Welded square pipe, a varied assortment of which allows you to select a product with the required geometric parameters, is produced according to the requirements contained in GOST 30245-2003. Replacing the outdated GOST 30245-94, this regulatory document defines the requirements for the range and geometric parameters of not only square, but also profile rectangular pipes, also classified as welded.

Square steel pipe

Read and download GOST 30245-2003 and GOST 30245-94

You can familiarize yourself with the contents of the document of state standard 30245-2003, which regulates the main parameters, nuances of the manufacture and operation of square pipes, and also download this GOST below.

GOST 30245-2003

GOST 30245-2003 Bent closed welded square and rectangular steel profiles for building structures. Specifications

Quite often, having set out to become familiar with the assortment of square pipes, people look for GOST 30245-94, which has now lost its relevance due to the fact that it has been replaced by a newer state standard document. But if you still want to compare them and find out what changes have been made, then this GOST can be downloaded for free below.

GOST 30245-94 Steel bent closed welded square and rectangular profiles for building structures. Specifications

Production of square profile pipes according to GOST

GOST 30245-2003 is an official regulatory document that specifies not only the dimensions of square pipes, but also the technological features of their production. Naturally, profile pipes that are produced by handicraft methods are strictly prohibited from being used in capital construction. Such products most often do not comply with GOST requirements not only in terms of geometric parameters, but also in terms of strength characteristics. In addition, they are not marked and are not considered goods admitted for public sale.

Line for the production of profile pipes

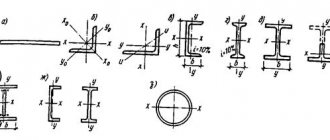

Basic geometric parameters of the product

The state standard stipulates a whole list of geometric parameters that metal profile pipes with a square cross-section must comply with. These parameters include:

- h – side dimensions or profile height;

- b – profile width (this parameter may differ from the height if the pipe has a rectangular cross-section);

- t – wall thickness;

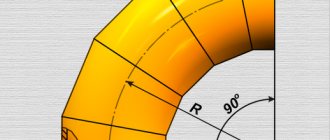

- R – radius of curvature (outer), measured at the intersection of the walls.

Parameters of the cross section of square profiles according to GOST 30245-2003

The regulatory document states that the geometric parameters of profile square pipes may have deviations, which must be within the limits presented below.

Along the outer radius of curvature

- for products with wall thickness up to 6 mm – 1.6t–2.4t;

- for products with a wall thickness of 6–10 mm – 2.0t–3.0t;

- for pipes with a wall thickness greater than 10 mm – 2.4t–3.6t.

According to the height/width of the sides of the steel pipe

- for pipes whose height/width of sides is 100 mm or less – from ±0.5 mm to ±1%;

- for products with side dimensions exceeding 100 mm – ±0.8%.

Based on the angle of intersection of the pipe sides (900), measured in the cross section of the profile

- ±1030´.

GOST 8639-82

GOST 8639-82 defines the geometric dimensions of finished square profile pipes, which can be manufactured using different technologies:

- by cold or hot seamless deformation;

- by electric welding cold deformation, electric welding.

The product range includes pipes with an outer diameter from 10 to 180 mm. Their cross-sectional area can be from 0.343 to 89.59 cm2, the wall thickness can be from 1 to 14 mm, and the weight of one meter can be from 0.269 to 70.33 kg.

The specified GOST provides information on the permissible size and weight of such products, as well as permitted deviations in dimensions during manufacturing and rounding of corners.

Thus, the permissible deviations of finished corrugated pipes from the requirements specified in GOST may be as follows:

- the curvature of the surface for each meter can be no more than 2 mm;

- deviations in external dimensions for electric-welded, cold-rolled products can be 0.25-0.4 mm, and for hot-rolled and electric-welded products with a diameter of more than 50 mm - 0.8-1.5%;

- the convexity and concavity of the sides can be from 0.5 mm (for pipes with a cross-section of up to 50 mm) to 1.5 mm (for products with a cross-section of more than 100 mm);

- deviation from a right angle in the cross section - no more than 1.5%;

- wall thickness, wall thickness - from +10% to -15%.

