Creating wooden cylindrical products is impossible without a hand tool - a chisel for a lathe. It is from under its blade that the unnecessary amount of material is removed and the workpiece acquires an artistic decoration.

Turning chisels can be bought ready-made, but such kits are very expensive, especially high-quality ones. Cutters for wood processing are easy to make yourself, which will be discussed further.

Carving tools

General principles

Wood carving is a fairly popular technique for decorating various products.

As a rule, the process itself follows this scheme:

Note! Sometimes undisturbed parts of trees are decorated with carvings. In this case, a fragment is selected whose shape has maximum decorative potential.

- Then a rough leveling of the surface of the workpiece is performed, during which all defects are removed from it.

A variety of tools are used for figured carving

- After this, the surface is processed with special cutters, with the help of which a part of the wood is selected. Due to this, a decorative relief is formed.

- After the actual carving is completed, finishing is carried out - grinding the cut areas, impregnation with protective compounds, full or partial painting, varnishing, etc.

The most important tools in this process are the wood carving cutters. In addition to the skill of the carver himself, it is the quality and correct selection of the cutter that determines how clean the ornament or plot image on the wood will be.

That is why below we will look at the main types of such tools and describe where and how they are used.

Main types of incisors

To create three-dimensional images, craftsmen use a variety of types of wood cutters. In principle, if you have the skill, you can do without some of the products listed below, but to achieve the best result, it is better to collect as extensive a set as possible and use each device for its intended purpose.

Cranberries with blades of different shapes

The main types of cutters are presented in the table below:

| Variety | Application at work |

| Blunt knives |

|

| Chisels | The most common type of incisors. A typical chisel is a long rod with a cutting edge formed at the end. |

Depending on the shape of the chisel edge, there are:

- Flat – used to form straight lines and recesses. Flat chisels with a wide blade are also used for roughing to cut or chip away surface defects.

- Angle - used for cutting V-shaped grooves and notches, as well as for forming shaped elements. The smaller the angle of closure of the planes of such a chisel, the deeper the relief it forms.

- Semicircular ones are one of the most common in figured carving. The rounded shape of the end blade allows you to effectively remove wood from the solid wood, forming a recess. Small semicircular chisels are also used for texturing and scoring smooth surfaces.

- Bracket - functionally similar to semicircular, but when wood is removed, a groove is formed with clearly defined internal edges.

- Reverse (round and bracket) - used to form semicircular and rectangular protruding parts, as well as to draw parallel lines.

Wood chisels of most varieties can be produced with both straight and curved shafts. In the first case, the design of the tool allows it to be used together with a mallet, in the second, the carving is carried out solely by muscular force.

Read also: DIY triac voltage regulator

Clukarza is usually used for finishing carvings with strong penetration, which allows the formation of a clear relief.

Generally, these tools are classified by blade shape:

- Direct.

- Semicircular.

- Oblique (distinguish between left and right incisors).

- "Swallowtails".

- Stapled.

- Reverse.

- Corner ones.

The main function of this device is to remove wood cleanly and in large volumes.

Spoon cutters of different shapes

Additional accessories

However, a master carver, in addition to chisels and knives of various shapes and sizes, also requires other tools.

The required minimum additional equipment includes:

- Wood saws (hacksaw or reciprocating saw for rough work, bow saw for finishing work).

- Jigsaws.

- Drills and rotators.

- Planers for leveling planes.

- Set of wood files (rasps).

- Mallet for processing hard wood with cutters.

- Devices for sanding wood.

Teslas of different sizes

If the master works with fairly large structures, then in addition to simple cutters he may also need figured hatchets - the so-called adzes. According to the principle of operation, they are similar to cutters (naturally, adjusted for the scale and purity of the work).

Tips for choosing

If you are planning to master the technique of wood carving with your own hands, then you need to start by selecting the appropriate tool. And here we are faced with a dilemma: really high-quality cutters are quite expensive, but if you buy a set for beginners “on the cheap,” then working with inconvenient and constantly losing sharpness devices will discourage you from engaging in this type of creativity for a long time.

