Currently, the market offers a wide selection of different knives. From familiar kitchen items to combat ones, with special certificates confirming the legality of production and sale.

Despite the huge assortment, not every purchased product turns out to be useful and pleases with its efficiency of use and long service life. The reason for this is the low quality of the product, which quickly becomes unusable.

Despite the presence of markings on the packaging of the product, it is difficult for the average buyer to understand the information presented, and visually identifying the best quality product is also not easy.

To buy a good quality knife, it is important to know some of the nuances of choice.

We carry out a visual inspection

In order not to buy the “wrong” knife, you need to carefully consider the product. To do this, you need to direct your gaze along its surface, which should represent an absolutely straight line. The existing curvature is a signal that the buyer has a defect in his hands, which may be the result of a violation of steel smelting technology. It's hardly worth buying such a knife.

Importance of processing

The next important point is checking the quality of processing. On the so-called heel of the blade, which is an unsharpened flat part at the “root”, if processed poorly, the cutting section of the blade will not fit tightly to it, which will create difficulties in use, and the knife will very quickly fail.

All elements of the product must be accurately adjusted and securely fastened. In addition, there should be no nicks on the surface. A good quality knife cannot have obvious traces of processing, and the transitions from one element to another must not have sharp breaks and be smooth and smooth to the touch.

What criteria must steel meet?

In order for the blade to remain strong and reliable for a long time, steel grades for knives must meet certain requirements:

- high hardness;

- wide operating temperature range: from -300 to +1000 degrees;

- strength, guaranteeing minimal deformation under mechanical stress;

- increased elasticity;

- corrosion resistance;

- the ability to maintain sharpness for a long period.

Failure to meet quality criteria directly affects the performance of the cutting tool. Consequently, the effectiveness of completing assigned tasks will be impaired.

The hardness of the alloy is standardly designated by the abbreviation HRC. In Europe, this parameter is abbreviated as RC. It is usually determined using the Rockwell scale, with 54-57 units taken as the standard. However, in reality, such blades quickly wear down, and their sharpness must be restored with a grinding stone. In Japan, the hardness of the blade exceeds HRC 59. Such blades remain sharp for a long time. They cannot be treated with musat; the blade begins to crumble. For sharpening, a special technology is used, which is based on the rules regarding the use of soft grinding wheels. The optimal blade hardness exceeds HRC 55.

Each country has individual markings for the steel from which knives are made.

| USA | Germany | Russia | Japan |

| 420 | X21Cr13 | 3X13 | SUS42011 |

| 420/425 Mod | X45CrMoV15 | 4X13 | SUS42012 |

| 440A | X15CrMoV15 | 65X13 | AUS6 |

| 4408 | X89CuMoV181 | 9X18 | AUS8 |

| 440C | X105CrMo17 | 95X18W | SUS440C |

What should the blade be like?

The first is not necessarily razor-sharp: according to experts, to a large extent this is a marketing ploy that has nothing to do with the real quality of the product. In fact, how well a knife will cut depends not on the sharpness of the sharpening, but on the cross-section of the blade: the narrower it is, the easier it is to cut. But a thick blade will be more durable and will last longer.

Another indicator that the knife is sharp and cuts well is the angle of the cutting surface of the blade. With use, it will increase, and the knife will become dull.

Sharpening features

Depending on the shape and size of the knife, cutting properties may vary. Thus, knives with a wide handle have several stages of sharpening, which allows them to be used for a long time without deteriorating the cutting ability of the product. Knives with so-called differentiated sharpening initially have better cutting abilities.

Good quality kitchen knives for “rough” work involving cutting up animal carcasses and chopping bones should have a strong blade and a convex sharpening. This configuration of the product adds strength and ensures that the instrument does not get stuck in the bone cut. At the same time, you can use such a knife without additional sharpening for quite a long time.

In Ali Askerov's online store KavkazSouvenir you can purchase high-quality kitchen knives made by Kizlyar craftsmen, which are distinguished by their strength and durability.

