Decoding

In accordance with GOST 380-2005, the full name of the steel is 3 st3Gsp. The brand indicates the chemical composition, serial number and degree of deoxidation.

- St means that this is a grade of steel of ordinary quality. The quality of steel is determined by the level of sulfur and phosphorus content; the lower the concentration, the higher the quality. There are ordinary, high-quality, high-quality and especially high-quality steels. The content of sulfur and phosphorus in ordinary alloys does not exceed 0.06% and 0.07%.

- Number 3 is the conditional number of the brand according to GOST. GOST 380-2005 regulates carbon steels of ordinary quality; the grade number is assigned to the alloy according to its chemical composition.

- The letter G indicates the manganese content.

- Cn degree of deoxidation of steel. Deoxidation of steel is the process of removing oxygen from it, preventing oxidation and “boiling” and the release of gas during solidification. There are calm (sp), semi-quiet (ps) and boiling (kp) steels. Strongly deoxidized steels are called calm, and weakly boiling steels. The weaker the deoxidation, the higher the porosity of the steel. St3Gsp steel is considered to be calm; it has a semi-quiet version - st3ps steel.

Differences between st3ps and st3sp

Alloys st3sp and st3ps, being varieties of the same steel, differ from each other in the degree of deoxidation.

- Steel st3sp is considered calm, the degree of deoxidation is maximum.

- St3ps steel is semi-quiet, with a medium degree of deoxidation.

As a result of deoxidation, the intensity of gas formation during steel hardening decreases. The resulting gas bubbles make the steel porous and, as a result, less strong, affecting technological properties such as weldability. Calm steel (sp) is the highest quality in terms of the degree of deoxidation, boiling steel (kp) is the least quality, and semi-quiet steel (ps) occupies an intermediate position between them.

The differences between calm and semi-quiet steel for widely used metals are insignificant; both varieties cope quite well with average loads. At the same time, mild steel is more expensive, its production process is more complicated, and its use is advisable where the requirements for the quality of the metal are increased.

Chemical composition

98% of the composition of St3 steel is iron. The carbon content in the composition of st3 is low. It is enough to provide hardness to the alloy, while at the same time it does not reduce the toughness of the steel and its ductility. You can also find in the composition:

- Silicon. This element is the main deoxidizer of the alloy. Thanks to it, St3 steel acquires a fine-grained structure, and it also increases strength without reducing ductility.

- Manganese. A deoxidizer that promotes the removal of sulfur. Thanks to manganese, steel improves its surface quality, steel is better welded, forged, and becomes resistant to wear.

- Sulfur. A harmful impurity that causes an increase in red brittleness and the risk of cracking during high-temperature processing.

- Phosphorus. A harmful impurity that greatly reduces the temperature range of use of steels. Due to phosphorus, steel loses its ductility at high temperatures, and at low temperatures it becomes prone to brittleness.

- Nickel, copper, chromium, nitrogen, aluminum. Elements may be present in the composition of steel 3, but do not affect its characteristics due to their insignificant concentration.

Phosphorus and sulfur have a negative impact on weldability and cause welds to become porous and prone to cracking.

Chemical composition in % of the material St3sp

GOST 380-2005

| C | Si | Mn | Ni | S | P | Cr | N | Cu | As |

| 0.14 — 0.22 | 0.15 — 0.3 | 0.4 — 0.65 | up to 0.3 | up to 0.05 | up to 0.04 | up to 0.3 | up to 0.008 | up to 0.3 | up to 0.08 |

Chemical composition, % (GOST 380-2005)

| steel grade | Mass fraction of chemical elements | ||

| carbon | manganese | silicon | |

| St3sp | 0,14-0,22 | 0,40-0,65 | 0,15-0,30 |

Types and grades of steel

Steel. Types and grades of steel. Their application.

Steel is an alloy of iron and carbon with other elements, the carbon content in it is no more than 2.14%.

The most general characteristic is that steel is classified according to its chemical composition:

- carbon steel (Fe – iron, C – carbon, Mn – manganese, Si – silicon, S – sulfur, P – phosphorus). Based on carbon content, it is divided into low-carbon, medium-carbon and high-carbon. Carbon steel is designed for statically loaded tools.

- alloy steel - alloying elements are added: nitrogen, boron, aluminum, carbon, phosphorus, cobalt, silicon, vanadium, copper, molybdenum, manganese, titanium, zirconium, chromium, tungsten, nickel, niobium.

According to the production method and impurity content, steel differs:

- ordinary quality steel (carbon less than 0.6%) - complies with GOST 14637, GOST 380-94. St0, St1, St2, St3, St4, St5, St6. The letters “St” indicate ordinary quality steel, the numbers indicate the marking number depending on the mechanical properties. It is the cheapest steel, but inferior in other qualities.

