An anchor bolt is a durable fastening element that is actively used in the construction of foundations. Anchor bolts are relevant not only in the work of ensuring reliable connections, but also in the construction of complex structures with large dimensions and weight.

A universal, powerful anchor bolt suitable for working with concrete foundations. Depending on the type of part, the scope of its application is determined. Certain modifications are made for fastening in porous materials with a fragile internal structure.

There are several types of anchor bolts based on their design features:

- Composite bolts. In their structure, they have two parts, which are connected to each other by a coupling. During the installation of the fastening system into the foundation, the lower part of the bolt goes into the concrete surface, and the upper part remains outside for screwing into the coupling.

- Bent bolts. Visually they have the shape of a hook. In the case of foundation work, they are first attached to a reinforced concrete base, after which they are filled with concrete mortar.

- Straight anchor bolts. Mounted in already hardened concrete. To do this, use a hammer drill to make a hole in the foundation, and then install a bolt. Epoxy gel is used for reliable fixation.

- Bolts with anchor plate. Installed before pouring concrete mortar. The design feature of the bolt is that it contains a metal plate. It is secured by welding.

- Anchor bolts with a tapered end. The fasteners are installed after concreting. Reliable fixation is ensured by an expanding collet. The structural element allows the use of bolts with a conical end for fastening furniture and plumbing fixtures.

- Removable bolts. The installation phase takes place in two stages. The lower frame is installed in the foundation. And the threaded rod is installed after concreting.

Bolt BSR GOST 28778-90

Price for 1 piece:

from 270.00 rub.

Foundation bolt GOST 24379.1-80

Price for 1 piece:

on request

View more in the catalog

Based on their structure, load-bearing capacity, and material, foundation anchor bolts are capable of providing a reliable connection. All manufacturers test products to withstand loads and operation under the influence of potential external factors. Bolt production standards are specified in accordance with GOST. All bolts must be marked, according to which their technical features, scope of application and environmental conditions can be determined.

Installing anchor bolts in the foundation: step-by-step instructions

Three conditions are determined due to which strong foundation bolts provide reliable fastening in the foundation:

- Bolt friction force. This is explained by the fact that the immobility of the element depends on the distribution of the load on the fastening element and the foundation itself.

- Emphasis. A strong anchor bolt independently compensates for loads.

- Gluing. Upon contact with the foundation, shear stress is formed, which also takes on part of the load.

Also, when working with foundation surfaces, glue-based bolts are used to enhance strength. Sloxane and epoxy adhesives are used in cases where it is necessary to secure a structure with asymmetry.

If the foundation is subject to constant loads in the form of vibrations, it is better to use spacer fasteners. Tapered bolt anchor bolts are excellent at withstanding static loads, but are not intended for installations where there is a potential risk of impact.

The foundation bolt installation process includes several steps:

- First you need to study the features of the foundation bolts that you plan to use for work. There are markings on the products. In accordance with it, you can determine the type of bolt and maximum permissible loads.

- If the high-quality anchor bolt is suitable for its intended purpose, you can begin work. At the preparatory stage, the locations for fixing the bolts are determined.

- There are rules for installing anchor bolts. For example, when calculating the distance between them, they are guided by the depth of the hole. The distance between the bolts is twice as large as the insertion itself.

- When installing anchor bolts in wet concrete, all work must be completed before it hardens. The anchors must fit smoothly, since even minor tilts can lead to further deformation.

- The final stage of installing durable anchor bolts. The bolts need to be fastened. A metal plate or wooden base is suitable for this. Some types (as described above) are installed in already hardened concrete. In this case, it will be enough to drill the surface and insert the fasteners.

What are foundation anchor bolts made of?

Considering the loads and functions that are placed on anchor bolts, fasteners are made from high-strength materials. The preferred choice is steel. Manufacturers also offer varieties of it for increased resistance to temperature changes and precipitation. Additionally, the bolts undergo heat treatment. This reduces the likelihood of a connection being lost.

Depending on the design of the bolt, the loads it can withstand, and the manufacturer, the cost of fasteners also differs. When purchasing foundation bolts, it is important to make sure that they comply with GOST standards and have passed all the necessary tests. Only after quality control can parts be used for foundation work.

