The Hook diving system, like Scuba, is quite famous among scuba diving enthusiasts. Even if you have never been scuba diving, you are probably familiar with the SCUBA system. Yes, you may not have known that it was called that way, but the image of a man with metal cylinders on his back is familiar to you (at least from films). The Hook diving system is significantly different from the Scuba diving system. There are both positive and negative aspects to this. However, the undeniable fact remains that the Hook diving system is simple and easy to use, even for beginners.

Who is this for?

It is suitable for those who are just starting to master this type of extreme recreation. At the same time, it is quite easy to use and safe.

Those who really want to dive, but cannot afford to purchase expensive professional equipment or do not have a certificate, cannot do without it.

The Hook system is suitable for absolutely all lovers of active recreation. It is often used by professionals. Some of them believe that the absence of heavy cylinders on their backs makes scuba diving more comfortable.

DIY diving compressor - Metals, equipment, instructions

The benefits of a compressor when performing various tasks in a workshop or garage are undeniable.

This unit has long ceased to be the property of construction crews and departmental vehicle fleets. Here is a superficial list of what can be done with a compressor:

- Painting work

- Sandblasting of any materials

- Blowing debris out of hard-to-reach cavities of units

- Cleaning the area

- Tire service

- Working with pneumatic tools.

An air compressor can be purchased at a store. Moreover, kits of any power and performance are offered.

However, such equipment is not cheap: if you do not plan to make a profit from it, purchasing it simply to facilitate manual labor may seem impractical. Therefore, many home craftsmen try to make a compressor with their own hands.

The simplest (and relatively safe) homemade compressor can be made from a regular car accessory. We will talk about a ready-made electrical device - a compressor for inflating wheels.

It would seem, where should it be used other than for its intended purpose? Design features do not allow large volumes of air to be supplied per unit of time.

This parameter deserves a separate explanation:

The compressor has two important characteristics:

Power

The ability to create high pressure without additional load on the engine.

Automotive units are in complete order with this. You can safely build up pressure up to 5-6 atmospheres. True, pumping up a wheel to the typical 2.5-3 units takes a good ten minutes (at zero initial pressure). During this time, inexpensive devices may simply overheat, so breaks are required.

This occurs due to the low performance of automobile compressors.

Performance

The ability to produce a certain volume of air “over the mountain” per unit of time. The higher it is, the faster the container is filled, and the more intense the flow from the nozzle when using compressed air directly.

To combine these qualities, a large volume of the piston group of the unit and a powerful engine with high speeds are required. Plus, it is necessary to ensure cooling of the cylinders, otherwise the compressor will overheat and jam. Such devices exist; even turbines can be used as a working unit.

But the cost of the equipment does not allow it to be used en masse, especially in everyday life.

Simply put , it’s either power or performance. How to get out of a vicious circle? Use a storage container - a receiver. In industrial designs, this is a steel cylinder, which is slowly filled by a powerful, but not very efficient compressor.

Homemade low-power compressor from an electric motor from a toy. A simple solution to a pressing problem. Such a compressor is quite suitable for supplying air to an aquarium. How to make it with your own hands in detail step by step in this video.

Once sufficient pressure has been created, a sufficiently large volume of air can be supplied from the receiver in a short time.

Then you need to wait until the compressor restores pressure. This is how all units work , including those installed on cars with pneumatic brakes.

Our “Kulibins” have long learned to create a semblance of industrial installations using an auto-compressor.

We take a spare tire, use our favorite “Berkut” to fill it with 3-4 atmospheres (the main thing is that the tire does not burst), and the high-pressure paint sprayer is ready.

The same device is used for purging when servicing the engine or suspension. Only instead of a spray gun a blow gun is used.

Automation is not required; it is enough to control the pressure manually using the built-in pressure gauge. Of course, you can’t start a pneumatic tool with such a unit, and you can’t make a sandblasting machine out of a wheel.

Air compressor from a fire extinguisher or gas cylinder

If you have a powerful auto compressor for inflating wheels (you can buy one for such a case), you can easily make a full-fledged air unit of medium power. It is enough to purchase an old carbon dioxide fire extinguisher or a gas cylinder and connect it to a ready-made “rocker”.

There are nuances that must be observed:

- The donor container should not have any corrosive or mechanical damage

- The pressure margin should be 100% of the planned one. That is, if you expect to “stuff” it up to 5 atmospheres, then the guaranteed rated strength must withstand at least 10 atmospheres

- It is necessary to install a sensor with an emergency switch. When the pressure reaches the nominal value, the compressor will turn off.

