Content

- Briefing upon hiring

- Safety requirements before starting work

- Safety during work

- Emergency situations

- What to do after finishing work

- Machine requirements

All workers must follow the labor safety instructions when working on a drilling machine. The safety and health of each employee depends on this. A machine is an object of increased danger, so violation of instructions often becomes the cause of industrial injuries.

Instructions for labor protection when working with drilling tools

These labor safety instructions have been developed specifically for personnel performing work with drilling tools.

GENERAL OCCUPATIONAL SAFETY REQUIREMENTS

1.1.

Workers over 18 years of age who have undergone a medical examination, introductory briefing on labor protection upon hiring and initial briefing at the workplace, as well as repeated and, if necessary, unscheduled and targeted briefings on labor protection, who have mastered safe techniques, are allowed to work with drilling tools performance of work and passed the knowledge test of labor protection requirements. 1.2. Employees allowed to perform work must comply with the internal regulations established by the organization. 1.3. When working with a drilling tool, you should follow a work and rest schedule. Relaxing and smoking are allowed in specially equipped places. 1.4. Drilling tools must be assigned to workers for individual or team use, placed in special tool cabinets, tables located next to or inside the equipment, if this is convenient, safe and provided for by the design. 1.5. Workers are required to perform only the work assigned by the work manager. It is not allowed to delegate your work to other employees and allow unauthorized persons into the workplace. 1.6. A worker may be exposed to hazardous and harmful production factors: - noise, - vibration, - unfavorable parameters of the production microclimate, - electric current, - gas and dust levels. 1.7. Workwear, special footwear and other personal protective equipment are issued to employees in accordance with current standards and the work performed. 1.8. Workwear, safety shoes and other personal protective equipment should be stored in specially designated areas in compliance with storage rules and used in good condition. 1.9. Workers performing work with drilling tools must comply with fire safety rules, know fire warning signals, the location of fire extinguishing equipment and be able to use them. It is not allowed to use fire-fighting equipment for business purposes, or to obstruct passages and access to fire-fighting equipment. 1.10. In the event of an accident, the victim should stop working, notify the work manager and seek medical help. 1.11. Workers who work with drilling tools need to know and observe the rules of personal hygiene. 1.12. If any questions arise during the work related to its safe performance, you should contact the employee responsible for the safe performance of work.

1.13. Employees who violate the requirements of this instruction are liable in accordance with the current legislation of the Russian Federation.

2. OCCUPATIONAL SAFETY REQUIREMENTS BEFORE STARTING WORK

2.1. Before starting work, you should put your work clothes in order: fasten the sleeve cuffs, tuck in the clothes so that there are no flapping ends, tuck your hair under a tight-fitting headdress. 2.2. Inspect the workplace, remove objects that interfere with work and clear passages. Organize your workplace so that everything you need is at hand. 2.3.

Make sure there is sufficient lighting in the workplace. 2.4. Check the serviceability of the tool: - the drill, countersinks and reamers must be sharpened; — the surface of the drills should not have cracks or signs of corrosion.

The grinding surfaces should be free of dents and roughness on the front and back surfaces, and there should be no decarburized layer on the surfaces of the belts and shank; — the presence of surface cracks (grids), blockages, crumbled places on the cutting part of the reamers and countersinks (on the plate), and rough spots on the grinding surfaces is not allowed.

There should be no traces of corrosion and solder residues (copper and flux) on the surfaces of the reamers; 2.5. Drilling tools and accessories should be used strictly for their intended purpose. 2.6. Before each start of the drilling tool, make sure that the start-up does not endanger anyone. 2.7.

Check grounding devices, devices for fastening tools for cracks, breaks, strength of fastening of hard alloy plates, chip breaking thresholds, etc. 2.8. It is not allowed to cool the cutting tool with wet rags or brushes.

2.9. Do not splash oil or liquid onto the floor. Install shields to protect against splashes.

3. OCCUPATIONAL SAFETY REQUIREMENTS DURING WORK

3.1. Work only with working tools and devices and use them strictly for their intended purpose. 3.2. While working, do not lean close to the cutting tool. 3.3. Install the workpiece correctly and securely to eliminate the possibility of breaking its fastening or other disruptions to the technological process during drilling.

3.4. Drilling, countersinking and reaming tools must be accurately centered in the machine along the spindle axis and tightly installed in the chuck. 3.5. Drills should only be used with the correct sharpening. 3.6. Installation of the tool should be done when the machine is completely stopped. 3.7. Changing tools should be done with the spindle lowered. 3.8.

