Business can be associated not only with the manufacture of products that are directly consumed by the population. Good results are shown by enterprises that produce equipment for production itself. What equipment is used for home and professional wax making, which is better and what is the price? Our article is about this and more.

Foundation is a thin wax sheet on which small hexagons are imprinted using a special pressing method: the bottoms of the cells. This is the material that forms the basis for the honeycomb, thanks to which the bees can devote all their efforts to collecting honey.

Types of foundation and methods of making it

The foundation looks like several thin sheets of wax, on both sides of which there are hexagonal depressions - cells.

Foundation is made from different materials, and therefore it is divided into several types:

- natural (produced by bees);

- similar in parameters to wax;

- plastic (mostly polypropylene).

Domestic beekeepers rarely use plastic foundation.

But production from wax or its analogues can be divided into 2 methods:

- The first is rollers equipped with different drives. The working components of these rollers have a relief in the form of cells. Namely, an already heated thin wax sheet will be passed between them;

- second - a press is used. The working parts are 2 plates with hexagonal protrusions, in which the necessary “honeycombs” are formed.

Important! Compared to rollers, the press does not have high productivity, and therefore it is better to use it for the production of several wax sheets.

Main types of equipment

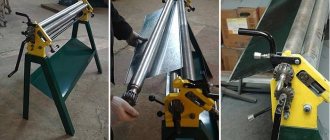

There are three types of foundation rollers:

- Manual rollers - this model is characterized by small dimensions. There are almost never any problems with its installation or maintenance. This equipment includes the following parts: a bed (it is represented by a massive base), feed rollers, receiving rollers, which are connected by a chain drive, and a set of clamps.

- Electric - these products are characterized by high performance. This is due to the use of an electric motor that activates an actuator that pulls the pipe through the rollers.

- Equipped with a hydraulic drive, these units are endowed with increased power. They belong to capital industrial equipment.

Of these three types of equipment, the manual model is mainly used in making foundation. The rollers on it are endowed with the same relief as the finished base for honeycombs. Creating a form is not considered an entirely easy process. The wax must be heated; it is always used in liquid form. After heating, this mass is rolled through rollers. Having taken the required shape, it gradually hardens.

Foundation rollers are used to roll out a thin strip of wax that forms the important component of the honeycomb. Experienced beekeepers know that the width of the cells on the combs differs in different zones of the CIS, it varies between 5.12 - 5.69 mm.

For our zone, according to measurements carried out by specialists, the cell width is 5.33 mm. If you believe the data of scientific beekeepers (and there is no reason to doubt their reliability), then bees are able to build their honeycombs with an accuracy of 0.015 - 0.020 mm. Such data should be taken into account when manufacturing foundation rollers.

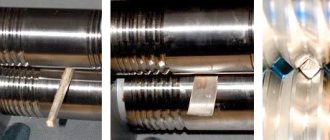

Three types of this equipment are usually used in production:

- two-roll - this model is represented by two shafts that are located parallel. The upper shaft has a small cross-section; this part is made of high-strength steel. The lower shaft is characterized by the presence of a cross-section with a large diameter. For its manufacture, steel is used, which is coated with rubber;

- three-roll;

- four-roll.

When processing metal sheets, three- and four-roll models are most often used. To make foundation, a two-roll unit is sufficient. It is considered more practical for use in beekeeping.

Now let's move on to the process itself with all the details to find out how to make your own rolling unit.

Features of foundation production using rollers

This unit consists of the following components: 2 engraved shafts, 2 gears, adjusting bolts and a base.

The rollers are placed in a container with a separation solution. It is used to make the manufacturing process easier: in this way, the softened wax will not stick to the protrusions, and only high-quality “pits” of the required shape will be formed on the sheet.

This solution is sold in specialized stores, but you can make it yourself. To do this you will need: liquid honey or a solution of 1 liter of water, 100 g of liquid soap without fragrances and 2 tsp. glycerin to form a thin layer on the surface of the foundation with an odor that attracts bees.

Video: Rollers for foundation

The wax production process is as follows:

- The wax sheet is placed in the bath.

- This sheet is carefully moved towards the gap between the rollers and directed into it.

- The handle is turned away from you, and the rollers begin to rotate. Thanks to this process, the sheet will be completely placed in the gap and passed through it.

