Bending a metal pipe is often a labor-intensive task that requires skill and knowledge, as well as special tools. It is especially difficult to make curved parts from thin-walled pipes and some types of profile pipes. A curved pipe at a private construction site, in a house, in a country house and in everyday life is needed not only for the installation and repair of internal pipelines, but also for various crafts, for repairing, strengthening structures and components of outbuildings, for small forms of landscape - it is difficult to list all the areas where curved pipe parts are required.

Electromechanical pipe benders

Most often, they are used to bend pipes with different cross sections. The main difference between an electromechanical pipe bender and other machines of this type is the high accuracy of the bending radius and the complete absence of the need for human effort.

The cost of these devices is quite high, so they are mainly intended for professional use. Using electromechanical pipe benders, you can bend pipes of significant diameters: the limitation in this case is solely the dimensions of the machine itself

When bending steel pipes in this way, it is important to strictly adhere to the relevant standards. For this purpose, there are special interchangeable templates in a wide range of sizes.

Method for measuring pipe curvature

This method for measuring the curvature of pipes establishes the procedure for measuring the curvature of pipes manufactured according to these technical conditions.

The methodology was developed based on GOST 26877.

1 Accuracy standards and measuring instruments

When performing measurements according to this method, the measuring instruments and their accuracy standards are in accordance with the Appendix to these technical conditions.

2 Measurement methods.

Measuring the curvature of pipes should be carried out by measuring the gap between the string (line) and the surface of the pipe in accordance with Figure B.1.

The overall curvature of the generatrix over its entire length is determined by using a string stretched over prisms and measuring with a ruler the greatest distance from the surface of the pipe to the string.

The value of the total curvature of the generatrix is determined as the absolute value of the difference between the measured distance and the height of the prism.

The curvature of the pipes is determined by:

- in the case of curvature of diametrically opposite generators of the same sign (both generators are convex or concave) - as the absolute value of the half-difference of the measured values;

- in the case of curvature of diametrically opposite generatrices of different signs (one generatrix is convex, the other concave, or one generatrix is curved and the other is straight) - as the absolute value of the half-sum of the measured values.

The curvature of pipes with a local change in diameter is not measured.

The permissibility of areas on a pipe with local changes in diameter is assessed by established requirements for diameter deviation.

Pipe bending methods and their advantages

Pipe bending is a technology where the desired rotation in the direction of the pipeline line is created by physical impact on the workpiece, the method has the following advantages:

- Reduced metal consumption; there are no adapter flanges, couplings or pipes in the line.

- Reduced labor costs when installing pipelines compared to welded joints.

- Low hydraulic losses due to unchanged profile section.

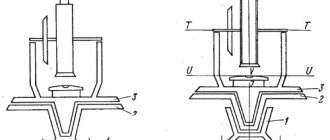

Rice. 3 Mandrels for pipe benders

- Unchangeable structure of the metal, its physical and chemical parameters compared to welding.

- High quality sealing, the line has a uniform structure without breaks or joints.

- Aesthetic appearance of the highway

There are two main bending technologies - hot and cold, devices and methods can be divided into the following categories:

- According to the type of physical impact, the pipe bending unit can be manual or electric with a mechanical or hydraulic drive.

- By bending technology - mandrel (bent using special internal protectors), mandrelless, and rolling installations with rollers.

- By profile - installations for metal profile rectangular or round products.

Rice. 4 Hot pipe bending methods

Hot bending

This technology, popular in everyday life, is used in cases where there is no pipe bending machine or it is not possible to carry out work using a cold method; the process consists of several operations:

- The workpiece is filled with fine-grained river sand without foreign inclusions in dry form. To do this, insert a plug at one end, fill it with sand and close the hole on the other side.

- The bending point is heated to a temperature of no more than 900 degrees to avoid burnout, and the part is gradually smoothly mechanically wound around a round template.

- At the end of the process, the plugs are removed and sand is poured out of the workpiece.

