aging is achieved in the best possible way.

- Aging stage. When the paint has dried, coat the surface with a special craquelure varnish. It is after this step that the metal object becomes covered with cracks, which create the effect of an old product.

Important! If non-metallic surfaces are being processed, then it is necessary to take a responsible approach to the choice of primer composition to achieve reliable adhesion with metallized paints.

On video: master class on applying patina to forged metal.

In the old days, many objects were made of bronze. Therefore, painting products in bronze will help to decorate the interior of the house in an old style. There are several technologies for coating metal with bronze. Let's consider the simplest options.

You can perform a single-color coating of metal with bronze as follows:

- First of all, we clean the old surface from dirt and rust. To do this, you need to clean it with sandpaper and then degrease it.

- To increase the adhesion of the dye to the surface, we perform a metal priming process. In addition to adhesion, the primer will help further protect the product from corrosion.

- At the final stage, we begin painting with bronze paint. It is necessary to apply 2-3 layers evenly. But each subsequent layer is applied only after the previous one has completely dried.

Decorative antique painting with a bronze effect is suitable for lovers of rare things. To do this, follow these steps:

- Preliminary preparation of the old surface is carried out according to the same rules as in the previous case. Also, do not forget to coat the product with a primer.

- After priming, one layer of bronze paint is applied to the surface. It is desirable that the composition be applied evenly, but for an antique effect it is better to use a brush.

- After drying, the bronze painted surface becomes covered with patina (paint of a darker color). It is applied to the recesses. Experts advise using a translucent patina. This allows you to adjust the shade of the bronze coating.

- The next stage is glazing, that is, processing with a brush that is barely moistened with light paint. The process is carried out on all protruding edges and corners. This aging method allows you to give the product the effect of wear and tear, which usually appears on metal over the years.

- Next, we wait a while, allowing the applied materials to dry completely, and finally we coat the product with transparent varnish.

Textured metallized compositions can transform a product, giving it an imitation of brass. The processing technology is almost no different from those provided above. The surface is pre-cleaned, sanded and degreased. For aging, a technique of decorative painting to imitate brass is used.

The application process is carried out as follows:

- Before applying decorative paint, the old coating is removed from the product. To do this, you can use a wire brush or sandpaper.

- The key to durability and reliability of painting is the primer. Use a compound specifically designed for metal.

- Brass paint is applied to the surface in one layer. You can age the resulting coating by painting it with craquelure. Burnt umber, which is applied very carefully using a dry cloth, will help enhance the effect. If excess is formed during the work, it must be removed before the substance dries.

- Finally, the surface of the painted and aged part is coated with a glossy acrylic-based varnish.

As you can see, designer antiquity is achieved in simple ways. When doing work with your own hands, paints that create the necessary effect of a bronze, brass, or copper surface help you get the desired result.

Possibilities of metal patination (24 photos)

What you need to know about paint

When deciding to independently design a metal door to look like antique bronze, you need to confidently navigate the method of preparing metal for the procedure, paints, and methods of proper application.

First of all, it is necessary to remember that metal products are dependent on the influence of external factors, the main one of which is moist air, which contributes to the formation of corrosive destruction. Metal paint is primarily intended to prevent such exposure. Secondly, modern paint compositions give the metal surface any color, durable protection, and if antique paint is used with the technique of “aging” the metal, it gives the appearance of almost any material suitable for the interior of a particular room or building.

To paint metal surfaces, paint and varnish mixtures are used, including organic solvents (such as white spirit and the like), as well as synthetic resins. During the drying process, they form protective paint films with characteristics of high density and strength. Such paints are used for processing metal elements in interior spaces, located on the outside of buildings and on streets.

How to putty walls with your own hands video before painting video? In this case, it is necessary to take into account the mode of use of the painted device or element. If this is an antique heating radiator, then the paint should be heat-resistant with high thermal conductivity.

Decorative metal painting | StroySovet

Bronze metal painting

Imitation of precious metals is very common, since not everyone can afford to actually use them. Paints “bronze”, “silver” and “gold” were invented a long time ago, but until recently they were prepared on the basis of organic solvents. These greatly narrowed the scope of their possible use due to a persistent unpleasant odor and intolerance to temperature changes.

Today, in any hardware store you can find water-based and acrylate-based metallic paint. It is safe, easy to use, resistant to high temperatures and even protects the metal base of the structure from corrosion.