Side dimensions and wall thickness of a square pipe

According to GOST requirements, the dimensions of the sides of profile pipes with a square cross-section can vary in the range of 50–300 mm. In the range of these products, each profile size corresponds to a certain wall thickness: the larger the dimensions of the sides of the steel square pipe, the greater the wall thickness (this parameter varies in the range of 2–14 mm) they are produced.

All parameters that square pipes must comply with are given in the table.

Basic parameters of square pipes

Steel profile pipes with a square cross-section can be produced not only according to GOST, but also according to TU - these are specially developed Technical Conditions. In accordance with the requirements of this document, which is approved by the state regulatory body, pipes with a square profile can be produced in non-standard sizes (length, wall dimensions and thickness). Such products, the marking of which contains the abbreviation TU, are produced mainly on special orders.

When reviewing and approving the Technical Specifications, the state regulatory body assesses the degree of safety of products with non-standard sizes, provides for their mandatory testing, and also determines whether it is possible to produce it on the equipment with which the enterprise is equipped.

Assortment of steel profile rectangular pipes

The use of these products is most rational in structures for which the direction of the main load is known. It is used in the construction of frames, columns, racks, and floor beams. The range of rectangular profile pipes - seamless hot- and cold-rolled, electric-welded, manufactured by furnace welding - is determined by GOST 8645-68.

Advantages of metal products with a rectangular profile:

- light weight, ensuring convenient installation and transportation;

- high bending strength;

- right angles, providing convenient storage and good compatibility with flat surfaces;

- possibility of implementing different design and architectural solutions.

Table of assortment of profile pipes: the most popular sizes

| Dimensions, axb, mm | Wall thickness, s, mm | Weight 1 m, kg | Meters per ton | Dimensions, axb, mm | Wall thickness, s, mm | Weight 1 m, kg | Meters per ton |

| 15x10 | 1,0 | 0,348 | 2874 | 30x15 | 1,0 | 0,661 | 1513 |

| 1,5 | 0,488 | 2049 | 1,5 | 0,959 | 1043 | ||

| 2,0 | 0,605 | 1653 | 2,0 | 1,23 | 813 | ||

| 20x10 | 1,0 | 0,426 | 2347 | 3,0 | 1,71 | 585 | |

| 1,5 | 0,605 | 1653 | 30x20 | 1,0 | 0,74 | 1351 | |

| 2,0 | 0,762 | 1312 | 1,5 | 1,08 | 926 | ||

| 20x15 | 1,0 | 0,505 | 1980 | 2,0 | 1,39 | 719 | |

| 1,5 | 0,723 | 1383 | 3,0 | 1,95 | 513 | ||

| 2,0 | 0,919 | 1088 | 35x15 | 1,5 | 1,08 | 926 | |

| 25x10 | 1,0 | 0,505 | 1980 | 2,0 | 1,39 | 719 | |

| 1,5 | 0,723 | 1383 | 2,5 | 1,68 | 595 | ||

| 2,0 | 0,919 | 1088 | 3,0 | 1,95 | 573 | ||

| 2,5 | 1,090 | 917 | 3,5 | 2,2 | 455 | ||

| 25x15 | 1,0 | 0,583 | 1715 | 40x20 | 2,0 | 1,7 | 588 |

| 1,5 | 0,841 | 1189 | 3,0 | 2,42 | 413 | ||

| 2,0 | 1,08 | 926 | 4,0 | 3,05 | 328 | ||

| 2,5 | 1,29 | 775 | 45x20 | 2,0 | 1,86 | 538 | |

| 30x10 | 1,0 | 0,583 | 1715 | 3,0 | 2,66 | 376 | |

| 1,5 | 0,841 | 1189 | 4,0 | 3,36 | 298 | ||

| 2,0 | 1,08 | 926 | 50x30 | 3,0 | 3,36 | 298 | |

| 3,0 | 1,48 | 676 | 4,0 | 4,3 | 233 |

Square Pipe Length Requirements

Steel profile pipes with a square cross-section, in accordance with the requirements of the regulatory document, can be produced in unmeasured, measured, and also multiple measured lengths. When cutting, you should adhere to the following requirements, which are regulated by GOST.