- quality steel (carbon or alloyed) - GOST 1577, carbon content is indicated in hundredths of % - 08, 10, 25, 40, the degree of deoxidation and the nature of solidification can additionally be indicated. High-quality carbon steel has high ductility and increased weldability.

Low-carbon high-quality structural steels are characterized by low strength and high ductility. Parts for cold stamping are made from sheet steel 08, 10, 08kp. Bolts, screws, nuts, axles, hooks, studs and other parts for non-essential purposes are made from steels 15 and 20.

Medium-carbon quality steels (st. 30, 35, 40, 45, 50, 55) are used after normalization and surface hardening for the manufacture of parts that have high strength and core toughness (axles, screws, bushings, etc.)

Steel 60 - steel 85 have high strength, wear resistance, and elastic properties. Crane wheels, rolling rolls, compressor valves, springs, leaf springs, etc. are made from them.

- high quality - complex chemical composition with low phosphorus and sulfur content - according to GOST 19281.

Steel is also divided by application:

a) construction steel - carbon steel of ordinary quality. Has excellent weldability. The number indicates the conditional number of the steel composition according to GOST. The higher the reference number, the higher the carbon content, the higher the strength of the steel and the lower the ductility.

St0-3 - for secondary structural elements and non-critical parts (flooring, railings, lining, washers)

St3 is used for load-bearing and non-load-bearing elements of welded and non-welded structures and parts that operate at positive temperatures. GOST 380-88.

The quality standard provides for steel with an increased amount of manganese (St3Gsp/ps, St5Gsp/ps).

b) structural steel - GOST 1050

Carbon-based high-quality structural steels are used in mechanical engineering, for welded, bolted structures, for roofing work, for the manufacture of rails, railway wheels, shafts, gears and other parts of forklifts. The numbers in the marking indicate the carbon content in tenths of a percent.

St20 - lightly loaded parts, such as rollers, copiers, stops,

St35 - experiencing small stresses (axles, rods, levers, disks, traverses, shafts),

St45 (St40X) - requiring increased strength (shafts, couplings, axles, racks)

Structural alloy steels are used for tractor tracks, the manufacture of springs, leaf springs, axles, shafts, automobile parts, turbine parts, etc.

c) tool steel - used for cutting tools, high-speed steel for cold and hot deformation of materials, for measuring instruments, for the production of hammers, chisels, chisels, cutters, drills, files, razors, rasps.

U7, U8A (the figure is tenths of a percent in terms of carbon content). Carbon steels are produced in high quality and high quality. The letter "A" stands for high quality carbon tool steel.

d) alloy steel - universal steel containing a special impurity. Silicon content more than 0.5%, manganese more than 1%. GOST 19281-89. If the content of the alloying element exceeds 1 - 1.5%, then it is indicated by a number after the corresponding letter.

- low-alloy steel - where alloying elements are up to 2.5% (09G2S, 10HSND, 18KhGT). Low-alloy steel can be used in conditions of the far north, from -70 degrees C. Low-alloy steel is distinguished by greater strength due to a higher yield strength, which is important for critical structures.

- medium alloyed (2.5 -10%),

- highly alloyed (from 10 to 50%)

Steel 09G2S is used for steam boilers, apparatus and containers operating under pressure and temperatures from minus 70 to plus 450 degrees; it is used for critical sheet welded structures in chemical and petroleum engineering, and shipbuilding.

Steel 10HSND is used for welded structures in chemical engineering, shaped profiles in construction, and carriage building.

18ХГТ is used for parts operating at high speeds under high pressure and shock loads.

e) special purpose steel - steel with special physical properties. It is used in the electrical industry and precision shipbuilding.

The weldability of steel is affected by the degree of its deoxidation. According to the degree of deoxidation, steel is classified:

- mild steel (st3sp) - completely deoxidized with a minimum content of slag and non-metallic impurities,

- semi-quiet steel (st3ps) - quality characteristics are similar to calm steel,

- boiling steel (08kp) - unoxidized steel with a high content of non-metallic impurities. GOST 1577.

Depending on the standardized characteristics, steel is divided into categories: 1, 2, 3, 4, 5. Categories indicate chemical composition, tensile mechanical properties, impact strength)

For example, category 1 - chemical composition is not standardized, category 3 - impact strength at a temperature of +20 is standardized. For the St0 grade, neither the chemical composition nor the yield strength are standardized.

Steel grades

Steel grade S245 - St3ps5

Steel grade S255 - St3sp5

Steel grade S235 - St3kp2

Steel grade S345 - 09G2S

Purpose

Steel 3 and other alloys of this class are superior in scope to all other types of steel. It is used for the production of forged products, fences, gates, and decorative elements. In construction as a material for load-bearing, non-load-bearing, welded and non-welded building structures. Pipes and fittings, parts of mechanisms for operation at positive temperatures are made from it. St3 steel is used in the chemical, oil and gas industries, as well as in mechanical engineering.