There are two options for painting “bronze”. Let's look at them step by step.

Method No. 1 Plain coloring:

- We clean the surface of the metal structure from dirt and traces of corrosion, and degrease it.

- We apply a metal primer to increase adhesion and create an additional polymer layer to protect against rust.

- After the primer has completely dried, apply metallic paint with a bronze tint in an even layer in 2-3 layers, each time waiting for it to dry completely.

- We prepare the metal similarly to the previous method, we also apply a primer and an even layer of bronze paint.

- All recesses are treated with a darker compound (patina), often translucent, so that the degree of darkening can be adjusted.

- After the previous layer has completely dried, glazing is carried out with an almost dry brush - you need to paint light paint on all corners and protruding elements of the metal structure as if it had simply been worn away by time.

- After waiting for the next layer to dry, we fix the result with transparent varnish.

- We prepare the surface of the metal structure for painting: we clean it from dirt, corrosion, grease traces, and grind it.

- Apply a layer of metallic paint to a dry and clean surface.

Note! To imitate antique metal, it is best to apply paint with a brush - a slightly uneven coating will only work to our advantage. - After the paint has completely dried, apply an even layer of craquelure primer. It can also be found at most hardware stores. This composition, after drying, forms a transparent polymer film on the product.

- The last stage is the top craquelure coating. This is what gives the material the color of old, corroded metal. After the layer dries, small cracks – craquelures – form on the surface.

- Clean the surface from ice, condensation, dust and dirt. Mechanical cleaning alone is not enough - a thin layer of condensate will remain, which will practically negate all further actions. Use a heat gun, gas or gasoline burner to dry the prepared surface.

- The drying time of the paint may increase by 2-3 times, so you should separate the painted structure from external factors with a film and install a heat gun.

Method No. 2 Ancient bronze

By following these instructions, you can “ennoble” any metal, and even other materials can be “bronzed”.

Article Sponsor

LLC NPP Spectr

Moscow

Business can be successful only when you do your job not just skillfully, but better than others.

We are always open for cooperation.

Do-it-yourself antique metal painting

There are a lot of interior styles that it is advisable to decorate with objects with traces of time: from classic to steam-punk. Real objects that were in use several decades, or even centuries ago, are very expensive, require special care and restoration, and often create discomfort in everyday life. The most successful option in this case is imitation of ancient metal.

Let's look at how to achieve this step by step:

Imitation of ancient metal is possible both on metal products and on any other material. You just need to choose the right primer for good adhesion.

Article Sponsor

LLC NPP Spectr

Moscow

Business can be successful only when you do your job not just skillfully, but better than others.

We are always open for cooperation.

A new word in imitation – blacksmith’s paints

For a long time it was not customary to use paint for forged products. Painting was thought to take away from the handmade charm by hiding the texture of the metal.

With the advent of forge paints, finishing forged elements not only became possible, but also opened up many horizons for the implementation of bold ideas. They allow you to achieve the desired effect, imitate another material, create a feeling of antiquity, the appearance of patina. Thanks to modern blacksmith paints, you can bring any artistic idea to life.

In addition, like any metal paint, forge paints protect the structure from the harmful effects of the environment and prevent corrosion.

The only disadvantage of this type of finishing is how much such paints cost. Looking at the manufacturers' price lists, it is easy to understand that finishing forged products, like forging itself, is not a cheap pleasure.

Is it possible to paint metal at sub-zero temperatures?

Painting is traditionally carried out at positive values of the mercury column and experts call the borderline permissible temperature +5 degrees. But in life all sorts of situations arise that explain the urgency of finishing here and now. If you follow the recommendations, the probability of successfully painting the metal structure will be quite high. There are two main differences between painting at sub-zero temperatures and similar work in warm conditions:

And the most important aspect of painting metal in the cold is choosing the right paint and varnish material. Jelly-like alkyd enamels with high adhesion rates are best suited for these purposes.

Article Sponsor

LLC NPP Spectr

Moscow

Business can be successful only when you do your job not just skillfully, but better than others.

We are always open for cooperation.

Source

Choosing paint for metal

On the modern market, paint and varnish materials are presented in a huge assortment, the most important thing is to choose the right coating from a variety of options. There are various compositions suitable for painting metal surfaces, but the most popular and widely used are oil, alkyd and acrylic compositions.

