Bronze BrKh0.6Tsr0.05 (BrKhTsr0.6-0.05) Bronze BrN10.5A0.5 (BrNA10.5-0.5) Bronze BrN2.5X0.7K0.6 (BrNHK2.5-0.7-0.6 ) Bronze BrN5Mts2T0.1 (BrNMtsT5-2-0.1) Bronze BrNTsr Bronze BrSr0.1 Bronze BrT5X0.5 (BrTKh5-0.5) Bronze BrKh0.2Nb0.1 (Alloy 204A; BrKhNb0.2-0.1) Bronze BrKh0.3Tsr0.09 (BrKhTsr0.3-0.09) Bronze BrKh0.4Ko0.4Kr0.2Mg0.04 (Alloy No. 50) Bronze BrKh0.4Nb0.25 (Alloy 204; BrKhNb0.4-0.25) Bronze BrKh0, 5В0.2Цр0.2 (ХВЦр0.5-0.2-0.2) Bronze BrХ0.6Т0.5 (BrХТ0.6-0.5) Bronze BrMts5 Bronze BrХ0.7 Bronze BrХ0.8 Bronze BrХ1 Bronze BrХ1Цр Bronze BrХНb Bronze BrKHNT Bronze BrKhTsrK Bronze BrKhTsrTV Bronze BrTsr0.2 Bronze BrTsr0.3 Bronze BrTsr0.4 Bronze BrTsr0.7 Bronze BrA9Zh4N4Mts1 (BrAZHNMts9-4-4-1) Bronze BrB2 Bronze BrA10Zh1.5 (BrAZh10-1.5) Bronze BrA10Zh 3Mts1.5 ( BrAZhMts10-3-1.5) Bronze BrA10Zh4N4 (BrAZHN10-4-4) Bronze BrA10Mts2 (BrAMts10-2) Bronze BrA5 Bronze BrA6Mg1 (BrAMg6-1) Bronze BrA7 Bronze BrA8.5Zh4N5Mts1.5 (BrAZhNMts8.5-4-5- 1.5) Bronze BrA9Zh4 (BrAZh9-4) Bronze BrA9Mts2 (BrAMts9-2) Bronze BrB1.7NT (BrBNT1.7) Bronze BrB1.9NT (BrBNT1.9) Bronze BrB1.9NTMg (BrBNT1.9Mg) Bronze BrN1.5Kr0, 5 (BrNKr1.5-0.5) Bronze BrB2.5 Bronze BrK0.4X0.6Ko1.6 (BrKHKo0.4-0.6-1.6) Bronze BrK1N3 (BrKN1-3) Bronze BrK3Mts1 (BrKMts3-1) Bronze BrKd0.5X0.15 (BrKdKh0.5-0.15) Bronze BrKd1 Bronze BrKo3Mts10 (BrKoMts3-10) Bronze BrMg0.03Tsr0.035 (BrMgTsr0.03-0.035) Bronze BrMg0.3 Bronze BrMg0.5 Bronze BrMg0.8 Bronze BrMts1 2A8Zh3N2 (BrMtsAZHN12-8-3-2)

Description

Bronze BrB2 is used : for the production of semi-finished products (strips, strips, rods, pipes and wire); springs and elastic sensitive elements in instrument making, spring parts for critical purposes; wear-resistant parts of all types; non-sparking instruments.

Note

Beryllium bronze BrB2 has high strength and wear resistance, good anti-friction properties, very good deformability in the hardened state, average electrical and thermal conductivity. An analogue of bronze BrB2 according to SEV 377−76 is bronze CuBe2Ni (Co).

Wear resistance and corrosion fatigue resistance

Wear resistance is a complex concept that may include the following aspects:

- Reliability in operation. Critical parts are made from BrB2.

- Good performance when working with parts made of other materials. This means that beryllium bronze parts do not wear out and at the same time are gentle on the mating mechanisms. Such a mechanism can generally be characterized as fail-safe.

- Parts made of this metal fit well with each other, are polished and interact ideally in mechanisms under given parameters.

- But even if operating conditions are violated, parts made of BrB2 are able to withstand heavy friction loads and other mechanical influences.

- During the operation of mechanisms during wear, BrB2 does not break off in large pieces, but wears out gradually, producing very small chips.

Corrosion fatigue is one of the indicators of the corrosion resistance of metals. When parts operate under the influence of large mass, cyclic dynamic loads in a corrosive environment, there is a high probability of failure of the structures in which they are used. The BrB2 alloy performs well in various corrosive environments and can be used for the manufacture of critical parts, since corrosion manifests itself quite slowly and does not have a significant effect on the mechanical and physical properties of parts made from this material for a long time.