Completely different requirements are placed on products for cutting vegetables and working with soft, pliable materials. They have a concave sharpening similar to a razor. This method is used in the best quality hunting knives, which are used for skinning a killed animal.

When purchasing knives with a convex or concave surface, it is important to remember the rule: cutting tools with a convex sharpening are for work with a large load on the blade, with a concave sharpening - for delicate activities.

Steel grades for knives: decoding

Steel grades for knives: explanation

Alloy steel has serious advantages over ordinary carbon steel, since strength, wear resistance, hardness and toughness depend on elements such as molybdenum, chromium, vanadium, nickel, silicon, tungsten, manganese. The addition of molybdenum simultaneously increases strength and toughness, and the high chromium content improves the cutting properties of the blade, increasing hardness, wear resistance, and also giving the steel anti-corrosion properties.

In order to understand the types, it is necessary to consider the characteristics of steel grades for knives:

- Russian stamps

- 65Х13

Steel grades for knives

The most common brand for mass production of knives. Alloying with chromium gives this steel grade high levels of anti-corrosion, resistance to oxidation and external factors. In addition, it is low in cost and can be sharpened quickly.

- 50Х14МФ

Steel grades for knives

A universal brand, similar in characteristics to those described above, but capable of corrosion during prolonged contact with water. With a high level of quality heat treatment, this steel produces hard and durable knives that hold an edge for a long time.

- 9ХС

A grade of alloy steel used to make tools and bladed weapons. It is used to produce parts that are subject to heavy loads and which must have increased wear resistance and bending strength: these are drills, reamers, cutters, taps, etc.

- 95Х18

High alloy steel with high hardness and good cutting edge properties. Designed for the manufacture of products with high strength and wear resistance. One of the best domestic steel brands.

- 40Х12

Mild steel used only for making kitchen or gift knives. Subject to deformation and often requires sharpening. It is a good option for the kitchen because it does not rust and can be easily repaired with musat, but the material is not used for other uses.

- 45Х13

Steel grades for knives

Good corrosion resistance, the material is easy to process. Used for making household and travel knives.

- X12MF

Steel - only - stainless steel

It is clear that not every buyer understands the grades of steel and alloys that are used to make knives, and the quality of the steel of knives is almost impossible to determine at a glance. But it is important to consider that products must not only be strong and durable, but also not react to the influence of aggressive substances that lead to metal corrosion and the appearance of rust on them.

If a knife begins to become covered with rusty spots after being placed in a humid environment, it will not last long and may be unsafe to use. Reaction with substances that cause a change in the color of the tool, the appearance of dark spots on the surface of the blade is an indicator of danger. Using food cut with such a knife can lead to chemical poisoning. In addition, you should be wary of the cost: products made from low-grade steel or alloy are much cheaper than high-quality analogues. They can only be used for technical work.

Safety knives are made of stainless steel and alloys that do not contain toxic or poisonous components hazardous to human health.

Steel for knives for various purposes

Steel is one of the most common and sought-after materials for making knives. It is steel that determines the main quality characteristics of a knife blade. Steel is an alloy of carbon and iron to which a number of ingredients are added to change the properties of this material. The properties of steel are also affected by the degree of hardening and heat treatment.

Steel for knives has the following quality indicators:

- hardness. This quality characterizes the ability of a metal to undergo deformation under the influence of external forces;

- strength. This characteristic of steel shows its resistance to chipping and crumbling when used for complex work. This indicator also demonstrates the ability of a given grade of steel to bend under load and not break. There is an inverse relationship between the hardness and strength of steel. Steel of higher hardness is less durable;

- wear resistance. This characteristic demonstrates the ability of steel of a given grade to abrasion under standard use;

- corrosion resistance. This indicator demonstrates the ability of steel to withstand external influences of various environments - water, acid, blood, etc. It shows how much a given steel will not rust under their influence. High performance of this characteristic of a knife, as a rule, is achieved by reducing the characteristics of other properties of the knife;

- duration of sharpening retention. This characteristic shows how long the sharpness of the knife will please its owner without sharpening.

