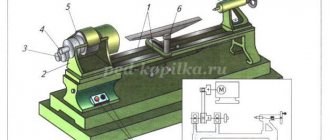

Wood lathes are an indispensable universal device for processing workpieces of various purposes, sizes and levels of complexity of work. In the standard machine chuck, small-sized cylindrical parts are fastened.

Large or non-standard elements require the use of special tools. Therefore, it is very important to understand the technical characteristics and features of the faceplate for a wood lathe, as well as to consider its types in detail.

What is a faceplate for a wood lathe?

A faceplate for a wood lathe is a part in the shape of a steel disk with holes for attaching a dimensional workpiece. Typically, a faceplate for a wood lathe is used in cases with those parts that cannot be clamped into a chuck.

Examples include flat workpieces, large-sized ones, or simply irregularly shaped parts. Such a device is simply necessary when processing products with a displacement of the spindle circumference, as well as products that may suffer from the impact of the chuck.

Faceplate at home

To assemble the unit at home, the master must know the work schedule; this will simplify the installation of all parts and allow the machine to be used for a long time. The technique is quite simple, but all points require specialist attention and dexterity. Step-by-step instructions for making a homemade faceplate:

- Take a flat steel sheet 10 mm thick.

- Steel, undamaged corner 50x50 mm, M8x30 bolts in the amount of 8 pieces, flat washers and nuts for them.

- Carefully consider how a homemade faceplate for a wood lathe will be attached to the spindle of the unit. Buy or machine a threaded bushing.

- Mark the steel plate with a circle of the required diameter. Draw two axes so that they pass through the center and intersect at an angle of 90º.

- Using a jigsaw, make a circle along the marked line and carefully sand it.

- Wet the through grooves along the central axes, not reaching 3 cm from the border of the part, moving a few centimeters away from the center. It is better to pre-drill holes of a slightly larger cross-section than the prepared bolts.

- Saw off four identical segments from a solid corner. Drill one flange of each segment with the same drill as the plate.

- Cut M8 threads in the other two corner flanges. Screw the bolts into it.

- Weld a threaded bushing for fastening to the shaft to the plate.

- Screw the corners through the washers to the faceplate using bolts.

- I made my own faceplate for a lathe. It is necessary to attach it to the spindle of the unit and begin work.

Attach the faceplates to the spindle

To fix the workpieces with such a washer, the corners are moved to the required position and secured with nuts. Each part is securely clamped using bolts; they are screwed into the shelves with an angle bracket with an M8 thread.

Description of design

Once again, the faceplate for a wood lathe is presented in the form of a cast disk made of metal, which has a so-called central threaded hole, designed for fastening it on a wood lathe, or rather on its spindle. In it, the workpiece is carefully secured using metal screws that pass through its holes and are firmly screwed into the wood.

When sold, a woodworking lathe is equipped with a faceplate having an outer diameter of 100–150 mm. If there is a need, then it is possible to additionally buy a faceplate for a wood lathe of any size, with a different location of the mounting holes, as well as a working thickness.

DIY vacuum chuck for wood

If your lathe's headstock spindle has a through hole for knocking out the gear center, you can add a homemade vacuum chuck to your arsenal. For this you will need:

- Powerful vacuum cleaner

- Closed bearing, approximately equal in outer diameter to a vacuum cleaner hose

- A piece of thick rubber hose for connecting the vacuum cleaner and the bearing

- Clamp

- Standard faceplate with hole in the center

- A small piece of MDF or thick plywood

- Textolite for adapter

A bushing is machined from the textolite, one side of which should be equal in diameter to the internal size of the bearing, the other - to the spindle. This homemade adapter is pressed into the bearing using glue; it will be held in the machine due to the tightness of the fit. The resulting structure is connected with a piece of hose to the vacuum cleaner and secured with a clamp.

A disk is cut out of MDF or plywood, attached to a faceplate and ground. It is better to make the surface slightly concave. To ensure a tight fit, linoleum or thin rubber is glued on top. The disk is drilled through the center to remove air. A similar self-made chuck provides a pressing force of 40 - 50 kg, sufficient to hold medium-sized parts during finishing.

Specifications

The design of the faceplate is suitable for machines not only of wood, but also of metal. It is presented in the form of a disk with workpiece assemblies made on it. The materials can be either cast iron or steel. Other materials are used in rare cases.

Tapered hubs and threaded holes serve as a tool for attaching the tooling to the spindle. Specific parameters are selected for certain dimensions of the output end of the shaft. Provided that the fixture, which is clamped directly into the machine chuck, is provided with a cylindrical hub.

