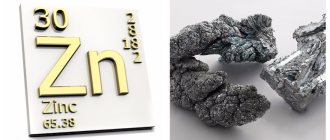

What is zinc? Zinc is a silvery-white metal with a bluish tint. Zinc, as a chemical element, in nature in its pure form .

According to the periodic table, Zinc is a chemical element of the 12th group (according to the outdated classification - a side subgroup of the second group), the fourth period of the periodic system. The designation symbol is Zn (lat. Zincum)

. Currently, five stable isotopes of zinc a have been well studied, with mass numbers accordingly 64,66,67,68,70. The most common stable isotope of zinc is Zn 64 (48.89%). Nine radioactive zinc isotopes are obtained artificially. These include 65 Zn. It is the longest-lived zinc isotope, with a half-life of 245 days, so it is used as an isotope tracer.

| Name, symbol, number | Zinc / Zincum (Zn), 30 |

| Atomic mass (molar mass) | 65.38(2)[1] a. e.m. (g/mol) |

| Electronic configuration | [Ar] 3d10 4s2 |

| Atomic radius | 138 pm |

Zinc is a brittle metal under standard climatic conditions. After heating zinc to 100 degrees and above (up to 150 degrees C), changes occur in the crystal lattice, as a result of which the metal becomes ductile, flexible, and can be subjected to additional mechanical processing. The structure of the crystal lattice is hexagonal.

| Lattice structure | hexagonal |

| Lattice parameters | a=2.6648 c=4.9468 Å |

| c/a ratio | 1,856 |

| Debye temperature | 234K |

History of discovery.

It is known that zinc has been used as a composite material since ancient times. The very first finds of brass objects (brass is an alloy of copper + zinc) date back to 1500 BC. (excavations were carried out in Palestine). Mentions of brass smelting processes can be found in the works of Aristotle and Homer, Pliny (the Elder). Ancient treatises describe various casting methods. One of them examines in detail the method of preparing brass by reducing a special zinc stone (the so-called cadmium) with coal in the presence of a copper component. It was especially noted in the scientific work that adding zinc to the alloy can solve several issues at once:

- change in the color scheme of the finished copper product (as a result of lightening, the shade changed to “golden”),

- the mechanical properties of the finished melted product changed dramatically for the better, ductility and elasticity increased, and the resulting alloy could be rolled into sheets. At the same time, by changing the percentage ratio of zinc to copper in brass, it was possible to change the range of mechanical characteristics.

The first mention of the process of obtaining zinc metal was found in India (5th century BC). Also, the method of smelting “fake silver” can be found in the historical treatises of Strabop (Rome, 60 - 20 BC). At the end of the 13th century, the famous traveler Marco Polo in his notes described in detail the process of obtaining metallic zinc, which he observed in Persia. Back in the 16th century, Paracelsus and Agricola tried to organize zinc smelting production in their laboratory. However, the attempts ended in failure.

Until the mid-18th century, pure zinc was considered rare in Europe. It was mainly imported from the countries of the East, China, and India.

In 1738, Champion W. developed and patented a method for producing metallic zinc by distillation.

In 1743, in the city of Bristol, he built the first plant in Europe for the production of metallic zinc.

The word "zinc" first appears in the writings of Paracelsus, who called this metal the word "zincum" or "zinken" in the book Liber Mineralium. The word probably comes from the German Zinke, meaning "tooth" (zinc metal crystallites are like needles).

Marggraf A.S. in 1746 in Germany he published a new method for obtaining pure metallic zinc. The essence of the method was that a mixture of coal and zinc oxide was calcined in special vessels without air access, followed by cooling in a refrigerator. As a result, the zinc vapor condensed, forming pure zinc. Retorts made of refractory clay were used as sealed vessels for experiments.

In 1805, another method of producing zinc was invented - rolling in the temperature range from 100-150 degrees C. The developers of the new technological method were Ch. Hobson and Sylvester Ch. (Sheffield).

The electrolytic casting method began to be used in 1915 (Canada, USA).

Receiving technology

Due to its chemical and physical properties, the metal is the fourth most popular in the world (only iron, aluminum, and copper are ahead). World production amounts to millions of tons annually.

It is mined from polymetallic ores (0.9-3.9% zinc). Ores are enriched by separation flotation. The resulting concentrates are: zinc (52-61%), lead, copper.

Electrolytic (hydrometallurgical) method

The main method for obtaining pure zinc:

- The concentrates are fired and treated with sulfuric acid.

- The result is dissolved sulfate, which is removed from impurities by precipitating with zinc dust.

- The product is loaded into baths with an internal lead or plastic coating.

