Welding aluminum products is not the easiest task. If a welder deviates even a little from the technology or selects an inappropriate welding machine for aluminum and consumables, he is guaranteed to receive a poor-quality weld. To choose the right welder for working with such metal, you need to know the features of its melting, understand the types of special devices and other nuances.

Features of aluminum welding

This metal is very capricious when welding due to its physical and chemical properties. Its surface is covered with an oxide film even at room temperature. On the one hand, this is even good, because the oxidized layer protects the material from corrosion. But if you try to weld it just like steel, for example, you may run into a big problem.

The melting point of the oxide on the surface of an aluminum billet is about 2000 °C, while the material itself melts at about 600 degrees Celsius. Welding in the usual way will lead to the fact that the filler material will simply be laid on the surface, preventing the proper quality of the weld. An increase in amperage will cause burnouts. In this case, the weld pool will rapidly oxidize.

Aluminum when welding:

- Crystallizes quickly.

Hardening occurs after cooling by only 15-20 °C. - Incredibly fluid.

When molten, it resembles water, which makes it difficult to weld if the surface of the product is inclined. It is also this property that increases the risk of through burns during manipulation. - Retains color after melting.

For this reason, it is more difficult to control the state of the weld pool and calculate the required amount of filler material. - Evaporates hydrogen.

This occurs due to contact with the atmosphere. As a result, pores are formed in the suture structure, which make the joint more fragile. - Characterized by increased shrinkage.

There is a possibility that, upon cooling, the weld beads will sag more than necessary. You will have to additionally weld the craters in the seam.

To achieve the desired effect, it is enough to block the access of ambient air to the melting zone. For this purpose, inert gas media are used.

Some features of aluminum and its alloys

Aluminum differs from other metals in its high thermal conductivity, chemical reactivity and low specific gravity. A welding machine for aluminum must work quickly and protect the weld pool well . Conventional equipment for metal structures and body welding will not be able to provide conditions suitable for welding aluminum.

Aluminum oxidizes quickly even when cold at room temperature. The oxide film formed on top is much harder than the base metal and melts at 2000⁰C, which is 2 times higher than the melting point of aluminum itself. Part of the strength of lightweight duralumin parts is provided by a hard film of aluminum oxide. When mechanically stripped to bare metal in the open air, the oxide film is restored very quickly.

Aluminum has a high coefficient of linear expansion when heated. If the parts are overheated, they will be severely warped.

High thermal conductivity contributes to the rapid spread of heat throughout the body of the part and the same almost instantaneous cooling of the seam, when the slag has not yet come out.

Conclusion

When choosing a semi-automatic welding machine for aluminum, you should understand exactly what you need it for. It’s one thing when you need to weld something at the dacha and another thing when you provide welding services or start production. Welding machines are not cheap, so choose the best option, taking into account:

- welding current strength;

- presence of synergetic management;

- versatility and the possibility of manual welding;

- protection class;

- completeness;

- presence of software functions and settings memory for different processes;

- price.

You should also make sure that your electrical network supports the power consumption of the device you are purchasing.

If you are interested in the topic of semi-automatic aluminum welding, express your opinion, offer ideas or argue with the author in the comments block. This is interesting.

The process and its features

Based on the characteristics of the metal and its alloys, a welding machine for welding aluminum must have the following characteristics:

- cracking the oxide film;

- fine adjustment of modes;

- work with pulsed and alternating currents;

- inert shielding gas;

- ability to work with aluminum and tungsten electrodes;

- high current;

- stable arc.

High temperatures are generated in the welding zone. It is necessary to cook aluminum quickly, without interruption . The duration of the burner operation is increased by water and air cooling of the holder and the body of the burner itself.

To weld aluminum, especially long seams, you should replace conventional cooled torches with Teflon ones. They are heat resistant and last much longer when operating at high currents.

Cooling in the welding zone will occur more slowly if the parts are completely heated to a temperature of 250 - 280⁰C before work. This will eliminate the formation of a transition zone along the seam and hot cracks.

The difficulty in welding aluminum is the inability to clearly see the weld pool. The metal does not change its color when heated and melted.

What should a welding machine be like?

Welding of aluminum alloys is carried out using machines in TIG mode, alternating and pulsed current with a frequency of up to 200 Hz and a current of up to 200 A. These include:

- semi-automatic;

- argon-arc welding machines;

- inverters.

An oscillator is used to break up the oxide film .

It is installed in the device body and increases the oscillation frequency to 300Hz. Welding equipment operates on three-phase current 380V. The pulse current is an axially cut sinusoid. A double pulse means that the sine wave is directed with protrusions in one direction and at a normal frequency of 50 Hz it reaches its peak value 100 times.