Changing tools while the machine is running can only be done with a special quick-change chuck. 3.9. When installing a drill or reamer with a tapered shank into the spindle, you should be careful not to cut your hands on the cutting edge of the tool. 3.10. Do not use a tool with a worn taper shank. 3.11.

When turning the product on the table along with the drill, it is not allowed to hold it with your hand, but you should stop the rotation of the tool, make the necessary correction or take the appropriate device. 3.12. If the tool jams, the drill shank, tap or other tool breaks, the machine should be turned off. 3.13.

When the fastening of the drill chuck and the workpiece is loosened, the rotation of the tool should be stopped. 3.14. When drilling deep holes, you should periodically remove the drill from the hole to remove chips. 3.15. Remove chips from the part being drilled and the table only after stopping the tool. 3.16.

Do not remove chips directly with your hands and tools; use special hooks and brushes for this. 3.17. When manually feeding the drill and when drilling through passage or with light drills, it is not allowed to press hard on the cutting tool. 3.18. Before stopping the rotation of the tool, move the tool away from the workpiece. 3.

19. If vibration occurs, stop rotating the tool. Take measures to eliminate vibration: check the fastening of the drill and parts. 3.20.

Stop the drilling process when: - temporary cessation of work; — interruption in the supply of electricity; — cleaning, lubrication and cleaning of the workplace and equipment; — installation, measurement and removal of parts; — checking or cleaning the cutting edge of the drill;

— technological maintenance of equipment and devices.

OCCUPATIONAL SAFETY REQUIREMENTS IN EMERGENCIES

4.1.

You should stop the work, turn off the equipment in use, and report the incident to the work manager if at least one of the following situations occurs: - malfunction of the equipment; — the protective fence is faulty; — faulty operation of vices and clamps; — damage to the working tool; — appearance of smoke or smell characteristic of burning insulation; — the appearance of increased noise, knocking, vibration; — faulty power wiring; — break of the protective grounding conductor; - lack of lighting. 4.2. In the event of an accident, you should: - take measures to free the victim from the traumatic factor; — provide the victim with first aid depending on the type of injury; - inform management about the incident; — if possible, maintain the situation if this does not lead to an accident or injury to other workers; — if necessary, call an ambulance by calling 103 or help transport the victim to a medical facility. 4.3. If a fire occurs, you should: - stop work; — turn off electrical equipment; — call the fire department by calling 101 and inform the organization’s management;

— begin to extinguish the fire using available fire extinguishing means.

5. OCCUPATIONAL SAFETY REQUIREMENTS AFTER WORK COMPLETION

5.1. Tidy up the workplace, put tools and accessories in a specially designated place, carefully stack the workpieces and finished parts. 5.2.

Take off overalls and other personal protective equipment and put them in a specially designated place. 5.3. Wash your face and hands with warm water and soap or take a shower.

5.4.

Inform the work manager about the work performed and any problems with the work.

Download Instructions

Briefing upon hiring

The machine operator must undergo training upon hiring and each time immediately before starting to operate the machine. The employee conducting the training must focus on the important features of working with the equipment.

Each machine operator must pass certification and receive permission to work before official employment. The instruction is a standard document. It is drawn up according to certain rules, certified by the signature of the head of the enterprise, and stamped.

Important aspects of safe operation of a drill press:

- You cannot start work without undergoing training and completing documents.

- The job description must contain the basic requirements for the performance of work.

- A beginner must undergo training before starting work.

- Employee knowledge should be systematically tested. Even those who are highly qualified and have been working in their specialty for many years.

- Each employee must sign in a special journal. It confirms that you have completed the training.

Safety requirements before starting work

What you need to do before starting to work on the drilling machine:

- Wear special protective clothing - a robe or apron with sleeves, as well as a headdress (beret, headscarf).

- Check that the belt drive housing is securely fastened.

- Make sure that the protective ground is securely connected to the machine body.

- Firmly fix the drill in the chuck.

- Run the machine idle to check the serviceability of the starting box by pressing the buttons.

- Securely secure the part on the machine table in a vice. Do not hold the part with your hands while drilling.

- Wear safety glasses.

Fixing the workpiece

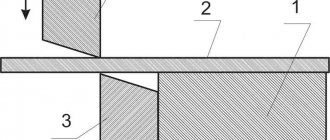

When fixing a polished workpiece, place pads under the jaws of the vice.

