Metals and alloys

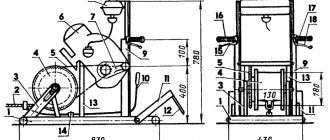

Alloy steels Elements whose content exceeds the normal limit value specified in the standards are called alloying steels

It's no secret that a car radiator is one of the most important automotive parts in the system.

Painting metal is not easy. Most of the colors we are used to are not friendly with it - they can’t stand it.

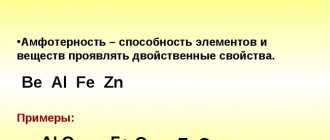

Simple substances similar to metal elements in structure and a number of chemical and physical parameters

What is zinc? Zinc is a silvery-white metal with a bluish tint. In its pure form

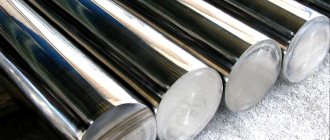

What is alloy steel? Physical properties such as strength, ductility, brittleness can be increased

09/04/2020 Author: VT-METALL Issues discussed in the material: Description of structural steel Classification of structural steels Spheres

Brass LO70-1 Brass LMtsA57-3-1 Brass LMtsAZhKS70-7-5-2-2-1 Brass LMtsZh57-1.5-0.75 Brass LMtsKA58-2-1-1 Brass LMtsKNS58-3-1.5-1 ,5-1 Brass LMtsKNSA58-3-1.5-1.5-1

When looking for alternative solutions for heating rooms, many people pay attention to a stove made of

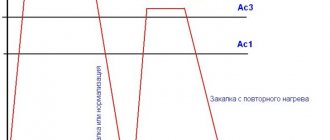

Re-hardening is carried out with heating to 850–900 °C (above point A3) so that complete