Ready set of tools

The optimal solution would be to buy several good cutters, and then, if necessary, expand your toolkit. To begin with, we will need at least one medium-sized blunt knife, as well as four to five chisels: one flat, several corner and semicircular ones with different blade curves.

High-quality products from a foreign manufacturer

As for specific instances, you need to pay attention to the following features:

- The blade must be durable and well-hardened, free from rust and other defects.

- The cutting part must be securely, without play, fixed in the handle.

Note! This does not apply to knives with replaceable blades - in any case, they will have minimal play that you will have to put up with.

- Handle material: wood or durable plastic. However, the second option is still somewhat worse, since the wooden handle fits much more comfortably in a sweaty hand.

- Naturally, the handle should be even and smooth, without burrs or cracks.

- If we talk about the shape of the handle, the most common are cylindrical options (suitable for impact carving with a mallet), conical and mushroom-shaped models.

- Some manufacturers produce chisels and jambs with anatomically shaped handles equipped with finger grips, but many novice craftsmen have complaints about their convenience.

- The manufacturing company also plays an important role: today on the market you can find both domestic and foreign forms that produce products of quite decent quality. But what you should refuse are the frankly cheap Chinese and some domestic cutters: yes, you will save on the purchase, but even if you cut these products, they won’t last long.

Purpose of turning tools

Types of wood cutters

This type of tool is designed to remove a specific volume of a part in a controlled manner. Structurally, they are similar to each other and consist of a cutting part for wood and a mounting point. The latter most often has a rectangular or square shape.

The cutting edge may be formed by one or more surfaces. Its main characteristics are the width of the blade, its shape and the ability to adjust the direction. In the vast majority of cases, the edge is an integral part of the cutter design. The choice of one model or another depends on the type of work.

The main difference between wood cutters is their location relative to the workpiece:

- radial. The cutter is installed perpendicularly and is designed for work on removing large volumes of wood;

- tangential. Processing occurs tangentially, which makes it possible to create a pattern of complex shapes.

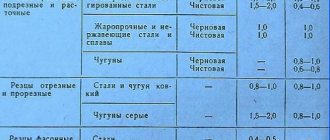

The latter is most often used for fine machining on automatic turning lines. Radial models for wood are most common in mechanical semi-automatic machines. Steel grades U8, U9, U10 are used for production. It must be hardened, since in some cases carbide brazing may be required to perform specialized work.

When choosing a specific model, it is necessary to take into account the processing material. Hard wood will lead to rapid dulling, which will affect the quality of further processing of the workpiece.

Manufacturing and service

Making the cutter yourself

Many craftsmen, either wanting to save money or not trusting third-party manufacturers, prefer to use homemade carving tools. In principle, making a knife or chisel is quite simple, the main thing is to choose the right material.

The photo shows a hacksaw blade and a simple jamb knife made from it

The raw materials for our design can be used:

- A saw blade for wood or metal is an almost ideal blank for a jamb knife. During the manufacturing process, we cut off a piece of blade on a machine or simply break it off at the angle we need, and then form a cutting edge.

- The wood saw blade also has acceptable characteristics. The carbon steel used to produce such saws holds an edge well, which means that the cutter will not become dull even when working with hard wood.

- Before making a semicircular chisel, you can look “in the bins” for an unnecessary punch. To make a tool, we will only need to cut off part of the wall diagonally - and we will get a very convenient device for sampling wood.

An important part of any cutter is the handle.

The instructions for its manufacture are also not complicated:

- We take a block of hardwood and cut a handle out of it.

- We make a hole at the end of the handle, the shape of which corresponds to the shape of the shank of the metal part.

Gluing the blade into the handle

- We glue the cutting part into the handle, and then clamp the structure with a metal ring.

Note! Sometimes the handle is made of two halves. In this case, the blade can be additionally secured with screws or rivets, and gluing should be done in a vice or clamps.

Sharpening cutters

You can only get a decent result if you work with a perfectly sharp tool. And since even the softest wood dulls the blade quite quickly, sharpening wood cutters is definitely included in the “minimum program” of training for a novice carver.

To perform this operation we will need:

- Bars of different grain sizes - from coarse to fine.

- Old leather belt for straightening.

- GOI paste (or similar composition).