Standards

| Name | Code | Standards |

| Wire made of non-ferrous metals and their alloys | B74 | GOST 15834-77, OST 4.021.108-92 |

| Rods | B55 | GOST 15835-2013, OST 4.021.024-92 |

| Sheets and strips | B53 | GOST 1789-2013, OST 4.021.069-92 |

| Non-ferrous metals, including rare ones, and their alloys | B51 | GOST 18175-78, GOST 28873-90, OST 4.021.009-92, TU 48-21-5062-89 |

| Ribbons | B54 | OST 4.021.082-92, TU 48-0812-12-89, TU 48-0812-15-90, TU 48-0812-26-89, TU 48-21-265-87, TU 48-21-743- 92 |

| Metal forming. Forgings | B03 | ST TsKBA 010-2004 |

Material BrB2 Chelyabinsk

Not a single production can operate without steel, be it heavy engineering or the manufacture of household electrical appliances. There are many brands of this product, as well as a large number of dispensing forms. Our company sells BrB2 material in large quantities and with a minimal margin. To clarify the properties and characteristics of a particular brand, you can contact the company’s managers.

Like all products, BrB2 material is purchased from leading manufacturers. Therefore, we are ready to provide a quality guarantee with full responsibility. The minimum number of intermediaries determines the low cost. Coupled with fast delivery, this enables our business partners to conduct stable and mutually beneficial cooperation.

In addition to tempering, in the form of one or another part (blank), our company carries out metal processing. All events undergo strict control for compliance with GOST and rules. The specialists of our company carry out such work as galvanizing, creating parts according to customer drawings, producing castings, manufacturing various profiles and much more.

Having the latest equipment and vast experience in our arsenal, we can offer product testing for a number of parameters, such as strength characteristics, chemical composition, alloy purity, and so on.

Each buyer is offered a huge range of products in various formats, as well as current services and works. To quickly understand and choose a product that meets your needs, you need to contact the company manager and receive detailed information on all issues of interest.

Mechanical characteristics

| Section, mm | sТ|s0.2, MPa | σB, MPa | d5, % | d10 | d10 | Brinell hardness, MPa | HV, MPa |

| Strips 1.0-6.0 mm as delivered according to OST 4.021.069-92 (transverse samples) | |||||||

| — | — | 390-590 | — | — | ≥30 | — | ≥130 |

| — | — | 640-930 | — | — | ≥2.5 | — | ≥170 |

| Strips and tapes according to GOST 1789-2013, OST 4.021.082-92. Hardening in air from 305-315 °C (holding time 2.5 hours + charge heating time) + Deformation 30-40% | |||||||

| 0.15-0.25 | — | 590-880 | — | — | — | — | ≥170 |

| 0.15 | — | — | — | — | — | — | ≥170 |

| 0.25 | — | 640-930 | — | — | ≥2.5 | — | ≥170 |

| Strips and tapes according to GOST 1789-2013, OST 4.021.082-92. Hardening in air from 305-315 °C (holding time 3 hours + charge warm-up time) | |||||||

| 0.15-0.25 | — | 390-590 | — | — | ≥20 | — | ≤130 |

| 0.15 | — | — | — | — | — | — | ≤130 |

| 0.25 | — | 390-590 | — | — | ≥30 | — | ≤130 |

| Stripes and ribbons according to GOST 1789-2013. Hardening in air from 305-315 °C (holding time 2.5 hours + charge heating time) + Deformation 30-40% + Aging (dispersion hardening) | |||||||

| 0.15-0.25 | — | 1130-1570 | — | — | — | — | ≥360 |

| 0.15 | — | — | — | — | — | — | ≥360 |

| 0.25 | — | 1170-1570 | — | — | ≥1.5 | — | ≥360 |

| Stripes and tapes according to GOST 1789-2013. Hardening in air from 305-315 °C (holding time 3 hours + charge heating time) + Aging (dispersion hardening) | |||||||

| 0.15-0.25 | — | 1080-1470 | — | — | — | — | ≥330 |

| 0.15 | — | — | — | — | — | — | ≥330 |

| 0.25 | — | 1130-1470 | — | — | ≥2 | — | ≥330 |

| Wire is soft (hardened), hard (cold-deformed after hardening) in the delivery condition in accordance with GOST 15834-77. Heating for hardening to 770-790 °C, holding for 10-20 minutes, rapid cooling in water | |||||||