Cold bending methods for round pipes

Cold methods have undeniable advantages over hot technologies: they do not damage the structure of the metal, are more productive and require less costs. The following defects occur during cold bending:

- reducing the cross-section of the pipe on the outside of the profile;

- curvature in the bend in the form of a corrugation on the inside;

- changing the profile shape at pipe bending points from round to oval.

Rice. 5 Bending metal profile blanks at home

Most often, such defects occur when thin-walled pipes are deformed, so when operating with them, an internal protector is used - a mandrel inserted into the internal cavity.

The mandrel is a device consisting of a rigid rod with movable segments on the edge of a spherical or hemispherical shape. Before work, the device is placed in the internal cavity of the workpiece so that its moving elements are located at the bending point; at the end of the procedure, the mandrel is removed from the finished element and the process is repeated.

e = . 100, w

where Dmox is the maximum diameter at the bending point, mm;

В min — minimum diameter at the bending point, mm;

IN NO. — nominal diameter at the bending point, mm.

The percentage thinning of the minimum pipe wall thickness (&) is calculated using the formula,

where is the wall thickness along the outer part of the bend, mm;

Shom—nominal wall thickness, mm.

Berezovka. Printing house. Zzk. hi 37-3000

|Ish. N" mean. 1_Signature and dago >In return. ina. Ht Ii.” Ht dubya. Signature and date

Permissible deviations when bending pipes according to the ovality of the cross-section are given in table. 5, according to thinning in table. IN.

Section ovality, %, no more

Nominal wall thickness, mm

Allowable wall thinning in relation to the nominal thickness,%> no more

Note: The reduction in the nominal wall thickness at the bending site should not exceed the sum of the tolerances: minus tolerance according to the standards specified in the introductory part, and thinning during bending - according to Table 6.

2.4. In places where pipes are bent, corrugations are allowed in height, mm, no more than:

2 - for pipe diameters up to 25 mm;

3 - with a pipe diameter of 25-60 w;

4 - with a pipe diameter of 60-100 mm:

5 - with a sales pipe diameter of 100 mm.

2.5. Cracks, stains, flaws, sinkholes and sunsets are not allowed on the surface of the pipes.

Plastic pipes

Bending plastic is a rather complicated procedure, since there is always a threat of damage to the material and a decrease in wall thickness. A more optimal solution is to purchase a special rotary adapter. If for some reason it is not possible to use a square, the procedure for bending a plastic pipe is carried out using a construction hair dryer.

The optimal temperature in this case is 140 degrees. Warming up the bending area should be done slowly to prevent overheating. The fact is that at a temperature of 175 degrees, plastic usually begins to melt.

After the product acquires the necessary plasticity, it is carefully bent. To ensure that the thickness of the outer walls does not change, it is covered with small pieces of plastic and also heated

In this way they are welded, and the area in the knee receives additional protection from breakthrough.

Results

Pipelines make people's lives much more comfortable and efficient, and this applies to both the domestic and industrial spheres. When arranging various communications, it is almost impossible to avoid turns and bends, for the organization of which various devices and methods are used

When bending pipes made of various materials, it is very important to avoid haste and strictly follow the rules for bending pipes.

Aluminum pipes

Aluminum pipes bend in much the same way as copper pipes, because the degree of flexibility of these metals is very similar. In general, bending aluminum pipes does not pose any particular difficulties. In addition to sand, in the case of aluminum, you can use water frozen inside the pipe. Naturally, this method can only be implemented in frosty weather.

To do this, you will need to plug one end of the pipe with a chopper in order to pour water inside it. After this, the product filled with water is exposed to the cold until the liquid freezes completely. The further procedure is carried out in exactly the same way as in the case of sand.

Example of pipe bending

Bending aluminum pipes is approximately the same as copper pipes. The reason for this is the malleability of these two metals. But in the case of aluminum, you can also use ice. To do this, simply pour water into the cavity, after placing the plug on one end. Bay, you need to put it outside (a prerequisite is frosty weather). After the water has completely frozen, you can gradually bend it. Ice works just as well here as sand.