- As a last resort, install a mechanical emergency pressure relief valve. And of course, the system must have an autonomous pressure gauge (in addition to the one installed on the compressor)

- The structure must be stable; it is useful to make a steel sheathing in case the receiver ruptures

- If you rarely use the unit you have built, do not leave the pressure high for long periods of time. 0.5 atmospheres is enough to maintain tightness.

How to make a full-fledged compressor with your own hands

The auto accessories option is good for its accessibility . However, power, performance, and most importantly, the duration of continuous operation, leave much to be desired. There is a proven option - a compressor from the refrigerator. The cost part depends on your ability to find shareware components.

And I must say, the unit turns out no worse than the factory one.

And so, what is required for production. An exhaustive list that takes into account all the nuances. It can be shortened, with the exception of security elements:

- Compressor from a household refrigerator (conditionally free)

- Receiver container: this can be a fire extinguisher, a gas cylinder, or a homemade one welded from a thick-walled pipe and sheet iron. The latter option is convenient from the point of view of fittings placement, but the issue of welding reliability is very important. The cost also tends to zero

- Air fittings: tubes, hoses, fittings, tees, air inlets

- Working pressure regulator (reducer)

- Pressure gauge (if there is a gearbox = 2 pcs.)

- Inlet air purification filters (to preserve the compressor piston group)

- Oil or water separator at the outlet (relevant for compressors with “wet” lubrication)

- Pressure switch (controls the operation of the compressor)

- Emergency valve (required for any configuration!)

What does the system consist of?

Her appearance may seem a little complicated, but it is not. All the components included in its composition are easy to find yourself. Is it possible to assemble a Hook diving system with your own hands? The answer is definitely: yes.

Let's look at it in more detail:

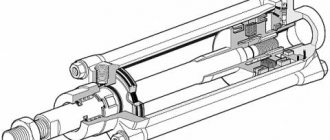

Compressor. It is distinguished by its relatively small size, which is very convenient for transportation, and can run on both a gasoline engine and electric traction. Charging does not require a lot of voltage: 220 V is quite enough. In such a system (diving), the diving compressor is the most important part. It is he who is responsible for pumping air through the hose to the diver underwater.

Reserve cylinder. This is a container in which air accumulates. Here it is cooled and dried, which makes breathing comfortable. There are situations when more air is required than the compressor can provide. In this case, the supply in the reserve cylinder will come in handy.

The air in the cylinder is also needed for insurance against accidents. There is always a possibility that the engine will stop working, no matter how well everything is debugged. Then the reserve tank will give you a couple of minutes to rise to the surface. Hose. It is the link between the compressor with the reserve cylinder and the diver. It is through this that the air is supplied. If you want the hose to serve you for a long time, do not use a rubber one. It quickly becomes unusable. Hoses made from vinyl-plastic are better and safer.

Regulator. This is actually a device for breathing. The Scuba regulator can be used in the Hook system, but only after preliminary modification. In the Scuba system, air is supplied under high pressure. This is not necessary for Hook, so modification is necessary. This should only be done at a specialized service center.

Harness. This diving system requires the use of chest straps. With their help, both hoses (from the regulator and from the compressor) are securely attached to the diver's back. This makes it impossible to yank the regulator out of your mouth if the hose gets caught on something, and also keeps it behind you so it doesn't get in the way when diving.

Typical resort huka diving

In many ways, resort diving is very similar to scuba diving. Participants begin with a short lesson that explains what to expect, safety requirements, and teaches them a few skills, such as how to clean a mask. Then, with an instructor, they dive to a depth of about 6 meters / 20 feet. In some places, codes and regulations require that the guide be licensed and use scuba gear. Since divers are tethered to a float, there is much less risk of a participant getting lost or going into deep water.

Advantages

There is no need to carry heavy cylinders with breathing mixture. There is no need to keep track of time: air supplies are unlimited. There is a connection with the surface via an air supply hose. Theoretically, you can pull a person up using it, if necessary.

You do not need to be certified to dive this way. The cost of such equipment is several times less, and it is much easier to use. Therefore, this diving method is suitable even for beginners.

Personal hook systems

Hook systems have tremendous flexibility outside of resort diving areas. The most common configurations allow a maximum of 4 divers to descend to 18 meters / 60 feet. Which is equivalent to beginner scuba divers (Open Water Diver). Some systems can allow two divers to go down to 30 meters/100 feet (advanced diver depth). The initial cost of a hook system for one diver is about the same as the initial set of a SCUBA diver. However, a hook system for two or even four divers is marginally larger. This makes them less expensive than multiple kits. Operating costs are also low; on a gallon of gasoline, most compressors can run for five hours while supplying air for four divers.

