What defects can occur during the bending process?

Different bending methods have different causes of defects. Most often, the following types of defects are formed: sink marks at the bend, cracks, folds, discrepancies in size and shape.

We talked about the sinking above; it not only distorts the shape of the workpiece, but reduces its strength. To reduce the likelihood of its formation, a preliminary set of metal is carried out at the bending site and the workpiece is upset during bending.

On the outer layer of the workpiece, cracks usually appear on metal characterized by low ductility (not heated enough). If you bend a cold duralumin blank, then the appearance of cracks is the minimum that can happen to it. Such bending can result in complete destruction of the metal.

The most serious requirements are placed on bending workpieces made of high-carbon and alloy steels. In such cases, it is important to choose the right temperature, bending scheme, not to make a mistake with the minimum radius, etc.

If it is necessary to strongly bend the workpiece using bending, it is important to avoid the formation of folds on the inside of the forging corner, since stress is concentrated in them, which reduces the strength of the entire product.

If after bending the workpiece you find an inaccuracy in dimensions, then most likely the error was made at the stage of determining the length (volume) of the original workpiece.

If the shape of the product is not as accurate as planned, then the wrong choice of bending transitions was probably made, the initial workpiece was poorly prepared, or the wrong tool or bending method was selected. This may also be due to the fact that the work was performed by an inexperienced blacksmith.

Features of metal bending

The quality of products obtained using this metal processing method depends on the bending technology used. There are different technologies for different options:

- single-angle (V-shaped bending);

- two-angle (U-shaped bending);

- multi-angle;

- radius, with the help of which products such as clamps, hinges, etc. are produced.

The forces used when bending metal are small, so this process is most often performed in a cold state. Bending of sheets of low-plasticity metals, such as duralumin, titanium and its alloys, high-carbon alloys containing large amounts of manganese and silicon, as well as workpieces with a thickness of 12-16 mm is carried out after preheating.

Bending is most often combined with other methods of sheet metal processing: cutting, cutting, punching. In the case of the manufacture of complex metal products, stamps are used that are designed for several transitions. A special case of bending is stretch bending. This option is suitable for creating narrow and long parts with large bending radii.

When bending sheet metal, the following can be used depending on the size and type of workpiece:

- horizontal bending machines (forging bulldozers);

- vertical press brakes (with hydraulic or mechanical drive);

- horizontal hydraulic presses with two sliders;

- pipe benders and profile benders;

- universal bending machines.

In some cases, steel is even bent using explosive energy.

Sheet bending machines are characterized by reduced deformation rates, low energy consumption, and increased die space sizes. With the help of such machines, the source metal is adjusted to all specified parameters, resulting in a product with the desired configuration. Even manual bending machines, which can be found in private workshops, can be used to deform galvanized material.

The bending technology is quite simple, but the balance of deformations and stresses in the workpiece is quite difficult to determine. During bending, stresses appear in the metal - first elastic, and then plastic. The deformation during bending is uneven: in the corners it is most intense, and at the ends of the workpiece it is almost imperceptible.

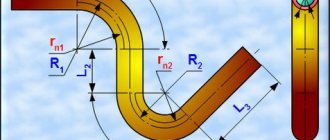

When bending thin sheet metal, the inner layers are compressed and the outer layers are stretched. The line separating these layers is called the neutral layer; this layer does not change its original length when the workpiece is bent. Such a line does not pass through the middle of the cross-section of the workpiece subjected to bending. Accurate determination of its location is one of the main conditions for defect-free bending.

During bending, rolled metal products receive the following distortions, which must be taken into account when developing the stamping process:

- spontaneous change in the final bending angle (springing/springing);

- change in thickness (this applies to blanks made from thick sheets);

- the appearance of metal flow lines;

- formation of folds on a metal sheet.