Foundation press

This is a fairly simple device with which you can obtain a limited amount of the finished product (the average productivity of a hand press is no more than 10 sheets per hour). Therefore, in large apiaries, the use of a press is impractical. The principle of operation of the device is similar to a waffle iron - the press consists of two halves with grooved internal parts. The factory press consists of two heavy plates, usually made of aluminum. They are connected to each other with a small gap, which is equal to the thickness of the sheet - from 0.2 to 0.6 mm. Sometimes beekeepers manage to convert old waffle irons into foundation presses, fixing silicone matrices for foundation inside.

Press for making foundation with your own hands

Despite its modest productivity, this type of foundation production machine is still consistently popular among beekeepers. Unfortunately, there are no domestically produced presses for sale, and the price of foreign tools goes through the roof for 50,000 rubles. For this money you can buy good rollers from a Russian or Ukrainian manufacturer. A simple press can be assembled independently without any problems or costs. For this you will need:

- Beeswax.

- Silicone for the mold. Any non-toxic variety of silicone or synthetic raw material used to make molds will do.

- Two wooden plates, fastening elements for the plates.

- Foundation sheet – 1 piece.

First of all, take one wooden plate and a ready-made sheet of foundation, and apply a layer of silicone to it. The silicone must be very carefully smoothed over the surface of the wax sheet so that all the cells are filled. Then silicone is applied to the plate itself and smoothed out thoroughly. Next, the foundation sheet is covered with a second layer of silicone, smoothed out, and connected to a wooden plate with the silicone-coated side.

As a result, the reverse side of the sheet remains clean, as does the second wooden plate. They are also treated with silicone in the same way.

The first layer of silicone is carefully smoothed over the surface, after applying the second layer, both wooden plates are connected to each other so that the wax sheet is between them.

Now you can attach metal loops to the wood-wax “sandwich” and wait until the silicone hardens completely. You can speed up this process by placing the structure in the oven and keeping it for some time at a temperature of 70-100 °C. Once the silicone is sufficiently strong, you can open the plates, attach the handle and additional side limit plates. For ease of use, you also need a tank into which excess wax will drain.

How to make wax on your press yourself

Working with the press is very simple: first, melted wax is evenly poured onto the lower wooden plate with a grooved silicone surface and pressed with the upper plate.

Important! There is no need to try to accurately calculate the amount of wax, its excess will flow into the tank and can be reused.

The remaining frozen wax on the edges of the plates can be cut off with a spatula. After this, the plates are unclenched, wait until the wax has completely hardened, and carefully remove the finished sheet.

To prevent the wax from sticking to the silicone, it is recommended to lubricate the matrix with a solution of laundry soap. However, as practice shows, sometimes bees build very poorly on foundation sheets that have traces of soap solution on them.

Important! Instead of a soap solution, it is recommended to use honey diluted in warm water as a lubricant for the silicone matrix (honey is full).

The result is a light, translucent corrugated sheet of fairly high quality. The only possible drawback of this design is that the edges of the hexagonal cells may be slightly less pronounced, which has virtually no effect on the construction of honeycombs by bees. Of course, this description of the wax production process is very superficial. In fact, every good beekeeper has his own secrets for making high-quality wax: special preparation of the wax, its repeated melting in a wax melter and in a water bath, dehydration, heating the press plates to a certain temperature, etc.

It is also worth considering the process of manufacturing plastic foundation in a press. In fact, it is not much different from making wax from natural material. You will need:

- Silicone (as a plastic substitute) and hardener for silicone.

- Spatula, tape.

- Actually, the press.

The workflow is as follows:

In a separate container, silicone and hardener are mixed in the required proportions. Using a spatula or knife, silicone is applied in an even layer to the matrix, after which it is pressed tightly on top with the press lid. After the silicone has hardened, the finished sheet is removed from the press and kept for some time until the artificial foundation has completely hardened.

Important! Before installing a plastic product in a frame, the surface must be covered with a thin layer of natural wax, since bees are very reluctant to build honeycombs on pure silicone.

Melt wax is applied to the silicone with a soft brush or roller. You can also dip the artificial foundation into melted wax - it will be faster.

Products made from silicone and other form-forming synthetic substances last quite a long time, and silicone matrices in a homemade press will last more than one season. The only condition is not to overheat the mold. Thus, using a press of even such a primitive design, it is possible to provide a small apiary with the necessary amount of natural, high-quality foundation.

Advantages of homemade rollers

Manual rollers are the most convenient and practical, since they do not require electricity to operate. The clamps, which are fed by rollers and have a chain drive, are mounted on the main frame, and therefore they are more reliable, compact, easy to adjust and durable. Do-it-yourself production is a time-consuming and painstaking process, but it will cost much less than store-bought equipment.

