Among the variety of hand tools, a hacksaw is most likely the most famous representative of this group of hand tools. What types there are, where they are used, as well as how to choose, and a review of prices for popular models is the topic of this article by the editors of HomeMyHome.ru magazine

A classic version of a hand hacksaw for metal, familiar to many from childhood and school.

Characteristics and purpose

The main purpose of a hacksaw is to cut various materials. The main one is metal, but since there are many small teeth on the blade, it can be used to separate:

- plastic;

- ceramics;

- polyvinyl chloride;

- Styrofoam;

- particle boards;

- laminate;

- plexiglass;

- tree.

When choosing a hand tool, you need to pay attention to the blade. Blades are manufactured according to the requirements of GOST R 53411-2009. This document describes the standards by which hacksaw blades are divided into three groups, differing in size:

- Double. The distance between the holes for fastening into clamps is 300 mm (permissible error 2 mm). Blade length - 315 mm. The height of the teeth is 20 mm. Thickness - 0.8 mm.

- Single. The distance between the mounting holes is 300 mm. The permissible error is 2 mm. Total length - 315 mm.

- Single shortened. The distance between the mounting holes is 250 mm. Total length - 265 mm.

The height of single panels is 12.5 mm, thickness is 0.63 mm.

Plexiglas in packaging (Photo: Instagram / rezka_stekla_soln)

Problems and difficulties

The disadvantages of hacksaws depend on the manufacturer and the craftsman who uses them. The main ones can be identified:

- quality manufacturers have a narrow range;

- hard wood species can damage the panel;

- the cheapest hacksaws are not re-sharpened;

- when choosing large teeth, the cuts are inaccurate;

- if the handle is not rubberized, it is inconvenient to work;

- may react negatively to humidity, but this depends on the material of the panel;

- The warranty does not apply to consumables.

Design

The hacksaw consists of several parts:

- Blades for hacksaws for metal. This is a removable item. It is used to cut workpieces made of different materials. It is a metal strip on which wedge-shaped teeth are located.

- Machine or frame. It is an arc that is made of different metals and alloys. The frame is needed to secure the canvas. It can be standard cast or sliding.

- Handles. It can be located in different places.

Modern hand tools can be equipped with additional mechanisms to increase comfort during work and expand functionality.

Hacksaw blades (Photo: Instagram / enerteh.by)

Guarantee

You can return or exchange the instrument within 14 days if the following conditions are met:

- there are no signs of use on the hacksaw: chips, scratches and abrasions;

- the box was opened carefully and not damaged;

- if the set included accessories (cases or additional sheets), they are all in place;

- Labels and factory marker are not erased.

Many manufacturers are so confident in the quality of their products that they offer a lifetime guarantee.

This concept means:

- maintenance of the hacksaw throughout its entire service life;

- free repairs are carried out if the breakdown occurred due to the fault of the factory;

- Blades and nuts damaged during operation are not covered by the warranty service - these are consumables.

Types of hacksaws

Varieties:

- Household. Standard hand tools for occasional household tasks. The handle is made of wood, and an adjustment screw is installed on the front of the frame.

- Hand saws. A compact tool designed for sawing metal in hard-to-reach places. Suitable for securing broken saw blades.

- Professional models. Their main difference is the high quality of materials from which the main parts of the structure are made.

You also need to pay attention to the division of hacksaws by drive type. They are electric and manual. Electric ones are divided into battery and network. The former allow you to work without connecting to the mains, which makes them more versatile, but the batteries gradually discharge and require charging, which reduces the time you use the power tool. Battery models are equipped with special systems to suppress vibrations.

Household hacksaw (Photo: Instagram / ploskogubtsy.ru)

What can break

The most common things that break in hacksaws are:

- teeth;

- whole canvas;

- pens.

In the first two cases, it is necessary to completely replace the panel. Each manufacturer has an assortment of canvases designed for each model. You can secure them yourself. As a rule, the canvas comes with mounting instructions.

Handles most often cannot be repaired; in this case, the hacksaw will have to be replaced.

Types of hacksaw blades

The hacksaw blade is considered the main part of the hand tool. The performance of the tool and the cutting accuracy depend on its type.

Metal cloth

It has a large number of small teeth. Large teeth will not cut metal.

Blade length - 150–300 mm. The canvas can be made from different materials:

- carbon steel;

- cobalt steel;

- carbon and high-speed steel.

Tungsten filament

Strings are made from tungsten carbide. Their length is 30 cm. They are suitable for fastening within standard hacksaws. String diameter - 2.7 mm. With its help you can make precise cuts. The string is suitable for straight and curved cuts, cutting out circles.

Diamond string

The basis of such a string is alloy steel, onto which diamond coating is applied. Coating thickness - 2 mm. The string is secured in the clamps using rings.

A high-quality diamond wire should quickly cut through various materials. When working, its surfaces and working area must be moistened with water to avoid overheating.

It is better to choose an arc with a handle and attach a diamond string to it. Such a hacksaw is cheaper than a professional hand tool, but it can be used to cut metal, concrete, stone, ceramics, etc.