Due to its simple chemical composition, availability, performance characteristics, and physical properties, steel 3 is one of the most common materials in industries that require a lot of steel. For example, in the construction of railways and pipelines for transporting natural gas or water.

Requirements for steel according to international standards ISO 630:1995, ISO 1052:1982

B.1 The chemical composition of steel according to the analysis of the ladle sample must comply with the standards given in Table B.1

Table B.1

| steel grade | Quality category | Rolled thickness, mm | Mass fraction of chemical elements, %, no more | Degree of deoxidation | ||||

| carbon | phosphorus | sulfur | manganese | silicon | ||||

| E 185 (Fe 310) | 0 | — | — | — | — | — | — | — |

| E 235 (Fe 360) | A | 0,22 | 0,050 | 0,050 | — | — | — | |

| IN | Up to 16 | 0,17 | 0,045 | 0,045 | 1,40 | 0,40 | — | |

| St. 16 to 25 | 0,20 | 0,045 | 0,045 | 1,40 | 0,40 | — | ||

| Up to 40 | 0,17 | 0,045 | 0,045 | 1,40 | 0,40 | NE | ||

| St. 40 | 0,20 | 0,045 | 0,045 | 1,40 | 0,40 | NE | ||

| WITH | 0,17 | 0,040 | 0,040 | 1,40 | 0,40 | NE | ||

| D | 0,17 | 0,035 | 0,035 | 1,40 | 0,40 | GF | ||

| E 275 (Fe 430) | A | Up to 40 | 0,24 | 0,050 | 0,050 | — | — | — |

| IN | St. 40 | 0,21 | 0,045 | 0,045 | 1,50 | 0,40 | NE | |

| 0,22 | 0,045 | 0,045 | 1,50 | 0,40 | NE | |||

| WITH | 0,20 | 0,040 | 0,040 | 1,50 | 0,40 | NE | ||

| D | 0,20 | 0,035 | 0,035 | 1,50 | 0,40 | GF | ||

| E 355 (Fe 510) | WITH | Up to 30 | 0,20 | 0,040 | 0,040 | 1,60 | 0,55 | NE |

| St. 30 | 0,22 | 0,040 | 0,040 | 1,60 | 0,55 | NE | ||

| Up to 30 | 0,20 | 0,035 | 0,035 | 1,60 | 0,55 | GF | ||

| St. 30 | 0,22 | 0,035 | 0,035 | 1,60 | 0,55 | GF | ||

| Fe 490 | — | — | — | 0,050 | 0,050 | — | — | — |

| Fe 590 | — | — | — | 0,050 | 0,050 | — | — | — |

| Fe 690 | — | — | — | 0,050 | 0,050 | — | — | — |

| Note 1 - The sign “-” means that the indicator is not standardized. Note 2 - NE - non-boiling steel. Note 3 - GF is a fine grain mild steel. The recommended mass fraction of total aluminum is not less than 0.020%. | ||||||||

B.2 Steel grades Fe 490, Fe 590 and Fe 690 are made semi-quiet and calm.

B.3 Maximum deviations of the chemical composition in finished rolled products must correspond to those given in Table B.2.

| Table B.2 | In percentages |

| Element | Maximum deviation for chemical composition |

| Carbon | +0,03 |

| Manganese | +0,10 |

| Silicon | +0,05 |

| Phosphorus | +0,010 |

| Sulfur | +0,010 |

Advantages and disadvantages

The main distinguishing feature of St3 steel is its combination of positive characteristics or versatility. This means that it does not have any one key advantage, it shows decent characteristics from all sides, which makes it the first on the market. This steel is not intended for highly specialized applications in special conditions, but is ideal for a wide range of everyday applications.

The disadvantages of steel include low performance at low temperatures.

Advantages of steel st3Gsp:

- homogeneous structure, due to which the steel becomes homogeneous, ductile and protected from adverse environmental influences;

- resistance to atmospheric corrosion;

- high elasticity and hardness;

- insensitivity to flakes;

- impact strength, allowing to withstand dynamic loads well;

- not subject to temper brittleness;

- simple production process, no expensive alloying additives;

- relatively low cost.

Separately, it should be mentioned that the material is perfectly weldable. It can be carried out using any known technology without preliminary and subsequent treatments.

Production

St3ps steel is produced in two ways: converter and open-hearth. A converter furnace is a pear-shaped vessel lined with brickwork on the inside and covered with sheet steel on the outside. Scrap metal (scrap) is placed into the converter, then liquid cast iron heated to 1400C is poured. At the oxygen purge stage, oxygen is supplied to the converter under high pressure, causing the oxidation of cast iron impurities, resulting in the formation of steel. In open hearth furnaces, steel is produced using the same oxidation method, but using a different principle through slag. Deoxidation and alloying (if necessary) is carried out at the final stages of production.