Example of pipe bending

RD 24.203.03-90 Radii and bending angles of pipes

Buy RD 24.203.03-90 - a paper document with a hologram and blue seals. more details

We have been distributing regulatory documents since 1999. We punch checks, pay taxes, accept all legal forms of payment without additional interest. Our clients are protected by law. LLC "CNTI Normocontrol"

Our prices are lower than other places because we work directly with document providers.

Delivery methods

- Express courier delivery (1-3 days)

- Courier delivery (7 days)

- Pickup from the Moscow office

- Russian Post

The guidance document establishes the radii and bending angles of copper pipes in accordance with GOST 617, seamless steel pipes in accordance with GOST 8732 and GOST 8734, seamless pipes made of corrosion-resistant steel in accordance with GOST 9940 and GOST 9941, steel water and gas pipes in accordance with GOST 3262, as well as pipes made of copper and aluminum alloys .

The RD does not apply to the bending radii of rolls, coils and pipes included in the apparatus of compressor refrigeration units.

Metal-plastic pipes

As metal-plastic pipes spread, many began to use them in all possible communications. They are reliable, practical, inexpensive and easy to install. But how to bend metal-plastic pipes? To do this, either simple manual labor is used (if the metal in the pipe is soft), or the bending method using a spring (discussed above). It is mandatory to fulfill the condition that the metal-plastic pipe cannot be bent more than 15 degrees for every 2 centimeters. If this parameter is neglected, the pipe may simply become unusable due to a large number of damages.

Bending in dies using pressing

Bending of blanks no longer than 70 centimeters can be done using stamping. In this case, hydraulic or mechanical presses are used. This method allows the production of structural elements with complex shapes.

Pressing blanks is the most expensive bending method. However, its productivity is the highest. This method allows us to produce a wide range of products.

Pipe bending machine equipment

Pipe bending on an industrial scale is carried out using machines.

Bending by rolling.

The most common machines are those that bend products using rolling. The most commonly used equipment is with three rolls, designed for bending long workpieces. It can be used to produce spiral pipes.

The product moves through rollers, the location of which determines its bending radius. At the same time, it is compressed on both sides by a deforming cylinder. It is located between the rollers, so that it is possible to bend the workpiece in weight. Rollers serve as a support during metal processing.

Compression processing

Often in production, machines are used that bend workpieces with a small radius using a compression method. They process workpieces of small and large cross-sections. The process occurs with local heating of the products and simultaneous axial pressure on them.

The machine consists of:

- bed with a heater located on it;

- support roller;

- pairs of pincer clamps, the first of them is bending and rotary, the second is sedimentary.

The device is capable of bending elements at an angle of 180º. It clamps the workpieces with a constant force, regardless of their cross-section and the value of the axial force generated at the epicenter of deformation during bending of the product. The equipment can process square and rectangular profiles.

Rotary stretch bending

Rotary pipe drawing is carried out on machines with electric or hydraulic supports for moving pressure rollers. The latter serve to obtain the desired configuration and thickness of the produced element.

With rotary drawing, products are produced from hollow rotating rods, deformed by rollers along a moving mandrel. Nowadays, CNC rotary drawing machines are used in most cases. Their program takes into account the resistance of the material when it is deformed. When manufacturing products, the corresponding GOST is used.

Conclusion

Watch the video

In small volumes, pipe bending can be done using hand tools. On an industrial scale, this is done on special machines. Before work, it is necessary to calculate the minimum permissible bending radius.

Add to bookmarks

Home craftsmen today independently carry out almost all vital systems for their farms: plumbing, heating, sewerage; they build low-rise buildings, utility rooms, and greenhouses. They invent inexpensive devices for the manufacture and processing of building materials, bending all kinds of profiles, cutting and bending various pipes, and use welding and casting technologies.