Diamond string (Photo: Instagram / abraziv_ykt)

Types of hacksaws, characteristic features of products

A hacksaw is a carpentry tool; it is a type of saw. Its main purpose is to cut blanks and products made of different materials.

Metal hacksaws can be manual or electric

Saws are divided into manual tools and electric hacksaws. The latter option is equipped with a motor, which ensures fast and less labor-intensive work. This reciprocating hacksaw can be presented in the form of a corded or battery-powered tool. The first type of device operates from the electrical network. This hacksaw is quite a powerful device. Its only drawback is the presence of a cord, which limits the operating area.

Reciprocating tools can be divided into electric hacksaws for metal, wood and stone; their blades differ in length, shape, size and number of teeth.

A cordless hacksaw is a more mobile device that runs on a battery. This type of device is characterized by lower productivity. One battery charge is not enough to operate the tool for a long time.

Depending on the purpose, there are hand saws for wood and for metal. The first type of device consists of a working blade equipped with sharp teeth and a handle for comfortable grip. This tool is often used for cutting drywall and aerated concrete.

Hand saws can be used for both metal and wood

A hand saw for wood can be classic, circular or tenon. The first option is used for longitudinal or transverse cutting of the workpiece. The teeth of the blade have a triangular shape and are located in increments of 1.5-6.5 mm. To increase sawing efficiency, you should study information on how to sharpen a hacksaw.

A circular saw is used to cut curved parts, which is achieved thanks to a narrow blade with fine teeth, which can be located on one or both sides. A tenon jig is used to remove protruding grooves and tenons to obtain a clean cut.

A hacksaw for metal is a universal tool that can cut a workpiece made of any material, including plastic, wood, foam, aerated concrete, etc. The working blade of such saws has fine teeth, making the cut more accurate and clean. During operation, small chips are formed.

Hand hacksaw for metal: tool design

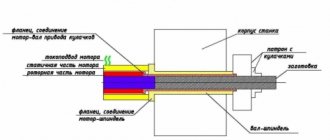

The tool for working with metal has a simple design. It looks like a bracket, between the ends of which the canvas is fixed in a tense position. The device consists of a frame, a cutting element and a handle.

Hacksaw design: 1 – stand; 2 – frame-holder; 3 – shank; 4 – handle

The frame is intended for fastening the canvas. It can be made of different materials. For cutting dense metal workpieces, frames made of high-strength composites are used. The design of an element is determined based on the conditions of its use. If you often need to make cuts in hard-to-reach places, you should purchase a small device that allows you to adjust the tilt of the blades.

The cutting part is represented by a thin steel strip. The blade is installed in the frame so that the teeth are on the opposite side of the handle. It is the most fragile element of the structure, so when making a cut you need to act especially carefully and carefully, since carelessness can lead to breakage of the product.

The cutting blade has wedge-shaped teeth. When choosing a device, you should pay attention to whether the cutters have been hardened, which increases the service life and productivity of the tool. This will also influence the solution to the question of how to sharpen a hacksaw (information can be found on the Internet). It is better to give preference to hardened, made of nickel-plated steel and having a dark color or bimetallic options, painted in any tone.

Important! For cutting hard products, you should choose blades with small cutters, and for soft workpieces, it is recommended to use a cutting element with large teeth.

Convenience and safety when using a hacksaw for metal is ensured by the handle

The handle is an important part of the tool, which ensures convenience and safety when using a hacksaw. The best is a two-component handle, which is equipped with durable rubber and special soft inserts. The handle can be placed on the side or on top of the hacksaw.

Selection principles

When purchasing a hacksaw for metal, you need to consider a number of criteria. It is important to study the strengths and weaknesses of the instrument and understand the manufacturers.

Criteria

Criterias of choice:

- The material from which the handle is made. Comfort when working with a hacksaw will depend on this. It is better to choose handles with rubber pads.

- The shape of the teeth, their size. They should not be large in order to cut metal without problems.

- Canvas size. Depends on the length of the workpieces being cut.

It is better to put aside a tool with a hollow handle, since it will break if pressed hard.

Mini hacksaw for metal (Photo: Instagram / wedotools)

Advantages

Positive sides:

- simplicity of design and maintenance;

- light weight;

- performing work in any conditions;

- reliability, durability;

- possibility of sharpening;

- application for sawing various materials;

- ease of use.

Manufacturers and prices

Manufacturers:

- "Enkor"

- Stanley;

- STAYER;

- GROSS;

- Top Tools.

The average price is 500 rubles.

Assortment of hacksaws (Photo: Instagram / stroi_it)

Classification of hacksaws by handle type

Metal saws can be equipped with different types of handles:

- Pistol type

- Straight

the convenience of working with the saw and the ease of manipulating the saw blade depend on the type of handle grip . It is generally accepted that a pistol grip provides a comfortable grip. And the straight type handle makes it possible to more accurately guide the saw blade.

If the master is faced with the task of processing workpieces with increased precision, then it is best, of course, to take a saw with a straight handle. If there are any special requirements for the processing accuracy of the workpiece, then it is best to take a saw with a traditional pistol handle.

