Hardening is a widely used heat treatment technology for steel products. Its essence is to heat the metal so that its temperature reaches a critical point, at which changes in the crystal structure occur or the process of phase dissolution begins to occur in the matrix formed at low temperatures of the part. After this, the metal cools sharply. As a result, the steel acquires a needle-type microstructure called martensite. Thanks to this phenomenon, the hardness of the alloy increases and its wear resistance increases.

Hardening temperature

The main criteria on the basis of which hardening modes are divided into types are the heating temperature and the speed of the technical process. There are also differences in such parameters as:

- time interval of exposure at certain temperature indicators;

- speed of the cooling procedure.

In general, based on the “heating temperature,” hardening can be of two types. Let's look at them briefly.

Complete hardening

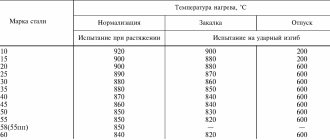

Hypoeutectoid steel is processed by complete hardening. It is heated so that the final temperature exceeds the critical point Ac3 by 30°-50°. Then the mixture of ferrite and cementite is completely transformed into austenite. With further cooling, a predominantly martensitic structure is formed.

Hardening is incomplete

Tool steels are most often subjected to the incomplete hardening procedure. Carrying out heat treatment of this type has the goal of heating the product until the process of formation of excess phases begins. In this case, the following temperature range must be observed:

Ac1≤Т≤ Ac2, where

- T – heating temperature;

- Ac1, Ac2 – critical points. In the first (+727°C), recrystallization begins - pearlite is transformed into austenite. In the second (+768°C) α-Fe transforms into β-Fe and the steel loses its magnetic properties.

If this temperature range is maintained, the martensite structure will retain a certain amount of ferrite after quenching the steel.

Incomplete hardening of a hypereutectoid alloy is of the highest quality if the product is heated to a level exceeding Ac1 by 20°C-30°C. Then, during the process of heating and cooling, cementite will not be transformed. Because of this, the hardness of martensite will increase. If the heating temperature of the part goes beyond the above range, this characteristic may, on the contrary, worsen.

What is the hardening of metal?

The ancient blacksmiths knew that the effect of high temperature on metal can change its structure and properties and actively used this in practice. Subsequently, it was scientifically established that hardening of products made of steel, which involves heating and subsequent cooling of the metal, can significantly improve the mechanical characteristics of finished products, significantly increase their service life and even ultimately reduce their weight by increasing the strength of the part. What’s noteworthy is that hardening parts made from inexpensive steel makes it possible to give them the required characteristics and successfully use them instead of more expensive alloys.

The meaning of the process, which is called hardening of steel alloy products, is to heat the metal to a critical temperature and then cool it. The main goal pursued by this heat treatment technology is to increase the hardness and strength of the metal while simultaneously reducing its ductility.

There are various types of hardening and subsequent tempering, differing in modes of implementation, which determine the final result. Hardening modes include the heating temperature, the time and speed of its implementation, the time the part is kept in a state heated to a given temperature, and the speed at which cooling is carried out.

The most important parameter when hardening metals is the heating temperature, upon reaching which the atomic lattice is rearranged. Naturally, for different grades of steel, the critical temperature value is different, which depends, first of all, on the level of carbon content and various impurities in their composition.

After hardening, both the hardness and brittleness of the steel increases, and a layer of scale appears on its surface, which has lost a significant amount of carbon. The thickness of this layer must be taken into account when calculating the allowance for further processing of the part.

Cooling Features

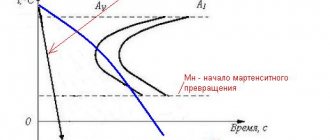

As is known, austenite is least stable at temperatures 550°С≤Т≤650°С. And the structure of martensite is formed when conditions are created for accelerated cooling of the alloy until its temperature index enters precisely this range. When the temperature falls below +240°C, the martensitic transformation is ensured by slow cooling. This technological solution leads to the fact that the stresses that arise in the metal body have time to level out. Moreover, without reducing the hardness of the formed martensite.

