Such a popular product as a brass pipe has a whole list of undeniable advantages. It is almost impossible to imagine furniture production without the use of pipes made of brass; they are successfully used for the installation of engineering systems for various purposes, in the production of industrial equipment, measuring instruments, and vehicles.

Pressed brass pipe L63

Regulations

You can familiarize yourself with the GOST requirements for brass pipes by downloading the document in pdf format from the link below.

GOST 494-90 Brass pipes. Specifications

The pipe, the material of manufacture is brass, can be produced in several ways - pressing, cold rolling, broaching. All brass pipes with a round cross-section profile, produced using such technologies, must meet the requirements specified by GOST 494 from the year 1990. This regulatory document stipulates that the dimensions and weight parameters of pipes manufactured using different technologies may differ. Thus, GOST regulates the following parameters of round brass pipes:

- outer diameter of cold-rolled and drawn products – 3–100 mm, extruded – 21–195;

- wall thickness of cold-rolled and drawn pipes is 0.5–10 mm, extruded pipes – 1.5–42.5;

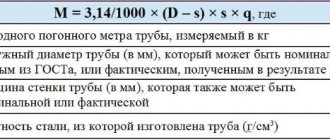

- the theoretical weight of one linear meter of products obtained by cold rolling and broaching is 0.0334–20.282 kg, pressed – 0.781–173.

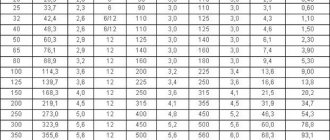

Weight of brass pipes (P - increased manufacturing accuracy; N - normal manufacturing accuracy)

Extruded pipes, which are made from brass alloys, are not divided into different categories based on the degree of accuracy. At the same time, a brass pipe produced using cold-rolled technology or the broaching method can be of normal or increased accuracy.

Regardless of the production technology, brass pipe can be produced in three lengths: measured, unmeasured (1–6 meters), multiple of measured. Brass products produced using broaching technology, the wall thickness of which does not exceed 1.5 mm (thin-walled), and the outer diameter of 10 mm, can have a length of 10 meters, and are sold to consumers in coils whose weight does not exceed 150 kg.

Thick-walled brass pipes are used in water heaters, air conditioners and refrigerators, as well as oil separators

The most important parameters according to GOST

When choosing a brass pipe, you should pay special attention to those parameters that are regulated by the provisions of the regulatory document. Thus, according to GOST, cold-rolled and drawn pipe products (both thick-walled and thin-walled) can correspond in terms of their hardness to one of three categories: soft, quarter-hard, semi-hard. A round brass pipe, if it is produced in a semi-solid version, must undergo a procedure during the manufacturing process such as the removal of internal tensile stresses.

The provisions of the regulatory document also set out the requirements for the surface condition of such profile products. Thus, in accordance with GOST, a round brass pipe should not have significant burrs, holes, or cracks on the surface. If the size of the defects, which also include dents, burrs and depressions, are insignificant and can be easily corrected by stripping, then their presence on the surface of the pipes is allowed.

Symbols for brass pipes

The regulatory document also allows the following defects on the surface of profile pipe products made of brass:

- redness;

- ringiness;

- traces of editing and tarnish;

- seam marks – for products produced by rolling and drawing methods from welded blanks.

GOST also stipulates such a parameter of brass pipe rolling as the cutting angle, which can be:

- up to 7 mm – for thick-walled pipes whose outer diameter exceeds 0.17 m;

- up to 5 mm – for pipes with an outer diameter from 0.1 to 0.17 m;

- up to 4 mm – for products with an outer diameter from 0.05 to 0.1 m;

- up to 3 mm – for pipes with a diameter of 0.02–0.05 m;

- up to 2 mm – for pipes whose diameter does not exceed 0.02 m.

Brass pipe L68 is a common type of non-ferrous metal, costing much less than similar copper products

For pressed brass pipes with an outer diameter of up to 12 mm, manufactured in quarter-solid and semi-solid versions, GOST specifies a parameter such as the degree of curvature per meter of length, expressed in mm. Thus, the following dimensions are specified:

- pressed pipes with an outer diameter exceeding 160 mm - 15 mm;

- pressed products of other diameters – 5 mm;

- pipes with an outer diameter of at least 13 mm, produced using cold rolling and drawing technology - 5 mm.

For cold-rolled and drawn brass pipes, which have a small outer diameter and are sold to consumers in coils, this parameter is not standardized.

There are also the following mechanical parameters for brass pipes:

- the value of relative elongation - for pipes made of brass grades LS59-1 and LS60 - 20%; for products made of brass brand L63 – 25–40%; LzhMts59-1-1 – 28%; Lc68 – 35–40%;

- the value of temporary resistance is 270–430 MPa.