The main problem in developing new types of steel is finding the optimal balance between strength and hardness. It is possible to create steel with extremely high hardness values, but a knife made from it can break if dropped on the floor from an average height. Conversely, a blade can be flexible and durable, but it will have to be sharpened every day. Therefore, there is no clear answer to the question about the best steel for knives. The choice of steel directly depends on the purpose of the knife. It is the purpose of its use that is the main criterion for choosing the type of steel for making a knife .

How to choose a quality folding knife

Folding knives do not go unnoticed either. They are compact, convenient, and have a beautiful design. The market offers products manufactured in Russia and by foreign companies. Buyers are offered combat, tourist, hunting, and multifunctional folding knives. They have their own characteristics that a potential buyer should know.

- The grade of steel will determine the wear resistance and quality of sharpening.

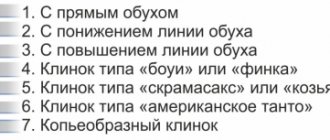

- Depending on the purpose of use, you need to choose the size of the blade and the geometry of the product.

- The handle of a folding knife should not be so much beautiful as it should be comfortable: it should fit comfortably in your hand.

- When purchasing, you must check the presence and serviceability of the lock.

- A universal folding knife is not cheap, so it is worth buying it if its functionality will be used to its fullest extent.

You can buy a good quality folding knife in Ali Askerov’s online store KavkazSouvenir. And most importantly, remember, regardless of the purpose of the knife, it must be made of high-quality steel, easy to use and durable.

Features of kitchen knives

Before moving directly to the features and parameters that you need to focus on when choosing a knife for the kitchen, it is important to understand how such a tool differs directly from products for other purposes, for example, tourist, hunting, folding and other models.

One of the main features of a kitchen knife is the geometry or design of the tool. The main task of a knife is to cut products, and at the same time it is important that the process is not accompanied by difficulties, the blade easily enters the product being cut, and the cut is smooth, without torn edges. This task is best accomplished by a tool whose blade is well sharpened, made in the shape of a triangle with equal hips, with straight slopes of the butt, and a thickness that decreases smoothly from the handle to the tip of the knife tip.

The second point that is inherent in kitchen appliances is the good ergonomics of the product. In most cases, this concerns the knife handle - it should be comfortable, fit well in the hand, and not have various decorative notches that will “get in the way” during everyday use of the tool. Ideally, the handle should have a flat surface and smoothed edges, which will reduce the likelihood of “rubbing” calluses on the hand. It is also important to have a stop, which will protect the user from accidental slipping of the hand towards the blade. Most kitchen knives are well balanced, have a center of gravity at the junction of the blade and the handle, or a slight “overweight” towards the tip, which will affect the ease of use of the tool in everyday use.

The following types of knives are considered the most popular in the kitchen:

- Chef's knife. The tool is often massive, with the length of the tip and handle from fifteen to thirty and from eighteen to twenty-two centimeters, respectively, and the width of the blade from two to four centimeters. The device is suitable for most manipulations associated with cutting products, often has excellent balancing, and can be made of different materials.

- A bread tool is a tool that differs from its other “brothers” in the even width of the cutting edge along the entire length, the “cut off” tip and serrated, serrated sharpening. Used for cutting bread products, cakes, muffins, pies and loaves.

- A vegetable knife is a tool that should be in every housewife's arsenal. This is a device with a straight, short blade, up to ten centimeters long, and a sharp tip, which allows you to cope with both peeling fruits and vegetables and slicing them. Sometimes, to peel vegetables and fruits, housewives additionally buy special tools, which are a blade fixed between two holders; however, their functionality is limited: they only allow cleaning food.

- A kitchen hatchet is another type of knife needed in everyday life for chopping meat products with bones; for example, with its resources it is easy to cut any carcass, as well as cut frozen meat.

In addition to the standard varieties of knives needed in the kitchen, you can choose tools for special purposes, which include fillet specimens, models for cutting meat, fish, slicing cheese and sausages, and other less popular variations of devices.