St3ps steel does not change its characteristics depending on the production method, but the converter method is cheaper, and therefore is considered more preferable.

Why does steel deoxidize?

Deoxidation is part of the metal refining process. If you do not deoxidize the steel before it hardens, the structure of the steel will be heterogeneous, porous, with gas pockets. Such steel welds worse, wears out and breaks faster. Deoxidized steel has a homogeneous and solid structure. Undeoxidized steel is also used in various industries, but is not suitable for the manufacture of loaded parts operating under pressure. The production of such steel has its advantages: it is waste-free, cheap and simple.

Characteristics

St3 is characterized as carbon structural steel of ordinary quality. Steel does not contain alloying additives that protect it from external influences. For use in aggressive chemical environments or conditions of high humidity, it is necessary to coat the steel with a protective layer. St3 has good weldability, high strength, and resists loads well, which allows it to be used in load-bearing structures. The price of St3 steel is optimal for the construction of facilities or laying communications that require a large amount of metal. Density St3 - 7850 kg/m3.

Specifications

The characteristics of ST3PS steel include: weldability, hardness HB (HB 10-1), melting range, density, increase in tensile length.

| weldability | weldable; |

| hardness HB 10-1 | 131 MPa; |

| melting range | 1300-1400 degrees; |

| density | 7850 kg/m3; |

| increase in length when stretched | 23-25%; |

Temperature of critical points, °C

| Ac1 | Ac3 | Ar3 | Ar1 |

| 735 | 850 | 835 | 630 |

Assortment

- Channels are parallel (P), with sloped flanges (U), equal-flange bent;

- round sections circle and reinforcement;

- VGP pipes, electric welded (ES), seamless (BGD);

- I-beams, wide-flange, column, special, with flange slopes;

- steel square;

- corners equal and unequal;

- square and rectangular profile;

- sheet steel: hot-rolled, corrugated, expanded metal, strip.

Types of delivery

- Hot rolled sheets, including strip and tape;

- forgings;

- rails;

- pipes;

- rod and wire.

Substitutes

A substitute is an alloy that is closest in performance characteristics to the main one. Substitutes for St3 are usually one of three domestic brands: S245, S285, VSt3Sp.

It is acceptable to use foreign analogues that differ in markings, but are available in any corner of the world map. They are:

IN THE USA:

- A57036;

In Great Britain:

- 40B;

- 722M24;

In Germany:

- 0038;

In France:

- E24-2;

- E24-4.

In Japan:

- SS330;

- In Italy:

- Fe360B;

In China:

In Austria:

In Hungary

Comparison with alloy structural steels

Steel st3 is a carbon structural steel of ordinary quality. It is used to produce welded and non-welded structures, heavily loaded trusses and other load-bearing elements. St3 is resistant to atmospheric corrosion, but without a protective coating it will deteriorate upon prolonged contact with moisture or an aggressive chemical environment.

Alloy structural steel is protected from corrosion by alloying elements, so it can be used without a protective layer when in contact with moisture and aggressive environments. Alloy steel is more difficult to produce, more expensive and more prone to brittleness. The processing of such steel may require special conditions, while the more affordable and easier to produce steel 3 does not require any special processing conditions.

Mechanical restoration

When processing parts made of ST3KP steel grade, you will need to carefully select the cutting tool. Sharpening and milling are carried out by elements made of hard alloys VK8 and T5K10. Thread cutting is carried out using taps and dies made of P18 and P6M5. Turning and milling work on a machine involves the use of cutting fluids. When manually cutting threads, experts recommend using castor oil, which will reduce labor costs during work.

The processing speed is selected based on the composition and characteristics of the alloy, the operating parameters of the machine and the type of processing. With a workpiece diameter of 60-100 mm, a 16x25 mm turning tool can be used. With a cutting depth of 3 mm, the feed speed should be 0.7-1.2 mm/rev, and the rotation speed should be 700 rpm.

Return to content

Comparison with alloy tool steels

Alloy tool steel is used in the production of tools. Alloying additives are aimed at improving the quality of steel, thanks to them it is possible to achieve a significant advantage over carbon alloys. These include:

- red fastness;

- high hardenability;

- resistance to impact loads (especially important for impact tools);

- wear resistance.

St3 steel is structural and, as a rule, is not used for the manufacture of moving parts of tools.

Production Features

The operating parameters of ST3KP steel are determined based on the composition and percentage of components in it. It is also important to consider how the material is produced.

The alloy is based on ferrite, which is a solid solution of carbon and alloying additives. In order for the strength properties of a component to increase, it is necessary to saturate it with carbon.

Undesirable impurities include sulfur (0.05%) and phosphorus (0.04%), which negatively affect strength when heated and increase brittleness when cooled. Red brittleness is another negative property that appears as a result of the formation of sulfur grains.