» data-medium-file=»https://odnastroyka.ru/wp-content/uploads/2014/11/fiksacia-zagotovki.jpg» data-large-file=»https://odnastroyka.ru/wp-content /uploads/2014/11/fiksacia-zagotovki.jpg" class="lazy lazy-hidden aligncenter wp-image-631 size-full" title="drilling machine" src="https://odnastroyka.ru/wp-content /plugins/a3-lazy-load/assets/images/lazy_placeholder.gif" data-lazy-type="image" data-src="https://odnastroyka.ru/wp-content/uploads/2014/11/fiksacia -zagotovki.jpg" alt="Fixing the workpiece" width="352″ height="352″ srcset="" data-srcset="https://odnastroyka.ru/wp-content/uploads/2014/11/fiksacia- zagotovki.jpg 352w, https://odnastroyka.ru/wp-content/uploads/2014/11/fiksacia-zagotovki-350×350.jpg 350w" sizes="(max-width: 352px) 100vw, 352px" /> After marking, before drilling a metal workpiece, it is necessary to fix it in a regular bench vice or in the vice of a drilling machine.

When fixing the workpiece in the vice of a drilling machine, the machine plate should be raised, thereby reducing the distance from the workpiece to the drill to 2-3 cm. Do not forget to fix the fixing screws for adjusting the height of the drilling machine plate. Otherwise, the slab may fall down during drilling. Which will lead to breakage of the twist drill, damage to the workpiece and even injury.

Safety during work

To avoid injury while operating the drilling machine, do not:

- place foreign objects on the bed;

- lower your head close to the drill;

- put on gloves and work in them;

- lubricate and cool the drill with a wet cloth: this can only be done with a special brush;

- try to stop the chuck or drill with your hands;

- leave the machine without turning it off.

Safety precautions when working on a drilling machine include the following rules:

- Do not use drills with worn taper shanks.

- It is necessary to smoothly feed the drill to the part after the machine spindle reaches full speed.

- Before you start drilling the workpiece, you should tilt the centers of the holes. Wooden parts need to be pinned with an awl.

- When the drill leaves the workpiece, you need to reduce the feed.

- When working with large pieces of wood, you need to place a small piece of plywood or a board under the part.

Safety precautions when drilling metal

Hello readers and blog visitors. Drilling metals is just as dangerous as cutting metal, and it also has its own secrets and subtleties. This is what I decided to write about today.

Twist Drill Selection

More often, when drilling metals, we use twist drills with individual sharpening of the cutting edge. And here it is important to observe safety precautions when drilling certain parts and workpieces.

It will be better if you always have at hand a set of twist drills for both wood and metal, of various diameters and lengths.

I recently bought myself a set of drills like this. Not a lot, of course, but it was enough for my purposes. And it's quite inexpensive.

Install a twist drill of the required diameter and length into the chuck of a drill press or electric drill.

When attaching the drill, make sure that the drill is installed clearly vertically, without any distortions.

When using small diameter twist drills (

To securely fix the drill, wrap 2-3 layers of thin copper or brass wire around its shank.

This trick will allow you to increase the diameter of the shank and securely fix the drill in a standard ordinary chuck.

Marking blanks

When marking workpieces, it is necessary to establish the exact position of the center and the required dimensions of the hole. This can be determined using a marking square, a caliper or a regular ruler.

To make the markings more visible, apply them with a center punch or permanent ink. The markings will fall into the drilling area and no traces will remain. Before drilling, it is better to mark the center of the intended hole with a center punch.

This reduces the risk of the drill moving to the side.

Fixing the workpiece

After marking, before drilling a metal workpiece, it is necessary to fix it in a regular bench vice or in the vice of a drilling machine.

When fixing the workpiece in the vice of a drilling machine, the machine plate should be raised, thereby reducing the distance from the workpiece to the drill to 2-3 cm. Do not forget to fix the fixing screws for adjusting the height of the drilling machine plate. Otherwise, the slab may fall down during drilling. Which will lead to breakage of the twist drill, damage to the workpiece and even injury.

Drilling the workpiece

Using the levers located on the body of the drilling machine, move the drill evenly towards the workpiece.

Some machines are equipped with a liquid/oil supply to the drill to avoid overheating and breakage of the drill, as well as fusion of the edges of the workpiece (if it is plastic). In this case, you need to ensure the correct supply of fluid to the drill/drilling point.

In any case, even if the machine is not equipped with an automatic fluid supply system, it will not be superfluous to cool the drill , including when working with a hand drill.