Successful heat treatment requires the correct choice of hardening medium. As such, the most commonly used are:

- mineral quenching oil;

- an aqueous solution of table salt (NaCl + H2O) or sodium hydroxide (NaOH);

- actually, water.

It is better to harden steel with alloying additives using oil. It is recommended to carry out this procedure with carbon alloys by cooling with water.

Features of hardening of various types of steel - methods, temperature, other nuances

One of the most common methods of heat treatment of metals is steel hardening. It is with the help of hardening that the required characteristics of the finished product are formed, and its incorrect implementation can lead to excessive softness of the metal (non-hardening) or to its excessive fragility (overheating). Our article will talk about what proper hardening is and what needs to be done to achieve it.

Characteristics of steel

In the context of this topic, steel has two important characteristics.

Hardenability

This characteristic reflects the fact how capable the steel is of becoming hard after undergoing the hardening procedure. There are alloys whose properties practically do not change as a result of this heat treatment, that is, the hardness remains at an insufficient level. They say about such a metal: “does not accept hardening.”

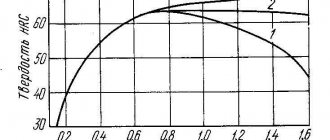

Metallurgy explains the high hardness of carbon-containing martensite by the distortion of its crystalline cells. This factor makes plastic deformation of the material difficult. The hardness index increases with increasing amount of carbon. In numbers it looks like this: the value of this parameter, established using the Rockwell method with the content of the element carbon (C) in steel at the level:

- 0.1%, equal to 30HRC;

- 0.7% is 64HRC.

But a further increase in the amount of carbon in the alloy does not lead to a significant increase in the hardness index. All this is displayed on the graph.

The following designations are used on it:

- pos. “1” – the heating temperature exceeds the Ac3 point;

- pos. “2” – the heating temperature of the product is 770°C, which is higher than only point Ac1;

- pos. “3” is an indicator of martensite hardness.

Typically, alloys with a carbon content of less than 0.3% are not subjected to the hardening procedure due to their low degree of hardening.

Hardenability

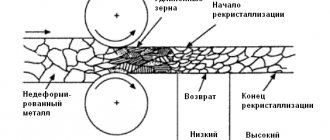

This characteristic indicates the depth of hardening of the steel. During this process, the core of the part cools more slowly than its surface. This phenomenon is explained by direct contact of the outer layer with a cooling substance that absorbs thermal energy. The situation is different with the central fragment of the product. Its heat is transferred through the thickness of the metal to the surface area, and there it is absorbed by the same cooling substance.

Hardenability is a characteristic derived from the critical hardening rate. This is understood as the lowest rate of supercooling of all austenite to the martensitic structural transformation. The depth of hardening is inversely proportional to this parameter. That is, the lower the speed of the above process, the deeper the hardening of the metal occurs. This is clearly manifested in alloys with large and small grains. The former are calcined to a greater depth than the latter, since they have a low critical speed.

Types of hardening

Quite a lot of methods for hardening metal have been developed today. When choosing a specific one, you need to consider:

- chemical composition of the material;

- design features of the product;

- a given hardness indicator of the final product;

- cooling process conditions.

Quenching in one environment

To better understand the features of the hardening procedure, consider the image below. It shows graphs of cooling lines characteristic of various methods of such heat treatment.

The progress of hardening in one environment is shown by curve “1”. This method can be implemented without any particular difficulties. But it does not apply to all steel products. In particular, problems may arise with parts with variable cross-sections. An accelerated decrease in their temperature indicators leads to:

- formation of internal stresses;

- temperature unevenness.

The combination of these factors usually causes warping and cracking of such products.

When performing this hardening method, cracks can also form in parts made from alloys with a high content of the element carbon. In this case, volumetric transformations of structural stresses cannot be excluded. For hardening in one environment, products with a simple configuration made from hypereutectoid steels are better suited.

Hardening in two environments

This method is represented by curve “2” in the above figure. Hardening in two environments is most often applied to tools made from steels with a high carbon content. This heat treatment method is implemented in 2 stages:

- the product is first immersed in water, where its temperature will enter the range of 300°C≤T≤400°C;

- then the part is moved into an oil-cooling working environment. There the product remains until it cools completely.