Foundation bolts are considered durable and reliable. Due to the high demand for high-strength bolts, various types of fastening systems are produced, differing in function.

The foundation anchor is attached to the structural support or wall elements. They are used to install massive equipment in industrial workshops.

Popular product brands

Many companies are engaged in the production of foundation bolts. These products are quite simple to manufacture and are quite in demand. The most famous foreign companies include Simpson Strong-Tie, Hillman Group, USP. In Russia, Neva Resources is also the largest.

- The cost of products depends on the size, the quality of the steel, and the design.

- A straight carbon steel foundation bolt will cost 70 rubles. per kg. The same stainless steel fasteners cost from 613 rubles. per kg.

- A bolt with a conical end costs from 320 rubles. per kg. But just a flat anchor plate for a bolt will cost 3,202 rubles. per piece

- A composite foundation bolt costs from 355 to 5750 rubles. per piece

A foundation anchor is a special type of fastener designed to fix heavy structures to dense material. It is indispensable when fastening equipment, for example, or building structures, but is practically not used in other areas.

Types of anchor bolts

Steel anchor bolts for foundation work are produced in accordance with GOST. The standards were written back in 1980. In 2012, based on them, they developed a modern standard, which all manufacturers must adhere to. The document regulates the types of bolts, their sizes, and purpose.

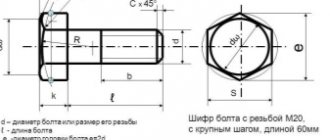

- Bent bolts. Made from high strength steel. According to their design features, they have a bend at the bottom. It is made at an angle of 90 degrees or in a Z shape. The diameter of the curved bolts ranges from 1.6 to 4.8 cm. The length of the rod is from 500 to 2500 mm. It is secured with two nuts and a washer between them.

- Straight bolt with threaded ends. This option features an anchor plate. This is a steel platform with a hole in the middle. The foundation bolt passes through it. This type has a number of modifications in the shape and diameter of the rods. The washers themselves differ in shape and size.

- Bolts are composite rods. The rods are fastened together with threaded bushings. The fourth type of anchor bolts is considered to be easily removable, so it is used if there is a possibility that the structure will need to be dismantled.

- Type 5 foundation bolts are threaded with a smooth textured shank.

- Bolts marked 6.1, 6.2 and 6.3 are distinguished by thickening at the bottom of the rod. For fastening you will need auxiliary elements - a bushing and an expanding collet. These bolts are installed after the concrete solution has hardened.

Varieties

No matter how simply a monolithic foundation is constructed, in reality it turns out that there are many factors at work here that significantly affect the reliability of the fastening. Accordingly, foundation bolts have many varieties.

By design features

Based on their design features, foundation anchor bolts are divided into the following types.

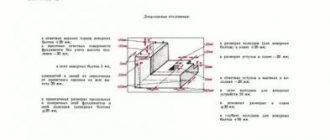

- Curved - consists of a stud, washer and two nuts. One end of the pin has a curved shape - a hook. According to GOST, the maximum length of the product reaches 180 cm. An anchor is used for fastening metal and reinforced concrete structures. The washer can be of different sizes to suit equipment with different mounting holes. Fasteners are used if the height of the foundation does not depend on the depth of the anchor.

- With anchor plate - at the lower threaded end of the pin there is an anchor plate secured with threaded nuts. The slab determines the reliability of fastening in concrete. The structure can be different, which is determined by the structure of the foundation. The maximum length of the product is 5 m. An anchor is used for fastening metal and reinforced concrete structures. This option is installed for concreting. It has a smaller embedment depth, and therefore is used when the height of the base depends on the embedment depth.

- Composite with anchor plate - in addition to the threaded rod and anchor plate, a coupling appears, which allows you to connect the two parts of the anchor bolt. In this way, two structural elements mounted by turning or sliding are connected. The general installation scheme is as follows: a part of the stud with a coupling is concreted into the foundation, then the mechanism is installed and the upper part is screwed into the coupling. The screw-in length is at least 1.6 times the thread diameter.