- The length of the cut profile products should be in the range of 4–13 m.

- The most common pipe lengths supplied from the manufacturer's warehouse are 6 and 12 meters.

- Products of measured and multiple measured lengths should not have a deviation along it of more than 60 mm.

- The length of pipes supplied from the manufacturer’s warehouse is determined by the customer, but it must be within the limits specified in the regulatory document.

Long square pipes

Regulations for square pipes according to GOST

The technical parameters of square pipes are determined by GOST and deviations from the current standard are not allowed. Products produced by handicraft methods without the use of generally accepted technology are prohibited from being used in mass construction. Such products are not allowed to be labeled and are not considered goods.

Dimensions

The range of profiles with equal cross-sectional sides according to GOST determines the following product sizes: from 50 to 300 mm.

Within each side size, the product is sorted by wall thickness. The larger the cross-section applied to the pipe, the greater the wall thickness used. The range of products in wall thickness varies from 2 to 14 mm. Table 1. Parameters of square profile welded pipe

| h | t | Cross-sectional area A, cm2 | Reference values for axes | Weight 1 m, kg | ||

| mm | Ix,Iy cm4 | Wx,Wy cm3 | ix,iy cm | |||

| 50 | 2 | 3,9 | 14,4 | 5,7 | 1,96 | 3,0 |

| 2,5 | 4,7 | 17,2 | 6,8 | 1,93 | 3,6 | |

| 3 | 5,5 | 19,9 | 7,9 | 1,91 | 4,3 | |

| 4 | 7,1 | 24,5 | 9,8 | 1,86 | 5,5 | |

| 5 | 8,6 | 28,3 | 11,3 | 1,83 | 6,7 | |

| 80 | 2,5 | 7,7 | 74,6 | 18,7 | 3,12 | 6,0 |

| 3 | 9,2 | 89,5 | 22,4 | 3,12 | 7,2 | |

| 4 | 12,2 | 115,3 | 28,8 | 3,07 | 9,6 | |

| 5 | 15,0 | 138,0 | 34,5 | 3,03 | 11,8 | |

| 6 | 17,8 | 158,1 | 39,5 | 2,98 | 14,0 | |

| 100 | 3 | 11,6 | 180,2 | 36,0 | 3,94 | 9,1 |

| 4 | 15,3 | 231,3 | 46,3 | 3,89 | 12,0 | |

| 5 | 18,9 | 278,7 | 55,7 | 3,84 | 14,8 | |

| 6 | 22,6 | 326,3 | 65,3 | 3,80 | 17,7 | |

| 7 | 26,2 | 373,9 | 74,8 | 3,75 | 20,5 | |

| 120 | 3 | 14,0 | 315,1 | 52,5 | 4,76 | 11,0 |

| 4 | 18,5 | 408,5 | 68,1 | 4,71 | 14,5 | |

| 5 | 22,9 | 497,9 | 83,0 | 4,66 | 18,0 | |

| 6 | 27,4 | 583,4 | 97,2 | 4,61 | 21,5 | |

| 140 | 4 | 21,6 | 657,9 | 94,0 | 5,52 | 17,0 |

| 5 | 26,9 | 808,4 | 115,5 | 5,48 | 21,1 | |

| 6 | 32,1 | 947,1 | 135,3 | 5,43 | 25,2 | |

| 7 | 37,2 | 1077,1 | 153,9 | 5,38 | 29,2 | |

| 8 | 42,3 | 1201,7 | 171,7 | 5,33 | 33,2 | |

| 160 | 4 | 24,7 | 989,7 | 123,7 | 6,33 | 19,4 |

| 5 | 30,7 | 1214,6 | 151,8 | 6,29 | 24,1 | |

| 6 | 36,8 | 1435,1 | 179,4 | 6,24 | 28,9 | |

| 7 | 42,8 | 1640,8 | 205,1 | 6,20 | 33,6 | |

| 8 | 48,7 | 1836,9 | 229,6 | 6,15 | 38,2 | |

| 180 | 5 | 34,6 | 1749,1 | 194,3 | 7,11 | 27,2 |