Steel grade ST3KP is processed in open hearth and converter furnaces. The performance characteristics of the alloys are almost identical, but the second production method is much cheaper.

Return to content

Foreign analogues

| Europe EN 10027-1 (EN 10027-2) | S235JR (1.0038) |

| Germany DIN | RSt37-2, USt37-2 |

| USA (AISI, ASTM) | A238/C |

| France (AFNOR) | E 24-2 |

| UK BS | 40B |

| Czech Republic (CSN) | 11375 |

| Poland PN/H | St3SV, St3SJ, St3S4U |

Physical properties

Physical properties of the material St3ps

| T | E 10- 5 | a106 | l | r | C | R 109 |

| hail | MPa | 1/Grad | W/(m deg) | kg/m3 | J/(kg deg) | Ohm m |

| 20 | 7850 |

Technological properties

Technological properties of the material St3sp.

| Weldability: | no limits. |

| Flock Sensitivity: | not sensitive. |

| Tendency to temper brittleness: | not inclined. |

Temperature of critical points, °C

| Ac1 | Ac3 | Ar3 | Ar1 |

| 735 | 850 | 835 | 680 |

Standardized indicators of St3sp steel by rolled category (GOST 535-2005)

| Category | Chemical composition | Temporary resistance σв | Yield strength σt | Relative elongation δ5 | Cold bending | Impact strength | ||||

| KCU | KCV | |||||||||

| At temperature, °C | After mechanical aging | At temperature, °C | ||||||||

| + 20 | -20 | + 20 | -20 | |||||||

| 1 | — | + | + | + | + | — | — | — | — | — |

| 2 | + | + | + | + | + | — | — | — | — | — |

| 3 | + | + | + | + | + | + | — | — | — | — |

| 4 | + | + | + | + | + | — | + | — | — | — |

| 5 | + | + | + | + | + | — | + | + | — | — |

| 6 | + | + | + | + | + | — | — | — | + | — |

| 7 | + | + | + | + | + | — | — | — | — | + |

Parameters for the use of electric-welded straight-seam pipes made of St3sp steel (GOST 32569-2013)

| Steel grade, strength class, standard or specifications | StZsp5 GOST 380 | StZsp4-5 GOST 380 | StZsp4 GOST 380 | ||||

| Technical requirements for pipes (standard or specifications) | GOST 10705 group B | GOST 10706 group B | TU 14-3-377-87 | TU 14-3-1399-95 | GOST 10706 group B | ||

| Nominal diameter, mm | 10-500 | 450-1400 | 200-400 | 200, 350, 400, 500 | 400-1400 | ||

| Types of tests and requirements (standard or specifications) | GOST 10705 | GOST 10706 | TU 14-3-377-87 | TU 14-3-1399-95 | GOST 10706 | ||

| Transported medium (see designations in table 5.1) | Group B, C environments | Group B media Group B media, except LPG | Group B media, except steam and hot water | All media except group A(a) and LPG | Group B media, except LPG | ||

| Pipeline design parameters | Maximum pressure, MPa | ≤1,6 | ≤2,5 | ≤1,6 | |||

| Maximum temperature, °C | 300 | 200 | 300 | 200 | |||

| Pipe wall thickness, mm | — | ≤12 | — | ≤10 | — | ||

| Minimum temperature depending on the pipe wall thickness with stress in the wall from internal pressure [σ], °C | more than 0.35[σ] | minus 20 | |||||

| no more than 0.35[σ] | minus 40 | ||||||

Parameters for the use of electric-welded spiral-welded pipes made of St3sp steel (GOST 32569-2013)

| Steel grade, strength class, standard or specifications | StZspZ, StZsp2 GOST 380 | StZsp5 GOST 380 | ||

| Technical requirements for pipes (standard or specifications) | TU 14-3-943-80 | TU 14-3-954-80 | ||

| Nominal diameter, mm | 200-500 | 500-1400 | ||

| Types of tests and requirements (standard or specifications) | TU 14-3-943-80 | TU 14-3-954-80 taking into account the requirements of clause 2.2.10 GOST 32569-2013 | ||

| Transported medium (see designations in table 5.1) | All media except group A and LPG | All media except group A and LPG | ||

| Pipeline design parameters | Maximum pressure, MPa | ≤1,6 | ≤2,5 | |

| Maximum temperature, °C | 200 | 300 | ||

| Pipe wall thickness, mm | ≤6 | ≤12 | ||

| Minimum temperature depending on the pipe wall thickness with stress in the wall from internal pressure [σ], °C | more than 0.35[σ] | minus 30 | minus 20 | |

| no more than 0.35[σ] | — | minus 20 | ||

Application of St3sp steel for fasteners (GOST 32569-2013)

| steel grade | Technical requirements | Acceptable operating parameters | Purpose | |

| Wall temperature, °C | Medium pressure, MPa (kgf/cm2), no more | |||

| StZsp4 GOST 380 | STP 26.260.2043 | -20 to +300 | 2,5 (25) | Studs, bolts, nuts |

