Using different planting methods allows you to get a good harvest. The problem of sowing crops with small seeds is solved by using a manual seeder. Models on sale range from simple attachments to trailed devices for a walk-behind tractor or cultivator. When choosing, they are guided by the number of containers, additional accessories, adjustment parameters, and weight.

Advantages

A manual seeder for small seeds with your own hands allows you to save money and simplifies planting crops. Its characteristics are not very different from cheap purchased devices.

Positive aspects of self-production:

- from scrap materials,

- cheap.

Flaws:

- seeds of only one diameter (one crop),

- single row planting.

Note! Several seeders with different hole diameters practically automate seeding. A universal device is more difficult to make; manufacturing will require skill in working with metal and plastic.

Constructions

All models introduce seedlings into the ground; they differ in the method of sowing. Spreaders and planting equipment are provided.

Operating principle of spreaders

There are two types of spreaders:

- Manual: seeds pour out through the holes when you turn the handle of the device; there is a built-in distributor inside. The ability to adjust the diameter of the holes allows us to classify the devices as universal. Usually made of plastic. They are used for spreading fertilizers, but mainly as a manual lawn seeder.

- Mechanical: there is no motor, but there is a moving part. Seeds fall into the ground by periodically pressing a button on the handle while moving. One or more containers for seedlings are attached to the axis.

The main disadvantage of spreaders is the unevenness of sowing, so they are rarely used for vegetables, more often as a disperser for lawn grass.

Precision Fitting Devices

To uniformly sow vegetables, precision sowing devices are used, created on the principle of transmitting torque from the wheel to the shaft:

- Simple: the device moves, the shaft with recesses rotates, the seed from the cone-hopper falls on it, lingers in the recess, and then falls into the prepared groove with a given step. The seeding density depends on the distance between the recesses.

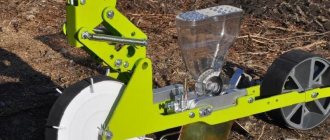

- Complex: the principle of operation is the same, but additional devices are added. Blades or spikes are attached to the front wheel to create grooves during movement, while the rear wheel is made level, which allows you to level the ground after landing. The supply of seeds to the shaft is regulated by a valve, and the seedlings move from the hopper along a special spout .

They are suitable for crops with small seeds, just like a seeder for regular lawn grass.

Note! The device allows you to work in a comfortable position, increases the sowing speed, and the seeds are distributed evenly.

Recycled materials, jars or plastic bottles will be useful when making a simple version of the product, and iron sheets, wheels, etc. will be needed for complex designs.

Kinds

Mechanical seeders are divided, in turn, into rotary and precision seeders.

A rotary seeder scatters seeds over a specified distance. At the same time, it works faster, but scatters randomly. The result may not please you.

With such sowing, the lawn may become overgrown unevenly, and you will again have to deal with bald spots on it.

A precision seeder is a mechanism for creating a perfect, even lawn. It is equipped with a coulter that makes furrows to a given depth. Seeds are fed from above and evenly placed in the furrows.

Have you decided to buy a seeder, and are you faced with the question of choosing a manufacturer? First of all, you should focus on your needs - the size of the plot, the range of functions and ease of operation of the mechanical seeder.

One of the main manufacturers whose products are in constant demand is GARDENA.

The price-quality ratio is the main advantage of this product.

GARDENA Classic 300

If you do not need a complex machine, pay attention to the brand of spreader-seeder GARDENA Classic 300. Its technical characteristics:

- spreading width – 45 cm;

- Hopper volume – 10 liters;

- ability to load different sizes of material;

GARDENA Classic 300

- locking the spread when moving backwards (allows you to control the planting volume);

- the presence of a special table for dosing seeds or fertilizers;

- elastic spreading cylinder ensuring uniform distribution of seed;

- two-wheel drive;

- Convenient control via T-handle:

- durable, corrosion-resistant hopper material;

- "tractor" wheel profile.

The seeder is small in size and is recommended for lawns of about 300 square meters. m. It can be used at any time of the year, it is convenient to store. Estimated cost – 3000 rubles.

GARDENA Comfort 500

This model is equipped in the same way as the previous one. It differs from it in a more capacious hopper - 14 liters - and a spreading width of 53 cm. The seeder is designed for sowing an area of up to 500 square meters. m. Cost about 4000 rubles.

GARDENA Comfort 500

Both models are convenient for applying fertilizer. A special measuring table allows you to very accurately set the dosage per 1 square meter of area.