- Removable - mounted in a poured foundation. The anchor plate can have different designs: welded, cast, flat anchor plate. This option is designed for fixation into a concrete, brick or stone foundation. Most often they are used to secure rolling equipment, since it is subject to high dynamic loads. Also, removable fasteners are required in cases where, as practice shows, the bolts will have to be replaced over time. The removable bolt is mounted slightly differently: only the anchor part is concreted into the foundation, and the stud is installed after the foundation is laid out.

- Straight is the simplest modification, consisting of a metal pin and nut. The length can reach 140 cm. This option is designed for installation in a ready-made solid foundation, when deformation loads are excluded. A straight anchor is attached to an adhesive or cement mortar and is held in place by adhesive forces. Their usual application is construction work.

- Spacer with a conical end - installed in a finished foundation, a hole is pre-drilled for it. The fasteners are fixed using expanding collets or cement mortar. Fasteners are also used in construction work, but when constructing structures subject to vibration loads.

Foundation anchor bolt (varieties)

According to operating conditions

Fasteners vary depending on operating conditions:

- calculated - the anchor absorbs the load that occurs during operation of the equipment and transfers it to the foundation;

- constructive - their main task is to ensure stable operation of mechanisms and prevent accidental shifts. In this case, resistance to overturning or displacement is provided mainly by the weight of the structure or machine itself.

By installation method

Based on the installation method, the following types of foundation bolts are distinguished:

- installed before concreting - most types are fixed in this way: curved, with an anchor plate, and so on;

- those installed in a finished foundation are straight and spacer. To install them, you need to drill a hole in the concrete. An anchor that is fixed into a finished base is prohibited from being used in the construction of high-rise buildings, since the wind load is the main one for them.

The production of foundation anchor bolts is captured in this video:

Rules for installing anchor bolts

There are two installation methods - in wet concrete and in the foundation after the concrete has hardened. In both cases, it is important to correctly mark the installation locations of the bolts. Experts highlight several basic rules for installing anchor fasteners that must be taken into account.

- foundation bolts, according to GOST standards, type 1.2 with an anchor base, are best installed before the concrete hardens. That is, the technology of installation in wet concrete is used. Before hardening, you must fix the anchor according to the rules;

- Bolts marked 1.2 are suitable for installation in a solid foundation after the concrete has hardened. After installation, they are additionally strengthened with a solution of a similar composition. In fact, the concrete mixture for making the foundation and the fixing mixture must be of the same type;

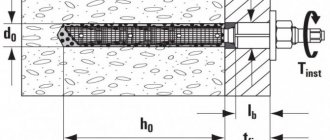

- An anchor bolt with an expansion of the lower part is mounted only in pre-formed holes. The diameter of the loophole must correspond to the rod;

- Only a vertical position of the rod is permissible;

- the distance between steel anchor bolts is calculated by the formula: hole depth X 2;

- during foundation work, the bolts are fastened in the middle of the strip base;

- It is not recommended to use fastening bolts of this type for partitions.

Foundation bolts are made in the form of a rod with a thread at one end and a bend at the other. Due to the latter, it is possible to obtain a connection. Anchor bolts are suitable for durable building materials. For porous surfaces, separate modifications with two bushings are produced.

Mostly foundation bolts can withstand temperature swings from -50 to +50. If you plan to install them in temperature conditions beyond these limits, you need to additionally take into account the features of the foundation. The most suitable type of anchor bolt is determined by the size of the structure and its material.

The most difficult part of installing foundation power bolts is drilling into a confined space. If the square footage of free space allows, you can use a hammer drill. For tighter spaces, a right angle drill is required. It usually takes a little longer.