The workpiece is secured using clamps, crutches, various clamps and other clamping devices. For this purpose, a lathe chuck is installed and used. It can be assembled on a faceplate either along the axis or with its offset. It is worth paying special attention to the faceplate when using production safety precautions.

Large dimensions, non-standard fastenings and non-cylindrical shape of surfaces pose a serious danger both to the turner himself and to others. At the beginning of work, it is necessary to balance and secure all the elements so that the structure does not fluff up and individual components do not fly apart.

What are the varieties?

Due to the widespread use of faceplates for wood lathes, there are a huge number of modifications and mounting options, and from here the number of varieties is increasing. The faceplate for a wood lathe itself has a simple design and a wide range of uses, which has led to an increase in the methods of securing the elements being processed. Below we will consider in detail each of the types of faceplates for a wood lathe.

T-slot disc

This design is a surface with recesses on it. All fastenings are made using screws. You can find a huge number of types of products for installing this equipment. It is important that the quantitative factor of the grooves changes, namely, the larger the number of grooves themselves, the purpose increases.

During the manufacturing process, disk parameters can easily change and adapt to a specific situation. This type of faceplate for a wood lathe is the most common because it is convenient and versatile, and has many uses.

With through grooves

Faceplates with through grooves are especially suitable for processing metal, not just wood. Through grooves are their main difference. Their size and frequency depend on the task of use.

In most cases, the holes are located along the entire circumference at a certain distance. There are models where the groove is solid and continuous. Installed with screws. Often the part is placed on the disk with the reverse side if a particular product has corresponding holes.

As a rule, other mechanisms are installed on the surface of the adapter. They make it possible to make the range of clamps more diverse, necessary for working with the disk and increasing its adhesive capabilities.

With holes

The entire line of varieties has a common feature - a central recess. Thanks to this, the disc fits easily onto the chuck, which is why threads are used. All other holes are located according to specific regulations. The number of grooves directly depends on the product line. They can be round, oval, or even elongated.

There is also more than one option for fastening the workpiece in the faceplate; in addition to screws, clamps can also be used, which significantly increase the number of options.

Drive faceplates

Such discs have a special recess along their entire circumference, which holds the clamp. Due to this type of disk, the parts are placed between centers, and the torque is transmitted from the shaft to the product.

The clamp, in turn, encircles the product itself, thereby being similar to a coupling. In addition, on the disk itself there are holes of different sizes, having a T-shaped format; their number can be any. A faceplate of this type is not limited to clear parameters; they completely depend on the purpose of use.

With a square

This type of faceplate for a wood lathe has a so-called additional adapter with an angle shape. It is attached to part of the disk, while releasing the other side with an empty flat surface. The workpiece is located on this adapter.

The essence of this additional part is to reduce the mechanical factor for the part. Therefore, it is better to use it if the product is vulnerable or has soft areas and thin parts.

In order for the stability to have the maximum indicator, it is necessary to install fixation at one point on the surface, and also select at least three. You can choose more, but it all depends on the characteristics of the material that is used. It is important to use additional fasteners.

For example, if the shape is quite thin, but at the same time elongated, then a special adapter is quite suitable. The trident cartridge is used when working with long wooden structures with a flat base.

Jaw chucks

The most convenient and functional. They work both in compression and expansion, so they can grip the workpiece both from the outside and from the inside. They differ in the number of cams and their drive mechanism. Unlike metalworking, two- and three-jaw chucks are practically not used for turning wood. Options with a spiral drive and non-removable cams are also not popular. The most common type of lathe chuck for woodworking is self-centering four-jaw, with a rack-and-pinion transmission mechanism and replaceable jaws. They are supplied to the Russian market by the brands Axminster, Jet, Barracuda and other, less well-known companies.

Jaw lathe chuck

4-jaw lathe chuck Ø150 mm

4-jaw lathe chuck Ø100 mm

Types of cams

According to their shape and purpose, replacement jaws for wood lathe chucks are divided into several types, which have special markings:

- A, G, M – for compression, differ in size and depth of grip;

- D and F – act on unclenching;

- C and H are universal. Different shapes of sponges;

- To work with soft, compression-sensitive wood, cams with rubber fastenings are used.

Advice and recommendations from experts

The faceplate is a widely used device in metalworking and woodworking. Due to the fact that it is intended for the production of non-standard parts, the tasks before them can be very diverse. Therefore, during production, it is necessary to take into account many nuances.

From this it is clear that specialized stores have a huge number of faceplates. Sometimes even this is not enough. In this case, turners make them themselves, focusing on their own needs and requirements for a given faceplate, which helps to tailor it to a specific production goal.

It is important to always have a whole set on hand, including faceplates for various purposes. However, some of the kits may be homemade. It happens that some variations may not be available on the market or in the assortment of a specialized store.