Pipe bending is used to create metal fences; this allows you to eliminate the need for welding and achieve the desired result by simply bending a solid pipe at the required angle.

There are no recurring reasons for frequent bending of pipes in private households.

The task is to take and bend the required part.

Methods and features of bending square pipes

In order to bend the corrugated pipe at a certain angle, you can use several methods:

The pipe bender is designed for cold bending with tension. This method significantly reduces the possibility of the formation of a corrugated surface on the pipe bend.

- The use of a special machine is a reliable, proven modern method that requires the presence of professional equipment that may not always be at hand. A profile bender—that’s what this machine is called—will bend metal elements of any cross-section, but it is not possible to find it at the right time.

- If bending a professional pipe is a one-time job, you can use pipe benders for round pipes. The pipe bender has a small but significant drawback: the work will require a gigantic effort to bend a corrugated pipe of even a not very large cross-section, so this option has to be discounted.

- If you do not have heroic strength and a large amount of financial resources to purchase professional equipment, then you can contact one of the many workshops where you will quickly and inexpensively be provided with services for bending any metal, including profile ones. This option is optimal and will allow you to bend the pipe to the desired radius or angle the first time and not damage additional pipes during training.

Pipe bending radius for devices used in everyday life and industry

On the construction market you can find a large number of devices for individual use for bending pipes, from simple springs to complex electromechanical machines with hydraulic feed.

Manual pipe benders

Pipe benders of this class are low cost, have a simple design, low weight and dimensions; the process of bending the workpiece occurs due to the physical effort of the worker. Based on the principle of operation, manual units produced by industry can be divided into the following categories.

Lever. Bending is achieved through a large lever, which reduces the applied muscle force. In such devices, a workpiece is inserted into a mandrel of a given shape and size (punch) and, using a lever, the product bends around a template surface - the result is an element of a given profile. Lever devices allow a 180-degree radius of curvature and are suitable for small diameter soft metal pipes (up to 1 inch). To obtain curves of various sizes, replaceable punches are used; to facilitate work, many models are equipped with a hydraulic drive.

Rice. 7 Hand-held crossbow devices

Crossbow. During operation, the workpiece is placed on two rollers or stops, and bending occurs by applying pressure to its surface between the stops of a punch of a given shape and cross-section. The units have replaceable punch attachments and movable stops that allow you to set the bending radius of a steel pipe or non-ferrous metal workpieces.

The bending shoe is mounted on a rod, which can be moved by a helical gear, hydraulic fluid pressure when manually pumping, or by electrically driven hydraulics. Such devices allow bending of pipes made of soft materials with a diameter of up to 100 mm.

Three-roller units (pipe bending rollers). They are the most common type of pipe bending units in everyday life and industry; they operate on the principle of cold rolling. Structurally, they are made in the form of two rollers, in the grooves of which the workpiece is installed, the third roller is gradually brought to the surface, simultaneously rolling the product in different directions. As a result, the workpiece is deformed without folding into a larger cross-section than in other manual pipe benders.

A distinctive feature of the unit is the impossibility of obtaining a small radius of curvature (the usual value is 3 - 4 times the internal diameter).

All of the listed devices are mandrelless units, therefore they are ineffective when bending thin-walled products; it is also undesirable to use them when working with workpieces with a welded joint of the walls - with plastic deformation, individual sections of the seam may open.

Rice. 8 Pipe bending rollers

Electromechanical pipe benders

Electromechanical units are mainly used in industry and provide the following technological processes.

Coreless bending. The machines are used when working with workpieces, for bending radii of 3 - 4 D., they are capable of bending thick-walled pipes for the furniture and construction industries, and main pipelines. The machines have the simplest design and control compared to other types, and are characterized by small overall dimensions and weight.

Booster treatment. Units that operate using a special technology for advancing the carriage with the part using an additional unit are designed to produce complex bends without thinning the walls. They are used for the manufacture of coils of various shapes in the thermal energy, boiler and water heating industries.