| 10 (100) | Washers | |||

Conditions for using St3sp steel for bodies, covers, flanges, membranes and valve assembly made from rolled products, forgings (stampings) (GOST 33260-2015)

| Material | ND for supply | Temperature of the working medium (wall), °C | Additional instructions for use |

| St3sp GOST 380 | Forgings GOST 8479 Long products GOST 535, categories 3-5 | -30 to 300 | For welded fittings for pressure PN≤2.5 MPa (25 kgf/cm2) |

| Sheet GOST 14637, categories 3-6 | -20 to 300 | For welded fittings for pressure PN 5 MPa (50 kgf/cm2). For categories 4, 5, sheet thickness for St3sp is no more than 25 mm; for category 3 sheet thickness no more than 40 mm |

Resistance of structural materials against crevice erosion (GOST 33260-2015)

| Durability group | Point | Erosion resistance against steel 12X18H10T | Material |

| Unstable | 6 | 0,005-0,05 | Steel VSt3sp3 and its welded joints. |

NOTE. The coefficient of erosion resistance of a material is the ratio of the rate of erosive wear of the material to the rate of erosive wear of steel 12Х18Н10Т (taken as 1).

Mechanical properties of rolled products under tension, as well as cold bending test conditions (GOST 535-2005)

| steel grade | St3sp | |

| Tensile strength σв, N/mm2 (kgf/mm2), for rolled thicknesses, mm | up to 10 incl. | 380-490 (39-50) |

| St.10 | 370-480 (38-49) | |

| Yield strength σт, N/mm2 (kgf/mm2), for rolled thickness, mm (not less) | up to 10 incl. | 255(26) |

| St. 10 to 20 incl. | 245(25) | |

| St. 20 to 40 incl. | 235(24) | |

| over 40 to 100 incl. | 225(23) | |

| St. 100 | 205(21) | |

| Relative elongation δ5, %, for rolled thicknesses, mm (not less) | up to 20 incl. | 26 |

| over 20 to 40 incl. | 25 | |

| St.40 | 23 | |

| Bending until the sides are parallel (a - sample thickness, d - mandrel diameter), for rolling thicknesses, mm | up to 20 incl. | d = a |

| St.20 | d = 2a | |

NOTE

- By agreement between the manufacturer and the consumer, the following is allowed:

- reduction in yield strength by 10 N/mm2 (1 kgf/mm2) for shaped steel with a thickness of over 20 mm;

- reduction in relative elongation by 1% (abs.) for shaped rolled products of all thicknesses.

- It is allowed to exceed the upper limit of tensile strength by 49.0 N/mm2 (5 kgf/mm2), and by agreement with the consumer - without limiting the upper limit of tensile strength, provided that other standards are met. At the request of the consumer, exceeding the upper limit of temporary resistance is not allowed.

Impact strength of rolled products (GOST 535-2005)

| steel grade | St3sp | ||

| Rolled thickness, mm | St. 5.0 to 10.0 incl. | ||

| KCU, J/cm2 (kgf*m/cm2), not less | Sample type according to GOST 9454 | 2,3 | |

| At temperature, °C | +20 | 108(11) | |

| -20 | 49(5) | ||

| After mechanical aging | 49(5) | ||

| KCV, J/cm2 (kgf*m/cm2), not less | Sample type according to GOST 9454 | 12,13 | |

| At temperature, °C | +20 | 34(3,5) | |

| -20 | — | ||

NOTE

- The “-” sign means that the indicator is not standardized.

- Determination of the impact strength of round rolled products is carried out starting from a diameter of 12 mm, square - starting from the square side of 11 mm.

- It is allowed to reduce the value of impact strength on one sample by 30%, while the average value must not be lower than the standards specified in this table.

- Impact strength KCV is determined for rolled products with a thickness of up to 20 mm inclusive.

How to weld

St3ps steel is unpretentious in processing; it can be welded without restrictions by any existing method. Pre- and post-temperature treatment is not required. The seams are strong and not prone to cracking. The following types of welding are widely used:

- contact using high voltage current;

- automatic submerged arc using a welding machine with a wire electrode;

- electroslag using molten flux (slag);

- manual arc welding with coated electrodes;

- manual argon arc manual welding in an argon gas environment;

- mechanized welding in a carbon dioxide environment with a consumable electrode in a gas environment.