Step hardening

The features of stepwise hardening are shown by curve “3”. This method is done like this:

- First, the steel product is placed in a bath of molten salts. Here it is necessary to control that the temperature of the coolant exceeds the martensitic transformation temperature (this range is 240°C≤T≤250°C);

- then the part is cooled in oil or in open space under natural environmental conditions.

With step hardening, the likelihood of warping or cracking of the product is zero. Workpieces with a cross-section of no more than 30 mm, made from steels with alloying additives, as well as products with a cross-section not exceeding 8 - a maximum of 10 millimeters, made of carbon alloys, are subject to such heat treatment.

Isothermal hardening

In the above figure, heat treatment of this type corresponds to curve number 4. The technique for performing it is similar to the previous method. The difference lies in the length of time the alloy is kept in a bath of molten salts. For isothermal hardening, this time interval is longer.

This technological solution ensures comprehensive decomposition of austenite. On the graph, the shutter speed is shown by points “a” and “b” on the S-shaped line. There are no restrictions on the cooling rate of the alloy subjected to isothermal hardening - it can take values from any range. This heat treatment method has another advantage: the metal of the final product acquires toughness.

Light hardening

Carrying out light hardening requires the use of a specially equipped furnace. It must contain a protective environment. To obtain a light surface for the workpiece, which also does not have visible flaws, it is recommended to use step hardening. Upon completion, the steel must be cooled in a molten substance with the following chemical formula: NaOH is a caustic alkali. Before the hardening procedure, the product is heated in equipment called a salt bath filled with sodium chloride. The temperature should exceed the Ac1 point by 20°C-30°C. During cooling, the temperature of the medium is maintained in the range of 180°C-200°C. It includes:

- caustic soda (NaOH) – 25%;

- caustic potassium (KOH) – 75%.

This mixture is diluted with water in an amount of about six to eight percent of the total mass of alkaline components.

Hardening with self-tempering

This method is used in the production of tool steel. The essence of the technology is the removal of a steel product from the cooling environment until it cools completely. After this operation, thermal energy is retained in the thickness of the metal. At her expense, in fact, further vacation is carried out.

But you need to perform subsequent actions related to this procedure while monitoring the temperature of the part. Only when this characteristic reaches the value required for tempering is the product moved to a quenching environment, where it is finally cooled.

Control of the tempering itself is carried out on the basis of tarnish colors. They represent a spectrum of different shades that appear on the surface of the alloy when an oxide film forms on it. This phenomenon occurs when the metal temperature varies in the range 220°С≤Т≤330°С.

Self-tempering hardening is used in the manufacture of hammers for masons and mechanics; chisels of all kinds, from scarpels to cross-mixers; sledgehammers, both sharp- and blunt-nosed. In general, for tools that require high surface hardness without sacrificing toughness.

Cooling methods

When hardening steel parts, which is carried out with accelerated cooling, the likelihood of significant internal stresses occurring is very high. For this reason, metal warping occurs. Even cracking is possible. Preventing these negative phenomena is possible by cooling products in an oil environment, of course, if their production technology allows this.

A different approach is relevant for carbon steels. They cannot be cooled in oil. Therefore, this operation must be performed in water.

In addition to the cooling medium, the method of immersing workpieces into it is important from the point of view of the formation of internal stresses. In this case, the following rules should be followed:

- It is necessary to immerse parts, the design of which includes thin and thick fragments, into the hardening substance, starting with the larger one;

- drills, tools with which internal threads are cut - taps - in general, products characterized by an elongated configuration should be immersed without allowing their longitudinal axis to deviate from the vertical. Then they won't warp.

There are cases when it is necessary to harden only part of the part. This problem is solved by using local heat treatment. Only the required fragment of the product is heated, and the entire part is subject to immersion in the quenching liquid.

What does proper hardening of steel improve?

If you ask the average person who has nothing to do with knife forging, the question “What does hardening give?” he will first talk about strength. In general, he will be right, although of the several qualities that hardening improves, hardness will still be the leader. But first things first.