Operating principles

To make cutting metal with a hacksaw more effective, when working with hand tools you must adhere to some rules:

- You need to hold the tool with both hands so that the blade does not bend. It is better to secure the workpieces in a vice.

- The ease of use of the tool can be increased by changing the cutting angle.

- The pressure must be increased when moving forward, and decreased when moving backward.

- It is important to practice in advance in securing the canvas in the clamps. It is important that it does not move when sawing.

Before you start working with a hacksaw, you need to check the sharpness and integrity of the teeth, their location relative to each other. If there are irregularities, the teeth move in different directions, the blade needs to be replaced.

Cutting a metal pipe (Photo: Instagram / ekb_tools)

Elements of a hacksaw: what main parts does it consist of?

The instrument became popular also because of its structure. Outwardly, it resembles the letter C, to the ends of which a cutting blade is attached. This tool contains the following elements:

- Pen. Modern hacksaws have handles that are made using two-component materials. This allows you to increase the service life of the tool. The shape of the handle is made so that it is very convenient to use. Usually it is located either at the top or on the side. In the first case, the tool is used to work in places where it is difficult to get to.

- Frame. Takes on the main load. It is this that dampens all vibrations that occur during operation. Modern hacksaw frames are made from a wide variety of materials. Very often, an element is installed on the tool that regulates the tilt of the blade, which allows you to work in places with difficult access. Frames come in two options. They can be solid or have the ability to move apart. It is possible to place a canvas of any length on the sliding frame.

- Canvas. To cut metal, it is made from very hard alloys. It is very thin and fragile. There are many small teeth throughout. The work requires special care. You need to buy a fabric that is hardened. If it is not there, then it will fail very quickly. An element with sparse teeth is more productive. A high-quality cut can only be achieved by those with closely spaced teeth. Recently, bimetallic sheets have begun to appear on sale.

@pilous-mim.kz

Manufacturing

Any person without practical skills can make a homemade metal hacksaw. It is important to study in advance the structure of hand tools and how to connect the main parts.

A handle with an arc can be made from large-diameter wire, fittings, metal strips, profiled or plastic pipes. All that remains is to think about fastening the canvas.

A hacksaw is a hand-held tool for sawing workpieces made of different materials. To create high-quality cuts, you need to learn how to choose blades. We must not forget about the rules for choosing a frame with a handle. It is important that the tool is comfortable to work with and that the blades are securely held in the clamps.

Which is better

The best features of a hacksaw are controversial. They depend on the purpose for which the tool will be used.

- It is easier to saw the material if more than ten teeth are involved in the cut.

- The process will happen faster if the hacksaw has large teeth. But at the same time, the edge of the cut comes out uneven. This is due to excessive vibrations arising from too few teeth simultaneously engaged.

- Small teeth are sawed more slowly due to complications in removing sawdust, but the edge of the cut is much smoother and cleaner.

- The handles must be rubberized. They are more convenient to work with, they do not rub and, when used for a long time, do not cause unpleasant sensations when interacting with the skin.

- Hardened teeth are more durable.

The simplest machine with a wooden horizontal handle

It is an ancient and inconvenient design. The horizontal position of the handle forces the hand to be turned forward, which leads to rapid fatigue. The frame is made from a single rectangular strip. To tension the canvas, either a thumb in the front of the frame or a handle rotating along its longitudinal axis is used. As a rule, such hacksaws allow you to rotate the blade 90° by rearranging the square fingers to which the blade is attached in the square holes in the front and rear of the frame. The finger and the hole on one side can be round, then the blade is fixed at the desired angle only on one side, but with a normally tensioned blade, this is quite enough. Machines of a similar design are also produced for blades with a length of 150 mm.

Scope of application of a hacksaw

Tools are made not only manual, but also electric. Their main task is to cut metal. Naturally, they can be used to make grooves, as well as much more. The canvas is made from various materials, so its properties may be different. A hacksaw is not only suitable for sawing metal parts. By changing the type of blade, you can cut objects made of plastic, ceramics or plexiglass. Among the entire range of hacksaws, there are three main types:

- For use in the household. Similar models are the most common. They are ideal if you need to do something not particularly complicated. They are very easy to use. To secure it, you need to insert it into the grooves and tighten the special screws. The main thing is to remember that the canvas must be well stretched so as not to damage it during operation. These hacksaws are much cheaper than others.

- There are also professional types of hand tools. They are used when you have to work for a long time, and the cut must be clean and even. The peculiarity of such tools is a comfortable handle, as well as a mechanism for quickly replacing the saw element. If you need to cut something very often, then it is better to use just such models.

- Hacksaw-handle. The appearance of this tool resembles a staple. They do not need to have great physical strength to work. It is used exclusively in places where the usual variety simply cannot be used. Due to its design, it is also possible to install broken blades into a bench saw.

pilous-mim.kz

In the assortment of stores you can find hacksaws, the operation of which depends on electricity. Their productivity, of course, is much higher, but in terms of mobility and autonomy they are much inferior to mechanical types.