- The current is started (electrolysis process).

- Zinc is accumulated on cathodes.

From there it is scraped off and sent for smelting in a furnace.

Pyrometallurgical (distillation) method

The concentrate is fired, sintered, and then reduced with coke or coal. The resulting metal vapors are converted into condensate and poured into molds.

Liquid metal is purified from iron and lead by settling at 500°C. Impurities remain at 1.3%. Purity of 99.994% (plus cadmium extraction) is achieved by rectification.

Zinc in nature

Pure zinc metal can only be obtained industrially. In nature, zinc occurs in the form of minerals. Currently, more than 60 natural mineral compounds are known. The most common zinc minerals are willemite, zincite, sphalerite, calamine, and franklinite. Sphalerite deposits are considered the most numerous. This mineral consists of

- zinc sulfide (ZnS) is the main component,

- various impurities - additional components.

Additional components determine the final color of the mineral. In common parlance, the mineral is called “zinc blende” (due to the difficulty of definition in nature, translated from Greek as “deceptive”). For example, a mixture of zinc blende and brown spar has a striped structure. Deposits of such “chipmunk” ore are often found by geologists in the Altai Territory (Russia).

Zinc is present in various compounds

- in the earth's punishment,

- in water,

- in living organisms.

Approximately 10% of zinc (in various compositions) is found in the earth's crust. At the same time, studies have shown that in basic rocks of volcanic eruptions the content of zinc compounds ranges from 1.5% to 10%, in acidic rocks the percentage ranges from 6 to 10.

Studies have revealed a large presence of zinc in the waters of thermal springs (mainly various compounds of zinc and lead). Zinc sulfides extracted from thermal waters are currently actively used in industry.

Zinc is present in dissolved form in both surface and groundwater. In an aquatic environment, hydrogen sulfide, clay, and many others serve as adsorbing elements for “migrating” zinc.

The presence of zinc in living organisms ranges from 5 to 10-4%.

TsAM alloy composition

This is a type of zinc alloy, the main alloying elements of which are aluminum and copper. The abbreviation TsAM itself stands for zinc-aluminum-copper. The numbers indicated after the name of the alloy indicate the percentage of metals. So the designation TsAM 4-1 says that the alloy includes approximately 4% aluminum, 1% copper and 95% zinc. Also, TsAM always contain a small amount (up to 0.1%) of magnesium.

Zinc is a ductile metal of silver color and white hue. Quite fragile. It has a low melting point, high fluidity and low cost. It is the basis for TsAM.

Aluminum reduces the solubility of iron in the alloy, which has a beneficial effect on the mechanical and casting characteristics of TsAM. In addition, aluminum reduces the effect of zonal segregation. Promotes grain grinding.

Copper is introduced into the alloy in order to increase its strength characteristics. One percent copper increases the hardness value of TsAM by approximately 7%. The downside of this alloying is the deterioration of the corrosion-resistant and ductile properties of the alloy.

Magnesium is the component responsible for inhibiting the formation of corrosion foci by TsAM, including its worst type - fine-grained. It also slows down the aging process in the alloy. Excessive doping of TsAM with magnesium (over 0.1%) leads to deterioration in ductility, strength and the appearance of signs of red brittleness.

In addition to the main elements, the alloy includes components that negatively affect its properties - harmful impurities. The reason for this is the imperfection of smelting technology and the purity of the charge used. The most common impurities are:

- Tin (up to 0.001%).

- Lead (up to 0.007%).

- Cadmium (up to 0.003%).

- Iron (up to 0.1%).

The ingress of these metals with TsAM leads to a decrease in mechanical characteristics, fluidity and increases the tendency to crack formation.

Metallurgy offers over 25 varieties of TsAM, but the most widespread among them are the following brands:

- TsAM 4-1 GOST 19424-97.

- TsAM 4-3 GOST 19424-97.

- TsAM 9-1.5 GOST 21438-95.

- TsAM 10-5 GOST 24438-95.

Physical properties

The density of TsAM is 6700 kg/m3. The melting point ranges from 380-387 degrees depending on the grade of the alloy. TsAM begins to boil at a temperature of 710 C

Zinc alloy conducts heat well. The thermal conductivity coefficient is 110 W\m*K. Has an insignificant coefficient of linear expansion. When the temperature increases by 20 degrees, the length of the TsAM bar increases by 27.7 microns.

Mechanical properties

The strength of TsAM is comparable in value to the strength characteristics of steel 20. The tensile strength is 245 MPa. It begins to deform at a load of 120 MPa. The hardness of alloys on the Brinell scale is 95-100 units.