- The hardness of blade steels is typically measured using the Rockwell Hardness Scale (HRC); European knives barely reach 60 HRC, Asian knives slightly exceed this mark. If we scratch two identical alloys of different hardness against each other, marks will remain on the softer one; Thus, hardness gives us an idea of how well an alloy resists mechanical damage.

- Strength usually means steel’s resistance to destruction (bending, impact, etc.) - for a knife this is important when, for example, we test it “for bending”. If the steel is damp, the blade will remain partially deformed after bending. True, if the steel is overheated, it will be even worse - the blade will break; Therefore, when hardening, it is important to maintain a golden mean.

- Elasticity. This is exactly what we talked about a little higher - the ability to return to its original shape after removing the load. If the hardening is done according to all the rules, everything will be fine with this indicator: when bent by about 10 degrees (and for thin kitchen knives up to 30), the blade will return to its original shape.

- Wear resistance. The correct hardening regime improves all the indicators that are included in this concept: the ability to resist mechanical and abrasive wear, the ability to hold an edge and resistance to shock loads.

The main thing in the pursuit of all these qualities is to achieve by hardening such a compromise of all the above properties so that the knife cuts well and is durable.

Possible defects during hardening

During the hardening process, some defects may appear in the workpieces. Only the most significant ones are described below.

Insufficient hardness

Insufficient hardness in a product that has undergone a hardening procedure most often appears when:

- the temperature of the heat treatment performed was incorrectly selected;

- the cooling rate was lower than that specified in the flow chart.

For example, during hardening of hypoeutectoid steels, this defect usually occurs due to the retention of ferrite in the structure of the alloy. This phenomenon occurs due to a violation of technology. In this case, the quenching temperature was simply not brought to the value corresponding to point Ac3.

Continuing the conversation about hypoeutectoid alloys, it is necessary to note another possible reason for the insufficient hardness of the material. This is overheating. As a result, martensite is formed, characterized by a coarse-needle structure. This structure not only reduces the hardness of the metal, but also reduces its impact strength. By the way, overheating manifests itself in a similar way in hypereutectoid steels.

Formation of soft spots

The reasons for the formation of soft spots are as follows:

- heterogeneity of the alloy structure;

- during the cooling process, the products came into contact with each other;

- uneven cooling;

- the presence of grease stains on the surface of the parts.

To correct this defect, the product is hardened again. Elimination of structural heterogeneity is carried out by preliminary normalization.

Carbon oxidation and combustion

Decarburization (the so-called burnout of carbon during hardening) and oxidation occur as a result of the interaction of the surface layer of the product with molten salts or furnace gases. The combination of these defects poses a particular danger to cutting tools. Its durability decreases significantly.

Such a defect in heat treatment cannot be corrected. The only thing that can save the situation is a sufficient allowance. Then the defective layers are removed by mechanical processing, and sometimes only grinding is sufficient.

Burnout

Burnout occurs when the heating temperature approaches the melting point of the metal. For this reason, what happens:

- penetration of oxygen into the thickness of the steel, accompanied by the formation of oxides at the grain boundaries;

- melting the material along the grain boundaries. This phenomenon, although rare, does happen.

As a result, the continuity of the alloy is broken, which puts it in the category of irreparable defect. That is, it is unsuitable for use.

Hardening cracks

The reasons for the appearance of hardening cracks are as follows:

- a part in the design of which there were sharp changes in the configuration of sections was subjected to heat treatment. It is in these places that significant internal stresses are formed, causing cracking;

- cooling was carried out extremely quickly;

- heating was carried out unevenly and also unnecessarily accelerated.

Another possible option for the appearance of cracks is that the product was subjected to a tempering procedure with some delay (not directly after hardening), due to which the internal stresses were not leveled in a timely manner.

Warping and deformation

Distortion of the product configuration - warping - causes uneven cooling. The change in volumetric characteristics - deformation - is associated with structural transformations that occur during heat treatment. These defects in the hardened alloy are due to the difference in the specific volumes of the formed structures. In particular, the value of this parameter of pearlite is less than that of martensite. In addition, thermal and structural stresses have different effects on the change in shape of different products.

To prevent the formation of these defects, the cooling procedure must be carried out at a slow rate in the temperature range of martensitic transformation using both isothermal and step hardening methods.