| 0.06-0.08 | ≥235 | 343-686 | — | 15-60 | — | — | ≥100 |

| 0.1-1 | ≥235 | 392-637 | — | 20-60 | — | — | ≥100 |

| 1.1-5 | ≥235 | 392-637 | — | 25-60 | — | — | ≥100 |

| 5.5-12 | ≥235 | 392-588 | — | 30-60 | — | — | ≥100 |

| 0.06-0.5 | ≥735 | 931-1372 | — | — | — | — | ≥180 |

| 0.55-1 | ≥735 | 833-1274 | — | — | — | — | ≥180 |

| 1.1-5 | ≥735 | 735-1176 | — | — | — | — | ≥180 |

| 5.5-12 | ≥735 | 735-1078 | — | — | — | — | ≥180 |

| Wire subjected to dispersion hardening from soft (hardened) and hard (cold-deformed after hardening) states as delivered in accordance with GOST 15834-77. Heating for hardening to 770-790 °C, holding for 10-20 minutes, rapid cooling in water + Aging (dispersion hardening) at 310-330 °C, holding for 3 hours. | |||||||

| 0.06-0.9 | ≥1078 | 1078-1470 | — | — | — | — | ≥320 |

| 1-12 | ≥1078 | 1078-1568 | — | — | — | — | ≥320 |

| 0.06-12 | ≥1372 | ≥1176 | — | ≥1 | — | — | ≥360 |

| Cold-deformed wire for the manufacture of parts and springs in the delivered condition according to OST 4.021.108-92 (longitudinal samples, relative elongation δ1 is indicated) | |||||||

| 0.1-1 | — | 392-637 | — | 20-45 | — | — | — |

| 1.2-5 | — | 392-637 | — | 25-60 | — | — | — |

| 5.6-12 | — | 392-588 | — | 30-60 | — | — | — |

| 0.1-0.5 | — | 931-1372 | — | — | — | — | — |

| 0.6-1 | — | 833-1274 | — | — | — | — | — |

| 1.2-5 | — | 735-1176 | — | — | — | — | — |

| 5.6-12 | — | 735-1080 | — | — | — | — | — |

| Round extruded rods in as-delivered condition according to GOST 15835-2013 | |||||||

| 42-100 | — | ≥440 | ≥20 | — | — | — | — |

| Round drawn rods as delivered according to OST 4.021.024-92, GOST 15835-2013 (longitudinal samples) | |||||||

| 5-40 | — | 390-590 | ≥25 | — | — | 100-150 | — |

| 16-40 | — | 640-880 | ≥1 | — | — | ≥150 | — |

| 5-15 | — | 740-980 | ≥1 | — | — | ≥150 | — |

| Round drawn rods after dispersion hardening (aging) in accordance with GOST 15835-70 (longitudinal samples, the state of delivery indicates what condition the samples were aged from) | |||||||

| — | — | ≥1080 | ≥2 | — | — | — | ≥320 |

| — | — | ≥1180 | ≥2 | — | — | — | ≥340 |

Basic properties of BrB2 bronze

The BrB2 alloy is very specific, different from other copper alloys. The specificity of this alloy is due to the beryllium (Be) it contains. Beryllium bronzes belong to the class of so-called dispersion-hardening alloys, a feature of which is the dependence of the solubility of alloying components on temperature, which makes it possible to control the properties of bronzes, both in the production of rolled products and in the manufacture of products. In industrial alloys of the Cu-Be system, as in most materials with the effect of dispersion strengthening, the concentration region is located near the boundary of maximum solubility in solid solution, and corresponds to approximately 2% Be content. At beryllium concentrations of 1.6 to 2.0% by weight, a modification of beryllium known as the β phase is present at temperatures below 600˚C. This phase forms as a result of the limited solid solubility of beryllium. This factor most contributes to hardening during heat treatment (“aging”). When the alloy is heated to a temperature of 780˚C, beryllium dissolves in the α phase (α + β solid solution). Rapid cooling to room temperature maintains beryllium in solid solution. This process, called annealing, makes the alloy soft and malleable, helps regulate the size of the crystals, and prepares the alloy for the “aging” operation. Heating a saturated solid solution to a temperature of 315˚C and holding it at this temperature for 2-3 hours causes precipitation of the strengthening phase and gives the alloy high hardness. One of the important properties of the material used for sliding bearings is resistance to heat. Table 1 shows the change in the mechanical properties of the BrB2 alloy containing 2% Be, depending on the temperature and duration of heating. Before heating, the samples were subjected to aging at T=320 ˚C for t=2 hours.

