Classification of quality carbon steels

High-quality carbon steels and structural steels can be classified according to the following criteria:

- By purpose:

- for use in mechanical engineering;

- for use in construction;

- According to the amount of impurities that reduce quality:

- ordinary quality;

- quality;

- High Quality;

- especially high quality;

- By composition:

- presence of carbon: low carbon;

- medium carbon;

- high carbon;

- low alloy;

- By delivery method:

- forged;

- rolled;

- calibrated;

- By processing:

- ordinary;

- boiler rooms;

- automatic;

- According to the degree of deoxidation:

- boiling (kp);

- semi-calm (ps);

- calm (no designation).

Visual classification of steel types

Deoxidation affects the homogeneity of the internal structures of the metal. The best in terms of homogeneity is calm (a, d), followed by semi-calm (c, f) and lower quality boiling (b, e). The internal structure is clearly shown in the figure.

Application of spring steels (some directions)

Spring steels live up to their name. An example are options marked 50ХФА, 60С2ХВА, 70С2ХА, others. They are characterized by excellent density qualities; it is worth noting the strength, reliability, elasticity, and viscosity of the material, which are also valuable when obtaining metal and subsequent use for its intended purpose. The described materials include low-alloy options, medium-carbon ones with a carbon content of 0.6 - 0.8%. If they are connected by welding, microscopic holes may appear, even in a longitudinal direction. They are used as raw materials in the production of various types of springs; they are also suitable for the production of springs for various areas of use.

There is a category of structural steels called upgradeable steels. In the middle they contain martensite, similar in shape with needles. When considering the dense content of these alloys, one can notice the exclusion of non-metallic additives, carbide segregation, and mesh. The main advantage of low-alloy and high-carbon steels with a C2 amount of less than 1.05% is a high degree of hardness; another factor is the percentage of wear.

One of the features that you should pay attention to is the marking starting with the letter “Ш” (ШХ5, ШХ 15СГ).

General characteristics of high-quality carbon steels

The main differences between high-quality steels and ordinary quality steels are:

- a small amount of quality-reducing impurities: sulfur and phosphorus;

- narrow range of carbon amounts;

- increased amount of manganese or silicon.

The steel is supplied from the manufacturer with a guarantee of the declared composition of chemical elements and their inherent mechanical properties.

Speaking about the characteristics of high-quality steels, the most significant ones should be highlighted:

- high strength;

- plastic;

- impact viscosity.

Changes in the structure of steel ingots during hardening

But to improve performance characteristics, employees of institutes and laboratories are experimenting with the chemical composition, methods of increasing the strength and hardness of surfaces, heat treatment methods, and methods of melting and casting metal. The mechanical properties of high-quality carbon alloys depend on the chemical composition.

Properties inherent in carbon alloys:

- Low carbon – low strength with high ductility. They are used in the production and manufacture of parts and assemblies with complex structures and light loads. Properties inherent in carbon alloys:

- 15-20 – for non-critical parts that do not require additional heat treatment or have been subjected to normalization.

- Medium carbon - for the manufacture of parts that require high hardness, but with reduced ductility. Products that require heat treatment: hardening of the surface layer, improvement, normalization. To facilitate cutting, medium carbon steels are annealed.

- High-carbon, as well as with additionally introduced manganese, have high elasticity and wear resistance. Therefore, spring products are made from it.

- Automatic – used for processing on automated machines. Phosphorus and sulfur in greater quantities contribute to the formation of small chips, which has a positive effect on the machinability and durability of the tool, but the roughness of the machined surfaces suffers.

Download GOST 1050-88

Use in construction industry

For structural steels that are purchased for use in construction, you should choose options with a low content of alloying components (silicon, chromium, manganese). Carbon should be 0.1 - 0.2%. This composition allows you to achieve high-quality connection of parts during welding. Features useful for the functional characteristics of construction buildings also appear. These include:

- malleability, viscosity;

- relative stretch;

- density of the crystal lattice structure, viscosity.

The choice for the industry associated with construction types of work in favor of low-alloy steels makes it possible to invest less money on the necessary raw materials. The savings percentage can be up to a third of what is needed. Alloying increases the degree of hardening, and the yield limit parameter also increases.

The most popular categories of the described steels, which come into production in the form of long metal, sheets, strips and rods, include options 14G2; 15HSND; 10G2S1; 18G2; 25G2S; 35GS.

Use of high-quality structural carbon steel

The scope of application is quite wide. The main consumers of alloys are the engineering and construction industries. One of the advantages is considered to be good weldability.

As the name suggests, “structural” means used for building metal structures. Another name is reinforcing steel.

Considering the main grades of quality steel used by industrial enterprises, they can be divided by purpose.

- High-quality low-carbon steels 05-10. Their main purpose is the production of responsible and high-quality structures using welding (increasing the amount of carbon helps to reduce weldability). A small amount of carbon after welding does not provoke the formation of cracks in both hot and cold conditions.