Mandrel bending. Units of this type allow high-quality bending of thin-walled elements with an outer diameter of up to 120 mm. Industrial machines can be automatic or semi-automatic with numerical control.

Three-roll bending. The design is widely used for bending any metals and alloys; it is versatile: it copes well with round or rectangular profiles, corners and flat plates. The versatility of the unit is achieved by changing rolls with different types of working surfaces and sizes.

Using this unit, it is convenient to bend elements of long length with the same large radius of curvature throughout.

Rice. 9 Industrial pipe benders

Tools and equipment

To bend small-diameter steel pipes when installing utility pipelines, hand tools and the cold deformation method are used. So, a cold pipe can be bent using devices using the following methods:

- using template rolling for round pipes up to 76 mm in diameter. On machines that use rolling, it is not possible to obtain high-quality roundness of the section radius at the bend;

- by winding onto a stationary slider, with longitudinal movement of the rolling roller;

- based on the transmission of force by a pneumatic or hydraulic cylinder to the bending point with emphasis on two movable rollers;

- with broaching through movable guide rollers, which makes it possible to produce bends with a small radius angle, used on universal bending machines.

Bending of a profile pipe along the radius of a square or rectangular cross-section is carried out in the same ways as round steel pipes. The main difference between profile pipe bending machines is in the form of rolling rollers, templates and running-in, which, accordingly, have a rectangular cross-section.

Pipes of large diameters are bent exclusively using hot methods on special machines, using the following method:

- deformation of the workpiece on the die, which makes it possible to produce products with several bends in one or several planes at once;

- broaching on a special horn, makes it possible to obtain not only the minimum radii, but also the specified curvature of the radius, while maintaining a uniform cross-sectional diameter of the pipe due to simultaneous calibration on the inner core.

How to hot bend pipe blanks in production can be seen in this video.

Sheet metal bending technology: features and classification

Bending technology, depending on the required modification of sheet metal, includes the following types:

- Single-angle (V-shaped) - considered the simplest. Under the influence of the bending force, the upper surface of the workpiece is compressed, and the lower surface is adjacent to the walls of the mechanism and stretched. This way the desired radius is achieved.

- Double-angled (U-shaped) - performed in a similar way except for the number of processing steps.

- Multi-angle bending.

- Radial bending of sheet metal (rolling) – allows you to obtain a smooth bend. Used to create hinges, clamps, etc.

This technology for processing workpieces does not require enormous effort, so preheating the material is not required.

Hot bending along a radius is used only for thick sheet blanks (12–16 mm), as well as low-plasticity metals. The latter include duralumin, high-carbon steels and their alloys.

This method of processing sheet material is often used in combination with other operations, for example, cutting, cutting or punching. The result is complex three-dimensional metal products. To make them, they resort to stamps that can be used in several transitions.

From the point of view of spatial positioning, there are two ways to bend along a radius:

- Longitudinal - in this case, cold work technology is used, which does not allow processing thick sheet blanks.

- Transverse - includes several stages: first of all, the edges of the metal part are bent, then it is heated. Afterwards, the actual production operations begin: bending, upsetting and drawing.

For radius bending of sheet metal, a specialized manual or industrial machine is required. Its design is modified depending on the required shape of the product.

Working in cold technology requires maintaining an optimal ratio of bending radius, metal thickness and the size of the sheet itself. Deviation from the limit value is fraught with loss of strength characteristics of the workpiece and the possibility of damage.

Giving a radius shape to a workpiece under the influence of high temperatures can change the structure of the material. Thus, during cooling after heating, the bonds between the molecules in a sheet of metal become closer and more ordered, which helps to increase its hardness, strength and elasticity. In addition, the elongation at break decreases at this point. The plasticity of the material changes little.

Pipe bending methods without factory equipment

In domestic conditions, there is often a need to bend pipe blanks when carrying out construction work or installing gas pipelines. At the same time, it is not economically feasible to spend financial resources on purchasing factory pipe benders for one-time operations; many use simple homemade devices for these purposes.