| 6 | 41,4 | 2063,5 | 229,3 | 7,06 | 32,5 | |

| 7 | 48,2 | 2372,1 | 263,6 | 7,01 | 37,8 | |

| 8 | 54,8 | 2663,3 | 295,9 | 6,97 | 43,0 | |

| 9 | 61,5 | 2976,5 | 326,2 | 6,91 | 48,3 | |

| 10 | 68,2 | 3300,7 | 353,5 | 6,86 | 53,5 | |

| 200 | 5 | 38,4 | 2410,0 | 241,0 | 7,93 | 30,1 |

| 6 | 45,6 | 2832,0 | 283,0 | 7,88 | 35,8 | |

| 7 | 52,8 | 3236,0 | 324,0 | 7,83 | 41,4 | |

| 8 | 59,8 | 3621,0 | 362,0 | 7,78 | 46,9 | |

| 9 | 66,7 | 3987,0 | 399,0 | 7,73 | 52,3 | |

| 10 | 73,4 | 4336,0 | 434,0 | 7,68 | 57,6 | |

| 11 | 80,0 | 4667,0 | 467,0 | 7,64 | 62,8 | |

| 12 | 86,5 | 4980,0 | 498,0 | 7,59 | 67,0 | |

| 13 | 92,9 | 4685,0 | 527,0 | 7,54 | 72,9 | |

| 14 | 99,2 | 4408,0 | 554,0 | 7,49 | 77,9 | |

| 250 | 8 | 75,8 | 7315,0 | 585,0 | 9,82 | 59,5 |

| 9 | 84,7 | 8092,0 | 647,0 | 9,78 | 66,5 | |

| 10 | 93,4 | 8840,0 | 707,0 | 9,73 | 73,3 | |

| 11 | 102,0 | 9559,0 | 765,0 | 9,68 | 80,1 | |

| 12 | 111,0 | 10251,0 | 820,0 | 9,63 | 86,8 | |

| 13 | 119,7 | 10917,0 | 872,0 | 9,58 | 93,4 | |

| 14 | 127,0 | 11150,0 | 924,0 | 9,53 | 99,8 | |

| 300 | 8 | 89,9 | 12812,0 | 846,0 | 11,94 | 70,5 |

| 9 | 101,0 | 14302,0 | 949,0 | 11,90 | 79,3 | |

| 10 | 113,0 | 15712,0 | 1047,0 | 11,79 | 89,0 | |

| 11 | 124,0 | 17080,0 | 1139,0 | 11,74 | 97,3 | |

| 12 | 135,0 | 18330,0 | 1222,0 | 11,65 | 106,0 | |

| 13 | 145,0 | 19580,0 | 1309,0 | 11,62 | 113,8 | |

| 14 | 155,0 | 20784,0 | 1386,0 | 11,58 | 122,0 | |

In addition to standard products, non-GOST pipes can be found on the building materials market. Such products are manufactured in accordance with specifications (technical specifications), which are approved by the regulatory government body. The abbreviation TU in the marking indicates that deviations from standard sizes were deliberately made during production. As a rule, products according to specifications are manufactured to special order. For example, pipes with a length of more than 12 meters, or with a side size of more than 300 mm, with non-standard wall thickness, etc.

When establishing specifications, the controlling state body evaluates the possibility of producing a non-standard product on the existing equipment of the plant, the degree of safety of the pipe and technical strength tests.

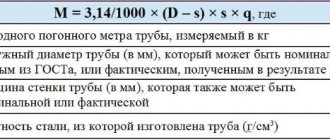

Geometry of steel pipes according to GOST 30245

The regulatory document establishes a certain geometry of profile pipes obtained by welding. Products must correspond to the profile shown in Figure 1.

where h – profile height; b – profile width; t is the wall thickness of the product; R – outer radius of curvature

Size deviations are allowed:

Outer radius of curvature:

- with a wall thickness of 6 mm – 1.6t…2.4t;

- from 6 to 10 mm wall thickness – 2.0t…3.0t;

- more than 10 mm – 2.4…3.6t.