Before welding aluminum and high-alloy steel, including stainless steel, you should select refractory electrodes and appropriate additives. In both cases, a non-consumable electrode and filler wire with silicon and chromium are suitable.

Tips for setting up a semi-automatic machine

In order for semi-automatic stainless steel welding to be of high quality, it is important to correctly configure the welding equipment. The modes are set based on the thickness of the workpieces being welded and the wire diameter used. The electrode feed rate and gas consumption are also significant. Optimal indicators for different values are presented in the table.

| Thickness of the sides of the parts, mm | Wire diameter for PA, mm | Current strength, A | Wire feed speed, m/h | Gas consumption, l/min |

| 1 | 0,8 | 55-65 | 100-150 | 6-7 |

| 1,5 | 0,8 | 80-115 | 150-220 | 6-7 |

| 2 | 0,8 | 100-130 | 200-250 | 6-7 |

| 3 | 1 | 150-170 | 400-500 | 8-10 |

| 4 | 1 | 220-250 | 500-600 | 8-11 |

| 4 | 1,2 | 250-280 | 450-650 | 10-13 |

| 5 | 1,2 | 300 | 500-700 | 11-16 |

| 6 | 1,2 | 330 | 600-800 | 11-16 |

Technology requirements

The technology begins with careful preparation of the ends to be welded . Before work, the welding area on aluminum and duralumin parts is thoroughly cleaned of oxides. A grinder with a fine-grained wheel is suitable for this. The suture is applied continuously in one pass. Welding of aluminum pipes is done in 2 passes, from bottom to top.

The gas is turned on before the arc ignites. The process begins at high currents. Welding is completed at low currents. Welding machines must change current and voltage after starting work.

To weld aluminum, a tungsten consumable and non-consumable electrode is used . Filler rods for aluminum are used in two types: pure metal and cast aluminum with the addition of silicon.

Welding thin aluminum with argon. Thick sheets and parts are boiled in a protective argon-helium gas.

Before starting welding, the electrode should be sharpened . Melting into a semicircle. The non-consumable one is sharpened at an angle of 40⁰ with a small platform. During the welding process, there should be a drop of pure metal at the end that is smaller than the diameter of the electrode.

The arc length when welding aluminum should be constant within 12 - 15 mm. A shorter one will burn through the sheet, especially thin ones. A long arc will not heat up the metal as it should.

Welding of duralumin is carried out using the same technology as pure metal . Only the current decreases. When choosing the best way to weld duralumin, you should choose aluminum wire. On pulse devices, it simply flows in a stream into a heated bath and connects with the metal.

If a hobbyist has a boat and needs to repair it, a pulse inverter with an oscillator and a tungsten electrode with aluminum filler wire will do. A cheaper option for rare applications is AC argon-arc welding. For workshops with a large volume of work, it is better to choose a high-performance pulse machine or semi-automatic machine.

Installation regulators

Aluminum requires fine adjustments and lowering the current during the welding process. The main functions that an aluminum welding machine should have:

- contactless ignition;

- zoolocation – adjusting the arc polarity ratio;

- AC balance adjustment.

Non-contact ignition ensures the ignition of the arc without striking the part and its constant burning.

When operating in AC mode, the polarity of the arc changes from direct to reverse and vice versa. Zoolocation allows you to select the optimal direction of the current and the frequency of polarity changes.

The duration of pauses and pulses is adjusted by a balancer depending on the thickness of the metal being welded.

Additionally, the welder sets:

- starting current;

- magnitude and nature of the main current;

- Arc forcing.

In addition to these functions, several timers ensure high-quality welding. They are responsible for:

- gas supply before welding;

- current decay time;

- supply of gas after completion of work.

shielding gas is supplied before the start of the welding process - ignition of the arc. This ensures that the bath is completely closed before the melting process begins.

You need to start welding aluminum at a high current, then lower it. The timer automatically reduces the current after a certain time after starting operation.

Aluminum cools quickly, but it still takes time to prevent the seam from oxidizing and cracking. After the electric arc is turned off, gas is supplied to the working area for another 5–7 seconds .

Connection of stainless steel and black steel

Welding of such materials is carried out at direct current. The position of the wire is strictly perpendicular to the working area.

Stainless steel wire must contain manganese and nickel, for example, ESAB OK, Autrod. A special transition wire deposits a buffer layer, which connects the parts.

When welding St40 steel to stainless steel, you can use 08G2S wire. This strengthens the seam between two dissimilar metals after cooling. The most important thing in the process is that the stainless steel does not become too fluid, and the ferrous metal does not remain solid. The seam is made as wide and as deep as possible.