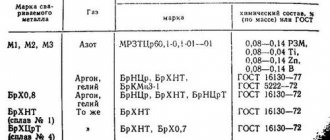

Welding materials for electric arc welding

| Base material grade | Electrode type according to GOST, TU (recommended brands of electrodes) | Application temperature, °C | Additional instructions |

| St3ps | E42, E46 GOST 9467 (ANO-4, ANO-5,OZS-6) | Not lower than -15 | — |

| E42A, E46A GOST 9467 (UONI-13/45, UONI-13/45A, 0ZS-2, SM-11) | Not lower than -30 | — | |

| E50A GOST 9467 (UONI-13/55) | below -30 to -40 | After welding, heat treatment normalization plus tempering (630660) °C, 2 hours |

Welding materials for gas shielded welding

| Base material grade | Welding wire grade according to GOST 2246, TU, recommended shielding gas or mixture of gases | Application temperature, °C |

| St3ps | Sv-08G2S Carbon dioxide GOST 8050, argon GOST 10157 | -20 to 300 |

Welding materials for submerged arc welding

| Base material grade | Welding wire grade according to GOST 2246, TU, Recommended flux grade according to GOST 9087 | Additional instructions | ||

| Electrodes, type according to GOST 10052 (recommended brands) | Welding wire, GOST 2246 or TU | |||

| Group A | Group B | |||

| 10Х18Н9Л, 12Х18Н9ТЛ GOST 977 08Х18Н10Т, 12Х18Н9Т, 12Х18Н10Т, 12Х18Н9 GOST 5632 08Х18Н10Т-VD TU 14-1-3581 10Х18Н9, 10Х18Н9-VD, 10Х1 8N9-Sh TU 108.11.937 15Х18Н12СЧТУ (EI 654) GOST 5632 10Х17Н13М3Т (EI 432) 10Х17Н13М2Т ( EI 448) GOST 5632 | St3ps GOST 380 | E-10Kh15N25M6AG2 (EA-395/9) E-10Kh25N13G2 (OZL-6, ZIO-8), E-11Kh15N25M6AG2 (NIAT-5, TsT-10) | Sv-07Х23Н13 | The welded joint is of unequal strength |

| E-10Х15Н25М6AG2 (EA-395/9) 582/23, 855/51 | Sv-10X16N25AM6 Sv-06X15N35G7M6B Sv-03X15N35G7M6B | The welded joint is of unequal strength. Welding materials are used for products under the jurisdiction of Rostechnadzor | ||

Welding materials for welding St3ps steel with other steels

| Grades of welded steels | Welding materials | Application temperature, °C |

| St3ps | Sv-08, Sv-08A AN-348A, OSTS-45 ANTS-1 | Not lower than -20 |

Temperature of preliminary and accompanying heating and tempering when welding structures made of St3ps steel

| Grades of welded steels | Thickness of welded edges, mm | Temperature of preliminary and accompanying heating, °C | Interval between the end of welding and the start of tempering, hour | Temperature, °C | |

| welding | surfacing with austenitic class materials | ||||

| St3ps | Up to 36 | Not required | Not required | Not limited | Not required |

| Over 36 to 100 | 630-660 | ||||

| Over 100 | 100 | ||||

Recommended welding modes for correcting weld defects

| Welding materials | Main material | Diameter of electrode, wire, mm | Welding current strength, A | Arc voltage, V |

| USENI 13/45A* USENI 13/55 | St3ps | 3,0 4,0 5,0 | From 100 to 130 From 160 to 210 From 220 to 280 | From 22 to 26 |

| Sv-08G2S | 1,6 | From 100 to 120 | From 12 to 14 | |

| 2,0 | From 140 to 160 |

NOTE. * - along with the electrode brand UONI 13/..., it is possible to use the brand UONII 13/..., depending on the designation of the brand in the specifications of the electrode manufacturer.

Modes of electric arc welding of samples and products

| Electrode brand | Main material | Electrode diameter, mm | Welding current strength, A | Arc voltage, V |

| USENI 13/45A*, USENI 13/55 | St3ps | 3 4 5 | From 110 to 130 From 160 to 210 From 220 to 280 | From 22 to 26 |

NOTE. * - along with the electrode brand UONI 13/..., it is possible to use the brand UONII 13/..., depending on the designation of the brand in the specifications of the electrode manufacturer.

Modes of argon arc welding of samples for incoming inspection of welding materials

| Electrode brand | Main material | Electrode diameter, mm | Welding current strength, A | Arc voltage, V |

| Sv-08G2S | St3ps | 1,6 2,0 3,0 | From 100 to 120 From 150 to 170 From 200 to 240 | From 12 to 14 |