We do the work like this:

- First, we moisten a coarse-grained block, place the cutter on it at the selected angle and sharpen it using pressure from ourselves.

- We switch to a block with medium abrasive grain and repeat the operations until a clearly defined sharpened edge appears.

- We carry out the finishing on a diamond stone, removing the metal chamfer that appears on the tip of the cutter.

- Then we apply a layer of GOI paste (a composition based on chromium oxide) to the belt and polish the working part to a mirror shine.

Editing on the belt

Advice! Finishing on the belt can be done more often than the main sharpening - this way we can correct a slightly dull blade.

It’s easy to check the quality of our work: if the cutter cuts the newspaper without effort, it means we’ve done everything correctly, and we can start working on the workpiece.

Overview of species

The cutters differ in functionality, design nuances and other parameters.

By purpose

Here we are talking about the materials with which the cutter works.

- On wood. In markets they can be found in sets with rings, combs, reiers, hooks, and meisels. The cutters and rotation mechanisms are fastened together.

- For metal. When you need to weld or solder a plate, that’s when they talk about the optimal choice for cutters. Hard alloys and high-speed alloys are used more often in this case. Installation of such cutters is possible not only on lathes, but also on slotting, planing, special-purpose and others.

This classification is small, the choice here will not be difficult.

By design

These are solid cutters in which the shaft and head are articulated by one system. Or is it a tool with welded plates, they are very firmly connected to the head. If the soldering of the plates was carried out without technical precision, cracks may subsequently form on the working surface. Such cutters are widely used because they are suitable for a wide variety of machines.

By type of processing

Here the cutters are divided into fine and semi-finish. For finishing machines, the feed rate is low; material with a small thickness is removed from the blank. Most often, such tools are represented by a through cutter. Semi-finish ones are very similar to the previous version, but they are weaker in characteristics than finishing ones. But they can be used for the same tasks.

By type of installation

Tangential cutters are a tool that is installed at a certain angle, any angle except the straight one. This is measured relative to the axis of the surface that is undergoing the operation. And the tool is distinguished by a complex fastening scheme for internal turning.

The radial cutter is distinguished by fixing an exclusively right angle on the surface that is being processed. A popular option for industrial purposes. And the radial version has a big advantage - it is a simplified fastening system.

By feed type

Here everything is even simpler: left-handed cutters are tools with the right-hand side of the cut, and it is towards it that the metal being processed is turned. The right incisors have a cutting part on the left; the metal surface for processing is turned onto it.

By fastening the cutting part relative to the rod

And this characteristic presents 4 types of incisors. The bent ones are distinguished by a special curved line, a characteristic feature of the projection axis of the upper position. And lateral localization ensures the straightness of the lines. Straight incisors are those whose axis of projection maintains an even line, both from above and from the side.

In retracted incisors, the head and shaft are different in size, the head will be smaller. It is attached to the incisal axis. The part is characterized by some displacement relative to the axis of the cutters, in any direction. Well, curved incisors in the upper localization are connected to the projection axis by a straight line, while the lateral projection is connected to a curved line.

By processing method

And there are many varieties here.

- Trimming. If it is a machine with cross-feed workpieces, the tool is easily connected to the equipment. These are either the edges of different surfaces, or stepped elements.

- Walkthroughs. Functional for metalworking with cross and longitudinal feed equipment. This is relevant if trimming concerns the ends, cylindrical and cone-shaped workpieces.

- Boring. Needed for through and blind holes, for recesses and recesses.

- Round. Here the shape determined the name.

- Threaded. External and internal threads are formed, with a trapezoidal cross-section, as well as round and rectangular. The products themselves can be smooth, round, or convex.

Wide selection of shapes and models

When processing wood blanks professionally, it is important to correctly select the appropriate tool for wood turning. A wide selection and large sets with diverse tips will allow you to cover a significant part of the work.

Based on functionality, wood chisels are usually divided into the following groups:

- Rough peeling . The tool has a pair of working edges that meet at an acute angle. It is believed that this design is significantly safer than radius analogues.

Raiser for rough roughing

- Finish turning . Similar types of cutters for a wood lathe remove a small layer of chips and are not intended to give the workpiece a shape, but their purpose is to give external smoothness to the outer surface. Metal tips are available with left or right sharpening.

