Operating principle of the extractor

It is not difficult to use a reversal device if you first understand the intricacies of its operation. The problem of a broken screw is solved by the following steps: first, a small hole is drilled in the center of the fragment, which is smaller in diameter than the diameter of the body of the fragment. The extractor is inserted there, screwed into the fastener and unscrewed together with it.

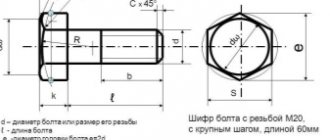

How to unscrew a hex or sprocket head bolt

In the automotive industry and other equipment, hex tool bolts are often used. How to turn out a torn cap that has broken edges:

- Make a horizontal notch on the head with a grinder or file. In this case, a strong screwdriver is used to unscrew the broken screw.

- Using a special TORX sprocket, which is driven into the head. The nozzle is selected in size, slightly larger than the torn cap, for a strong connection between the walls.

- A set of extractors that can be purchased at a hardware store. Before using the extractor, a hole is drilled with a drill in the base of the bolt, then the extractor is inserted, and the screw is removed with pliers or a special clamp.

- Using a left-handed drill with a slightly smaller hole diameter. Work with the tool is carried out in reverse mode, with this method it is possible to damage the thread.

How to unscrew a bolt with torn edges manually

Broken nuts are more difficult to unscrew, since during work there is a possibility of damage to the threads. The simplest way is to use chemicals; the surfaces are cleaned and treated with the product for 15 minutes. If the edges are torn off, it is impossible to use a wrench or socket. In such cases, a chisel is used to destroy the main part of the nut, then removed and replaced with a new nut.

How to remove a bolt if the head has broken off

A broken head of the structure can cause a lot of trouble during work. How to act in such a difficult situation without resorting to using a serious tool. If the element is small, it is possible to make a notch with a grinder, the recess of which will allow the use of a screwdriver with sharp edges. To perform more complex work, you will need an extractor, drill and reamer. The base of the threaded connection is drilled exactly in the middle, after making the hole, the tool is screwed in counterclockwise.

When performing sequential actions, unscrewing a damaged structural element will not be difficult even for those who are encountering this problem for the first time. It is necessary to correctly assess the situation and use a good quality tool for a productive result.

How to drill out a broken bolt

A drill made of high-quality material is used for the work. The size must be selected in accordance with the torn edges; the diameter of the drill should not be larger than the hole. A high-quality drill has a higher price, but its use eliminates rapid wear and the possibility of breakage during operation.

You should use the tool slowly, and before completing the task, correctly assess the situation. It is necessary to monitor the position of the tool during operation; drilling is carried out strictly in the center, without deviations in different directions.

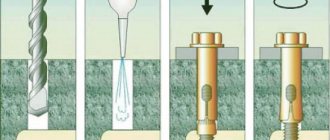

Step-by-step instructions for removing debris

When unscrewing a broken fastener, it is recommended to follow simple rules:

- Before removal, the jammed bolt fragment is coated with a lubricant.

- Old or rusty debris is treated with a product that dissolves rust.

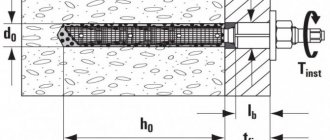

- A hole is drilled at the end of the bolt leg, centering the drill with the guide sleeve included in the kit.

- The rod is driven or screwed into the hole.

- After reliable jamming, the extractor is unscrewed along with the old part. This is done with a wrench or an adjustable wrench.

How to unscrew a broken hairpin: a non-standard solution

This method is suggested by experts in cases where you have already tried several radical options.

The chemical method is a non-standard solution to the existing problem, but it is worth paying attention to. To unscrew the remnants of a stud after it breaks or corrodes, you will need citric acid, drills, and a thermometer. Also prepare a dropper or make a homemade one, an air heating element larger than 1 kW.

Initially, you need to mark the center of the broken pin. Drill a hole along the recess of the stud. Then we take a drill larger than the diameter and thicken it. To minimize the risk of drill breakage, you need to make passes with magnification. We do everything gradually, without a sudden transition to wide-circle drills. The challenge is how realistic it is to drill out the stud. Only the thread should remain where the stud was drilled.