Alphabetical index of terms in Russian

| anchor | 4 |

| driven anchor | 29 |

| screw-in anchor | 30 |

| injection anchor | 23 |

| capsule anchor | 24 |

| adhesive anchor | 21 |

| metal anchor | 12 |

| mechanical anchor | 10 |

| plastic anchor | 13 |

| drop-down anchor | 19 |

| expansion-adhesive anchor | 22 |

| countersunk anchor | 27 |

| anchor with press washer | 26 |

| anchor with wedge clip | 16 |

| anchor with extension | 15 |

| rigging anchor | 28 |

| disc anchor | 25 |

| persistent anchor | 14 |

| friction anchor | 18 |

| chemical anchor | 11 |

| self-tapping anchor screw | 17 |

| sleeve anchor | 20 |

| anchorage depth | 35 |

| anchor embedment depth | 34 |

| depth of installation hole for anchor | 33 |

| anchor group | 5 |

| diameter of mounting hole for anchor | 32 |

| temperature range for anchor installation | 39 |

| temperature range of anchorage operation | 40 |

| anchor dowel | 8 |

| anchor expansion zone | 31 |

| anchor fastening | 1 |

| pre-installation anchor fastening | 2 |

| Anchor fastening for through installation | 3 |

| construction base | 6 |

| Ultimate condition of anchorage | 37 |

| anchorage load-bearing capacity | 36 |

| anchor life | 38 |

| anchor rod | 7 |

| disc element | 9 |

GOST standards

Anchor bolts are considered the most common method of securing buildings to the foundation. In parallel with assessing the quality of the parts themselves, there must be a thorough check of the foundation. Otherwise, there is a risk of breaking the bolted connections. The concrete must be strong enough to hold the anchor bolts. If the concrete is weak or porous, drilling bolt holes may cause cracking or crumbling. Therefore, no guarantee of strength exists in such cases.

Although supporting walls can provide structural stability, additional measures must be taken to reduce the likelihood of damage. Projects are developed taking into account not only permanent impact factors, but also potential seismic hazards. According to the Uniform Building Code, developed based on GOST, it is established that foundation slabs must be bolted to the foundation with bolts with a diameter of 1/2 inch at a distance of no more than 1.8 meters from each other. One bolt should be placed within 30.5 cm of each end of the plate section.

GOST standards regulate not only the structural features of bolts, but also prescribe the material from which parts should be made. The basic rule for all types of durable anchor bolts is production technology from alloy and carbon steel. If this is due to marking according to GOST, zinc is additionally applied to improve the properties of the bolts. It improves quality by protecting fastening systems from corrosion.

Zinc can be applied in two ways:

- Galvanic. The bottom line is that a hydrolysis bath is used for processing. Zinc atoms coat the surface of the anchor bolt.

- Diffusion. Galvanization occurs under the influence of high temperatures. Using the heating method, atoms penetrate the surface of the fastener.

Both methods have worked well, so you can use any of them to achieve results. It is important to adhere to the rules and regulations set forth in the building code.

Equipment according to GOST

GOST was developed on the basis of regulatory construction documents. It regulates the size of products, their quality, storage and transportation features.

As for the packaging requirements, the fasteners must consist of the following parts:

- main rod;

- anchor fittings;

- tile and sleeve;

- coupling and washer;

- clamping scurvy;

- screw;

- pipe.

Some components may be missing depending on the modification. To understand, in straight bolts the thread is screwed on only one side. Also there is only the center rod and nut. If we consider other more complex fasteners, their structure is improved and designed depending on the functions performed, the specifics of the fastening and the application. There can be several fasteners in the form of nuts and washers.

Advantages and disadvantages of foundation bolts

If you intend to use anchor bolts for the installation of massive structures, evaluate their advantages:

- withstand heavy loads. Limit indicators are calculated taking into account the weight of the structure and the characteristics of the foundation;

- an abundance of species that differ in design. Depending on the tasks, you can select high-quality fasteners with guaranteed service life;

- There are 2 types of installation (described above). Due to this, it is convenient to install bolts not only during concreting, but also after, on the finished foundation;

- They use reliable material – high-strength steel with the possibility of galvanization.

The disadvantages include the following fastener characteristics:

- limited scope. Foundation bolts are used for mounting structures to concrete foundations, natural stone or brick;

- To work with anchors, you need some experience, competent calculation of distances and study of the features of the foundation.

The use of such hardware

The area of use of the foundation anchor is determined by its qualities: high load-bearing capacity and durability. Application is limited to the base material.

Fasteners can only be installed in heavy, dense materials:

- concrete – heavy and especially heavy;

- natural stone;

- solid brick; fastening into hollow brick is prohibited.