Plastic properties strongly depend on the quantitative content of alloying elements in the composition. Based on their content, the relative tensile elongation can range from 0.4 to 1.0%.

Chemical properties

TsAM alloys are characterized by good resistance to corrosion. Although a prerequisite for this should be the preliminary application of galvanic coatings to their surface. Actively interacts with most acids and alkalis.

TsAMs do not enter into chemical reactions with chemical elements such as nitrogen, carbon, hydrogen, boron and silicon. Inert to ammonia at temperatures up to 480 degrees.

Zinc is a chemical element. Areas of use

- Zinc is actively used in the mining and extraction of precious metals (gold, silver) from enriched rocks. For example, if precious metals are mined by underground leaching, zinc metal is used as a reducing agent.

- In mechanical engineering, various methods of zinc coating are used to protect metal products from corrosion destruction.

- In the production of accumulators and batteries, zinc is used as a material for the negatively charged electrode. Zinc-air batteries have the highest specific energy capacity.

- In printing, printing plates made of zinc are used.

- Paint production – zinc white (zinc oxide).

- Zinc compounds are used in the production of semiconductors.

- Zinc sulfide is used to make the luminescent composition.

- In instrument making, zinc is specially introduced into some types of hard solders in order to reduce the melting point.

- Fiber production - zinc chloride is added to the flux for soldering metals and various components.

- The application area of zinc-copper alloy – brass – is wide. Most often, this alloy is used in mechanical engineering in the production of critical parts (precision casting).

- Zinc compounds are used in the manufacture of automobile rubber tires.

- In optics, zinc is used in the manufacture of special optical glasses that have a low absorption coefficient (in the mid-infrared spectral range).

- Medicine. Zinc. Zinc oxide is used to produce antiseptics and anti-inflammatory drugs.

- Rodent poison also uses zinc compounds (zinc phosphide).

Warning

Uncontrolled entry of metal into the body causes poisoning. It is generated by sulfates or chlorides. They can form when storing food in galvanized containers.

Symptoms of zinc vapor poisoning:

- Intense thirst.

- Sweetish taste in the mouth.

- Loss or decrease in appetite.

- Dry cough.

The person feels overwhelmed and tired. Feels drowsy, chest pain.

For severe poisoning, 1 gram of zinc sulfate is sufficient.

You need to remove toxins immediately. Their presence provokes anemia, growth inhibition, and infertility.

Properties and characteristics

So, what properties does zinc have?

Physical

- It is a medium hard metal.

- Zinc has no polymorphic modifications.

- Cold zinc becomes a brittle metal.

- It acquires plasticity at a temperature of 100-100 ºС.

- At a higher temperature of 250 ºС it again turns into a brittle metal.

- The melting point of solid zinc is 419.5 ºС.

- The temperature of transition to steam is 913ºС.

- The boiling point is 906 ºС.

- The density of zinc in the solid state is 7.133 g/cm3, in the liquid state - 6.66 g/cm3.

- Relative elongation 40-50%.

- Easily soluble in acids.

- Easily soluble in alkalis.

To learn how to properly melt zinc, watch the video:

Chemical

Chemical properties of zinc:

- 3d 10 4s 2 - atomic configuration.

- Zinc is considered an active metal.

- It is an energy restorer.

- Electrode potential: -0.76 V.

- At temperatures below 100 ºС it loses its shine and becomes coated with a film.

- In humid air (especially if it contains carbon dioxide), the metal is destroyed.

- During intense heating, zinc burns violently, producing a bluish flame.

- Oxidation state: .

- Acids and alkalis act differently on zinc depending on the presence of various impurities in the metal.

- When zinc is heated in water, a process of hydrolysis occurs with the formation of a white precipitate.

- High-strength mineral acids can easily dissolve zinc.

Physical properties

- Atomic number: 30.

- Atomic mass: 65.37.

- Atomic volume: 9.15

- Density: 7.133 g/cm3.

- Temperature required for melting: 419.5 C o.

- Boiling point: 906 C o.

- Surface energy: 105 mJ/m2.

- Specific electrical conductivity: 16.2*10 -6 S/m.

- Molar heat capacity: 25.4 J/(K*mol).

- Molar volume: 9.2 cm 3 /mol.

Zinc has weak mechanical properties; at normal temperatures it easily breaks and crumbles, but at temperatures of 100 C o -150 C o it becomes quite malleable and is easily deformed: it is forged and rolled into sheets. Plain water is safe for metal, but acids and alkalis easily corrode. Because of this, zinc in its pure form is not used for the manufacture of parts, only alloys.