Some polymeric substances for painting metal, for example, compositions based on epoxy resin, are rarely used for domestic purposes. The reason for this is their toxicity; moreover, the main purpose of such paints is to protect structures from high temperatures, which is not so important in everyday life.

The basis of oil paints is drying oil, which is usually made from natural oils. Such substances are well suited for painting indoor objects, but they are rarely used for outdoor work, since they react poorly to high temperatures. For example, you cannot cover a metal roof with this composition. In addition, over time, oil paints on the surface dry out to such an extent that they begin to crack. Water gets into the cracks and the metal rusts. Such materials do not tolerate ultraviolet radiation well - they quickly fade.

Alkyd enamels are often used for painting metal. This coating is best suited to galvanized metal. Alkyd compounds adhere perfectly to any surface, but do not tolerate excessive heat, and are also flammable.

Acrylic paints for painting metal are very popular. They appeared on the market relatively recently, but quickly took a leading position among other materials. Such compositions serve for many years, perfectly protect metal from rust, do not lose color, create a strong and elastic film, and do not crack. Acrylic paints tolerate heat well, so they can be used to coat heating radiators. They do not contain harmful components and do not burn.

Among the compositions for painting metal, it is worth highlighting silver paint. It is a finely dispersed aluminum powder, which is diluted with varnish in certain proportions before application. This coating creates an additional durable layer on the metal surface, characterized by a beautiful silvery shine.

You can buy an already prepared composition in the store, or you can buy powder and make paint from it yourself. Let's take a closer look at how and how to dilute silver for painting metal. First, you should determine the type of powder - it can be coarse and finely ground. Coarse particles are labeled as PAP-1, and fine particles are labeled as PAP-2. Powder with large particles is poured into a container and BT-577 varnish is added in a ratio of 2:5. Then the substances are mixed until smooth and a paste-like consistency is obtained. You can dilute the paint to a more liquid state with solvent, turpentine or another solvent.

When diluting silver PAP-2 to 1 part of powder, add 3-4 parts of varnish, which can be replaced with synthetic drying oil. Please note that natural drying oil cannot be used in this case. It is best to mix the components with a construction mixer to achieve a homogeneous structure.

How to paint metal like old bronze

Light antique painting is a fairly popular operation when creating various interiors. It is traditionally believed that antique items add an element of sophistication and luxury, emphasizing the style and wealth of the owner of the room. However, genuine antiques are highly expensive and often require restoration and special care.

It is much easier to simulate the aging of an object. And today this art is mastered not only by artists, but also by painters and simply amateurs. So, it will be quite possible for you to paint antique furniture if you set yourself such a task. But before you tackle your great-grandmother's chest of drawers, practice on something less valuable.

Methods for aging wood and other materials

There are several ways to age furniture and other types of materials:

Painting wooden elements

The most ordinary things can be turned into decorative furniture or accessories that are not inferior to antique items in terms of sophistication and the ability to create a special atmosphere in the room.

The question of how to paint antique wood arises when you want to make original and sophisticated-looking details using existing interior elements.

Antique painting of wood is quite possible at home; all you need is the most common tools. Before painting, it is necessary to carry out preliminary preparation of the object to be decorated.

Before aging a product, several stages of work are carried out:

- The surface of the object being processed is cleaned. Varnish, old paint, and any other coating are removed from wood. Those parts and fittings that are not planned to be painted are dismantled.

- The surface is polished and then cleaned from dirt and dust.

- The surface is primed with antiseptic compounds to avoid subsequent rotting or mold damage. The primer will also ensure the paint adheres better.

It is not recommended to use putty when preparing to age wood. With this design solution, the emphasis is on the presence of small defects in the wood, so you should not completely mask the flaws.

Creating the effect of dilapidation and wear

Artificially giving wood a shabby and dilapidated look is called brushing. The production uses sandblasting, during which soft fibers are removed from the top layer, causing the structure of the wood to become more pronounced.

When processing antique wood in a similar way with your own hands, the surface is first covered with matte acrylic paint. After it dries, abrasions are formed using a metal sponge or sandpaper, while individual areas can be affected more intensely to obtain a more natural look. The product is cleaned and a second coat of paint is applied.

At the end of the processing, it makes sense to go over the wood with a fine-grained abrasive tool.

Without using paint, you can achieve the effect of antiquity by painting wood with stain. This special material stains the wood by penetrating into its outer layer.

During absorption, the stain colors the wood in its natural color, while emphasizing the texture. There are also colorless compositions that perform exclusively protective functions.