Reserve cylinder

The next stage of the system is the reserve cylinder. This piece of equipment functions as a storage tank that constantly contains a supply of air. If the diver is doing heavy lifting, he may need more air than the compressor can provide. When breathing becomes more intense, the accumulator provides the diver with an additional volume of air. The reserve cylinder cools and compresses the air. The air temperature coming directly from the compressor can reach 190 degrees. After air enters the reserve cylinder, it will become cold. The air in the reserve cylinder is also dehumidified. Due to its small size, the compressor is not able to independently remove moisture from the air, so the compressor itself supplies sufficiently humid air. The reserve cylinder regulates possible uneven air supply. In the event of an unexpected engine shutdown, the reserve tank gives the diver about two minutes of extra breathing time.

Air supply hose

The next component of the Hook system is the air supply hose. The hose is made of vinyl plastic, resistant to oils, gasoline, and solar radiation. Ordinary rubber hoses cannot be used for such a system, as they gradually deteriorate and become toxic. The hose diameter is usually 3/8 inch. The inside of the hose is made of vinyl and reinforced with nylon, with a PVC coating. The hose does not twist or break. For better visualization, Hook hose is usually made in bright yellow or orange. Since the hose is buoyant, the extra length of hose will not get in the way underwater, but will float on the surface while you dive.

Where to start underwater search

Underwater search begins with an inspection of the main equipment - a metal detector. First of all, I had to send my E-Track for improvement, which took two weeks. Much was redone; all that was left of the E-Track were the “brains”, which were placed in a moisture-proof box. We changed the battery box and replaced the original battery with three AA batteries. To search underwater, I had to buy an 8-inch coil, which will make it easier to detect the target.

"Underwater E-Track" searches underwater

I also had to put away my wireless headphones and change them to wired underwater headphones . All cable entries into the unit were redone so that water would not get in there. In turn, in order to search not under water, two rods were made to the upper rod: a short one, for searching under water, and a long one, for standard searching. We also had to send a standard coil so that the plug could be remade.

I had to give up wireless headphones

Read on “E-KLAD”: A couple of hours and the search was successful (video)

Huka – surface air for divers

One of my favorite documentaries about human interaction with the ocean is BBC's Human Planet. I highly recommend everyone to watch it. We often show it in the evenings at our freedive camps and trips. The most impressive aspect of the film for me is the story of the Paalin fishermen in Palawan, who catch fish with nets, breathing underwater through ordinary garden hoses, which are supplied with air from a compressor on the ship. There is part of this story here on Youtube. Young guys stick hoses from which air blows directly into their mouths without any regulators. The hoses poison and get tangled with each other. The compressor is antediluvian. Due to the great depths, rapid ascent and long stay under water, many people develop decompression sickness. Complete hell!

And recently I found out that this activity even has a name - huka diving. Professional equipment is produced for it, which is used in some places for the entertainment of tourists and recreational diving. By analogy with SCUBA (scuba diving) this is called SNUBA and there is even an organization Snuba International. Below is a translation of an article about hook diving from Deeperblue.

Hookah (from the English Hookah - hookah) or a system of supplying air from the surface for diving, as recreation and entertainment, has become very popular in many places around the world. Resorts market this activity as a mix of snorkeling and diving without the need for certification. While different equipment suppliers may add their own name to the activity, the general term used is hookah diving. Essentially, the huka system provides a person underwater with air, the source of which is on the surface. An air hose running from the air source to the regulator connects the person to the system. There are various variations in existing systems.

The biggest difference is whether the systems are dynamic or static. A dynamic system uses an air compressor to provide the required air at the proper pressure. These systems often have a small storage tank to ensure constant pressure. As air is removed from the reservoir, the compressor pumps in new air to maintain pressure. Compressors can be free-floating or fixed. They can also be petrol or electric. The static system uses a cylinder of compressed air as the air source for divers. Many static systems use scuba gear for this.

Methods of working with a wood burner

A classic device for wood burning can perform various types of application of objects based on the general idea of the future painting.

A popular option is contour burning, where only the boundary lines of objects are processed. In the case of silhouette burning, some figures or background are completely burned out. Experienced craftsmen can resort to decorative burning, which allows them to convey shadows.

Mastering the chiaroscuro method will allow a sophisticated creator to draw pictures that convey volume and dynamics using a homemade burner.

Making a simple burner

If you wish, you can assemble a wood burner with your own hands. To do this, you will need a small set of tools and some improvised means, commonly used household items. To assemble a homemade burner you need the following materials:

- Wood bead.

- Insulating adhesive tape.

- Power unit.

- Nichrome alloy filament.

- Soldering device.

- Flux for soldering.

- Tin for solder.

- Electric drill with attachments.

Other materials may be added to the list, such as sewing threads and rubber thermal tubes.