Devices for planting carrots

In country garden beds, carrots occupy a small area, so for planting it is enough to use improvised means.

Manual planters

An easy way to spread seeds evenly in the garden is to use common household items to help plant the seeds at some distance from each other. Manual carrot planter includes:

- medicine box with dispenser - sowing is done by squeezing,

- medical syringe - push version,

- old salt or pepper shaker - the holes are widened for planting.

It’s useful to know, read: — Choosing a manual seeder for small-seeded crops.

A do-it-yourself carrot planter can be made from different materials:

- from a plastic bottle: you can drill or punch a hole in the cap using a nail or screwdriver. For sowing, a tube is inserted and the seeds are mixed with sand. If you cook a paste from flour or jelly from starch, and then add seedlings to it, then the tube will not be needed;

- from a block: screw or nail bottle caps to the board at a distance of 1.5–2 cm. They squeeze out holes in the garden bed, fill them with seeds, water them and cover them with soil. If the lids are replaced with wooden pins 5 cm long, you will get a manual garlic planter;

- from a wooden rake: the teeth are fixed perpendicular to the ground, they are used to make holes in a loosened bed, and plant a vegetable.

Seeders for garden beds

A more convenient way of planting is to make simple devices. A do-it-yourself carrot seeder includes a roller and consists of a round body, an axis of rotation and a handle-handle. In the body, the central hole provides the ability to rotate around an axis, and the diameter of the holes is for planting crops. The handle sets the roller in motion, the body rotates, and the seeds fall out.

Note! When using a homemade roller, you do not need to bend towards the ground. The height of the handle is adjusted to the height of the person. Allows you to plant other crops with small seeds.

A manual carrot seeder, made with your own hands: metal tubes that are bent at an angle depending on the height of a person are suitable for the work; the container for grains is made in the form of a cone or funnel from a sheet of iron. A hopper (one or several) with the top down, wheels and handles are attached to a metal axle.

Precision seeding mechanism

An important task of using seeding structures is to ensure uniform planting . To plant seeds in the ground at a strictly defined distance, manual precision seeding drills are used; these mechanisms are easy to make with your own hands, just like the simplest devices described above.

Design

The device consists of one or more containers with seeds, a frame on wheels, and a control handle. To independently manufacture such a unit, you will need a turning tool or a drill to drill metal sheets, the thickness of which is approximately 1 or 2 mm, and the diameter is about 5-8 mm.

When planning a connection between a seeder and a walk-behind tractor, it is better to use rigid bolts that are more vibration-resistant instead of rivets . The front wheels are designed to form furrows in the beds, where the seeds fall from the hopper. Using the rear wheels, the resulting holes are filled with loose soil.

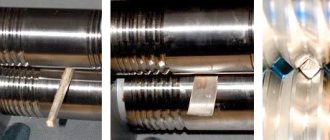

The basis of the precision seeding design consists of a rectangular metal frame. Containers are attached along the edges into which seeds are loaded. It is recommended to buy the blocks necessary for turning the shaft separately, since it is very difficult to make them yourself without special skills and tools. For example, containers that are used in conventional manual seeders or in conjunction with walk-behind tractors are perfect.

The precision seed drill is driven by reversible wheels, which also adjust the height of the head, designed to get the seeds into the ground . Each container must be secured separately. The wheels are connected on a springy and rigid base.

The sowing unit is a container in which the seeds are placed. When the seeder is dragged along the ground, a mechanical wheel with blades, also located in the container, is activated. At the end of the container there is a narrow slot where only one unit of planting material can be placed, so seeding is uniform and very economical. The size of the hole can be changed to accommodate seeds of different sizes.

Operating principle

When working with a manual precision seeder, first do the assembly, move the handle to the working position, and put the rear wheel on the axle. The marker can be adjusted if necessary. Depending on the crop being sown, a disc of a certain size is installed in the hopper. The depth of the chalk is adjusted to the size of the seeds.

This device forms the required depth of the holes. When the seeder is put into action, the front wheel of the structure begins to spin; with the help of a belt drive, the rotational movement is transmitted to the disk, which captures the seeds from the hopper.

Using a marker, smooth planting rows are formed. It is often recommended to carry out the first sowing along a certain contour for a more uniform distribution.

DIY making

The bunker container must be made of plastic. This makes it easier to visually control the number of seeds poured. Take the following components:

- A bolt that will be used as an axis on which the seed-filled container will rotate.

- A plastic pipe equal in length to the dimensions (depth) of the bunker. Steel pipe of the same length.

- Aluminum wire.