Steel pipes

Steel is a fairly rigid and durable material that is very difficult to deform; the main method of changing its configuration is bending in a heated state with a filler under simultaneous physical impact. For thin-walled stainless steel pipes, the following technology is used to obtain a long section with a small bend radius:

- Place the workpiece vertically, close it at one end with a stopper and pour very fine dry sand inside; after it is completely filled, insert the stopper on the other side.

- Find a pipe or low vertical pole of the required diameter and firmly fix the pipe end to its surface.

- Wrap the part around the pipe axis, turning the template or walking around it.

- After winding, the end is released and the curved part is removed from the template, the plugs are removed and sand is poured out.

Rice. 11 How to obtain the required bending radius of a copper pipe

Copper pipes

Copper is a softer material than steel; it is also convenient to bend when heated or with the help of sand poured inside. You can also use a household mandrel substitute for bending - a steel spring with dense thick coils and a cross-section slightly smaller than the workpiece. When carrying out work, the element is inserted inside and located at the point where deformation occurs, and after the necessary operations it is easily removed out. But it is much easier to bend copper pipes with a special spring pipe bender (these products can be purchased at the retail chain), which are effective on short routes and work due to the uniform distribution of the applied force on the surface. The spring device works as follows:

- The spring is placed over the pipe in the desired place, after which it is manually bent along with the pipe.

- With further bending, the spring is moved and bent at another point.

- Upon completion of the operation, the spring segment is easily removed without the use of auxiliary means.

Another popular material is aluminum, which is easier to bend when heated with a torch.

Rice. 12 How to bend pipes without an aluminum machine

Metal-plastic pipes

When bending metal-plastic pipes in households, an internal or external spring (conductor) is used. The technology for carrying out the work is similar to operations with a copper pipe; when bending, the permissible radius restrictions must be observed to avoid damage to the product.

Plastic pipes

The main element for changing the configuration of plastic pipes is a construction or household hair dryer; sand can be used to facilitate the work. Products of complex shape are bent as follows:

- Self-tapping screws are screwed onto a wooden plate using a screwdriver according to the desired configuration of the workpiece.

- The pipe end is inserted between two screws and the pipe wall is heated with a hairdryer, ensuring the direction of the product with turns and flexibility along a given route.

- At the end of the work, unscrew the screws and remove the workpiece.

Rice. 13 Methods for bending metal-plastic pipes using external and internal conductors

You can use another simple technology:

- Pour sand into a plastic pipe and tightly close its ends.

- Place the product in boiling water for a while and then remove it to the surface.

- Give the workpiece the desired shape, fixing it in the desired position and waiting for cooling.

Rice. 14 How plastic elements are bent

Existing industrial and household methods for obtaining the required bending radius make it possible to carry out these operations with any materials of various diameters. To carry out the work, special devices of a manual or electromechanical operating principle are used, which often use hydraulic units. In households, effective bending methods are the use of special springs and heating of products with gas burners or a household hair dryer (when bending plastic).

Volume of water in the pipeline

Knowing the volume of water that can be in a pipe is useful in many situations. This calculation can be useful when working on the heating system, water supply, and sewerage. The formula for an ordinary round pipe is not complicated. To carry out the calculation, you need to arm yourself with a caliper and a tape measure. To make the calculations easier, a calculator would be helpful.

First, measure the diameter of the pipe along the inner edges with a caliper. Divide the resulting value in half to find the inner radius. Based on the radius, we find the cross-sectional area of the pipe.

Next, you need to measure the length of the pipe with a tape measure. We multiply the resulting parameter by the previously calculated cross-sectional area. Ready! We found the volume of water that can be in the pipe. The volume can be expressed either in cube. m, or in l. These units correspond like this: 1 cubic meter. m = 1000 cubic meters dm = 1,000 l. However, this formula is only suitable if the pipe is completely filled with water.