Table 1 Change in mechanical properties of samples of copper-beryllium alloy BrB2, with increasing temperature and duration of exposure at a given temperature.

| No. | Temperature, C | Exposure time, hour | Tensile strength, MPa | Proof of yield strength 0.2%, MPa | Elongation, % |

| 1 | 20 | 1 | 1265 | 1065 | 6,8 |

| 2 | 250 | 1 | 1350 | 1050 | 5,8 |

| 3 | 250 | 500 | 1260 | 1005 | 3,9 |

| 4 | 250 | 1000 | 1020 | 945 | 3,9 |

| 5 | 300 | 1 | 1178 | 940 | 2,0 |

| 6 | 300 | 500 | 1022 | 750 | 3,0 |

| 7 | 300 | 1000 | 971 | 730 | 4,0 |

| 8 | 400 | 1 | 795 | 416 | 7,0 |

| 9 | 400 | 500 | 532 | 300 | 16,0 |

| 10 | 400 | 1000 | 492 | 287 | 20 |

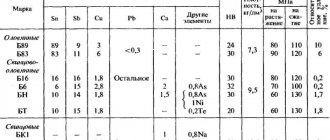

Conclusion: As can be seen from the table, up to 250˚C the mechanical properties practically do not change even when held for 1000 hours, which indicates the good resistance of beryllium bronze to temperature effects. The most important properties of bearing material are wear resistance and antifriction. Due to the high hardness that products made from copper-beryllium alloys acquire after aging, they also have high wear resistance with good anti-friction properties. The friction coefficient of tempered copper-beryllium alloy BrB2 in a pair of axial railway steel and spindle oil lubrication No. 2, obtained when tested on an Amsler machine, is 0.05. Good sliding is ensured by the presence of an oxide film on the surface of the product. In addition, the CTE of BrB2 bronze is close to the CTE of tool steels, which also contributes to the reliable operation of these materials in one unit. Foreign experience in using beryllium bronze as a material for sliding bearings. Test results. Brush Wellman Inc (USA), a recognized world leader in the production of beryllium bronzes, recommends Alloy 25 alloy (C17200) for the production of bearing supports for heavily loaded units and devices operating in aggressive environments. Alloy 25 in its aged state achieves maximum strength and hardness after cold forming treatment. Ultimate tensile strength can exceed 200 ksi (1290 MPa) with a hardness of 45 HRC. Alloy 25 also exhibits exceptional resistance to stress relaxation under elevated temperature conditions. The Russian analogue of Alloy 25 is the BrB2 alloy, which is identical to Alloy 25 in chemical composition (Table 2) and has the mechanical characteristics given in Table 3 Table. 2 Comparative characteristics of beryllium bronzes by chemical composition,%

| Alloy grade | Be | Co | Ni | Co+Ni | Co+Ni+Fe | Impurities | Cu |

| Alloy 25 | 1,8-2,0 | — | — | 0.2 min | 0.6 max | 0.15Al; 0.15Fe; 0.15Si; 0.005Pb; amount-0.5 | Balance |

| BrB2 | 1,8-2,1 | — | 0,2-0,5 | — | — | 0.15Al; 0.15Fe; 0.15Si; 0.005Pb; amount-0.5 | Balance |

Table 3 Guaranteed mechanical characteristics of semi-finished products from BrB2 in comparison with BrKmTs3-1

| Alloy grade | GOST | Semifinished | State | Diameter, mm | σ, MPa | δ, % | NV |

| BrB2 | 15835-70; 1789-70 | Drawn rods | Soft | 5,0-40,0 | 392-590 | ≥25 | 100-150 |

| BrB2 | 15835-70; 1789-70 | Drawn rods | Solid | 5,0-15,0; 15,0-40,0 | 735-980; 640-880 | 1,0; 1,0 | 150; 150 |

| BrB2 | 15835-70; 1789-70 | Drawn rods | Aged from soft | 5,0-40,0 | ≥ 1080 | 2,0 | ≥320 |

| BrB2 | 15835-70; 1789-70 | Drawn rods | Aged from solid | 5,0-40,0 | ≥ 1170 | 2,0 | ≥340 |

| BrB2 | 15835-70; 1789-70 | Pressed rods | Pressed | 42-100 | ≥ 442 | 20 | — |

| BrKmTs3-1 | 18175-78; 1628-78 | Drawn rods | Solid | 13-41 | ≥ 490 | 15 | 160 |