While working, control the direction of the drill. The main thing is not to catch the block itself. At the end of the drilling, when you have achieved your goal, you can proceed to preparing the acid solution. Citric acid diluted with warm water should be poured into the drilled hole. Since over time the liquid will become less, which is explained by the evaporation of water, it will be necessary to add acid. It is convenient to use a dropper. This will help maintain the desired fluid level. The thread must always be filled with water.

In parallel with dropwise oxidation, the block is heated. This is done by applying a heating element. It is connected via a thermostat. We maintain a temperature of 80 degrees. Use paper to protect the cylinders. Be sure to soak it in oil. This is a great way to protect your cylinders from citric acid.

Remember that citric acid may lose its properties over time. To maintain the reaction, periodically change the fluid in the hole. This is a good and really working way to unscrew a broken hairpin yourself. How long it will take to achieve the goal is difficult to estimate. It all depends on the cause of the breakage, condition, size of the stud, and its location.

Classification and design

To unscrew old bolts and studs with broken heads, you can use one of three types of extractor.

Wedge-shaped rod - has the shape of a faceted cone. It is hammered into the prepared hole in the end, wedged and unscrewed. The wedge extractor is easy to use, but requires precision in drilling the center hole to extract effectively. Once completed, it can be difficult to remove the extracted part from the turnout.

Broken pin: why does this happen?

Most often, the pin breaks when a lot of force is applied.

If the master did not calculate his efforts and twisted the hardware too much. A broken car stud is a problem that is mostly faced by owners of used cars. If the stud has rusted to the thread over the years, this means that the car was not used or stored properly. High humidity could lead to stud corrosion. Since the studs are in constant contact with water, the likelihood of rust formation is high. Another factor that makes it difficult to unscrew a stud from a block is exposure to high temperatures. When the exhaust manifold heats up, the temperature of the part can reach 500 degrees. Consequently, this leads to fracture and deformation. Corrosion is a process that can last for years.

As a result, the vehicle owner wonders how to unscrew the stud from the block.

Extractor kits

For convenience and insurance for any unforeseen event, experts recommend buying a set with extractors. It has all the tools you need to easily remove a broken and stuck bolt.

Sets include tools of different diameters:

- bushings for removing the extractor using a wrench;

- bushings for centering the drill;

- drill;

- extractors.

Such kits are considered universal and convenient. But if you wish, you can purchase the tool separately.

How to prevent edges from being torn off

To prevent such a problem as torn edges of a bolt or splines of a screw or screw from taking you by surprise, you must adhere to simple rules:

- You need to buy only high-quality fasteners that have high strength and reliability;

- When tightening and unscrewing screws or screws, do not allow the screwdriver to slip through the slots. This leads to their abrasion and it will be difficult to unscrew such fasteners;

- You should always monitor the condition of the instrument. If a screwdriver or key has licked edges, then it will be difficult to unscrew a screw, bolt or screw with their help.

It is much easier to prevent the edges of bolts, screws and screws from licking off than to then unscrew damaged fasteners.

Do not panic if a problem appears such as a licked bolt head or slots on the head of a screw or screw. There are many ways to solve it. It is necessary to adequately assess the situation and choose one of the available options.

Basic Debris Removal Methods

During normal unscrewing of a bolt, different situations occur. The head may break off below the surface level, or above. The location of the break affects how to unscrew the broken bolt without much effort.

The list of standard manipulations looks like this:

- The fragment is coated with lubricant or rust solvent if the part is old.

- Select the diameter of the extractor, and, based on its size, drill a hole in the center of the screw body (to accurately determine the center point, use the guide sleeve included in the kit).

- Screw or drive in the tool and jam it firmly.

- The fixed extractor is unscrewed together with the stuck hardware using a key or wrench.

Benefits of using the tool

Compared to traditional methods, the device has a significant advantage. Once installed, the fixture practically becomes part of the broken part, but with higher strength. The tool was developed by professionals. Then serious tests were carried out. The optimal shape of the product, pitch of notches, sharpness and number of edges were calculated.

It is impossible to achieve a similar result with improvised means. Only an extractor for unscrewing broken bolts has unique characteristics for holding a broken part. The advantages include minimal time for the procedure. With skill and ordinary auxiliary tools, you can remove the fragment in a minute.

Effective ways to unscrew broken fasteners

Now let's look at how to drill out a broken bolt without special rods. A broken pin or bolt can be unscrewed without the help of extractors, but it all depends on the situation. If the breakage has already occurred at the exit from the thread, and part of the body of the fastener protrudes above the surface, then you can try to tighten it with pliers, a wrench or other tools.