For incomplete filling of pipes with water, much more complex geometric constructions and formulas are used to calculate the volume of liquid. We offer a drawing for your reference that shows how to make such calculations:

The throughput capacity of various pipes is determined using special tables. So, a pipe with a cross-section of 25 mm per minute passes up to 30 liters in 1 minute. If the pipe has a diameter of 32 mm, it is already capable of flowing up to 50 l/min. However, most faucets are capable of passing through no more than 5 liters of water in 1 minute.

It is also worth making allowances for the material from which the pipe is made. The fact is that polypropylene pipes have significantly smoother walls than metal pipes. This means that their ability to pass water with the same diameter will be higher. Limescale deposits that accumulate in metal pipes can have an even greater impact on throughput. Therefore, any table shows throughput only approximately.

How to determine the minimum radius

The minimum bending radius of a metal pipe can be determined according to the calculation below and based on the drawing.

The minimum permissible bending radius at which critical deformation may occur is determined by the ratio:

Rmin = 20*S,

where Rmin is the minimum possible bending radius of a metal pipe, S is the pipe wall thickness in mm.

Hence the radius along the central axis of the pipe will be:

R = Rmin + 0.5 * D,

where D is the nominal diameter of the pipe.

A prerequisite for correct calculation of the minimum bend radius is the need to take into account the ratio:

Kt =S/D,

where Kt is a criterion that takes into account the thinness of the pipes.

Thus, we obtain a universal formula for calculating the permissible bending radius:

R= 20*Кt*D + 0.5 *D,

Provided that the calculated radius R is greater than (20*Кt*D + 0.5 *D), then we use the cold bending method; if it is less, then it is necessary to additionally heat the pipe before bending, otherwise deformation of the walls cannot be avoided.

It is also necessary to take into account that if the value of the thin-wall criterion lies in the range 0.03 < Kt < 0.2, then the minimum permissible conditional bending radius of metal pipes without the use of a mandrel must be greater than the value:

R ≥9.25*((0.2 - Kt )**0.5),

if the minimum permissible conditional bending radius is less than the obtained value, then the use of editing is a prerequisite.

The correction for the pipe bending radius, taking into account springing after the load has been removed, can be obtained using the formula:

Rav =0.5 *Ku*Dm,

where Dm is the diameter of the bending mandrel, Ku is the reference value of the elastic deformation coefficient for a given metal.

Thus, for enlarged calculations, we can take the value of the elastic deformation coefficient equal to 1.02 for pipes with a diameter of up to 40 mm, made of steel or copper, and for pipes with a nominal diameter of more than 40 mm, this value will, accordingly, be equal to 1.014.

To more accurately calculate the angle at which it is necessary to bend the pipe, taking into account the amount of elastic deformation, you can use the formula:

α = α *(1 + 1/m),

where α is the rotation angle of the central axis, m is the value of the reference elastic deformation coefficient.

So, if the calculated radius is two to three times larger than the pipe diameter, then the value of the elastic deformation coefficient can be taken in the range from 40 to 60.

Determination of the conductor cross-section at the input

You can check the nominal values in the Energosbyt company or in the documentation for the product.

For example, the rating of the machine at the input is 25 A, the power consumption is 5 kW, the network is single-phase, 220 V. The cross-section is selected so that the permissible current of the cores over a long period is greater than the rating of the machine. For example, a three-core copper conductor VVGng, laid in an open manner, was installed in a house. The optimal cross-section is 4 mm2, so you will need VVGng 3x4 material.

After this, the indicator of the conditional shutdown current for a machine with a nominal value of 25 A is calculated: 1.45x25 = 36.25 A. For a cable with a cross-sectional area of 4 mm2, the parameters of the continuous permissible current are 35 A, conditional - 36.25 A. In this case, it is better to take the input copper conductor with a cross-section of 6 mm2 and a permissible maximum current of 42 A.

Standards for permissible defects in pipe welds using non-destructive testing methods

These standards provide for the testing methodology and permissible defects in welded seams of pipes supplied according to the technical specifications TU 14-158-116-99 using non-destructive testing methods.