- High-quality low-carbon steels 12-20. Their main purpose is the production of structural elements and parts that are not critical, lightly loaded, and subsequently cemented. Processed by cutting, cold stamping, complex drawing. Surface requirements: wear resistance, high hardness with a soft core. We manufacture mechanical engineering elements (shaft, axle, bolt, coupling, fork, lever, flanges and others), as well as elements of boiler equipment operating at high pressure and temperatures from -40°C to 450°C (pipeline, tee, connecting flange and others).

- High-quality medium carbon steels 25-35. Parts made from this material operate under medium loads and low stresses. After chemical-thermal exposure, they have high strength of the surface layer, wear resistance, but with insignificant strength of the core of the part (nut, screw, pawl, hook, cam, sprocket, etc.).

- High-quality medium carbon steels 40-45. After heat treatment, products made from this material can withstand medium loads (shaft, gear, connecting rod, etc.) well. To obtain blanks, the method of hot die stamping is used. Subject to all methods of heat treatment. In all medium-carbon steels, after quenching and subsequent high tempering, the internal structure becomes tempered sorbitol. In connection with this, viscosity increases with plasticity, and this means low sensitivity of stress concentrators. As the diameter of the product increases, its hardenability decreases.

- High-quality medium carbon steels 50-55. Parts made from these steels are highly loaded elements of mechanisms and assemblies (clutch, gear, spring ring, etc.).

- High-quality high-carbon steels 60-80 (G). Parts are manufactured that are subjected to constant compression stresses, which are operated under friction conditions (eccentric, spring, spring, etc.), as well as those operating under heavy dynamic and static loads (torsion bar, cross).

- High-quality boiler steel 12K-22K. They are used in the manufacture of parts whose operation involves elevated temperatures and high pressure. To improve weldability, titanium is introduced into the composition, and deoxidation is carried out by aluminum. Vessels and boilers that work with turbines, combustion chambers on ships and steam units are made from it.

- Automatic steel. Widely used in the industrial production of fasteners for automobiles and assemblies operating under static loads (bolt, nut, stud).

Grades and characteristics of structural alloys for mechanical engineering

Engineering steels for special purposes are made with the addition of nickel or a combination of iron and nickel. Divided into the following groups:

- used for the manufacture of products by casting;

- automatic;

- with increased durability;

- with high corrosion resistance;

- ball bearing;

- spring;

- with high temperature resistance;

- cryogenic, do not lose their properties due to negative treatment; temperatures;

- heat-resistant.

Heat-resistant alloys, which contain a small proportion of silicon, can be used even in conditions in which the temperature limit reaches 5500 0C. Such carbon-containing steels, in addition to their own heat resistance, are distinguished by a number of significant data: they are well used in acidic and carburizing substances, and do not react with the appearance of rust in a gaseous environment. A significant disadvantage is the manifestation of creep properties when creating conditions under heavy loads. This is also important to take into account when selecting materials, calculating the required loads, and parameters for them. The presence of surrounding environments is also important.

The most popular alloys of such metals are 12Х13, 15Х25Т, 20Х20Н14С2, 15ХМ and others. From them you can produce:

- containers in which cementation of metal elements is carried out;

- parts of piston category engines;

- pipe products of various functionality.

The class of low-temperature alloys, which are distinguished by their highest viscosity and plastic properties, also includes steels with low carbon content and high-alloy alloys. Interestingly, the creep characteristics increase not only after the heating is reduced during the operating process. Heat treatment with normalization and tempering also has an effect. A symbolic designation of this type corresponds to GOST 5632.

Structural carbon-containing steels with heat resistance have a high degree of creep. They are also characterized by resistance to rust in certain conditions of an aggressive environment. Such materials are ideal for the production of rolled pipes, parts of turbines operating on the basis of steam and gas with temperatures ranging from 400 to 6500 0C. The most popular types among buyers are alloys 15ХМ, 15Х5М, ХН70У.

There is a group of steels described that is resistant to rust - corrosion. This was achieved by adding chromium to the composition (from 12.5%). It is this that improves quality indicators, including under the influence of aggressive environments. For this reason, they are used to produce parts of carburetors, pipes, steam turbine blades, and other things.

In turn, they are divided according to the structural features into the following types:

- martensitic (30Х13, 20Х17Н2, 95Х18);

- martensitic aging (09Х15Н8У);

- with austenitic and ferritic (12Х18Н10Т, 15Х28).

To obtain structural carbon steels with good weldability, the metal is tempered. Despite the fact that the properties of metals are different, including thermal stability, ductility and toughness, cryogenic steel, heat-resistant and heat-resistant steel are classified as alloys characterized by anti-corrosion properties.

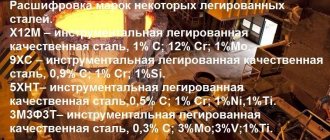

Marking features

An alphanumeric index is used for designation. The numbers indicate the percentage of carbon content (0.00%). The letters (kp, ps or sp) indicate the degree of deoxidation, the increased amount of manganese (G), aluminum (U), vanadium (F) and the processing method. The letter A in front of the numbers indicates an automatic alloy, the letter K after the numbers means a boiler alloy, PV is made by hot rolling, OSV is a metal for the production of railway car axles. To designate high-quality steels, in contrast to ordinary quality, “Steel” is written before the marking.