This can be done by periodically pouring water from a bottle on it, or by lowering the end of the drill into a container of water.

Articles - Safety precautions when cutting rolled metal

Metal is used as a structural material much more often than other materials. However, it is extremely rare for a metal workpiece to be found in the form required for further operation. To give rolled metal the desired shape, it is cut, chopped, filed, straightened and many other different operations are performed on it.

Due to the fact that metal (in particular steel) has quite significant strength characteristics, significant effort is required to manipulate the workpiece. This effort must be applied in doses, in the right direction, and most importantly, follow safety measures.

In this article, SkladMetal specialists will talk about how important safety precautions are when processing metal at the domestic and professional level.

In general, to work safely with metal you will need:

- gloves or mittens

- Eye protection goggles or mask when working with open flames and sparks

- respirator, which is especially important for enclosed spaces

- Closed clothing if possible

- - headdress

- working tools (faulty ones greatly increase the risk of injury)

Depending on what technological operation you will perform and with what tool, the specified “security set” may change somewhat, but not much.

It is important that there is a first aid kit in the immediate vicinity of the work site for possible first aid.

If the work involves significant dust generation, then it is very advisable to equip the workplace with a point supply and exhaust ventilation system. This is necessary so that dust and smoke are removed directly from the place of its formation, without spreading to the entire room.

In some types of metal processing, quite strong heat generation and overheating of the workpiece and the processing tool are observed. Uncontrolled overheating should not be allowed (the tool will deteriorate, the part may fail). This problem can be dealt with by local cooling of the heated zone or by periodic operating cycles.

Safety precautions when cutting metal

In everyday life and small-scale production, sheet and rolled metal products are most often cut with hand hacksaws or a grinder. Cutting with a hacksaw only in appearance seems to be a simple operation. The most important thing in this process is not to warp the canvas and not to press too hard, since in addition to the crooked cut itself, a nuisance may occur in the form of the canvas bursting.

To prevent the bursting of the blade from injuring your hands, you need to wear mittens. It is better to start working with an angle grinder under the direct supervision of a more experienced comrade.

The grinder is a very insidious tool that can cause serious injuries (without exaggeration). The main problem that can occur is disk jamming.

To do this, it is enough to tilt the tool a little or cut with a large feed.

Therefore, you need to cut with a grinder with a minimum feed and only with a disk designed for this type of material. It is absolutely unacceptable to cut metal with “toothed” steel discs (see Fig.

1), no matter how productive they may seem. It is unacceptable to remove the protective cover for supposedly better visual control of the process.

It is better for beginning craftsmen to choose disks with a small diameter (125 mm).

Emergency situations

In the event of an emergency, remember these rules:

- If the power goes out, you need to turn off the machine as quickly as possible.

- If the unit, drill breaks down, or the housing grounding is faulty, work should be stopped. It is necessary to remove the drill from the part, turn off the equipment and notify the authorities about the breakdown.

- If the machine or its individual parts catch fire, you must turn off the unit and immediately extinguish it using sand or a carbon dioxide or powder fire extinguisher.

- If one of the employees is injured, you need to provide first aid and report the incident to your superiors. If the injury is serious, the victim should be taken to the hospital.

Auxiliary processes to facilitate drilling

To increase the efficiency and safety of the operation, there are measures to regulate the process.

Cooling

When processing metal, the drill, as well as the material itself, become very hot and can melt. Due to the increase in temperature, the cutting edges wear out faster and the holes are of poor quality.

To combat this phenomenon, cooling emulsions, cutting fluids, and even water are used. The composition can be supplied through channels on the drill. Some machine models provide cooling directly at the processing site.

Hit

This function of the hammer drill is used in finishing work (for drilling holes for sockets, channels for cables), in dismantling walls and ceilings.

The equipment of the device quickly penetrates into hard substrates due to the force of impact. The tip can simultaneously rotate and deliver shocks, destroying the material.

Machine requirements

You can only work on working units. Over time, machine parts become unusable even with proper operation and proper care. They need to be changed periodically. The heaviest loads during equipment operation fall on the chuck and transmission belt. They are the first to fail. Untimely replacement of worn parts worsens the quality of work and increases the likelihood of accidents and injuries.

Drilling machine - dangerous equipment

. When working with it, it is very important to follow safety precautions. Only if you have the appropriate qualifications and excellent knowledge of safety regulations, you can be sure that the operation of the machine will be safe.