1 CONTROL METHOD AND EQUIPMENT

1.1 Defective areas of pipe welds are determined by 100% automated ultrasonic testing (AUT) with assessment of the acceptability of reflectors by manual ultrasonic testing (RUT), 100% X-ray television testing (RTK), and 100% X-ray television testing of end sections of welds (RTKK) at a length of 150 mm.

1.2 The assessment of the admissibility of reflectors for RUZK is carried out by flaw detectors of the UD2-12 type, and for RTK - by X-ray television installations according to the regulatory documentation of the manufacturer.

2 REFERENCE SAMPLES

2.1 Standard samples for adjusting the sensitivity of ultrasonic equipment are made from defect-free pipes of the same material and standard size as the tested pipes, and are templates without a welded joint with artificial reflectors for AUT of the type of a cylindrical through hole with a diameter of (1.6 ± 0.16) mm , for RUZK type notches with a depth of (1.6 ± 0.16) mm, a width of (2.5 ± 0.25) mm, and an area of 4 mm2.

2.2 To assess sensitivity for RTK and RTKK, 2% plate or wire standard samples (penetrometers) are used.

3 STANDARDS FOR ASSESSING THE QUALITY OF WELDED JOINTS

3.1 The criterion for assessing the quality of a welded joint during AUT is the amplitude of the echo signal from the reflector.

3.2 A reflector is considered unacceptable if the amplitude of the echo signal from it exceeds the level of the signal from an artificial reflector of a standard sample (notches with an area of 4 mm2) and the conditional length is equal to or exceeds 10 mm.

For any 120 mm of welded joint length, the total conventional length of permissible reflectors should not exceed 30 mm, and the number should not exceed 5 pieces.

3.3 The maximum dimensions and distribution of slag inclusions and pores visible on the screen of the video control device of the X-ray television installation must not exceed the limits specified in Tables A.1 and A.2.

Table A.1 “Weld defects such as elongated slag inclusions”

| Maximum permissible size, mm | Minimum distance between defects for every 150 mm of seam length, mm |

| 1,5´13 | 150 |

| 1,5´6,5 | 75 |

| 1,5´3,0 | 50 |

Notes:

1 The sum of lengths for every 150 mm should not exceed 13 mm

2 If it is not possible to accurately determine the type of defect and the identified defect can be classified not only as a slag inclusion, but also as a crack or lack of fusion, the pipe section with this defect is rejected.

Table A.2 “Weld defects in the form of round slag and gas inclusions”

| Maximum size, mm | Size of adjacent defect, mm | Minimum distance between defects, mm |

| 3,0 | 3,0 | 50,0 |

| 3,0 | 1,5 | 25,0 |

| 3,0 | 0,8 | 13,0 |

| 3,0 | 0,5 | 9,5 |

| 1,5 | 1,5 | 13,0 |

| 1,5 | 0,8 | 9,5 |

| 1,5 | 0,4 | 6,5 |

| 0,8 | 0,8 | 5,0 |

| 0,4 | 0,4 | 3,0 |

Notes:

1 The sum of the diameters of all defects for every 150 mm should not exceed 6.5 mm.

2 Two defects with a diameter of not more than 0.8 mm can be located at a distance of one diameter from each other, provided that they are separated from any other defect by a distance of at least 13 mm.

Copper pipes

If there are usually no problems when bending steel products, then copper pipes can burst or be damaged during the bending process (read: “How to bend a copper tube - proven and reliable methods”). One of the easiest ways to protect yourself from such phenomena is to use simple sand. It is poured into the pipe before the procedure begins.

The sand must be dry. Next, using a burner, the bend area is heated. To check for the optimal heating temperature, just bring a piece of paper to the pipe: if it lights up, the burner can be turned off. The required bending radius of the copper pipe is determined gradually - sudden movements in this case will be unnecessary. It is accuracy that will allow you to avoid unwanted tears in the material.