The percentage deviation of profile height/width is:

- with a profile side value of up to 100 mm - no more than 1 cm in the direction of decreasing or increasing;

- with a size of more than 100 mm, a deviation of 0.8 mm in one direction or another is allowed.

- The strict geometry of the corners indicates the high quality of the products, however, GOST allows a degree deviation of 1030'.

Profile length

According to the standard, steel profile products are determined by measured and unmeasured lengths. Pipes of measured length can be multiples. When slicing, manufacturers adhere to the following parameters:

- Products must be at least 4.0 m, but not more than 13.0.

- The most commonly used lengths of profile pipes: 6.0; 12.0.

- Deviations in length are established by GOST in the amount of no more than 6 cm in one direction or another.

- The length of the profiles is determined by the customer, subject to the manufacturer's compliance with regulatory documentation.

How to understand the markings

The marking of square steel pipes, the requirements for which are also specified in GOST, reflects the following characteristics.

At the top of the marking (numerator):

- geometric parameters of the products of the marked batch (height, width, wall thickness);

- number of the regulatory document in accordance with which the product is manufactured.

At the bottom of the marking (denominator):

- grade of steel from which the profile pipe is made;

- number of the regulatory document to which the material of manufacture of the product corresponds.

Marking of square pipes contains information about product parameters

As an example, let's look at how a square-section profile pipe with side dimensions of 100 mm and a wall thickness of 6 mm, made of S390K steel, is marked:

100x100x5 GOST 30245-2003/S390K GOST 2772-88.

Features and advantages of square profile pipes

Such structures are excellent for use in frame and connecting elements of various buildings due to their following features:

- resistance to deformation, temperature changes, ultraviolet radiation, and resistance to wind loads;

- low weight compared to professional pipes of other sections;

- convenience and ease of installation, regardless of the type of structure, thanks to which it is possible to create various architectural structures, even non-standard ones;

- convenient shape, making storage, unloading and transportation much easier;

- high strength, resistance to even strong static loads;

- savings during construction work.

Features of the use of such products determine the advantages that characterize square corrugated pipes. They have the following advantages:

- reducing the cost of constructing even a massive foundation;

- high technology;

- simplicity and reliability of node connections;

- high speed of construction of various structures;

- minimum number of welded joints. It is possible to control their reliability and quality;

- ease of installation on flat surfaces;

- ensuring high-quality fire protection of structures in the construction of which square-section corrugated pipes are used, and compliance with fire safety requirements;

- reducing the metal consumption of the building being constructed. When using corrugated pipes of this cross-section instead of a standard I-beam, metal consumption is reduced by at least a quarter;

- ease of sanitary and hygienic treatment;

- use of wire when welding to facilitate installation work;

- the ability to build modern structures made of concrete and metal;

- high resistance to rust in comparison with other types of long products.

In Western countries, profile pipes of square and rectangular cross-section are actively used for the construction of original structures with non-standard shapes. They are built from concrete, metal and glass, and such profile products, due to their features and advantages, allow architects to realize the most daring ideas.

Profile square pipes are economically profitable to use in various construction fields. This will allow significant savings and ensure high reliability and stability of the buildings being built.

Dimensions and weights of square profile pipes

The dimensions of the profile square pipe must comply with GOST 8639-82, and the technical requirements of the entire product must comply with GOST 13663-86. This state standard regulates the assortment of general-purpose profile pipes made of carbon steel.