Finishing tool

- wood cutter They are used to work with non-standard surfaces.

Shaped can have almost any configuration

- Cut-off cutter . It is currently relevant for one operation in which it is necessary to separate some part from the workpiece.

Cutting width 10 mm

- Boring . With the help of such products, excess material that appears during the processing process is removed. A special ledge located in the cutting area helps in such an operation.

Boring tool to remove excess wood

- Round wood turning tools They are used for processing radius workpieces. The working part can be either radius or with small technological teeth.

Reyer for turning bowls

- Wood turning at the end is carried out using a conventional cutting file.

- As auxiliary equipment, special stops are used on cutters that limit the depth of cut.

In addition to the standard set, professionals use homemade wood lathe cutters in their work. This approach increases productivity and helps expand the range of finished products.

If you plan to engage in wood processing for a long time, then you cannot do without high-quality tools, which are made from tool-grade steel. It is able to withstand high production intensity, which homemade products are not always capable of.

Homemade wood turning tools

The greatest difficulty in the production of each type of chisel for a lathe is the selection of blanks for the cutting part. In addition to ensuring appropriate hardness, you have to think about the possibility of installing the metal part in the holder. It will allow you to fix the cutter in the desired position for comfortable processing.

The most acceptable material for homemade cutters is tool steel (U8, U10, U12, etc.). It is worth considering that it will be problematic for processing in a garage or at home. This is due to the high initial hardness of the material.

Traditional practice is to manufacture cutters from carbon steel for a lathe and then harden it. The tool itself is made from the following raw materials:

- Steel reinforcement or rods. It is preferable to select workpieces with geometric parameters as close as possible to the future cutting shapes.

- File or rasp. Knives for home use are made from used files that have lost their original appearance and cutting ability. It is important to check the workpiece for cracks and severe chips in order to obtain a quality product.

- Pieces of springs from cars. Such steel is problematic to process without preheating and giving it the closest possible shape. For this operation, an autogen or welding machine is used.

A good alternative is to make a basic turning body in which you can change the cutters. However, such a situation requires the presence of mounting elements in the design of the finished product. During operation, they are required to hold a significant load and not change the original position of the cutting part.

Rasps or files that have already served their useful life can be used as workpieces

When the workpiece has been bent to the required shape, it is necessary to pre-sharpen the edge. At the next stage, the working part is hardened. This is done by heating the tip over an open fire, such as with a gas burner or in a blacksmith's forge. Next, we provide rapid cooling in a large volume of machine oil.

High-alloy and high-carbon steels should not be heated in water, as the internal stresses of the material will lead to cracks, brittleness and failure of the workpiece.

Self-made wood cutting auxiliary equipment for a lathe is recommended to be tested on soft wood. This will help avoid possible negative consequences with it. After a short test, you need to check that the original sharpening and shape of the tool are intact.

VIDEO: How to make a reyer with your own hands (rough cleaning)

VIDEO: Do-it-yourself Meisel (finishing)

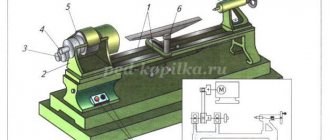

Components of a mini metal lathe

The composition of any turning device is traditional; all of the following elements are present regardless of how it is made - manually at home or industrially.

The devices consist of the following components:

bed

The main load-bearing element of the entire structure, giving it rigidity and strength. The bed of a homemade metal lathe is made from wooden beams or metal blanks in the form of ready-made corners.

The main requirement for the bed is the necessary strength, since the structure of the machine is exposed to strong vibration during the processing process.

Drive unit

The main element of the part responsible for the power of work. The drive must be selected very correctly based on the power required. This is not an easy task and one that needs to be thought through carefully.

A used drive from a washing machine, a construction mixer, or something else will suffice if you are making a lightweight machine for metal work.

The number of revolutions with such drives is about 1500 rpm, and the power is 200 W or slightly higher.

- Tailstock. This is a special steel plate to which a steel corner is also welded. It is needed for tight fixation of the workpiece to the bed for high-quality processing.