- Washers for fixing the pipe.

Assembly is a step-by-step process. Let's describe the algorithm :

- A through hole must be drilled in the center of the selected plastic jar. The cover is removed and an additional hole in the form of a rectangle (through) is made in the side wall. The hopper will be filled with seeds through it.

- We install a plastic pipe in the center of the jar to prevent the seed from spilling out. A steel pipe is installed into it, a bolt and nut are screwed in. The rotation mechanism is ready.

- On the side of the hopper, points are marked for holes at a distance of 30 mm. They are then pierced with a hot nail. The seeds should fit into the holes.

- They make a handle. A through hole is drilled in the wooden handle at the end. Using a bolt and nut, attach the handle to the seeder.

- To automate the process, a device is made from an iron sheet to fill planting holes with seeds.

- The workpiece is attached to the handle above the seed hopper.

The device is ready. Before starting sowing work, it is recommended to prepare the site and loosen the hardened soil.

Let's make a seeder from a plastic bottle

This seeder is inexpensive and simple.

Prepare a used plastic bottle and tool. A suitable bottle will be the one that suits you in volume: 0.5 liters, 1 or 2 liters.

Holes in the bottom of a plastic bottle can be drilled or pierced with a hot nail. To avoid getting burned, hold the nail with pliers over a fire or heating device. Holes must be made all over the bottom: first, a little and check by pouring the seeds, shake over the pan, if this is not enough, do more.

See the diagram for hole diameter:

Range of modern seeders

If making a planting unit yourself causes difficulties, it is recommended to immediately purchase ready-made structures. The assortment on the market is quite large. The American model of precision seeding “1001 - B” is equipped with 6 replaceable discs. With such a seeder you can plant 28 types of vegetable crops. Using the adjusting screw, you can change the planting depth.

Newtechagro seeders are single-row types. Designed for sowing beets, carrots, onions, and cabbage . But such designs are expensive.

But there are also cheaper analogues - precision seeders "SOR - 1/1". They are also single-row, can be equipped with a bush or brush sowing unit, the row marker is 0.5 m. This is quite enough for an average garden.

Using a manual seeder can significantly reduce labor costs, increases the speed of the planting process, simplifies the technology, significantly improves the quality of crops, and hence excellent harvests in the future.

Do-it-yourself precision fit device

The model is made according to a drawing prepared in advance. A simple version is made from a plastic or metal round jar with holes in diameter, their size is for the seeds of the planted crop, a pusher handle and an axis of rotation.

Another option is an axle with attached two wheels, a shaft, a grain hopper and a pusher handle. Notches are drilled into the shaft, but not holes. The seeds fall out of the hopper and are evenly distributed throughout the row thanks to these depressions. It is better to make the bunker out of plastic so that you can see the number of seeds, but a box made of wood or metal will also work.

You can attach a coulter to form furrows; to level them and cover them with soil, use a piece of foam rubber or a hoe. If several bins are installed on the axis, the planting width will increase.

Important! Before sowing, adjust the planting depth, row spacing, and seedling consumption rate.

A homemade seeder allows you to plant different crops with small seeds, beets, phacelia, etc.

The small seed model is suitable for small areas or greenhouses. It speeds up and simplifies the planting process and is safe to use. Depending on the budget, the device is purchased or made independently. Spreaders are suitable for planting lawns and alfalfa; precision sowing or universal models are suitable for vegetables.

Reviews from owners of lawn grass seeders

On the Internet you can find many reviews about lawn seeders, which often begin with the fact that their future owners were at first quite skeptical about the need to purchase such equipment. However, after trying it in action, they changed their minds. Indeed, it is convenient to use, saves time and nerves, and gives wonderful results. A smooth, dense lawn that brings considerable moral and aesthetic satisfaction to its owner. The owners note that the seeder becomes an indispensable assistant for this reason. Lawn grass seeds are very thin and small, so sowing them evenly by hand is quite a labor-intensive and difficult task. After the grass has sprouted, you need to repeat the sowing procedure several more times, achieving an impeccable result. With a lawn seeder, the same desired result is achieved much faster, more conveniently and easier.

“Refilling” the Gardena seeder with lawn grass seeds.

We are also pleased with the extreme simplicity of the design and use of such seeders. There is simply nothing to break in them, and in order to disable them, you need to set such a goal; it won’t work any other way. A lot of reviews also say about the need to carefully level the area for sowing the lawn; adding sand there and mixing it with soil; about the use of quality seeds. But this is, as they say, “a completely different story.”