The table below shows some possible product sizes, wall thicknesses, and specific gravity.

| Size of square professional pipes, mm | Length, m | Weight, mp |

| 15x15x1.0 | 6 | 0,479 |

| 15x15x1.2 | 6 | 0,501 |

| 15x15x1.5 | 6 | 0,605 |

| 20x20x1.2 | 6 | 0,689 |

| 20x20x1.5 | 6 | 0,841 |

| 20x20x2 | 6 | 1,08 |

| 25x25x1.2 | 6 | 0,877 |

| 25x25x1.5 | 6 | 1,07 |

| 25x25x2 | 6 | 1,39 |

| 30x30x1.5 | 6 | 1,31 |

| 30x30x2 | 6 | 1,7 |

| 40x40x1.5 | 6 | 1,78 |

| 40x40x2 | 6 | 2,33 |

| 40x40x2.5 | 6 | 2,85 |

| 40x40x3 | 6 | 3,36 |

| 40x40x4 | 6 | 4,3 |

| 50x50x2.5 | 6 | 3,64 |

| 50x50x3 | 6 | 4,31 |

| 50x50x3.5 | 6 | 4,94 |

| 50x50x4 | 6 | 5,56 |

| 60x60x2 | 6 | 3,59 |

| 60x60x2.5 | 6 | 4,43 |

| 60x60x3 | 6 | 5,25 |

| 60x60x3.5 | 6 | 6,04 |

| 60x60x4 | 6 | 6,82 |

| 80x80x3 | 12 | 7,13 |

| 80x80x4 | 12 | 9,33 |

| 80x80x5 | 12 | 11,44 |

| 80x80x6 | 12 | 13,46 |

| 100x100x3 | 12 | 9,02 |

| 100x100x4 | 12 | 11,84 |

| 100x100x5 | 12 | 14,58 |

| 100x100x6 | 12 | 17,22 |

| 100x100x7 | 12 | 17,3 |

| 100x100x8 | 12 | 22,25 |

| 120x120x4 | 12 | 14,35 |

| 120x120x5 | 12 | 17,72 |

| 120x120x6 | 12 | 20,99 |

| 120x120x8 | 12 | 27,27 |

| 140x140x5 | 12 | 20,86 |

| 140x140x6 | 12 | 24,76 |

| 150x150x5 | 12 | 22,43 |

| 150x150x6 | 12 | 26,64 |

| 150x150x8 | 12 | 34,81 |

| 160x160x4 | 12 | 19,38 |

| 160x160x5 | 12 | 24,0 |

| 160x160x6 | 12 | 28,53 |

| 160x160x8 | 12 | 37,32 |

| 180x180x5 | 12 | 27,14 |

| 180x180x6 | 12 | 32,3 |

| 180x180x8 | 12 | 42,34 |

| 180x180x10 | 12 | 52,03 |

| 200x200x6 | 12 | 36,06 |

| 200x200x8 | 12 | 47,37 |

| 200x200x10 | 12 | 58,31 |

| 200x200x12 | 12 | 68,89 |

| 250x250x6 | 12 | 45,48 |

| 250x250x8 | 12 | 59,93 |

| 250x250x10 | 12 | 74,01 |

| 250x250x12 | 12 | 87,73 |

| 300x300x6 | 12 | 54,9 |

| 300x300x8 | 12 | 72,49 |

| 300x300x10 | 12 | 89,71 |

| 300x300x12 | 12 | 106,6 |

The table contains the most common types of square profile pipes, but the range is much wider.

Performance characteristics and applications of square pipes

The performance characteristics of steel pipes with a square profile are determined both by the material of their manufacture and by the features of their design, which is a closed profile formed from a metal strip. The result is a pipe that is lightweight but can withstand significant bending and torsion loads. The requirements for its strength characteristics, as well as the test methods by which they are controlled, are also specified in GOST.

Profile pipes are often used in load-bearing frames of various structures

Due to their exceptional strength characteristics, low weight and manufacturability, profiled metal pipes with a square cross-section have found wide application in many branches of human activity. So, these products are most actively used for:

- construction of buildings for various purposes (such pipes are used to construct lightweight load-bearing structures for warehouses, shops, greenhouses, winter gardens, farms, sheds, etc.);

- reconstruction of construction sites (with the help of square steel pipes, frames of roofing structures and ceilings, entrance lobbies, etc. are created);

- furniture production (cabinets, racks, shelves, tables, chairs, etc.);

- production of various mechanisms and devices in mechanical engineering;

- creation and installation of advertising structures.