There are several effective ways to remove a broken part. First you need to complete several preparatory steps:

- clean the work surface from debris and dirt;

- treat the threads with machine oil or anti-rust agent. You can relieve internal stress by hitting the piece with a hammer or heating it with a soldering iron, if possible.

If a break has formed above the threaded surface, then it makes sense to try two extraction methods:

- Pliers and an adjustable wrench will help remove the body of the bolt, provided that the threads are loose and movable.

- A grinder and a metal saw are used to form a transverse cut at the end of the hardware. A screwdriver is inserted into this hole and the element is unscrewed.

- The third method is the most labor-intensive, but just as effective. You will need a welding machine. A bolt with a head of approximately the same diameter is selected for the broken part. It is welded to the fragment by welding and the old fasteners are unscrewed without any extra effort.

Methods for unscrewing bolts, screws, screws with licked edges

If the usual method fails to unscrew the fasteners whose edges have licked off, you can use one of several proven options.

Gas key

This method is used when unscrewing bolts, since they have a protruding head that you can grab onto. For this:

- Clean the bolt head.

- Lubricate the joint with kerosene or diesel fuel, a liquid like WD-40 works well, and leave for 15–20 minutes.

- Unscrew the bolt. They do this with a gas wrench. With its help, a lot of force is created and it is possible to grip even a round head well.

The disadvantage of this method is that it is not always possible to get a gas wrench to the desired bolt.

Cutting new edges

If the bolt is large, then using a grinder you can cut new edges on it. It is enough to make only 4 of them and use a smaller key to unscrew the bolt. You can cut new edges on a bolt with a file, but this is more difficult and takes longer. You can make a cut on the head of a screw or screw using a hacksaw or grinder.

You can make a deeper cut on the head of a screw or screw for a screwdriver.

Hammer and chisel or impact screwdriver

This option is more suitable for licked nuts or fairly large screws. The chisel is pressed against the head of the fastening element and, hitting it with a hammer, the screw or nut is gradually turned. Small screws or screws can be removed using an impact driver and a hammer. After loosening the fastening, the work is done with a regular screwdriver.

An impact screwdriver can be used to unscrew small screws or screws with licked slots.

Band or piece of rubber

In this case, use a small part of a medical tourniquet or a piece of thick rubber. The selected material is placed on top of the head of the screw or screw, after which it is pressed with a screwdriver and gradually turned. The presence of rubber will help increase friction and solve the problem.

The harness is placed between the screwdriver and the head of the screw or screw.

Extractor

An extractor is a special tool that is used to unscrew screws, bolts or screws with licked or broken heads.

Extractor - a tool for unscrewing screws, bolts or screws with licked or broken heads

The order of its application:

- Using a thin drill, a small hole is made in the head. In some cases, the extractor can simply be driven into the licked screw slot.

- Select an extractor of the required diameter. Drive or screw it into the prepared hole. This depends on whether a regular or screw tool is used.

- Unscrew the bolt.

Video: unscrewing a licked screw using an extractor

Regular or left hand drill

Left-handed drills with counterclockwise rotation are available for sale. They improve tool centering and reduce the load on the drill, which gives higher productivity and drilling accuracy. By inserting such a tool into a drill, you can unscrew a screw or screw with a licked head. If you don’t have a left-handed drill, you can try to drill out the stuck fasteners using a regular one. In this case, you need to take a drill whose diameter is smaller than the diameter of the bolt or screw

You must act carefully so that you do not have to cut threads for new fasteners later.

The drill bit should have a diameter smaller than that of the problem bolt

Glue

A nut of the appropriate diameter is fixed to the head of the problematic screw or screw using epoxy glue or glue called “cold welding”. After the glue secures it securely, use a wrench to turn the nut and unscrew the screw or screw together with it.

Using glue, fix the nut to the licked head, and then unscrew the screw together with it.

Welding

If you have a welding machine nearby, you can fix a new nut on the head of a bolt or screw by welding it. After this you can immediately unscrew it.

A new nut can be welded to a problematic bolt or screw.

Solder and soldering iron

If you need to unscrew a small screw or cog, use a soldering iron and solder:

- Heated solder is dripped onto the head of the fastener with licked edges.

- While the tin has not hardened, insert a screwdriver into it and wait a few minutes.

- Unscrew the problematic screw and clean the solder tip of the screwdriver.