The stain is applied with a cotton-gauze swab - a piece of cotton wool is wrapped in folded gauze. The composition is poured into the cotton wool so that it saturates it, but does not leak out when you press the tampon. Then the stain is rubbed over the entire surface. The process is repeated several times.

Sandpaper creates abrasions on the treated surface. The result is a natural wooden plane with pronounced texture and wear, characteristic of antique interior items.

Using a special varnish coating

To create a surface cracked by time, craquelure compositions are used, forming a coating on the product with a characteristic pattern in the form of uneven violations of the integrity of the paint layer.

This technique is called crackle; the “aging” of the product is carried out as follows:

- The product is cleaned and the surface is covered with a layer of paint. Please note that cracks in the final coating will have the same color as the first coat of paint.

- The dried paint is covered with craquelure varnish, which must be applied in one direction. A transparent film will appear on the surface.

- A base layer of paint of the desired color is applied over the craquelure varnish. This layer cracks under the influence of the craquelure composition, and the entire surface takes on a characteristic appearance with small cracks.

- To protect the aged surface, it should be coated with a transparent varnish.

Patina coating

To imitate the oxidation process characteristic of products made from certain metals, patina paint is used. This creates a rather interesting and unusual image of wood with the effect of antiquity and the color of bronze.

In order for a wooden object to acquire a specific antique look, its surface is first varnished to increase strength and wear resistance. When the varnish is dry, a thin layer of patina paint is applied to the surface.

After 30–40 minutes, the treatment is carried out with an abrasive tool, sandpaper or metal sponge. The effect increases with increasing intensity of such treatment.

Using a cloth, the resulting dust is removed, and the product is treated with transparent varnish.

Painting in several layers

With the help of multi-layer coloring, the effect of an aged object, which was previously often repainted, is achieved. This antique painting of furniture is based on the factorial characteristics of wood and color differences.

The selected primary color is applied to the surface. This layer should be thin, so that the wood pattern is clearly visible. An abrasive tool creates abrasions and the product is painted with a second color. This layer is applied with light, careless strokes.

For additional realism of the color, in some places the second layer of paint is shaded so that the main background appears.

Aging of metal

New metal parts do not always fit into a sophisticated and thoughtful interior, primarily due to the presence of a characteristic shine. The use of antique metal objects is not available to everyone, so it is more advisable to artificially create the effect of antiquity using imitation paints or special surface treatment.

You can paint antique metal with your own hands sequentially as follows:

- The surface of the product is degreased and treated with a primer to improve the quality of subsequent painting.

- After the primer has dried, the product is painted over with metallic paint.

- When the paint is completely dry, it is evenly treated with a craquelure primer, which forms a transparent polymer film during the fixing process.

- The surface treated with this primer is covered with a craquelure composition, which adds characteristic cracks and gives the metal product the appearance of an antique item slightly touched by corrosion.

In addition, to give metal an antique effect when painting, you can use various pigmenting compounds. For these purposes, umber is often used, a mineral pigment that is resistant to light and alkalis.

Burnt umber is applied in a small amount to a piece of fabric and rubbed into the painted surface. The pigment remaining in the cracks of the coating completes the look of the antique item.

Painting brick walls

Brick itself often has a rather retrograde look, so painting such antique walls seems to be the simplest and is done by covering it with acrylic paints in the desired colors. Antique brick painting differs from conventional painting by a special method of applying acrylic.

Coating products with bronze paint protects their surface from the damaging effects of moisture and the spread of corrosion.

Anyone with the necessary tools and time can carry out painting.

Types of dye and their advantages

Previously, bronze paint contained organic solvents. This resulted in a strong odor coming from the paint. Nowadays, instead of outdated compositions, mixtures are used for coloring metals. They are water soluble and contain only natural ingredients.

Modern dyes now contain metallic pigments of natural origin. They use acrylic dyes as binding elements.

Painting metals bronze has the following advantages:

- Environmentally friendly and odorless.

- Low price, which is explained by the water-based paint composition for metal.

- Possibility of obtaining various natural stylizations (for example, antique).

- Ease of processing products.

- Reliable protection of metal surfaces from moisture and corrosion.

- The service life of surfaces painted with this composition is tens of years.

If the surface is pre-painted with a layer of electrically conductive paint, its corrosion protection is simplified due to the formation of a galvanized film.