Let us note that here and below, wear resistance (wear resistance) is understood as resistance under conditions when rubbing metals begin to weld, “seize” under the influence of high pressure, i.e. conditions arise for diffusion interpenetration of particles of rubbing metals. The Brush Wellman Engineering Center, justifying the choice of the Alloy 25 (BrB2) material, provides experimental wear resistance test data in Tables 4-8, obtained according to the ASTM -G98 method of the US engineering community. The methodology of the experiments was as follows: the wear of a pair of materials was measured in a device consisting of a stationary block of the test material, into the hole of which a cylindrical disk made of another contacting material is placed and loaded with an axial load, the latter being driven into rotation under dry friction conditions. In table Figure 4 shows data on the wear resistance of the Alloy 25 (BrB2) friction pair in contact with Alloy 25 (BrB2), subjected to various types of heat treatment and strain hardening. In table Figure 5 shows data on the wear resistance of Alloy 25 (BrB2) in contact with corrosion-resistant steels and alloys. Table 4 Wear resistance of Alloy 25 (BrB2) in contact with Alloy 25 (BrB2)

| Types of heat treatment of alloys in contact | Proof of yield strength, σ 0.2% | Threshold value of contact pressure of rubbing materials during testing |

| AT in contact with AT | 140ksi (903MPa) | 100ksi (645MPa) + |

| NT in contact with NT | 150ksi (968MPa) | 100ksi (645MPa) + |

| DST in contact with DST | 110ksi (709MPa) | 100ksi (645MPa) + |

NOTE: AT - Hardened and Aged HT - Cold Worked Hardened and Aged DST - Annealed and Aged to 100 -110 ksi + (no signs of wear) Tab. 5 Wear resistance of Alloy 25 (BrB2) in contact with corrosion-resistant steels and alloys

| Alloys in contact | Proof of yield strength, σ 0.2% | Threshold value of contact pressure of rubbing materials during testing |