Examples:

- Steel 10. Carbon content is about 0.1%, the degree of deoxidation is calm.

- Steel 10 kp. The carbon content is about 0.1%, boiling according to the degree of deoxidation.

- Steel 20G. Carbon content is about 0.2%, manganese up to 1%.

- Steel 30G2. Carbon content is about 0.3%, manganese up to 2%.

- Steel A20. Automatic with an average carbon content of about 0.2%.

- Steel 20K. Boiler room with an average carbon content of about 0.2%.

| Structural high-quality carbon steel, grades, GOST standards. standards | ||

| Russia, GOST 1050-88 | USA, AISI | EU, DIN |

| Steel 08 kp | A622 | Fe P04/St 14 |

| Steel 10 | A1010 | 1.0301 |

| Steel 15 | A1015 | 1.0401 |

| Steel 25 | A1025 | 1.1158 |

| Steel 20K | A285-A | Р265GH |

Foreign manufacturers of similar products produce labeling according to their own standards.

Features characteristic of carbon-containing alloys

Low carbon – low reliability with excellent flexibility. It is used to produce parts that have a complex structure in terms of design, and which are affected by minimal degrees of load. Distinctive parameters of carbon-containing alloys: about 18 for non-critical products that do not require heat treatment or normalization.

With an average C2 content - to produce products that require high strength, but with reduced flexibility. Parts requiring heat treatment: hardening of the upper part, quality improvement, normalization. To improve the cutting properties of steel with a medium carbon content, steel is annealed.

Steels with a high C2 content and with manganese impurities have improved qualities in terms of service life and elasticity. This makes it possible to use them as raw materials in the manufacture of springs.

Automatic – used in machine tools with automated control. Elements P and S in sufficient volume result in the production of chips. This fact is beneficial for the processing process. The downside is getting a surface other than smooth.

Structural steels in the engineering industry. The characteristic features of the chemical composition make it possible to note two large categories in structural steels used for the manufacture of engineering products:

- low-carbon, medium-carbon;

- low alloyed, medium alloyed.

Carbon alloys must meet a number of high-quality and mechanical properties, the most important of which include:

- impact strength;

- flexibility;

- reliability.

The structure of most structural carbon steels used for the manufacture of components in the mechanical engineering industry is equated to the hypoeutectoid pearlite type. The most popular models are 30Kh2GSN2VM, 25Kh2GNTRA and others. In order to increase the astringent properties of carbon-containing alloys of this type, molybdenum and nickel are added to the mixture of components.

Some items made from engineering-grade steel undergo hardening. Such products are divided into the following types:

- without hardening;

- the upper shell is strengthened;

- the entire presented volume is strengthened.

Single categories of structural alloys for mechanical engineering (08kp, 15kp, St.3). They are mainly used to produce sheet metal, without heat treatment. Precisely because sheet metal is used to make a wide variety of objects by changing the shape while cooled. The highest requirements are put forward for the quality of plasticity. Good ductility is due to a small amount of silicon and carbon. In addition to the ability to perfectly change shape when cooled, a model of such a material is characterized by good behavior when making connections by welding.

Structural metal alloys are of high quality; they also undergo heat treatment:

- hardening of the top coating, after which the metal is (not always) tempered;

- hardening carried out using standard methods. After it, a tempering is also needed (combining types of heat treatment of steel makes it possible to perform a high-quality welding connection);

- normalization of the environment.

Structural alloy steel

The production of this type of steel complies with GOST 4543-71. It can be of high quality

,

high quality

and

especially high quality

.

The property of alloyed structural steel, such as weldability, is not very high. This is due to the fact that this type of steel has a predisposition to hardening of the heat-affected zone and the formation of brittle structures in its composition. Therefore, when welding it is necessary to use special technologies developed specifically for this type of steel.

Production methods and quality division options

The production of carbon steels is based on the processing of cast iron and ferrous scrap with the reduction of sulfur, phosphorus and carbon to the required concentration. At the same time, various technologies are used, which affect the quality of the metal produced. As a result, the following types of steel alloys are obtained:

- high quality;

- quality;

- ordinary quality.

The first two types of carbon steels are produced using converters, open-hearth furnaces and more modern electric melting furnaces. The chemical composition of such steels and the concentration of impurities contained are strictly regulated by GOSTs 1435–99 and 1050–88. Thus, for high-quality steel alloys, sulfur can be used in an amount of no more than 0.04%, phosphorus - no more than 0.035%, for high-quality steel alloys, respectively - less than 0.018% and no more than 0.025%. Carbon steels of these categories have a structure of increased purity.

The smelting of steel alloys of ordinary quality is carried out on the basis of oxygen converters and open-hearth furnaces, then large ingots are formed from them. In comparison with the previous two categories, carbon steels of ordinary quality are characterized by the content of a large amount of harmful impurities. According to GOST 380–2005, they contain up to 0.05% sulfur and up to 0.04% phosphorus. Such material is subjected to hot and cold rolling in order to produce thin- and thick-sheet material and wide metal strips.