Also, the advantages of bronze dye include high resistance of the coating to UV radiation and external mechanical influences.

Bronze paint based on bronze powder: preparation and use

Paint made from bronze powder is successfully used to decorate products made from various materials.

Using this paint, you can give a characteristic texture and metallic shine not only to metal, but also to materials such as glass, plaster, cardboard, concrete, plastic, etc.

The reliability of adhesion of such a coating to the surface of the product being painted is determined by the characteristics of the binder material that was used to prepare the paint.

Bronze paint is often used to restore the finishing coatings of antique objects.

Main component of bronze paint

The main component of the paint, which allows you to paint products from various materials in a beautiful metallic color, is bronze powder. This powder, characterized by a very fine fraction, is produced by grinding metal in special mills.

The metal that determines the color of the resulting powder can be pure copper or its zinc alloys. Depending on the metal used, the color of bronze powder varies from light golden to quite rich red.

Bronze paint base is fine-grained copper alloy powder

The quality of painting is influenced not only by the composition of the material, but also by the size of the bronze powder fraction. Thus, paint powder is considered one of the best in quality, which, when sifted through a sieve numbered 0.045, gives a residue of no more than 1%.

In order to obtain bronze powder, the particles of which have a scaly shape, when grinding metal, this process is carried out with the addition of special lubricants to the mills.

The highest quality powder, providing coverage up to 4500 cm2/g, is obtained by grinding not pure copper, but bronze alloys.

Characteristics of bronze powder

Cooking features

In order to make paint from the powder obtained by grinding bronze, it is necessary to mix it with a binder material. The latter affects not only the characteristics of the paint and varnish coating and the scope of its application, but also the cost of the paint. Such a substance can be:

- varnishes intended for processing metal or wood;

- certain types of adhesive compositions;

- gelatin;

- egg powder dissolved in water, etc.

The components of bronze paint are thoroughly mixed before use and during the painting process, since metal particles quickly precipitate

The type of surface that will be painted with such a material influences its choice depending on the degree of its transparency. For example, to prepare bronze paint for wooden products, you can use a clear wood varnish.

The quantitative content of bronze powder in the paint determines the color intensity of the finished coating.

Accordingly, if the goal is to obtain a coating with an intense bronze color, it is necessary to mix a larger amount of metal powder with the binder.

As for the consistency, the finished paint should resemble thick sour cream, then with its help it will be possible to obtain a high-quality and reliable coating.

Application of coloring compounds

Before painting metal bronze, it should be prepared.

Applying paint and varnish material to unprepared areas will not produce results.

Careful surface preparation is required to remove traces of dirt and rust. If you apply paints and varnishes to areas damaged by corrosion, this will not protect the metal from premature destruction.

Preparatory work

Rust and remnants of old paint must be removed from the metal surface. To carry out such work, the following methods are used:

- Rough mechanical cleaning with a wire brush or abrasive disc mechanisms.

- Sandblasting. The advantage of this method is penetration into hard-to-reach areas. The downside is the relatively high price of the unit.

- Cleaning surfaces with chemical compounds that react with rust and old paint. At the end of it, everything can be easily washed with a soft cloth.

When carrying out this work, you will need protective equipment to protect your face and hands from damage by small particles and reagents (goggles, gloves made of thick cotton fabric and a respirator).

After cleaning operations, a primer is applied to the prepared surfaces (in two layers). This improves the adhesion of the metal surface. At the same time, an additional moisture-proof polymer coating is used. Once the top coat of primer has set, you can begin applying the bronze dye.

Tools and accessories

Carrying out painting work on any surface, including metal, requires the prior acquisition and preparation of the required number of devices and special accessories.

To prepare the surface:

- metal bristle brush,

- sandpaper of various sizes,

- possibly an angle grinder,

- drill with special attachments for cleaning metal,

- if it is necessary to remove old paint - a hair dryer and scrapers,

- rags.

For applying primer paint and varnish coatings:

- paint brushes of various widths, hardness and sizes,

- artistic brushes (if delicate works are required),

- various types of rollers,

- foam elements,

- It is possible to use a painting console.

- Paints and varnishes and solvents.

- Accessories in the form of various containers and more.

Important! Work on painting surfaces and elements should be carried out in a well-ventilated area or outdoors to avoid poisoning from fumes of paints and solvents. At the same time, compliance with fire safety rules must be ensured: exclusion of sources of fire, smoking and the possibility of sparking.