Production Features

A brass pipe can be made from alloys of various grades, which may include alloying additives to improve their quality characteristics. In addition to differences in chemical composition, the brass from which tubular products are made may also differ in their phase state. According to this criterion, such alloys are divided into cast and wrought.

Brass pipes are produced in three ways: horizontal casting, hot (pressed) or cold (drawn) deformation

Depending on the wall thickness, pipes for the manufacture of which brass alloys are used are divided into thick-walled and thin-walled. Thick-walled products, produced in one-piece design, without the use of welded seams, are used in cases where they must transport gaseous and liquid media under significant pressure. Naturally, it is not advisable to use such brass pipes for the installation of domestic water supply: they are mainly used for installing communications at large industrial enterprises.

Thin-walled pipes, for the manufacture of which brass alloys are used, are optimally suited for use in domestic conditions. Such pipe products are used for installing water supply systems, for arranging boiler systems, as well as for solving many other problems related to the transportation of liquid and gaseous media. Thin-walled brass products are produced using two technologies: cold rolling and pressing. The high popularity of such products is explained by their exceptional corrosion resistance combined with fairly high strength.

Areas of application of brass pipes

From brass alloys of various grades, pipes are produced not only with round, but also with square, rectangular, hexagonal and oval cross-sections. They can be easily processed in various ways and are well connected by soldering; they are actively used not only in the construction industry, but also in the production of furniture, finishing work, and also for the manufacture of decorative interior structures.

Varieties of cross-sections of brass pipes

Connection with threaded fittings

In order for the plumbing or heating system to function smoothly, proper installation is important. To implement it, it is necessary to use polypropylene and brass fittings. They are needed to connect pipes of different sizes within the same engineering project.

In addition, fittings and clamps provide connection between the water supply system and water-consuming points.

Combination and brass fittings are threaded. This means that the pipeline in which they were used is detachable.

Modern plumbing systems can be repaired for upgrades or renovations in any area. After dismantling, fittings or clamps are reused without loss of performance.

To ensure an ideal connection, specialists usually use high-quality seals:

- FUM tape;

- sanitary linen;

- plumbing thread.

The market offers fittings without special coating (yellow) or galvanized. They have a white metallic tint.

A special category includes fittings with external threads for pipe extension: squeegees. Most often, elongated brass leads with a length of 100 or 200 mm are used. But in normal practice, short runs (barrels) can also be used.

Pentacles for pumping station

It is important that adapters, clamps or fittings are used from reputable manufacturers. The use of polyethylene analogues is not recommended: they are inferior in strength and reliability.

Only branded fittings and plugs ensure the tightest, tightest connections and eliminate the possibility of an emergency. Therefore, reviews about them are the most favorable.

Reviews of STR brass tee LS-59 1/2 vvn

Use for installation of plumbing systems

The most traditional types of pipes used in plumbing systems are steel, plastic, metal-plastic and, in some cases, copper. A brass pipe for arranging water supply lines is used when it is necessary to ensure the minimum weight of their elements. In all other cases, it is better to use rolled pipes made from other materials for installing a water supply system.

If pipes made of brass alloys are used infrequently when arranging water supply systems, then fittings made of this material are used very actively. The reason for the popularity of brass connecting elements is that, having a sufficiently high rigidity, they are able to provide the required tightness and reliability of the formed connection. It is also convenient that fittings made of brass are very easy to install: there is no need to use special equipment that requires exposure to high temperatures.

The use of brass fittings allows for quick and high-quality installation of communication systems made of steel, plastic and metal-plastic pipes.

Pros and cons of brass products

Since brass pipe is resistant to mechanical stress, it is often used in the installation of water mains in a private home. Products made of brass are not exposed to temperature changes, so there are no restrictions on their use in regions with frequently changing climates.

Important! Brass products of any shape and volume are durable. Subject to compliance with operating rules, they last up to 50 years.

Disadvantages include the susceptibility to cracking of parts that are manufactured using cold pressure techniques.

This technology can leave microscopic cracks inside. They are invisible during visual inspection, but during long-term operation foreign substances can penetrate into the cracks. This significantly reduces the performance of the product.

However, this can be avoided. Products made with low-temperature annealing are of higher quality.

LTs40S, LS59, L63T

Slow deep heating of the metal followed by gradual cooling eliminates the occurrence of microcracks. The same is observed when using the casting technique.

What is brass rod

It can have a rectangular, hexagonal or square cross-section. Manufacturing method: drawing or pressing.

There are many areas where rods are used:

- in shipbuilding;

- aviation technology;

- mechanical engineering;

- in instrument making;

- shipbuilding.

They are also used to make nuts, screws and some types of fittings. The technical conditions for the production of brass rods (also called brass circles) are stated in GOST 24301-93 (previously GOST 24301-80 was relevant).