Despite the specificity, many works are carried out using anchors, both large industrial and household ones:

- first of all, this is the installation of industrial equipment: machine tools, machines, pressing and electrical equipment, and so on;

- when repairing foundations, new fragments are bolted to old ones;

- when installing a beam grillage - in this case, the anchor is fixed in the pile, and the tie-rods are attached to it. This method, in addition to reliability, also ensures the absence of cold bridges;

- anchors mount the base during installation in order to use them as fasteners for the facing material. This option is more reliable than laying hooks under the cladding;

- In everyday life, a foundation bolt is most often used when attaching large-scale attachments. The anchor is stronger and more durable than self-tapping screws and dowels.

Operating conditions for bolts during concreting

According to the specifics of operation, a distinction is made between design and structural foundation bolts. In the first case, the anchor distributes the load and transfers it to the foundation. In structural fasteners, the main task is the stability of the mechanisms. That is, the bolt prevents the structure from shifting, displacement and deformation.

According to the installation method, foundation bolts are classified into:

- installed before the concrete solution hardens. This is the most common installation method;

- by drilling a hole into the finished foundation. The method is relevant for expansion bolts and straight bolts. A hole is drilled to calculate the diameter of the fastener, where the anchor bolt is then mounted. This method is not suitable for connecting fasteners during the construction of high-rise buildings. They will not be able to withstand wind loads.

Foundation anchor bolts can be used for installation to solid foundations. Therefore, a preliminary assessment of the quality of the foundation is important. For example, it is prohibited to install anchor bolts into hollow bricks.

Scope of application of bolts:

- for fastening industrial equipment. These can be machines, technical units, pressing machines and others;

- reconstruction of the foundation. To strengthen it, you will need to install new ones in parallel with the old bolts;

- installation of reliable bolts to strengthen the base;

- fastening of attachments (domestic use).

Areas of application

The main task of foundation bolts is to ensure reliable adhesion of the walls to the base. Anchors are installed in several ways: by driving into a pre-drilled hole, and by laying at the stage of pouring the foundation. The second method is considered more reliable, but requires a careful approach to installation, since it is necessary to take into account not only the distance between the anchors and the depth, but also the accuracy of installation relative to the vertical axis.

In addition, anchors are used to attach machines to foundations. The main task here is to remove the load from the concrete that is created by the vibration of the machine. Such fasteners have a slightly different design, and can also be mounted at the pouring stage in the form of an embed or in drilled holes.

Anchors can also be used in the construction of extensions, when it is necessary to connect a new wall to an old one. In this case, the task of the hardware is not only to reliably connect the structures, but also to evenly distribute the load between them.

Purpose of the foundation anchor

In foundation work, the anchor bolt plays the role of a fixator. Its lower part is attached to the base, and the upper part is connected to the foundation itself using threads. Anchor bolts have proven themselves in the construction of prefabricated structures and installation of massive equipment.

Fastener properties:

- reliable fixation of the rod in the foundation;

- installing strong bolts before you pour the concrete;

- guarantee of durability during installation work.

Only with the right choice of bolt installation can you count on its benefits. To navigate the location and correctly calculate the position of the fasteners, it is better to proceed from the design of the object. Information about supporting structures is taken into account. Only under them can anchors be installed.

Methods for restoring foundation bolts

There are several options for restoring the integrity of anchor bolts if, as a result of incorrect calculation of the load, they have become deformed and succumbed to corrosion.

- Repair of existing anchor bolts. Anchor bolts connected to the foundation can be repaired using mechanical couplers or welding pin extensions. In these cases, the threads of the anchors must be replaced. Repairs can increase service life if the cause of negative consequences is correctly identified.

- Moving. The bolts are lowered into the wells. After adjusting the position, they are aligned by passing them through a hole in the supporting part of the equipment. Then secure with nuts. One of the main disadvantages when moving anchor bolts is the possible obstacles caused by the assembly of the reinforcement.

- Replacing the bolt. Most often, the best alternative is to completely remove and replace the fasteners. In the process, new anchor bolts are installed in the same place where the old bolts were. In this case, the fasteners can be longer with a larger diameter. Due to this, they can withstand more severe loads.

Before designing work using foundation bolts, you need to ensure their quality. The manufacturer is obliged to provide evidence of testing and compliance with GOST. Since fastening systems are used in conditions of installation of massive structures, installation errors are unacceptable. In addition to evaluating the fasteners themselves, do not forget about examining the foundation itself.