Unlike pipes with a round cross-section, which, when exposed to significant bending loads, can not only bend but also collapse, products with a square profile under the same value and direction of the load only bend, and when it is removed they return to their original state.

When choosing a square profile pipe to solve a specific problem, you must first make all the necessary calculations. As a result, it will become clear which product with what geometric profile parameters will be able to withstand the loads that will fall on it.

Performance properties of welded square profiles

The manufacturing method, profile geometry and steel properties further determine the scope of application of square pipes. Due to closed welded sheet metal, products are created that are unique in their strength and can withstand heavy loads. The technology and quality of manufacture, strength tests comply with the standards defined by GOST 30245-2003.

Application of Welded Square Pipe

The main applications of steel square pipes:

- Capital construction – load-bearing lightweight structures (farms, greenhouses, greenhouses, indoor summer gardens, warehouses, shops).

- Reconstruction in construction - frame structures, entrance groups, roofing and ceiling elements.

- Furniture – frame chairs, tables (school furniture), racks, shelves.

- Mechanical engineering.

- Advertising designs.

The main advantage of profile pipes is their relative lightness with increased resistance to loads and small wall thickness. The closed metal contour creates high resistance to bending and torsion.

For example, by overloading a round steel beam, you can only achieve its critical bending (fracture). A square pipe under the same load bends, but does not break, and when the stress (load) is eliminated, it returns to its original state.

Each product with certain parameters has a strength limit, after which the load is considered critical. This parameter is calculated taking into account the geometry of the profile, its dimensions, pipe material, and the type of load on the beam. When using square profile steel pipes in construction, engineering calculations of loads are required - the reliability and safety of the future structure depends on this.

Method for making square steel pipes

In the production of square pipes that comply with GOST 30245, the following steels are used:

- carbon and low-alloy with a wall thickness of 3 mm (according to GOST 27772, GOST 16523, GOST 17066);

- carbon for general purpose with a wall of 4 mm (GOST 14637);

- low-alloy with a wall of 4 mm (GOST 19281);

- carbon steel 10, 15, 20 (GOST 1050).

The manufacturing process is as follows:

- Steel strips are cut from rolled sheets.

- Each workpiece is passed through rollers that bend the profile at an angle of 90 degrees.

- The connecting seam on one side is welded using an automatic production welding machine.

- The weld seam is processed for lack of penetration, fusion, and sharp edges. As a rule, equipment settings exclude the appearance of gross defects, but in any case, the plant’s quality control service checks the quality of the profile.

Steel profile production methods:

- hot rolled;

- cold deformation.

Production Features

Pipes with a square profile that meet the requirements of GOST 30245-2003 can be made from various types of sheet steel, which include:

- steels of the carbon group for general purpose and low-alloy grades, produced with a sheet thickness of 3 mm in accordance with GOST 27772;

- general purpose carbon steels produced in accordance with GOST 14637 (sheet thickness 4 mm or more) and GOST 16523 (sheet thickness 3 mm);

- high-quality carbon steels of grades 10, 15 and 20, produced in accordance with GOST 1050;

- low-alloy steel grades produced in accordance with GOST 19281 (sheet thickness 4 mm or more) and GOST 17066 (sheet thickness 3 mm).

Profile pipes prepared for transportation are stored in the factory warehouse

The production of steel square pipes of this category is carried out in several stages.

- Sheet metal, initially in rolls, is unwound and cut into strips of the required width.

- The ends of the resulting strips are welded to form a long strip.

- The steel strip is fed to a forming machine, where it is formed into a product with a square profile using special rollers.

- The connecting longitudinal seam obtained as a result of bending is boiled.

- The burr is removed from the weld seam (its height should not exceed 0.5–1 mm, depending on the wall thickness of the product).

- The quality of the weld, as well as the surface of the resulting pipe, is monitored. After eliminating deficiencies, if any are identified, the pipes are cut into pieces of the required length and sent for packaging.

Finished pipes undergo instrumental control for compliance with GOST requirements

In addition to the technology described above, steel pipes with a square profile can be produced by cold and hot deformation.