- Headstock. This is the same part as the tailstock, but unlike the front one, it is fixed on the movable frame of the device.

- Front and back centers.

- Caliper.

This is one of the key factors for the working elements of the device, information about which you can read below.

Self-made cutter

To make a high-quality wood cutter at home, you need to follow these steps:

- Making blanks for a knife for a cutter. It is best to use an old circular wheel to create blanks. The metal must be cut using a regular grinder into small rectangular strips measuring 20x80 mm. It is worth noting that each strip can be turned into a good tool cutter in the future.

- Giving the correct shape to the main incisor. In order for the part to acquire the desired shape, it must be carefully ground. The procedure can be carried out in two ways: by forging or by sharpening on a machine. Forging is necessary to create the correct bend, and turning is necessary to obtain a good shape for the cutter knife.

- Correct sharpening of cutters for hand tools. To properly sharpen a knife, you will need a regular grinding machine with a fine-grit working wheel. The part itself must be held at an angle of 45 degrees. Depending on the total length of the cutter, the sharp part of the tool should be 20 or 35 mm. The knife itself can be sharpened not only manually, but also using specialized equipment.

- Making a handle for comfortable operation. To prevent wood carving from causing discomfort, it is necessary to make a high-quality wooden handle. Depending on personal preferences, the handle can be made manually or on a special machine. If you chose the first option, then after planing the product must be sanded with sandpaper.

- Connections between the knife and the handle. The metal cutter must be carefully inserted into the handle. To do this, you will need to drill a hole 20 or 30 mm deep in the center of the wooden handle. The blade of the cutter should be located outside, but the base itself is carefully driven into the handle. Separately, it is worth noting that for reliable fixation at the end of the metal workpiece, it is necessary to provide a special point in the form of a thin needle. At the moment of forgetting, it is advisable to use a guard made of thick fabric, so as not to dull the working blade of the knife by the end of the procedure.

- Installation of a crown for quality carving. In order to secure the manufactured knife, it is necessary to install a special metal retaining ring. A hole is cut out on a wooden handle, the contour of which corresponds to the size of the ring. Then the thread is made and the crown itself is secured. At the end of this procedure, the wooden handle should be crimped and the cutter should be securely fixed inside the product itself.

- Grinding the knife. In order for the process of wood processing to bring pleasure and good results, you need to bring the blade to readiness. For these purposes, it is best to use a small sharpening stone or simple ceramics. A little lubricant should be poured onto the surface of the sharpening product (motor oil can be used), after which the cutter can be safely sharpened perpendicularly.

After this, you are guaranteed to get a sharp tool, and if you sharpen the cutter correctly, then the wood carving will be of better quality and faster. If necessary, the cutter can always be upgraded and slightly modified.

Modern tools and wood processing technologies are directly dependent on each other

That is why, when purchasing specialized cutters, it is important to take into account not only the manufacturer’s brand and declared performance characteristics, but also the scope of their use. Standard and inexpensive kits are most suitable for minor household repairs and the creation of simple products.

Professionals will require more advanced and versatile tools that will make the process of processing wood workpieces faster and more comfortable.

And those who have already gained the necessary experience can make their own wood cutters, filling their collection with the most diverse and unexpected elements.

Knives for wood carving are a must-have accessory in the arsenal of a craftsman who makes decorative objects from natural wood.

Such tools can have different types and shapes, which directly affects the specific processing of individual parts. The most famous cutter, which is very popular among our craftsmen, is the Bogorodsk knife.

Types of machines (for wood and metal)

Universal

The universal lathe is designed for initial roughing, as well as sharpening, cutting and drilling. Also, using this equipment, carvings are applied to a wooden object.

Lathe-screw

This type of lathe is designed for processing cone-shaped workpieces and for applying threads.

Turning and milling

Most often, this equipment is used for boring grooves. If such a machine additionally contains a copying device, this will allow the work to be completed faster and more accurately. Also, such machines help to obtain objects of completely unusual shapes, real works of art.

Desktop

This equipment is suitable for domestic use only. Such machines can be located in an apartment, in a garage, in a private house and perform the most standard operations for processing wood products. It is on such machines that folk craftsmen make the most necessary and beautiful items for their interior.