Did you know? Bees can make not only hexagonal, but also pentagonal honeycombs. The latter are usually found between large and small cells.

Advantages of home rollers

A handmade model made independently is painstaking, but profitable. Savings and additional benefits in business. With little experience, every beekeeper can try to make such a machine. After work, it is important to monitor the condition of the shafts, wash and dry them. Lubricate bearings regularly. In addition, it is important to observe the storage conditions of the equipment so that it lasts a long time.

Making foundation is an effective method that allows you to produce enough material for the insects to fully work. Do not leave the bees without this material while he is looking for where to purchase factory material. Small size of the machine and no need to connect to the network. He is present with the beekeeper during movements to honey-bearing places. And they are much easier to use than a press.

It is important to ensure that children or strangers do not try to pass paper or pieces of rags through the rollers. This cannot be done.

Making wax with your own hands at home

Although it is difficult to make wax with your own hands, you can master this science. To do this, you will need to study the assembly technology, as well as prepare the tools for the job.

Tools and materials for work

You will need the following tools:

- pipe frame;

- U-shaped profile;

- threaded clamp;

- transmission chain.

Assembly technology

This process consists of the following steps:

- Mounting the main frame, which can be done using a pipe frame as a basis.

- Operation of the U-shaped profile. A deforming part of the mechanism is placed on top of the open part of this component, which is then secured using a threaded clamp.

- Operation of the transmission chain in order to assemble the mechanism.

- Mounting the chain on the sprockets. Then we pull it along the line and check it, and also install the feed handle.

- Manufacturing of rollers.

- Attach the rollers to the frames using rolling bearings.

Important! To make rollers, hardened steel is best. Thanks to it, the machine will last longer and be more reliable.

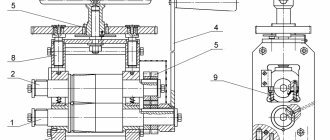

How to make a mini lathe yourself?

Any production must begin with the development of the project.

- At the design stage, specifications are developed. Specifications are a list of parts included in an assembly.

- There can be quite a lot of nodes in an installation. Some details may be repeated. But there may also be the presence of many very diverse blanks. The designer should strive to unify the parts used as much as possible, only then will the product be competitive in cost.

- After the first design stage, the selection of components begins. It will allow you to determine the actual design, where there will be a minimum number of original parts. Then it is easier to produce a working sample.

- When picking, parts are identified that are impossible to do without. They will have to be made. Everything else is cheaper to buy.

Lathe projections:

Most attention is paid to the headstock. The engine is located here, and a cartridge is installed at the same time. For wooden products, three-jaw fasteners are rarely used. Drive chucks are more often used; they require initial centering of the workpiece, and then installation of a driver, which will rotate the workpiece.

Lathe headstock option:

Some craftsmen make a drive from a drill. They have enough power (among modern power tools you can choose a drill up to 2…3 kW). They have a mechanism for smoothly changing the rotation speed. There is also a reverse.

Novice craftsmen are often interested in how much a small machine made by themselves costs. Sometimes a product will cost almost nothing, since components can be found for free. All that remains is to correctly assemble the machine and start using it effectively.

Possible manufacturing errors

During production, it is necessary not only to adhere to the collection technology, but also to avoid mistakes, which are the following:

- cracks on the surface;

- stretched surface at the point of greatest load;

- deformed parts.

Each of these errors will definitely have a negative impact on your machine, and therefore you need to do everything correctly, taking into account all the nuances and possible errors.

Did you know? The average working honey of a bee is 1/12 of one teaspoon.

Thus, making rollers yourself is quite difficult, but if you carefully study all the features of this process and adhere to the correct assembly technology, then this event will not be so difficult. But in any case, with this option you can save money and enjoy the convenience, compactness and reliability of the machine.

Workshop technical equipment

After studying the technological processes, equipment, tools, and materials for the production of foundation are purchased. Main mechanisms and devices: sterilizer, mechanized belt, rollers.

The last element included in the machine for the production of high-quality foundation is the basis of the technological process. Rollers require careful selection, since the result depends on them. They are mechanical and automated.

Each equipment manufacturer has different forms of production. Silicone matrices are widespread and have high quality, extended service life and convenience. If you don’t have the funds to buy an expensive device, then a plastic or cement matrix will do.