| Austenitic steels in contact with Alloy 25: | ||

| 303 | 45ksi (290MPa) | 40ksi (258MPa) + |

| 304 | 55ksi (355MPa) | 30ksi (194MPa) + |

| 316 | 44ksi (284MPa) | 30ksi (194MPa) + |

| Ferritic and martensitic steels in contact with Alloy 25: | ||

| 416 (0.95%Cr, 0.3%Mo) | 92ksi (593MPa) | 70ksi (452MPa) + |

| 440 | 79ksi (510MPa) | 50ksi (323MPa) + |

| Nickel-cobalt alloys in contact with Alloy 25: | ||

| Nitronic 50 (analogue 03Х14Р7В) | 79ksi (510MPa) | 60ksi (387MPa) + |

| Nitronic 60 | 56ksi (361MPa) | 55ksi (355MPa) + |

| Alloy 2205 | 87ksi (561MPa) | 80ksi (516MPa) + |

| 15-5PH | 149ksi (961MPa) | 90ksi (581MPa) + |

| 17-4PH | 146ksi (942MPa) | 90ksi (581MPa) + |

| Custom 445 | 132ksi (851MPa) | 60ksi (387MPa) + |

| Gall Tough | 6ksi (38MPa) | 50ksi (323MPa) + |

NOTE: Alloy 25 during wear test at 145 ksi + (no signs of wear) Table. Table 6, for comparison with the wear resistance of Alloy 25 (BrB2), shows data on the wear resistance of some nickel-cobalt alloys, the chemical composition of which is given in Table. 7 In table. For comparison with the wear resistance of Alloy 25 (BrB2), Figure 8 shows data on the wear resistance of silicon bonzes of the BrKN1-3 and BrKMtsZ-1 types, usually used as antifriction bushings. Table 8 Wear resistance of silicon bronzes, usually used in sliding bearings Analysis of wear resistance test data allows us to draw the following conclusions: 1. A pair of beryllium bronzes Alloy 25 (BrB2) - Alloy 25 (BrB2) has the highest wear-resistant properties compared to other antifriction pairs. 2. Alloy 25 (BrB2) demonstrates good wear-resistant properties in the aged state, regardless of the history of heat treatment and previous pressure treatment. 3. During friction in a pair of Alloy 25 (BrB2) - corrosion-resistant steel, wear is not observed at loads up to 0.8 of the yield strength for most of the materials considered. 4. Beryllium bronze Alloy 25 (BrB2) has significantly higher wear-resistant properties compared to silicon bronzes (see tables 3, 4 and table 7) with higher mechanical properties in the aged state (see table 2) Conclusion: During friction in pairs, BrB2 alloy on BrB2 alloy, BrB2 alloy on stainless steel, wear is not observed at loads of 0.7...0.9 of the yield strength of the alloy or stainless steel (depending on what the yield strength of stainless steel is). The indicated loads in friction pairs significantly exceed the maximum loads for most other alloys, including those used as plain bearings. However, it should be noted that the wear resistance of BrB2 - ordinary steel pairs is relatively low. And finally, the third indicator characterizing the reliability of sliding supports is their corrosion resistance. For example, sliding bearings for drill bits or vane pumps operating in oil fields must withstand the effects of suspended and corrosive substances contained in formation fluids at high pressures and temperatures. In terms of corrosion resistance, binary beryllium bronzes are very close to tin and aluminum bronzes. For example, the corrosion resistance of BrB2 in a 3% HNO3 solution is almost the same as that of bronzes with 10-14% Sn and aluminum bronzes with 6-8% Al. In a 3% HCl solution, only half the mass loss of beryllium bronze was observed compared to the loss of tin bronzes and approximately equal mass losses with aluminum bronzes. Beryllium bronzes show good resistance in cold fresh and sea water, in most acidic and alkaline solutions. In table Figure 9 shows data on the corrosion rate of BrB2 in various environments. Table 9 Corrosion rate of BrB2 under the influence of various reagents, µm/year Beryllium bronzes, when exposed to a humid or sulfur-containing atmosphere, darken over time, like copper. However, the film formed on their surface does not affect the mechanical properties. Good resistance in warm and humid air indicates the possibility of using copper-beryllium alloys for the manufacture of parts operating in tropical conditions. Beryllium bronzes are not very prone to intercrystalline corrosion, but in a stressed state under the influence of moist ammonia and air they are subject to corrosion cracking. At elevated temperatures, gases cause selective corrosion of copper-beryllium alloys, reacting primarily with the beryllium-enriched component. Under the influence of fluorine, chlorine, bromine and iodine, beryllium halide compounds are formed on the surface of copper-beryllium alloys, which are characterized by high volatility, resulting in loss of beryllium. This process occurs very vigorously at elevated temperatures. Therefore, copper-beryllium alloys should not be used where the action of these gases at elevated temperatures is possible. At high temperatures, beryllium bronze oxidizes less than copper and some alloys based on it. When studying alloys with 1-2.4% Be, it was found that with prolonged exposure at 800˚C, the oxidation of a binary alloy with 2.4% Be is extremely small. Comparative tests have shown that steel with 12.5% Cr is four times more oxidized at 610˚C than BrB2, and oxidized equally at 810˚C. Table 10 shows the results of a study of the influence of the composition of copper-beryllium alloys on the rate of their corrosion when heated in an air atmosphere. We tested samples of 30x40 mm, cut from strips 1.2 mm thick, made of: copper grade M1; alloy with 1.8% Be and 0.3% Ni; alloy grade BrB2.5 with 2.4% Be and 0.5% Ni. Table 10. Increase in mass when heated in an air atmosphere of samples of copper and copper-beryllium alloys * Average value from 5 observations. From the data in the table it follows that at 570˚C for 60 minutes, the BrB2.5 alloy is oxidized 29 times less than copper, and the alloy with 1.8% Be and 0.3% Ni - 4.4 times. At 670˚C, oxidation during the same heating period of the BrB2.5 alloy is 12 times less than copper, and for an alloy with 1.8% Be and 0.3% Ni - 7 times. Conclusion: In terms of comprehensive resistance to corrosion in various environments, beryllium bronze shows good and very good results. Thus, the presented experimental data on mechanical strength, wear resistance and corrosion resistance allow us to consider beryllium bronze as one of the best materials for sliding bearings used in sea water (pumping and drilling and other equipment in the development and operation of offshore fields), slurries containing abrasive and corrosive substances (mainland oil and gas, and other fields), as well as in the manufacture of other highly reliable equipment and machines.

Description of mechanical symbols

| Name | Description |

| Section | Section |

| sT|s0.2 | Yield strength or proportional limit with tolerance for permanent deformation - 0.2% |

| σB | Short-term strength limit |

| d5 | Elongation after break |

| d10 | Elongation after break |

| d10 | Elongation after break |

| H.V. | Vickers hardness |