Installation and shutdown

Regardless of what material needs to be welded, the equipment must be turned on and off in a certain sequence.

- Check the integrity of the housing, cables and grounding.

- Connect the cables to the device and parts.

- Place and secure the gas hose on the holder.

- Connect cooling.

- Set operating modes depending on the thickness of the metal and the length of the seam.

A duralumin sheet is placed on the slab and secured. After this, you can turn on the equipment. If the current is constant, then you should choose reverse polarity and special electrodes operating in AC/DC mode. They are convenient for welding materials that cannot be processed using standard methods.

After welding, you should wait a short time until the part cools down, without turning off the argon. Then turn off everything in reverse order.

Operation of equipment during operation

Aluminum is welded at high currents and high frequencies. For equipment, this mode poses a large load. The work-rest regime specified in the technical data sheet of the equipment should be observed.

You should fine-tune the device and check the grounding.

When working on a semi-automatic machine with aluminum wire, the length of the hoses should not exceed 3 meters. The nozzle should be chosen wider than usual. Aluminum wire is soft and expands greatly when heated. As a result, friction occurs and it jams.

The gas nozzle is selected with a wide nozzle and a mesh inside. The flow is uniform and covers the bath well.

Kinds

For aluminum, alternating current electric arc machining is mainly used . A hot plasma stream can easily melt any metal, but aluminum has a refractory film and will warp greatly when heated by a gas burner. In addition, it actively reacts not only with oxygen, but with nitrogen and carbon. The result is a brittle seam with a thick layer of slag and parts with a large lead.

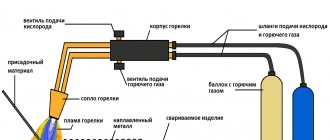

Semi-automatic

Semi-automatic welding machines use aluminum wire . It is fed into the burner at a constant speed and melts in the bath. Attached to the handle is a nozzle that supplies protective gas. The whole process is controlled by a semi-automatic machine; the welder’s hand only directs the molten pool to form a seam.

Semi-automatic welding is highly productive. It is good to use in production with a large number of parts for welding from different steels and metals. When working with aluminum, a continuous seam up to 5 m long can be applied.

Inverter equipment

For welding aluminum and its alloys, a conventional inverter with a cylinder containing argon gas connected to it is suitable. Argon, helium and their mixture are used as protective flux.

Most often, home welding work, from which aluminum and duralumin are welded, is carried out using simple inverters . The device produces a current sufficient for short-term welding of non-ferrous metals.

For welding, special electrodes are selected that are designed to work with metals with high thermal conductivity, these are the O3P and O3A series, diameter 2.5 - 3 mm. They are a rod made of a special alloy and coating.

Before welding aluminum with an inverter , the electrodes must be well calcined. If moisture remains in their coating, used as a flux , it forms pores in the weld metal and slag inclusions.

The seam should be applied slowly, ensuring that the bath has time to warm up and the slag to float to the surface. The inverter connection of parts gives a strong and beautiful seam with a small heating zone on the sides.

Argon welding

Manual argon arc welding is most often used by amateurs when repairing a car or boat, or welding small parts . Non-consumable tungsten electrodes and filler wire are mainly used as consumables. Together with them, argon, a shielding gas, is supplied to the welding zone.

Non-consumable electrodes create high temperatures using an arc. At the same time, the coating also does not burn; there is no flux that is usual for manual welding.

In addition to tungsten, carbon electrodes and special ones for welding metals with a high heat transfer coefficient, such as aluminum, copper and their alloys, can be used. They are designated A3. Available with rutile, cellulose and tungsten coating.

Argon welding can be performed on inverters and transformers. The main condition is the gas connection.

How long do the consumables of a semi-automatic machine last?

When thinking about semi-automatic welding of stainless steel, it is worth knowing how long the consumables will last. The most quickly worn element is the current collecting tip. Through it, voltage is transmitted to the wire. The outlet hole in the mouthpiece breaks, causing the wire to start “walking.” This complicates manipulations to control the electric arc and reduces the quality of the seam.

When working with a semi-automatic device for 6-8 hours every day, 1-2 current-collecting tips will have to be replaced per shift. The welder should always have such parts in stock. Moreover, each wire diameter has its own mouthpieces. When welding is carried out either with 0.8 mm or 1.2 mm wire, the mouthpieces also change.

The wire feed channel lasts for several years. Then it gets clogged with dirt and the wire starts to get stuck. The pressure rollers of the pushing mechanism “live” up to 5 years. With active use of the equipment, the mass clamp gradually wears out - the grip weakens, the clamping “lips” burn. The service life depends on the original quality of the element. For amateur devices, the clamp will last for a couple of years, for professional ones - up to 7-10 years.