Density ρ p kg/cm 3

| Steel grade | At test temperature, °C | |

| 20 °C | ||

| st3ps | 7850 | |

Young's modulus (normal elasticity) E, GPa

| Steel grade | At test temperature, °C | ||||||||

| 20 | 100 | 200 | 300 | 400 | 500 | 600 | 700 | ||

| VSt3ps | 213 | 208 | 202 | 195 | 187 | 176 | 167 | 153 | |

Mechanical properties

Mechanical properties of rolled products

| GOST | Delivery status | Section, mm | σ0.2, MPa | σв, MPa | δ5(δ4),% |

| no less | |||||

| GOST 380-94 | Hot rolled products | Up to 20 | 245 | 370-480 | 26 |

| St. 20 to 40 | 235 | 25 | |||

| St. 40 to 100 | 225 | 23 | |||

| St. 100 | 205 | 23 | |||

| GOST 16523-89 (transverse samples) | Hot rolled sheet | Up to 2.0 incl. | — | 370-480 | (20) |

| St. 2.0 to 3.9 incl. | (22) | ||||

| Cold rolled sheet | Up to 2.0 incl. | — | 370-480 | (22) | |

| St. 2.0 to 3.9 incl. | (24) | ||||

Mechanical properties of forgings

| GOST | Heat treatment | Section, mm | σ0.2, MPa | σв, MPa | δ5,% | ψ, % | KCU, J/cm2 | Hardness HB |

| no less | ||||||||

| GOST 8479-70 | Normalization | Up to 100 | 175 | 353 | 28 | 55 | 64 | 101-143 |

| 100-300 | 175 | 353 | 24 | 50 | 59 | |||

| Up to 100 | 195 | 392 | 26 | 55 | 59 | 111-156 | ||

| 100-300 | 195 | 392 | 23 | 50 | 54 | |||

Impact strength KCU (GOST 380-94)

| Type of rental | Pattern cutting direction | Section, mm | KCU, J/cm2 | ||

| +20 °C | -20 °C | after mechanical aging | |||

| no less | |||||

| Sheet | Transverse | 5-9 | 78 | 39 | 39 |

| 10-25 | 68 | 29 | 29 | ||

| 26-40 | 49 | — | — | ||

| Wide band | Longitudinal | 5-9 | 98 | 49 | 49 |

| 10-25 | 78 | 29 | 29 | ||

| 26-40 | 68 | — | — | ||

| Varietal and shaped | Same | 5-9 | 108 | 49 | 49 |

| 10-25 | 98 | 29 | 29 | ||

| 26-40 | 88 | — | — | ||

Mechanical properties at elevated temperatures

| tsp, °C | σ0.2, MPa | σв, MPa | δ5,% | ψ, % | KCU, J/cm2 |

| Hot rolled billet dimensions 140×120 mm | |||||

| 20 | 220 | 445 | 33 | 59 | 154 |

| 300 | 205 | — | — | — | 199 |

| 500 | 180 | 285 | 34 | 80 | 119 |

| Hot-rolled sheets and shapes up to 30 mm thick | |||||

| 20 | 205-340 | 420-520 | 28-37 | 56-68 | — |

| 200 | 215-285 | — | — | — | — |

| 300 | 05-265 | — | — | — | — |

| 400 | 155-255 | 275-490 | 34-43 | 60-73 | — |

| 500 | 125-175 | 215-390 | 36-43 | 60-73 | — |

| A sample with a diameter of 6 mm and a length of 30 mm is forged and normalized. Deformation speed 16 mm/min, strain rate 0.009 1/s | |||||

| 700 | 73 | 100 | 57 | 96 | — |

| 800 | 51 | 63 | 95 | 95 | — |

| 900 | 38 | 65 | 84 | 100 | — |

| 1000 | 25 | 43 | 79 | 100 | — |

| 1100 | 19 | 31 | 80 | 100 | — |

| 1200 | 14 | 25 | 84 | 100 | — |

Endurance limit

| Sample | σ-1, MPa | n |

| Smooth | 191 | 107 |

| Notched | 93 | 107 |

Type of delivery

| B03 - Metal forming. Forgings | GOST 8479-70; |

| B20 - Classification, nomenclature and general standards | GOST 380-2005; |

| B22 – Long and shaped rolled products | GOST 5267.0-90; GOST 5781-82; GOST 8239-89; GOST 8240-97; GOST 8510-86; GOST 8509-93; GOST 10884-94; GOST 30136-95; GOST 9234-74; GOST 4781-85; GOST 10551-75; GOST 25577-83; GOST 5422-73; GOST 535-2005; GOST 19240-73; GOST 19425-74; GOST 2590-2006; GOST 11474-76; GOST 2879-2006; GOST 2591-2006; GOST 30565-98; |

| B23 - Sheets and strips | GOST 14637-89; GOST 16523-97; GOST 8568-77; GOST 14918-80; GOST 19903-74; GOST 103-2006; |

| B24 - Tapes | GOST 3560-73; GOST 6009-74; |

| B34 - Tapes | GOST 19851-74; |

| B42 - Rails. Overlays. Linings. Crutches | GOST 8142-89; GOST 5812-82; GOST 16277-93; |

| B62 — Steel pipes and connecting parts for them | GOST 12132-66; GOST 10705-80; GOST 10706-76; GOST 3262-75; GOST 24950-81; GOST 8696-74; GOST 10707-80; GOST 20295-85; |